How Does The Magnetic Rotary 3 Click Board™ Work?

The Magnetic Rotary 3 Click Board™ as its foundation uses the AS5147, a high-resolution rotary position sensor for fast absolute angle measurement over a full 360-degree range from AMS AG. The AS5147 continuously generates the angle information, which the different interfaces can request from the device. The internal 14-bit resolution is available by readout register via the SPI interface, while the resolution on the ABI output can be programmed for 10 or 11 bits. It is also equipped with a Dynamic Angle Error Compensation block that corrects the calculated angle regarding latency by using a linear prediction calculation algorithm.

The core of the AS5147 represents a CMOS technology Hall-effect magnetic sensor that converts the magnetic field component perpendicular to the surface of the chip into a voltage. The signals coming from internal Hall sensors are amplified and filtered before their conversion by the ADC and then processed by the CORDIC block to compute the angle and magnitude of the magnetic field vector. The intensity of the magnetic field is used by the automatic gain control (AGC) to adjust the amplification level to compensate for temperature and magnetic field variations.

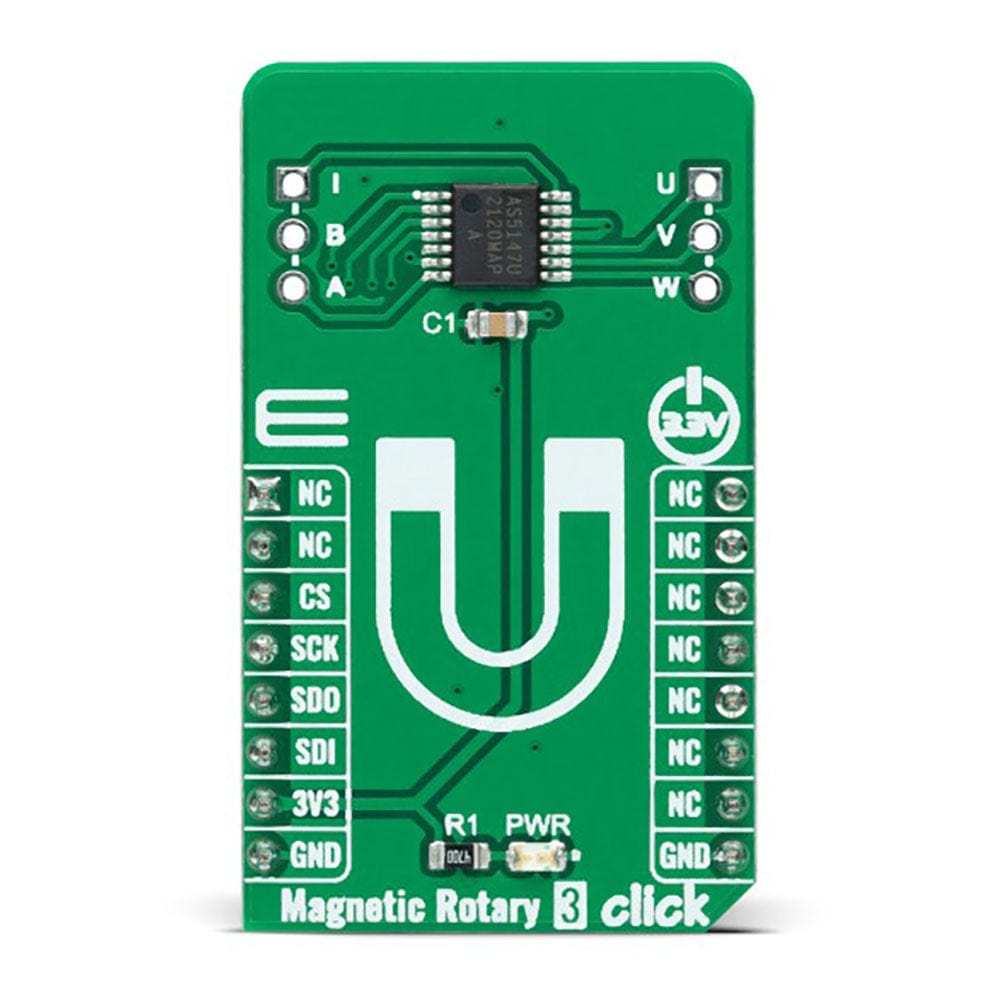

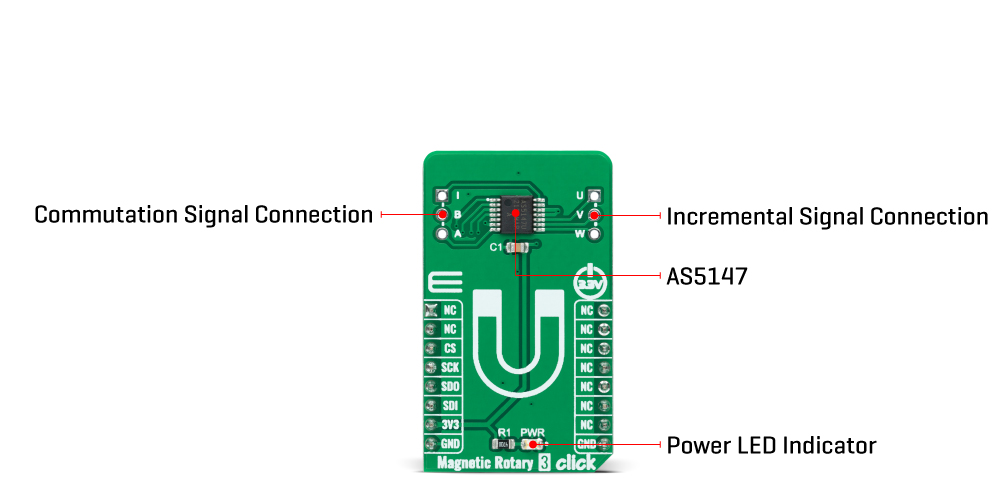

The Magnetic Rotary 3 Click Board™ communicates with MCU through a standard SPI interface supporting the common SPI mode, SPI Mode 1, allowing a host MCU to read 14-bit absolute angle position data from the AS5147. This Click board™ also comes with onboard headers reserved for incremental and commutation signals of their respective A/B/I and U/V/W signals alongside embedded self-diagnostics, including magnetic field strength too high, magnetic field strength too low or lost magnet, and other related diagnostic features. Incremental movements are indicated on ABI signals with a maximum resolution of 2048 steps / 512 pulses per revolution.

Besides, brushless DC (BLDC) motors are also controllable through a standard UVW commutation interface with a programmable number of pole pairs from 1 to 7. At constant rotation speed, the latency time is internally compensated by the AS5147, reducing the dynamic angle error at the SPI, ABI, and UVW outputs, while at higher speeds, the interpolator fills in the missing ABI pulses and generates the UVW signals with no loss of resolution. The AS5147 allows selection between a UVW output interface and a PWM-encoded interface on the W pin, which can be seen as an absolute angle position.

The Magnetic Rotary 3 Click Board™ can be operated only with a 3.3V logic voltage level. The board must perform appropriate logic voltage level conversion before using MCUs with different logic levels. However, the Click board™ comes equipped with a library containing functions and an example code that can be used, as a reference, for further development.

SPECIFICATIONS

| Type | Magnetic |

| Applications | Can be used to support BLDC motor commutation for the most challenging automotive applications |

| On-board modules | AS5147 - rotary position sensor for fast absolute angle measurement over a full 360-degree range from AMS AG |

| Key Features | Good resolution for motor and position control, independent output interfaces, self-diagnostics, immune to an external stray field, low power consumption, and more |

| Interface | SPI |

| Compatibility | mikroBUS |

| Click board size | M (42.9 x 25.4 mm) |

| Input Voltage | 3.3V |

PINOUT DIAGRAM

This table shows how the pinout on Magnetic Rotary 3 Click Board™ corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | NC | ||

| NC | 2 | RST | INT | 15 | NC | ||

| SPI Chip Select | CS | 3 | CS | RX | 14 | NC | |

| SPI Clock | SCK | 4 | SCK | TX | 13 | NC | |

| SPI Data OUT | SDO | 5 | MISO | SCL | 12 | NC | |

| SPI Data IN | SDI | 6 | MOSI | SDA | 11 | NC | |

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | NC | |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

ONBOARD SETTINGS AND INDICATORS

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| J1 | ABI | Unpopulated | Commutation Signal Connection Header |

| J2 | UVW | Unpopulated | Incremental Signal Connection Header |

MAGNETIC ROTARY 3 CLICK ELECTRICAL SPECIFICATIONS

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage | - | 3.3 | - | V |

| Rotation Angle Range | 0 | - | 360 | deg |

| Core Resolution | - | 14 | - | bit |

| Maximum Speed | - | - | 14500 | RPM |

| Operating Temperature Range | -40 | +25 | +120 | °C |

Software Support

We provide a library for the Magnetic Rotary 3 Click Board™ as well as a demo application (example), developed using MikroElektronika compilers. The demo can run on all the main MikroElektronika development boards.

The package can be downloaded/installed directly from NECTO Studio The package Manager (recommended), downloaded from our LibStock™ or found on MikroE Github account.

Library Description

This library contains API for the Magnetic Rotary 3 Click Board™ driver.

Key functions

-

magneticrotary3_write_registerThis function writes the desired data to the selected register by using SPI serial interface. -

magneticrotary3_read_registerThis function reads data from the selected register by using SPI serial interface. -

magneticrotary3_get_angleThis function reads the absolute position raw data and converts it to degrees (Angle).

Example Description

This example demonstrates the use of the Magnetic Rotary 3 Click Board™ board by reading and displaying the magnet's angular position in degrees.

void application_task ( void )

{

float angle;

if ( MAGNETICROTARY3_OK == magneticrotary3_get_angle ( &magneticrotary3, &angle ) )

{

log_printf( &logger, " Angle: %.1f degreesrnn", angle );

Delay_ms ( 100 );

}

}

The full application code and ready-to-use projects can be installed directly from NECTO Studio The package Manager (recommended), downloaded from our LibStock™ or found on MikroE Github account.

Other MikroE Libraries used in the example:

- MikroSDK.Board

- MikroSDK.Log

- Click.MagneticRotary3

Additional Notes and Information

Depending on the development board you are using, you may need a USB UART Click Board™, USB UART 2 Click or RS232 Click to connect to your PC, for development systems with no UART to USB interface available on the board. UART terminal is available in all MikroElektronika compilers.

MIKROSDK

The Magnetic Rotary 3 Click Board™ is supported with mikroSDK - MikroElektronika Software Development Kit. To ensure proper operation of mikroSDK compliant Click board™ demo applications, mikroSDK should be downloaded from the LibStock and installed for the compiler you are using.

Magnetic Rotary 3 Click Board

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.