Overview

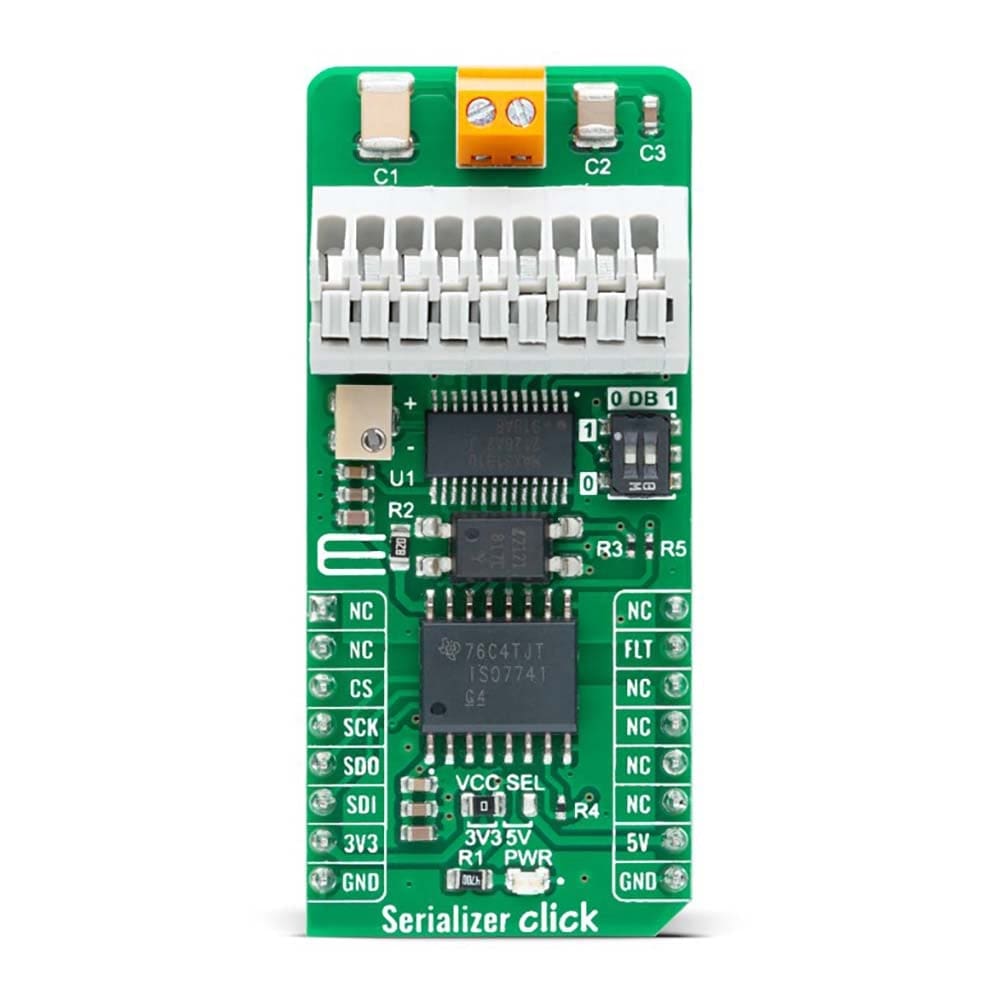

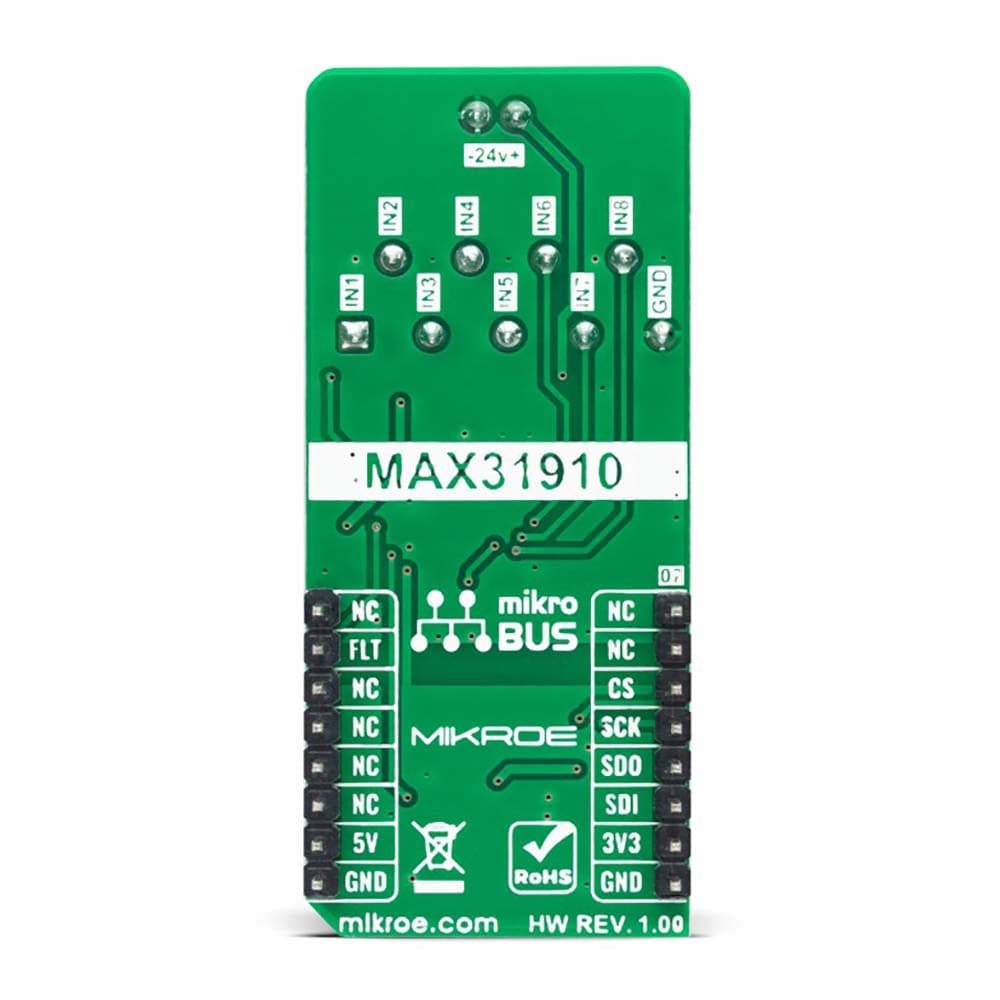

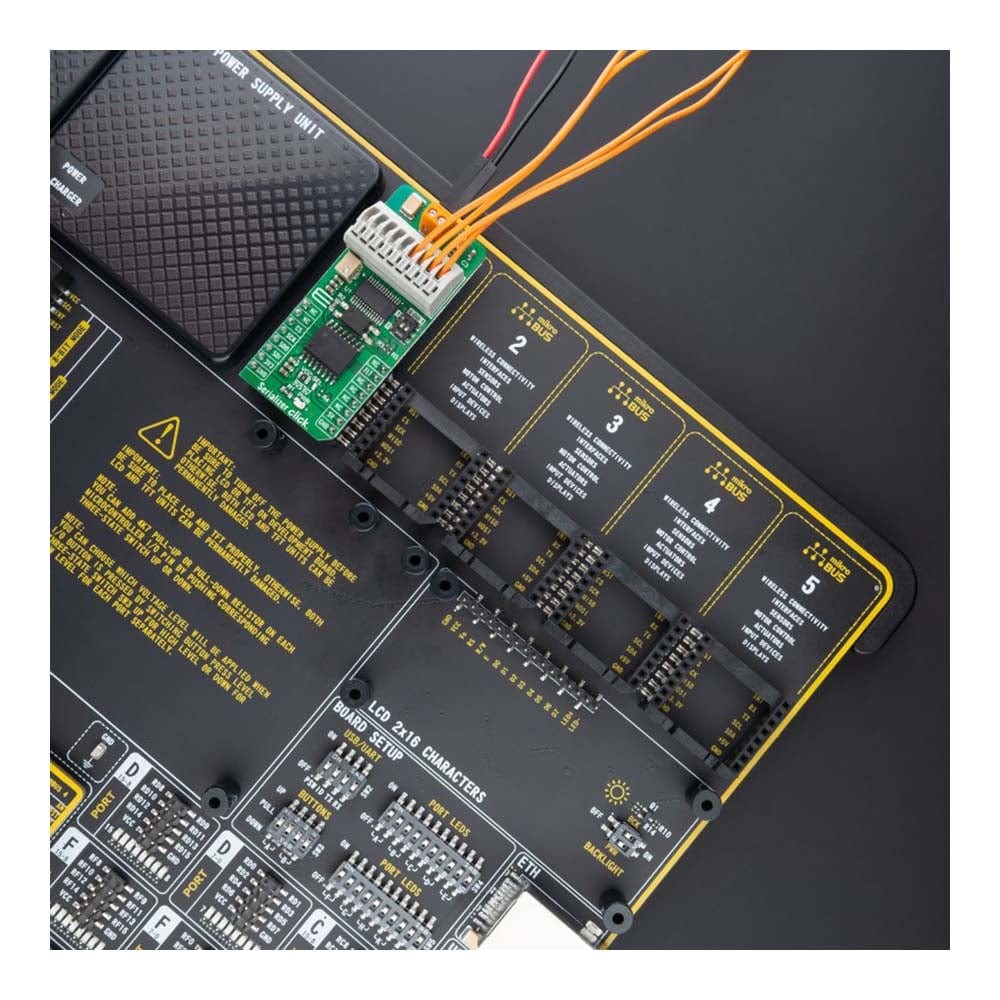

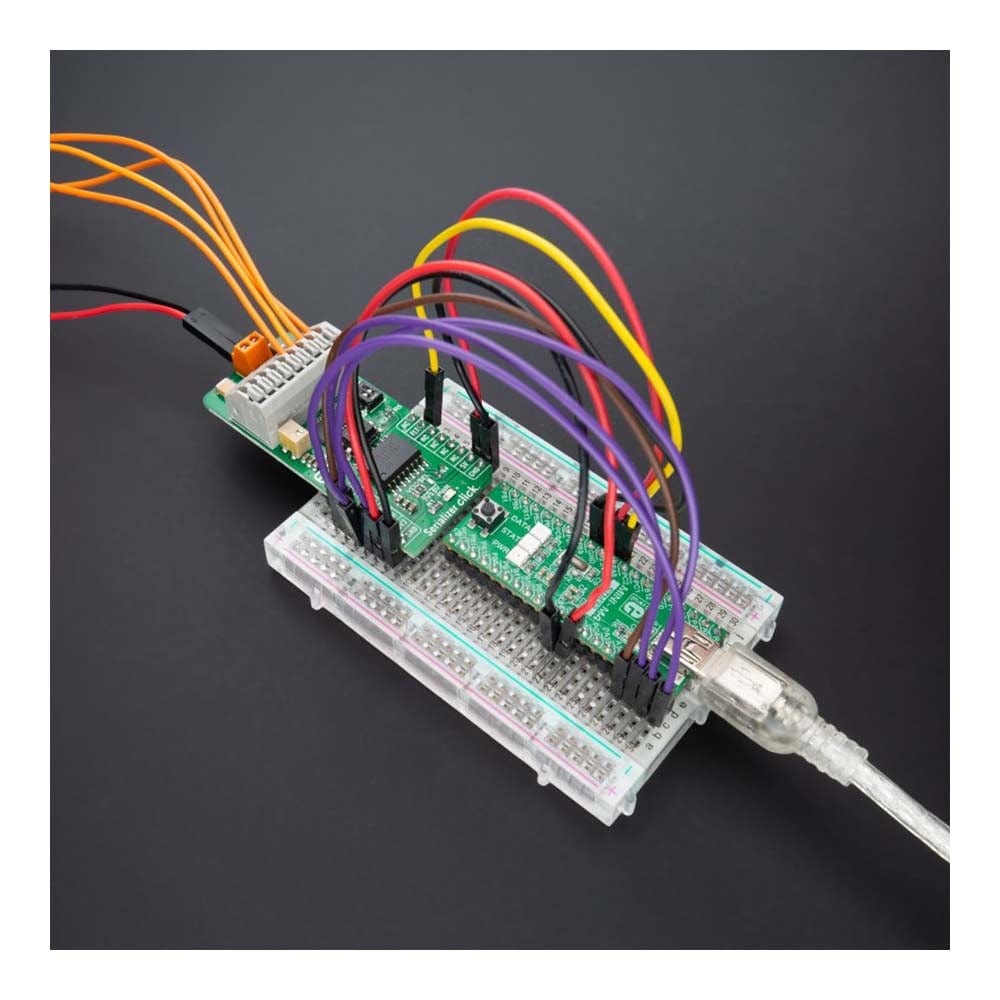

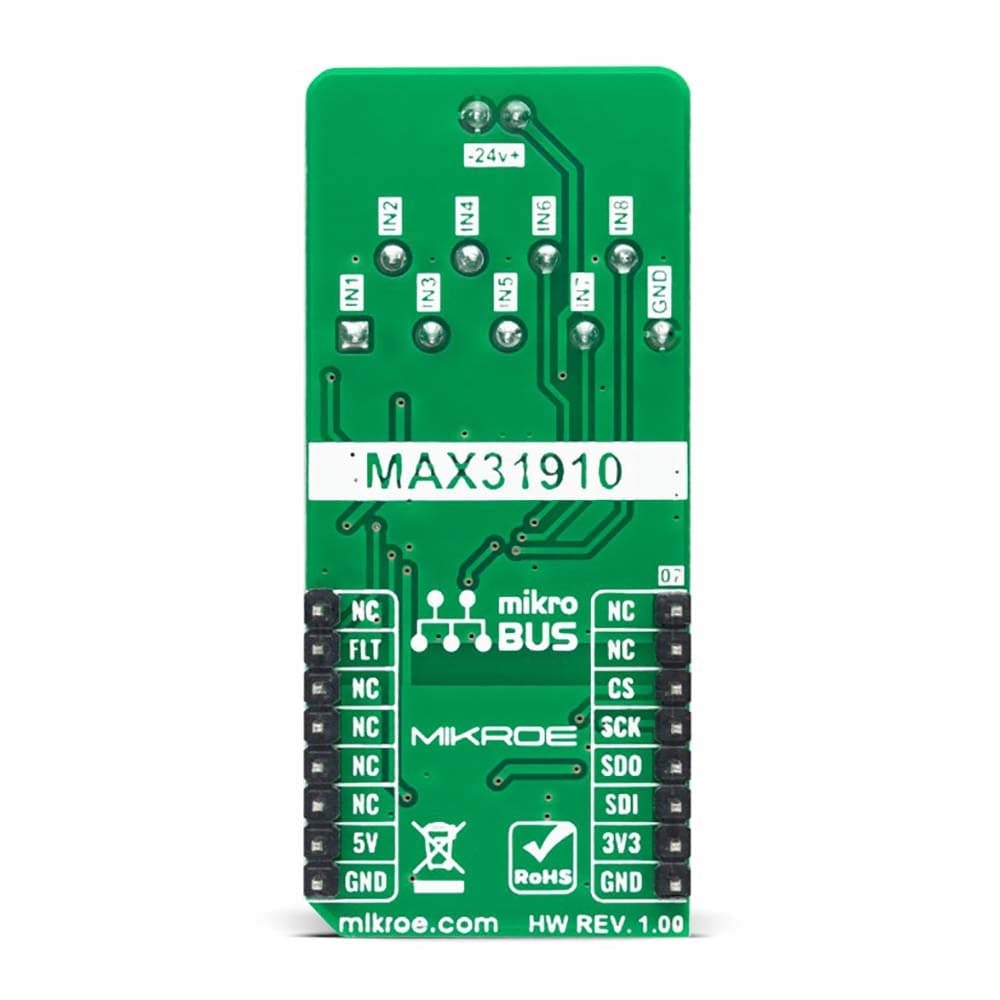

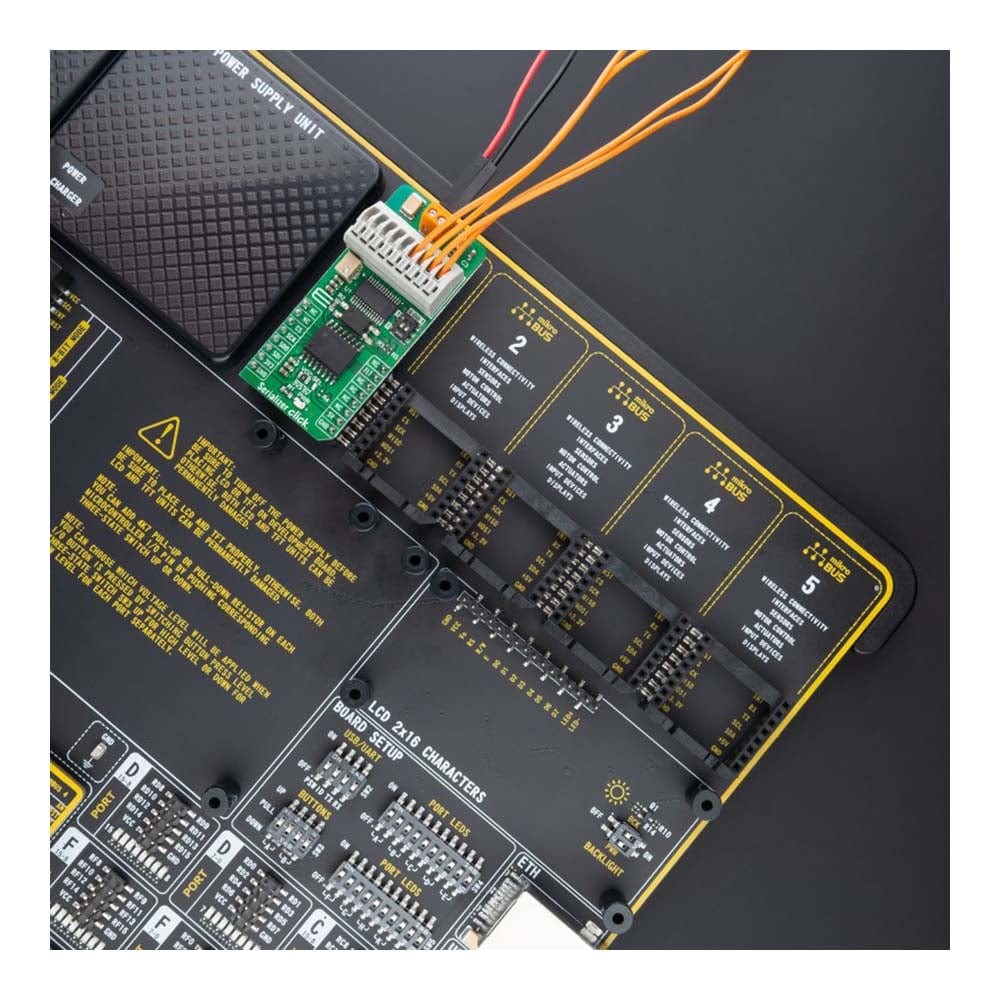

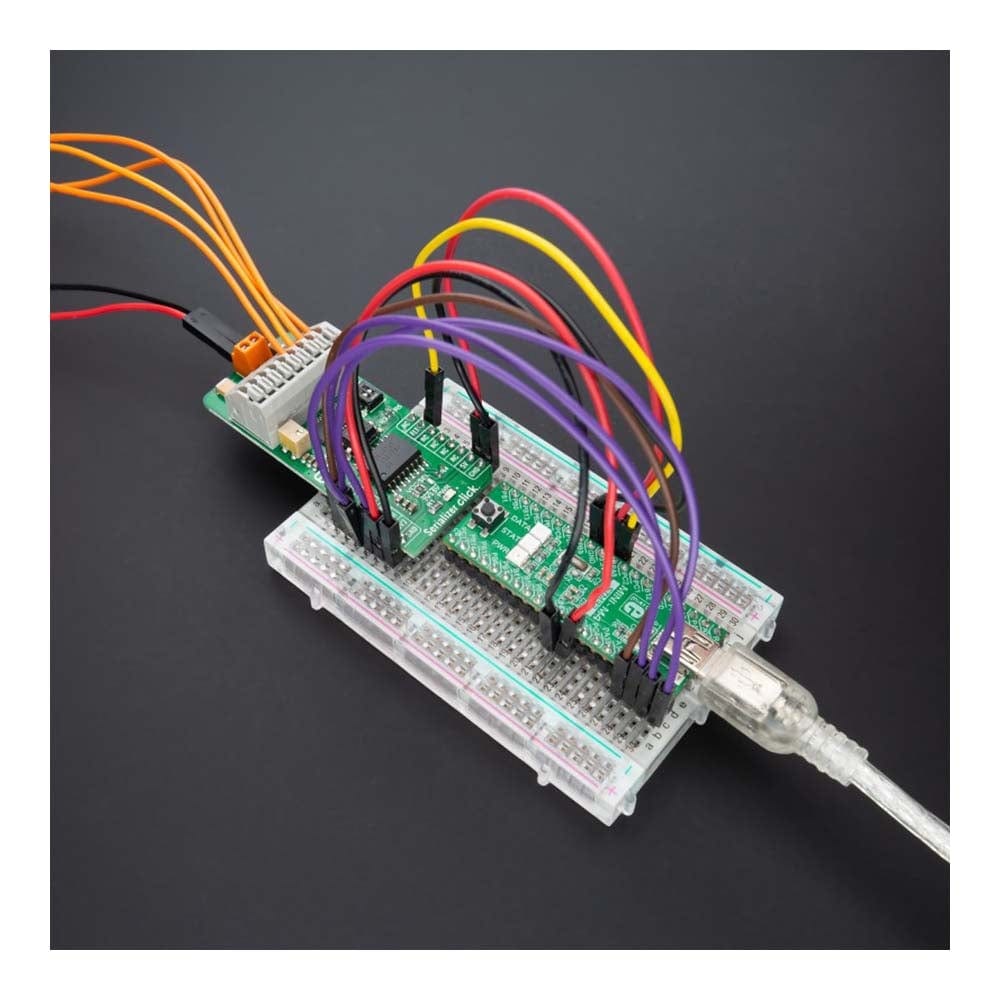

The Serializer Click Board™ is a compact add-on board that contains a digital input translator/serializer. This board features the MAX31910, an eight-channel digital input serializer for high-channel density digital input modules in industrial and process automation from Maxim. The MAX31910 translates, conditions, and serializes the 24V digital output of sensors and switches to 5V CMOS-compatible signals required by the MCU. It provides the front-end interface circuit of a programmable logic controller (PLC) digital input module. It communicates with MCU via the SPI interface and comes in configuration with an installed digital isolator.

The Serializer Click Board™ is suited for various applications such as industrial, process, and building automation, digital input modules for PLCs, and more.

Downloads

La carte Serializer Click Board™ est une carte complémentaire compacte qui contient un traducteur/sérialiseur d'entrée numérique. Cette carte comprend le MAX31910, un sérialiseur d'entrée numérique à huit canaux pour les modules d'entrée numérique à haute densité de canaux dans l'automatisation industrielle et des processus de Maxim. Le MAX31910 traduit, conditionne et sérialise la sortie numérique 24 V des capteurs et des commutateurs en signaux compatibles CMOS 5 V requis par le MCU. Il fournit le circuit d'interface frontal d'un module d'entrée numérique de contrôleur logique programmable (PLC). Il communique avec le MCU via l'interface SPI et est livré en configuration avec un isolateur numérique installé.

Le Serializer Click Board™ est adapté à diverses applications telles que l'automatisation industrielle, des processus et des bâtiments, les modules d'entrée numériques pour PLC, etc.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4925

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027389788

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.