Overview

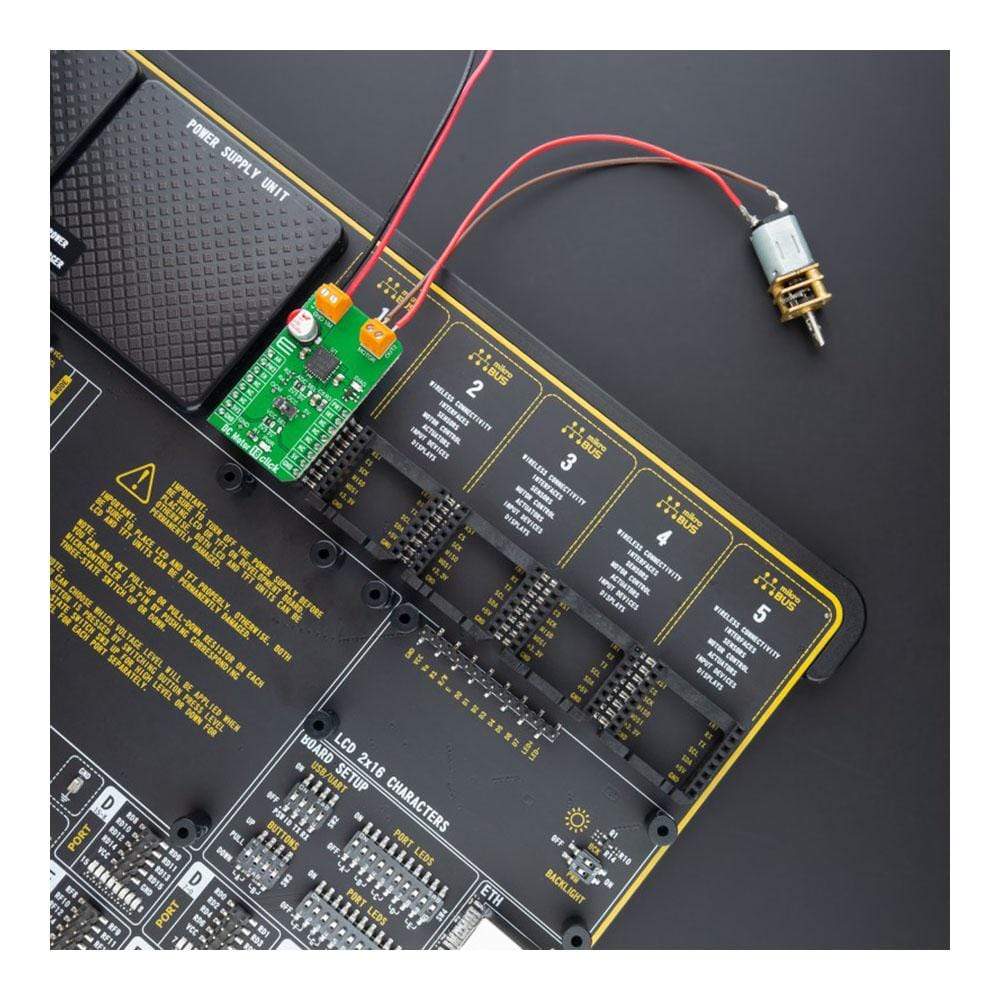

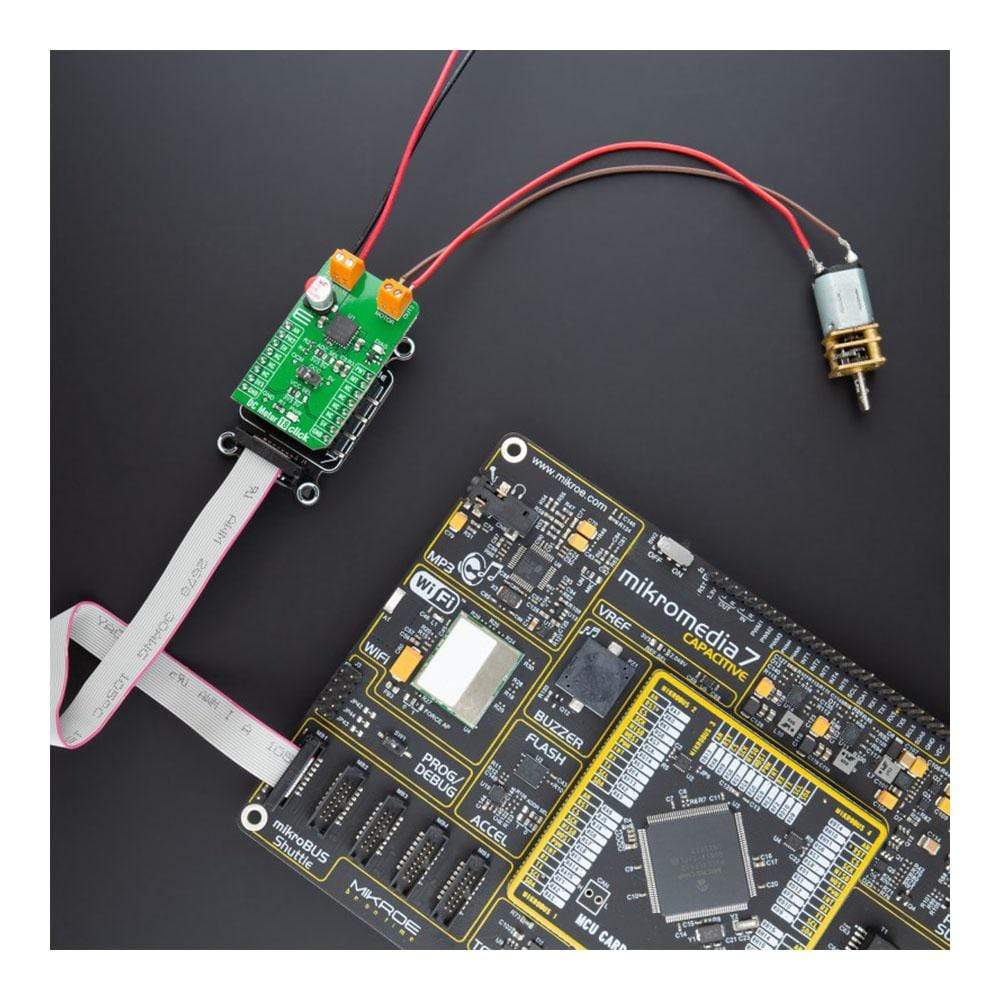

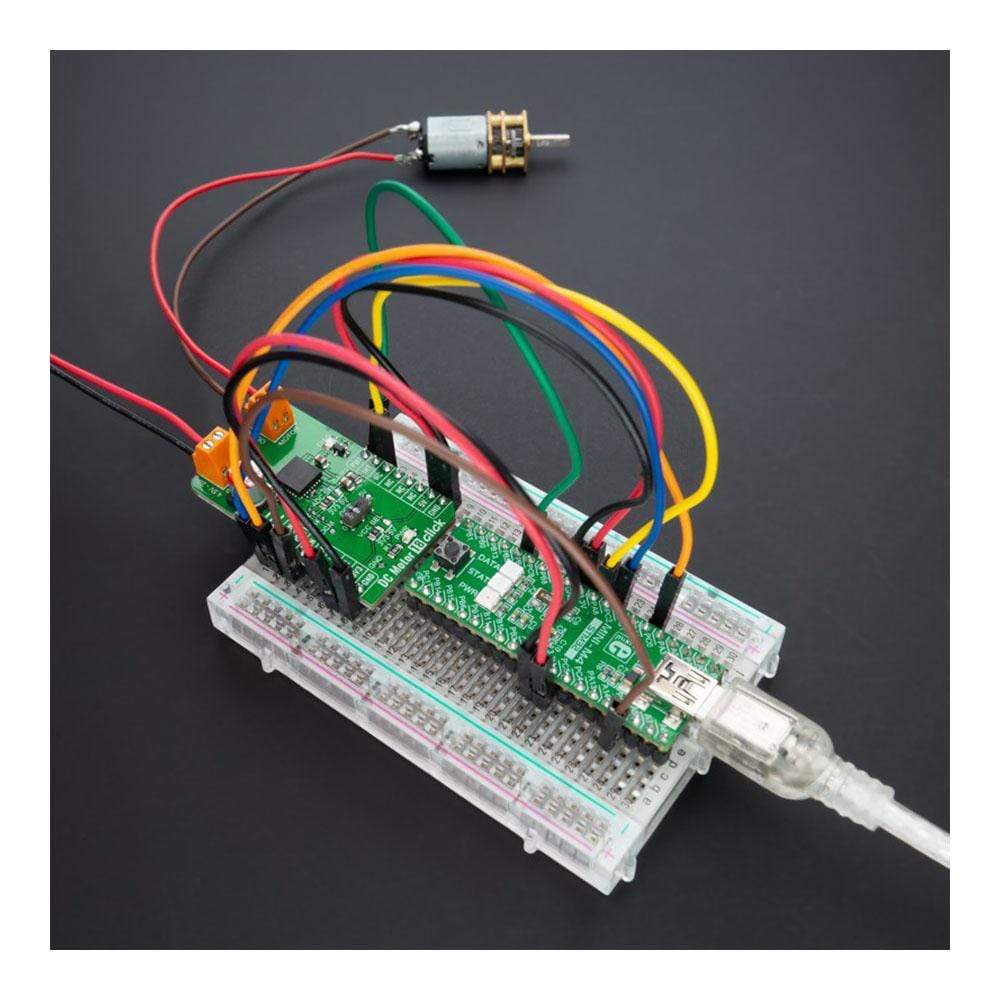

The DC Motor 18 Click Board™ is a compact add-on board that contains a brushed DC motor driver. This board features the TB9051FTG, an automotive PWM-type single-channel H-Bridge DC brushed motor driver from Toshiba Semiconductor. The Forward/Reverse/Brake mode can be selected according to PWM control signals, while the motor operation and stop mode can be chosen by an enable pin. It has a wide operating voltage range of 4.5V to 28V with an output current capacity of 5A max. Besides, it also features built-in protection against under-voltage, overcurrent, and overtemperature conditions. This Click Board™ is suitable for various automotive applications such as throttle and valve control, various engine bulbs, storing of door mirrors, and seat positioning.

The DC Motor 18 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

How Does The DC Motor 18 Click Board™ Work?

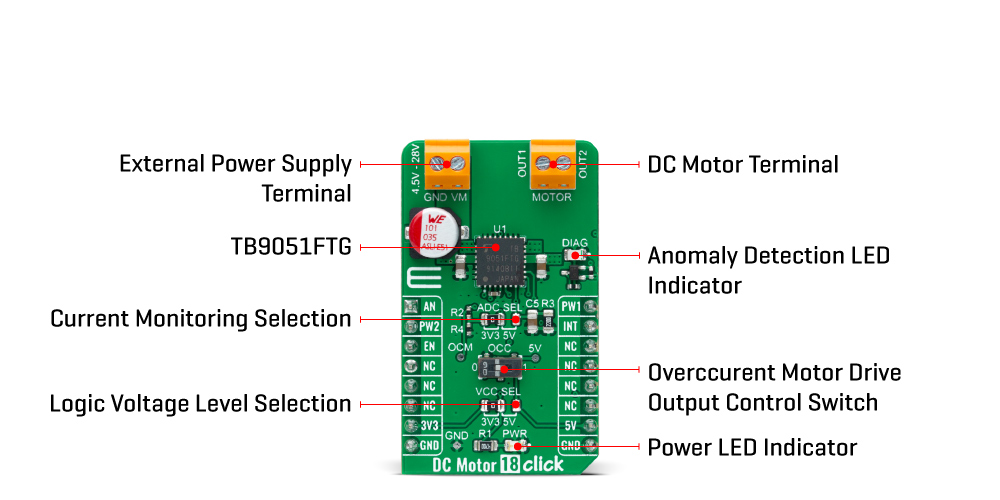

The DC Motor 18 Click Board™ as its foundation uses the TB9051FTG, a motor driver which incorporates the output driver for the direct drive of a DC brushed motor intended for automotive use from Toshiba Semiconductor. While primarily targeting vehicle engine applications, such as electronic throttle and valve control, the TB9051FTG can also be suitable for controlling onboard systems operating at up to 5A, such as control of wing mirrors and trunk locks. Control functions include motor-related (forward, reverse, brake), PWM control, current limit control, H-side current monitor, diagnosis output, and built-in detection circuits for overcurrent, overheat, and low/high voltage.

The DC Motor 18 Click Board™ communicates with MCU using several GPIO pins. The Enable pin, labeled as EN and routed to the CS pin of the mikroBUS™ socket, optimizes power consumption and is used for power ON/OFF purposes (driver operation permission). The Forward/Reverse/Brake mode can be selected according to PWM control signals routed to the PWN and RST pins of the mikroBUS™ socket.

The current, which flows to the high side in the H-bridge of motor-driven output, is monitored in real-time, where the user can select the way of the current monitoring. In the case of a 5V VCC power supply, the current can be monitored using the AN pin on the mikroBUS™ socket, and in the case of a lesser power supply (3.3V), monitoring is possible with the help of an added voltage divider between the OCM pin and GND. Selection can be performed by onboard SMD jumper labelled as ADC SEL.

This Click board™ also has an additional LED for anomaly indication. Suppose a state such as an overtemperature or overcurrent/under voltage is detected. In that case, such anomaly is indicated by a red LED marked as DIAG, which is also connected to the interrupt INT pin through which the user can also monitor the state of the diagnostic pin. In addition, there is the possibility of controlling the motor control output at the time of the overcurrent detection, which is realized through an onboard switch labelled as OCC. This switch is used for the judgment of whether the motor control output is ON(1) or OFF(0).

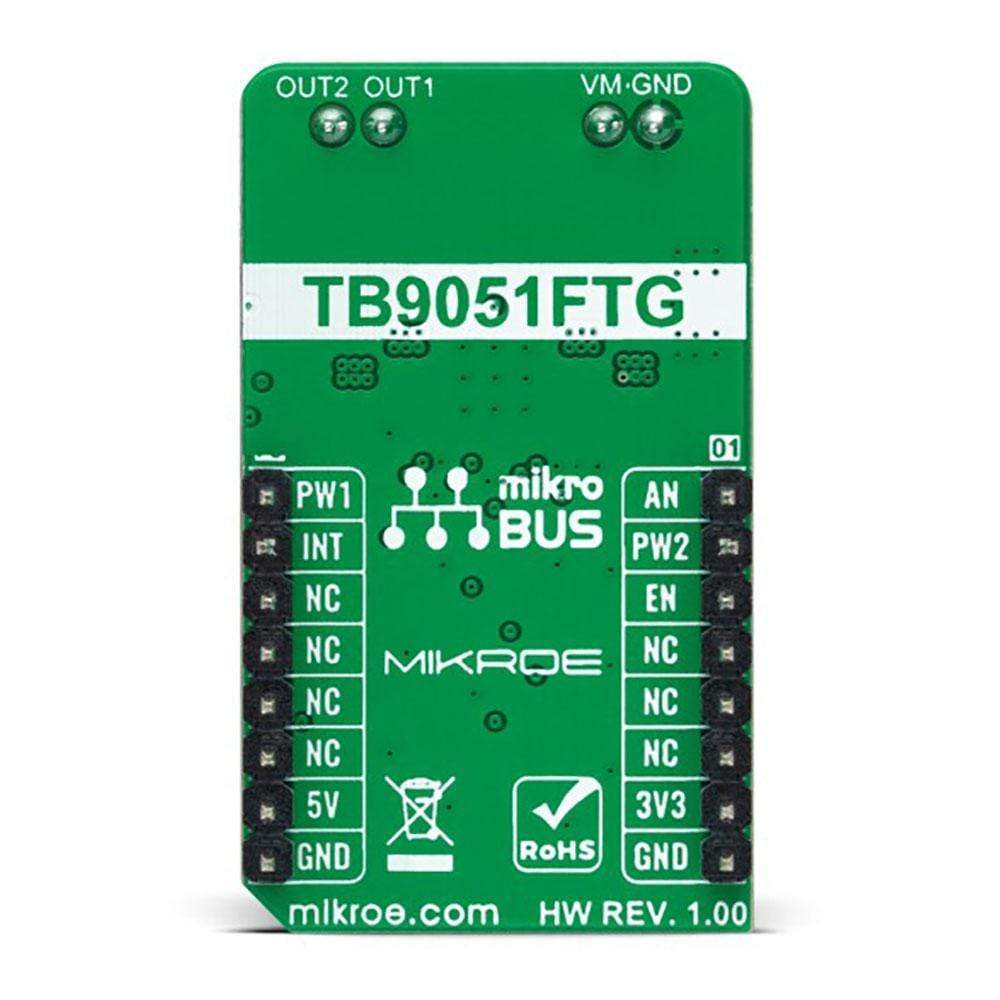

The DC Motor 18 Click Board™ supports an external power supply for the TB9051FTG, which can be connected to the input terminal labelled as VM and should be within the range of 4.5V to 28V, while the DC motor coils can be connected to the terminals labelled as OUT1 and OUT2.

This Click board™ can operate with both 3.3V and 5V logic voltage levels selected via the VCC SEL jumper. This way, it is allowed for both 3.3V and 5V capable MCUs to use communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Specifications

| Type | Brushed |

| Applications | Can be used for various automotive applications such as throttle and valve control, various engine bulbs, storing of door mirrors, and seat positioning |

| On-board modules | TB9051FTG - motor driver which incorporates the output driver for the direct drive of a DC brushed motor intended for automotive use from Toshiba Semiconductor |

| Key Features | Key Features Low power consumption, ultra low on-resistance, anomaly detection features, selectable motor operation, PWM control, high-side current monitoring, diagnosis indicator, and more. |

| Interface | Analog,GPIO,PWM |

| Compatibility | mikroBUS |

| Click board size | M (42.9 x 25.4 mm) |

| Input Voltage | 3.3V or 5V |

Pinout diagram

This table shows how the pinout on DC Motor 18 Click corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| Analog Signal | AN | 1 | AN | PWM | 16 | PW1 | Driver Control Signal 1 |

| Driver Control Signal 2 | PW2 | 2 | RST | INT | 15 | INT | Interrupt |

| Driver Enable | EN | 3 | CS | RX | 14 | NC | |

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | NC | ||

| NC | 6 | MOSI | SDA | 11 | NC | ||

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | 5V | Power Supply |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| LD2 | DIAG | - | Anomaly Detection LED Indicator |

| JP1 | VCC SEL | Left | Logic Level Voltage Selection 3V3/5V: Left position 3V3, Right position 5V |

| JP2 | ADC SEL | Left | Current Monitoring Selection 3V3/5V: Left position 3V3, Right position 5V |

| SW1 | OCC | Left | Overcurrent Motor Drive Output Control Switch |

DC Motor 18 Click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage | 3.3 | - | 5 | V |

| External Power Supply VM | 45 | - | 28 | V |

| Maximum Output Current | - | - | 5 | A |

| Operating Temperature Range | -40 | +25 | +125 | °C |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4786

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027383557

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.