Overview

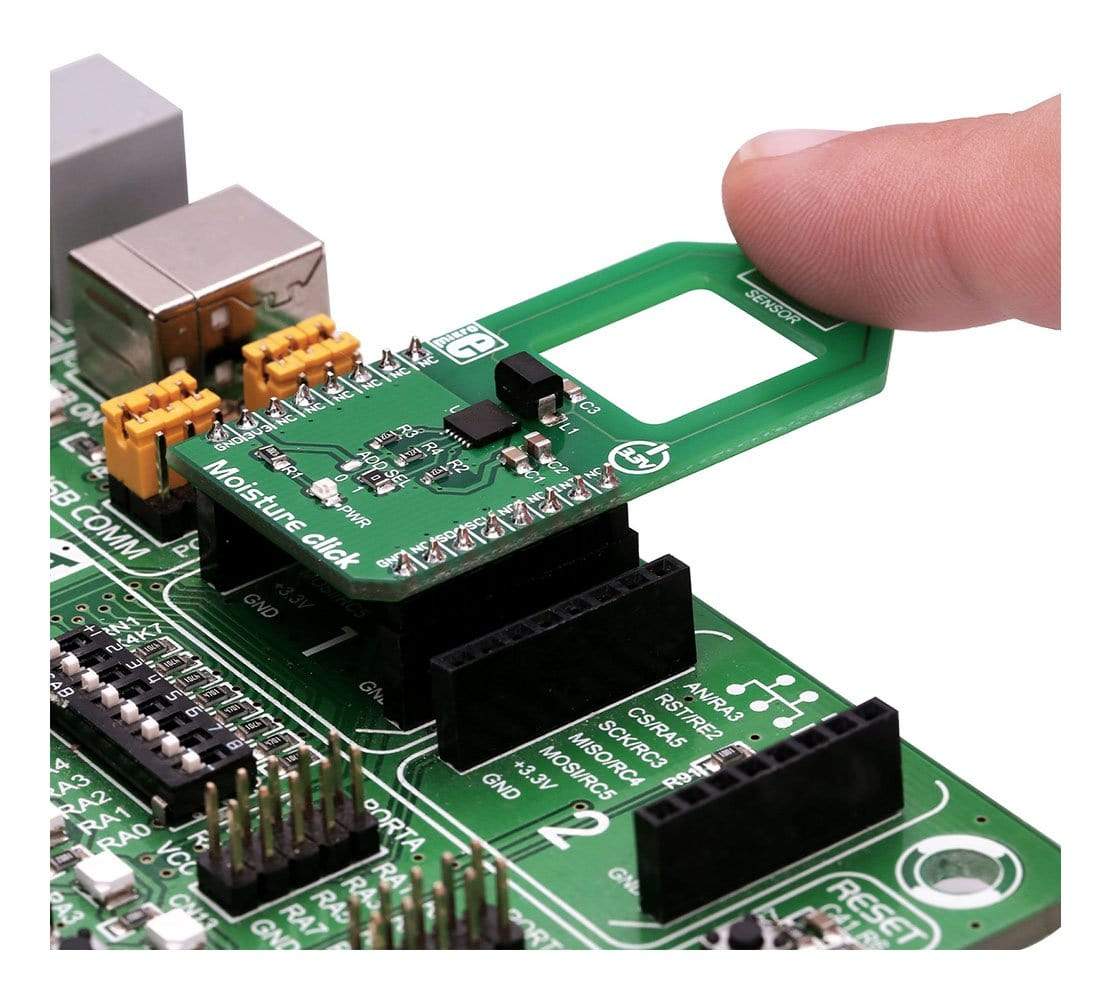

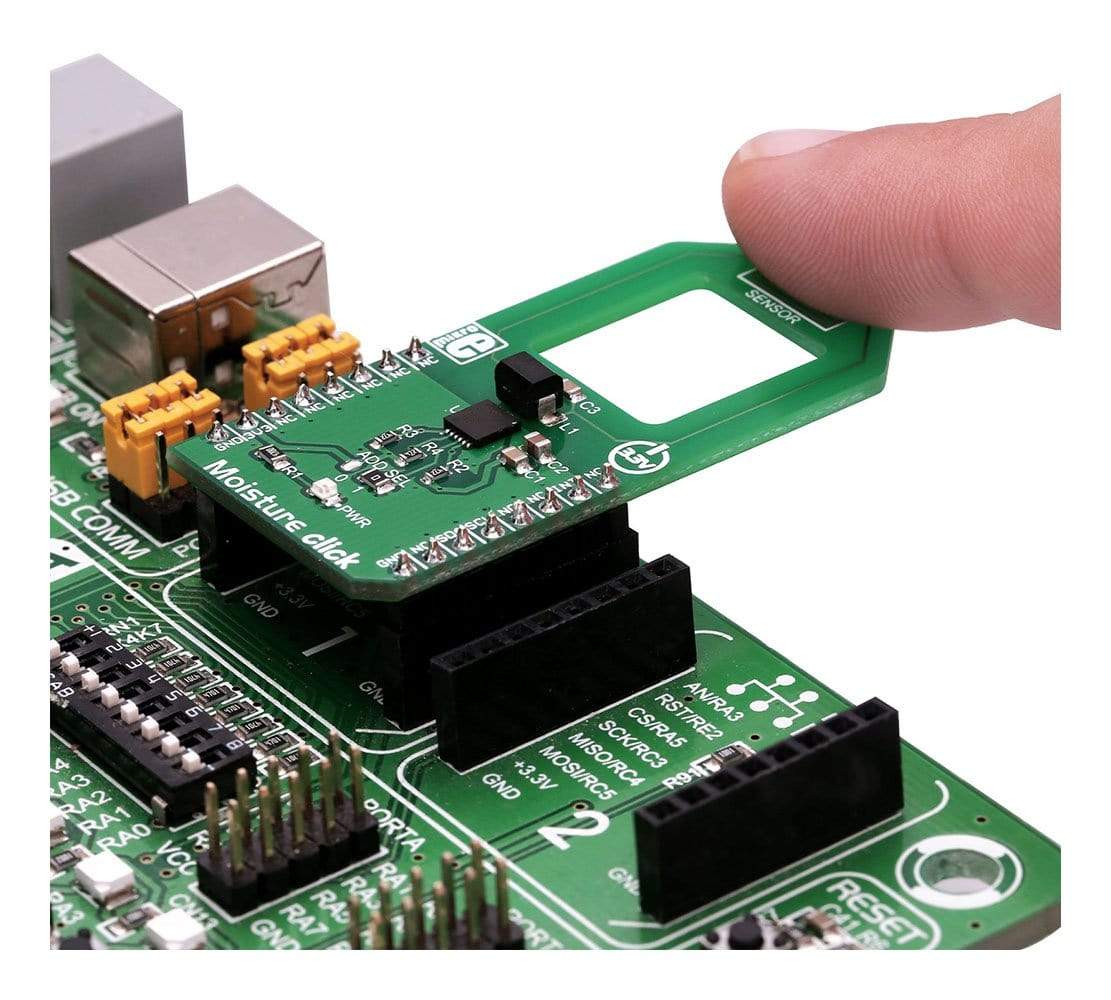

The Moisture Click Board™ can be used to easily detect a moisture level of the skin, by simply touching the sensitive surface of the PCB. The Click Board™ is equipped with the printed copper trace sensor, which is sampled by the accurate FDC2112 IC, a 12-bit capacitance to digital (FDC) converter, which employs innovative noise and EMI resistant capacitance measuring techniques. This sensor allows the Click Board™ to measure the skin moisture by measuring its capacitance, which changes depending on the skin moisture level (hydration state of the outer epidermis).

Downloads

Le Moisture Click Board™ peut être utilisé pour détecter facilement le niveau d'humidité de la peau, en touchant simplement la surface sensible du PCB. Le Click Board™ est équipé d'un capteur de traces de cuivre imprimé, qui est échantillonné par le circuit intégré précis FDC2112, un convertisseur de capacité en numérique (FDC) 12 bits, qui utilise des techniques de mesure de capacité innovantes résistantes au bruit et aux interférences électromagnétiques. Ce capteur permet au Click Board™ de mesurer l'humidité de la peau en mesurant sa capacité, qui change en fonction du niveau d'hydratation de la peau (état d'hydratation de l'épiderme externe).

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3084

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713233

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.