Overview

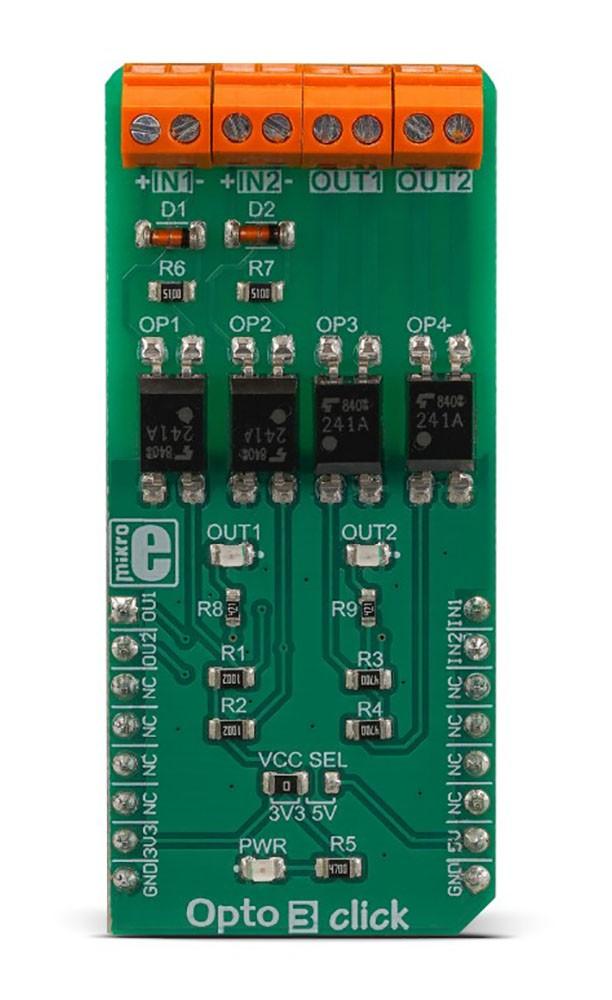

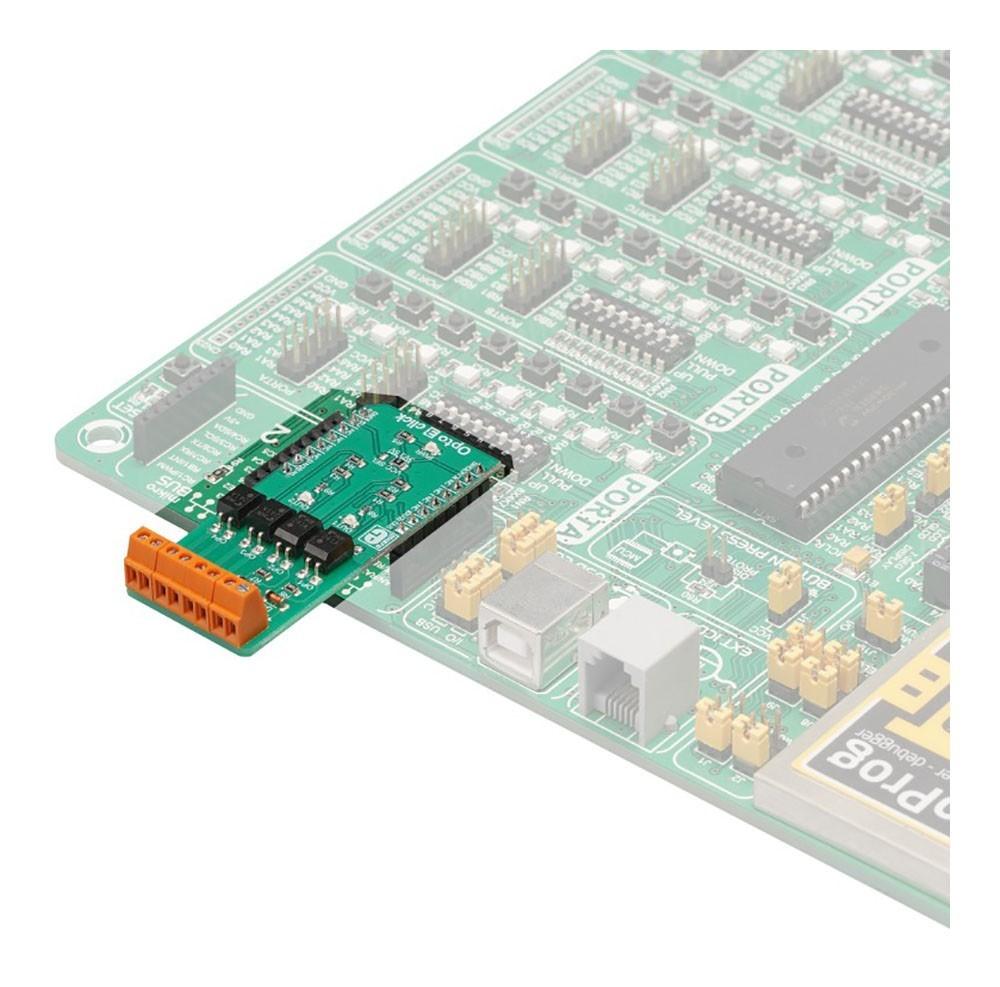

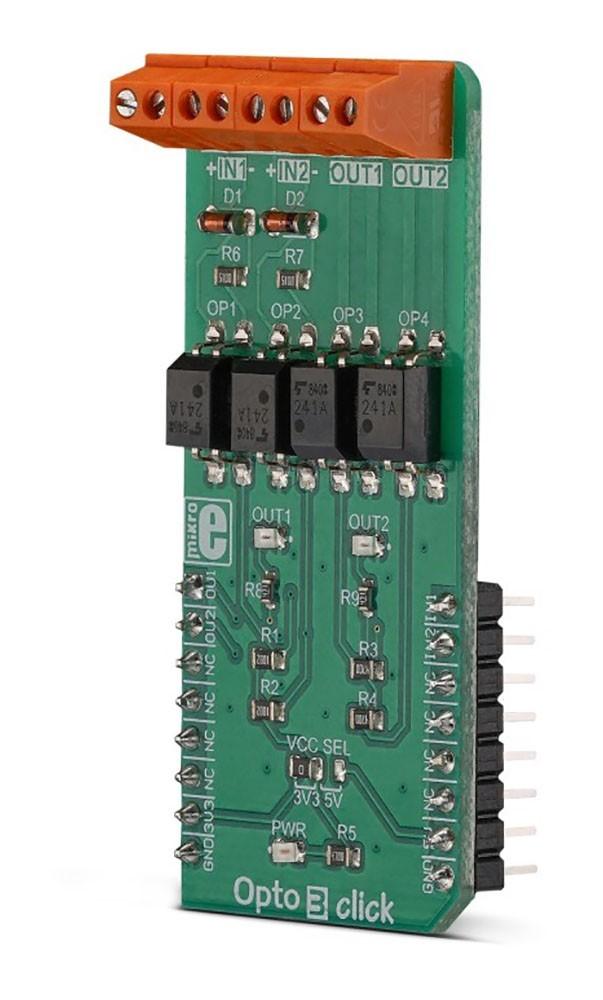

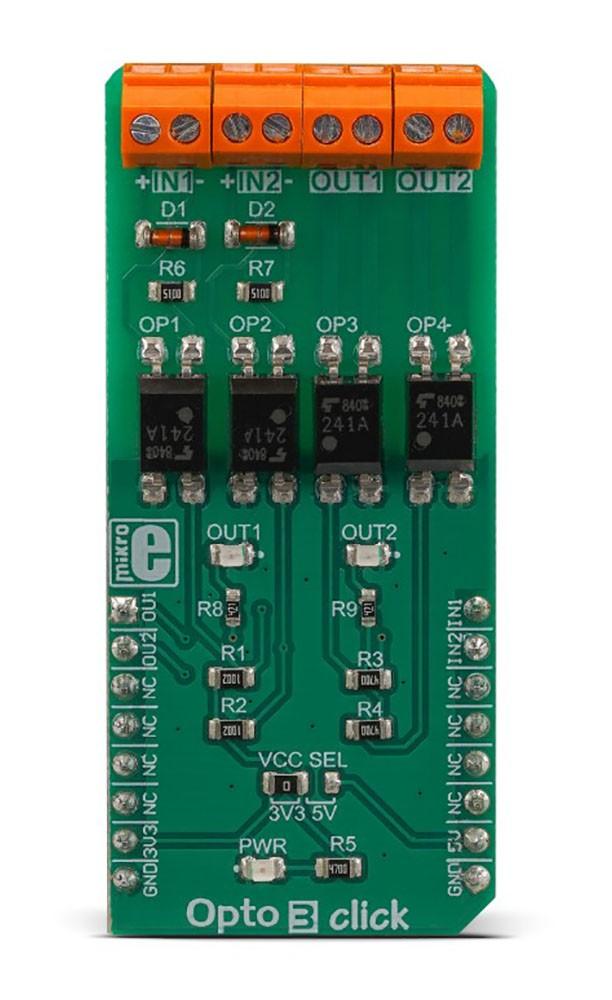

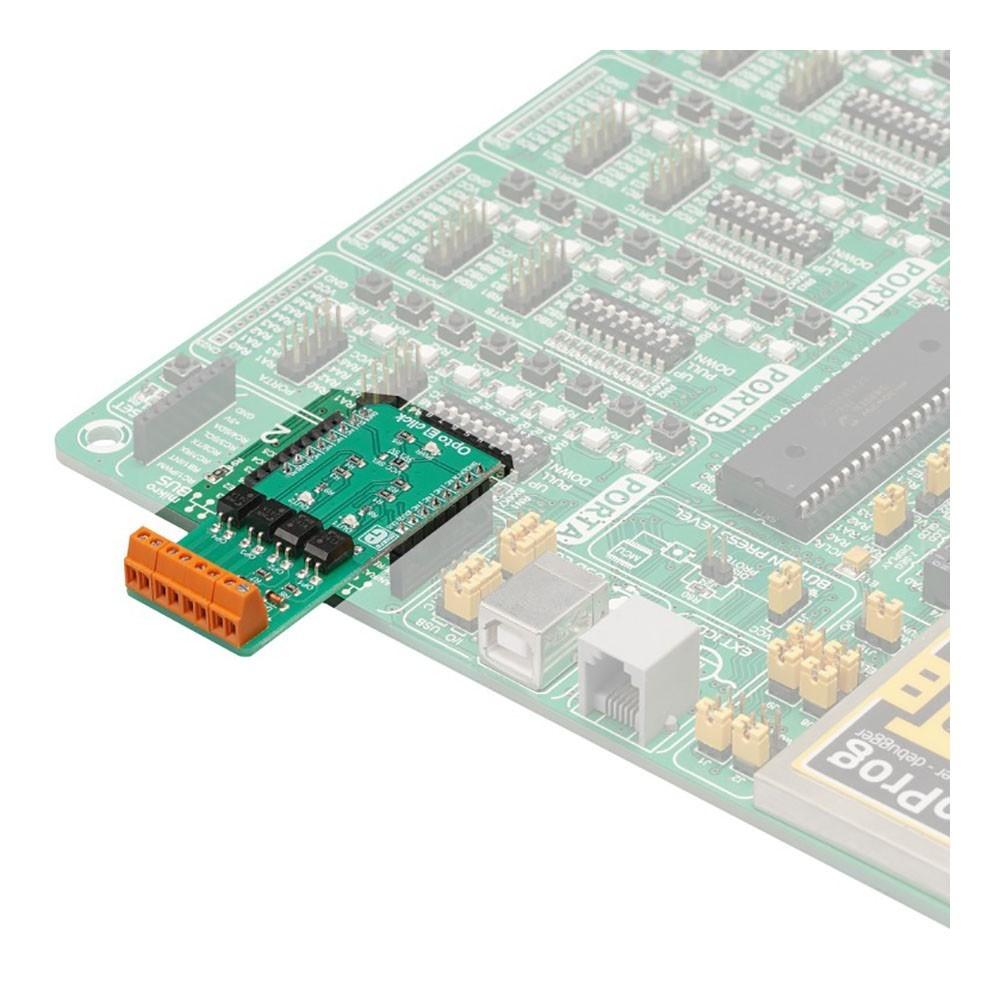

The Opto 3 Click Board™ is equipped with two pairs of optically isolated solid-state relays (SSR). One pair of SSRs is used to provide reinforced galvanic isolation for the external signals used to drive the microcontroller (MCU) pins, while the other pair of SSRs are used to allow the host MCU to drive some external equipment, allowing up to 40V between the SSR contacts in OFF state, and currents up to 2A while in ON state, thanks to a very low ON-state resistance.

The Opto 3 Click Board™ is to be used in applications that require reinforced galvanic isolation for both their input and output stages.

Downloads

Le Opto 3 Click Board™ est équipé de deux paires de relais statiques (SSR) optiquement isolés. Une paire de SSR est utilisée pour fournir une isolation galvanique renforcée pour les signaux externes utilisés pour piloter les broches du microcontrôleur (MCU), tandis que l'autre paire de SSR est utilisée pour permettre au MCU hôte de piloter certains équipements externes, permettant jusqu'à 40 V entre les contacts SSR à l'état OFF, et des courants jusqu'à 2 A à l'état ON, grâce à une très faible résistance à l'état ON.

L' Opto 3 Click Board™ doit être utilisé dans les applications qui nécessitent une isolation galvanique renforcée pour leurs étages d'entrée et de sortie.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3319

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.023 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018714261

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.