Key Features

Overview

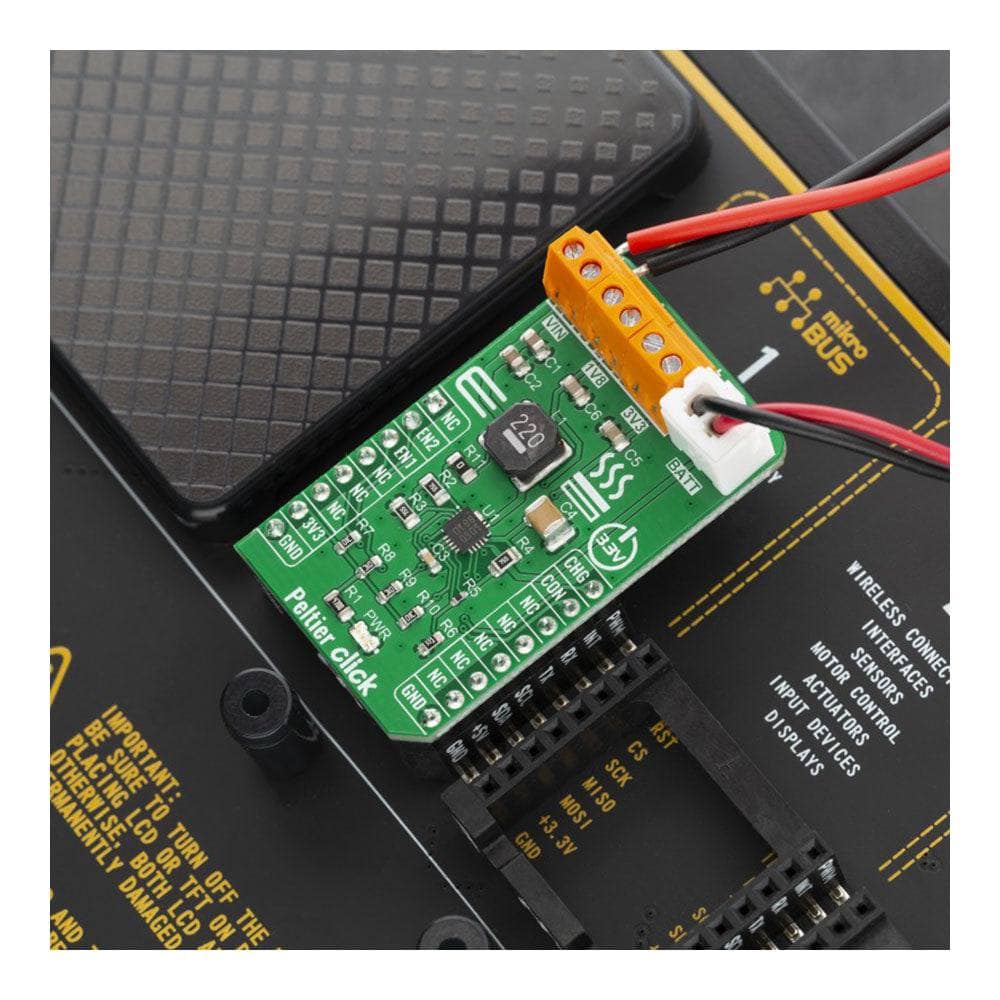

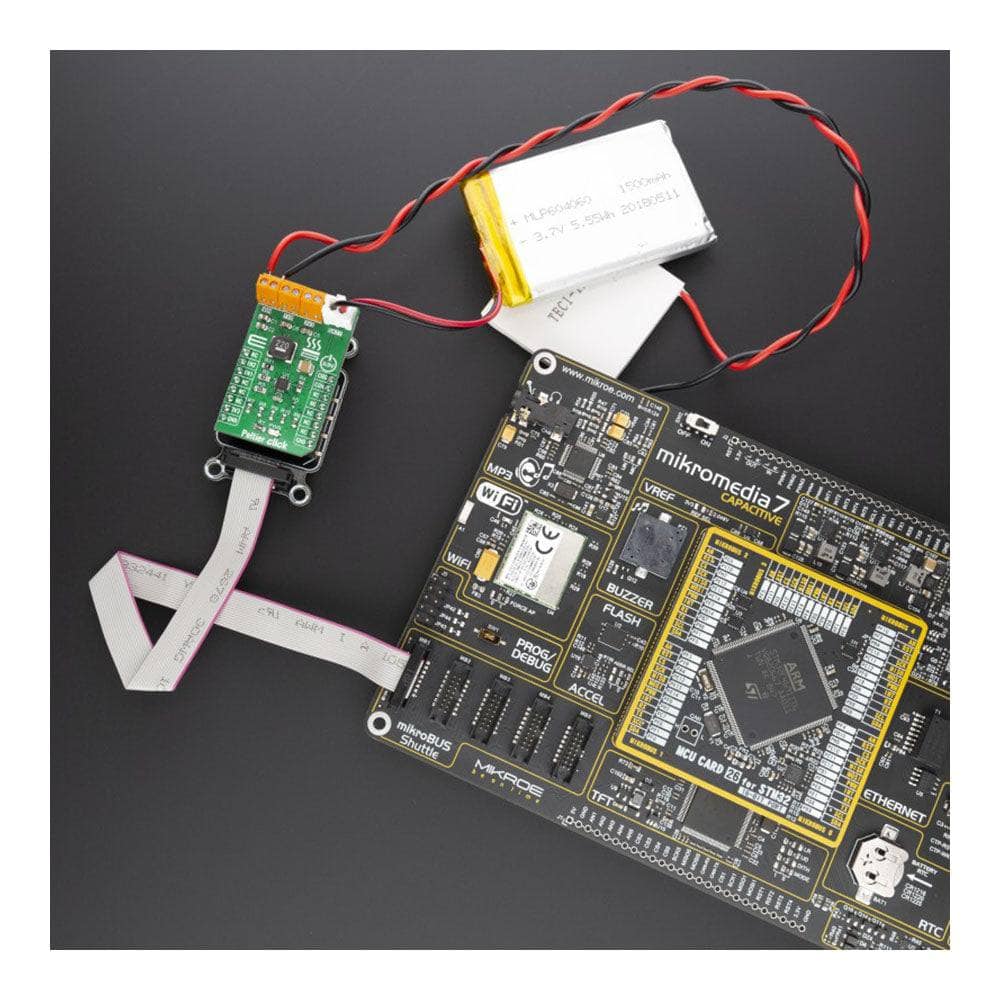

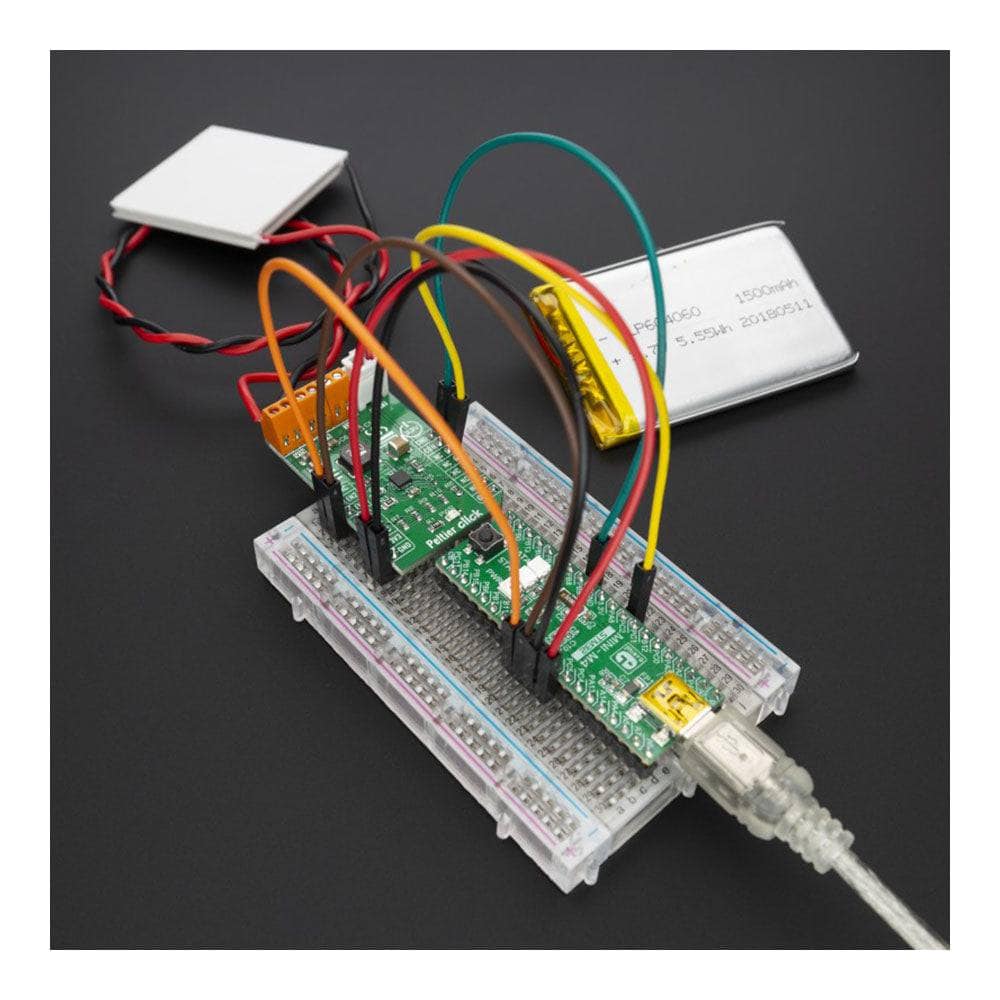

The Peltier Click Board™ uses the SPV1050, an ultralow-power energy harvester and battery charger from STMicroelectronics. The Peltier Click Board™ can charge lithium batteries using a thermoelectric energy harvesting device (TEG). A TEG converts heat directly into electrical energy according to the Seebeck effect. It can be used for various applications such as WSN, HVAC, building and home automation, industrial control, remote metering, lighting, security, surveillance, wearable and biomedical sensors and fitness.

The Peltier Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a thoroughly tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Note: The Peltier Element is available separately.

Downloads

How Does The Peltier Click Board™ Work?

The Peltier Click Board™ is based on the SPV1050, an ultra-low-power energy harvester and battery charger from STMicroelectronics that can charge lithium based batteries. A thermoelectric harvester produces green energy for energy harvesting with a multitude of advantages: maintenance-free, because of the use of highly reliable and compact solid-state device; silent and quiet; highly efficient in environmental terms because the heat is harvested from waste heat sources and converted into electricity. Because of this feature, the Peltier Click Board™ can be used for a variety of applications such as WSN, HVAC, building and home automation, industrial control, remote metering, lighting, security, surveillance, wearable and biomedical sensors and fitness.

The SPV1050 is an ultralow-power and high efficiency energy harvester and battery charger, which implements the MPPT function and integrates the switching elements of a buck-boost converter. The SPV1050 device allows the charge of lithium battery, by tightly monitoring the end-of-charge and the minimum battery voltage in order to avoid the overdischarge and to preserve the battery life. The power manager is suitable for TEG harvesting sources, as it covers the input voltage range from 75 mV up to 18 V and guarantees high efficiency in both buck-boost and boost configuration.

Furthermore the SPV1050 device shows very high flexibility thanks also to the trimming capability of the end-of-charge and undervoltage protection voltages. In such way any source and battery is matched. The MPPT is programmable by a resistor input divider and allows maximizing the source power under any temperature and irradiance condition.

Some of the key features of the SPV1050 are its transformerless thermoelectric generators and PV modules energy harvester, high efficiency for any harvesting source and it has up to 70 mA maximum battery charging current. It is fully integrated buck-boost DC-DC converter with a programmable MPPT by external resistors, 2.6 V to 5.3 V trimmable battery charge voltage level (± 1% accuracy), 2.2 V to 3.6 V trimmable battery discharge voltage level (± 1% accuracy) with two fully independent LDOs (1.8 V and 3.3 V output). The SPV1050 can enable/disable LDO control pins and it has a battery disconnect function for battery protection, and while the battery is connected and ongoing charge logic open drain indication pins.

The SPV1050 is basically an ultra-low-power energy harvester with an embedded MPPT algorithm, a battery charger and power manager designed for applications up to about 400 mW.

SPECIFICATIONS

| Type | Battery charger |

| Applications | Variety of applications such as WSN, HVAC, building and home automation, industrial control, remote metering, lighting, security, surveillance, wearable and biomedical sensors and fitness |

| On-board modules | SPV1050, an ultralow-power energy harvester and battery charger from STMicroelectronics |

| Key Features | Charge any battery type, including lithium based, solid state thin film and super-capacitor, 3.3v input voltage |

| Interface | GPIO |

| Compatibility | mikroBUS |

| Click Board™ size | M (42.9 x 25.4 mm) |

| Input Voltage | 3.3V |

PINOUT DIAGRAM

This table shows how the pinout on Peltier Click Board™ corresponds to the pinout on the mikroBUS socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | CHG | Charing | |

| Enable 3.3V | EN2 | 2 | RST | INT | 15 | CON | Battery connection |

| Enable 1.8V | EN1 | 3 | CS | RX | 14 | NC | |

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | NC | ||

| NC | 6 | MOSI | SDA | 11 | NC | ||

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | NC | |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

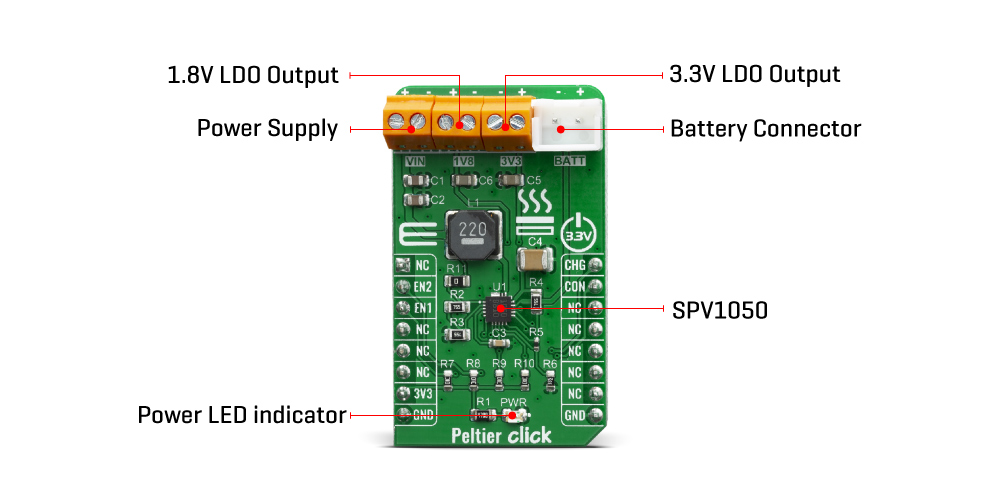

ONBOARD SETTINGS AND INDICATORS

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| TB1 | VIN | - | Power Supply |

| TB2 | 1V8 | - | 1.8V LDO Output |

| TB3 | 3V3 | - | 3.3V LDO Output |

| J1 | BATT | - | Battery Connector |

PELTIER Click Board™ ELECTRICAL SPECIFICATIONS

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Maximum battery charging current | - | - | 70 | mA |

| BATT pin voltage range | 2.2 | 4.2 | 5.3 | V |

| MPPT tracking period | 12 | - | 20 | S |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3814

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018719754

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.