Overview

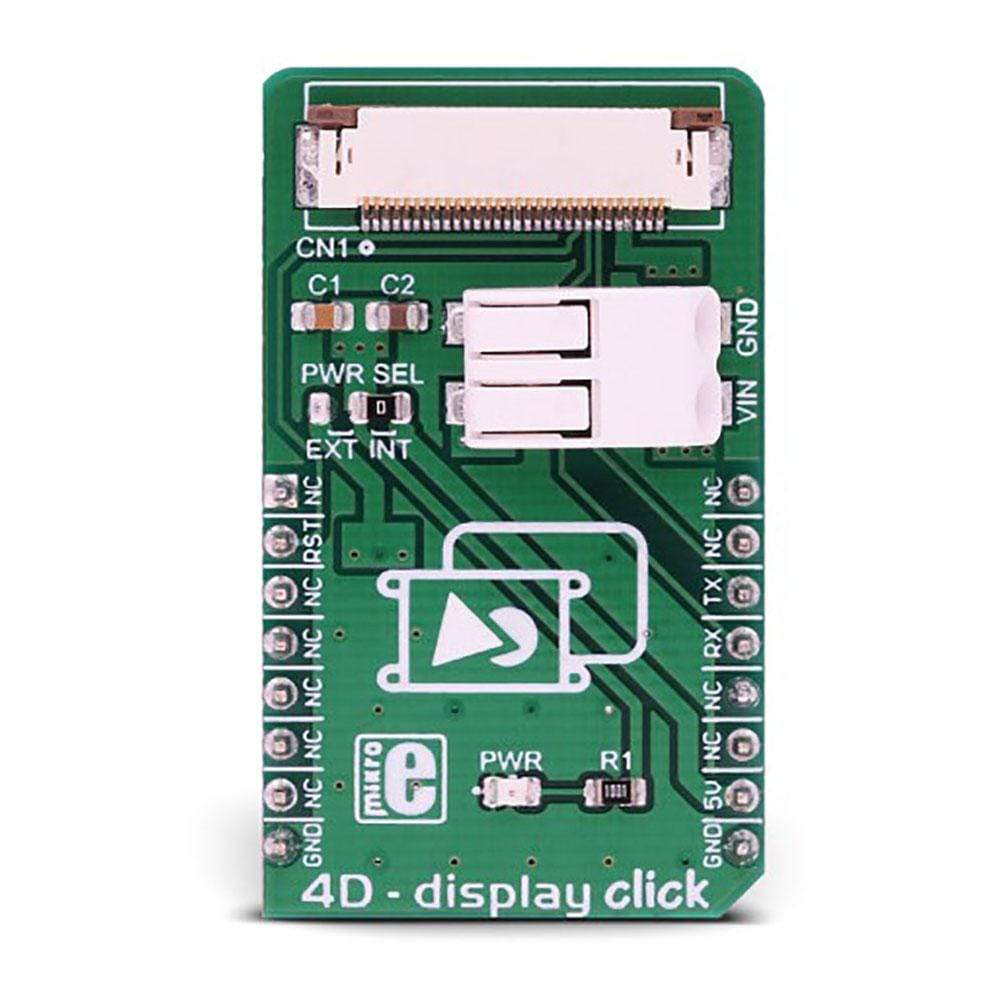

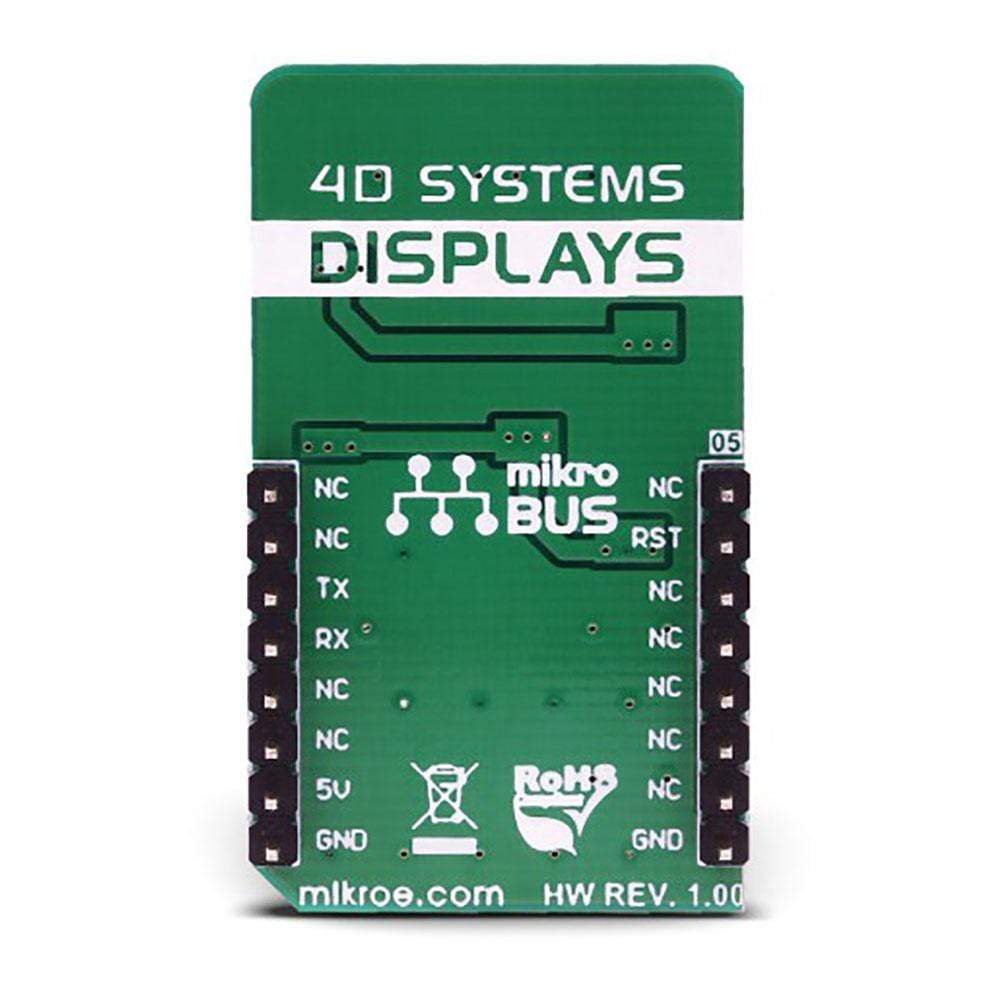

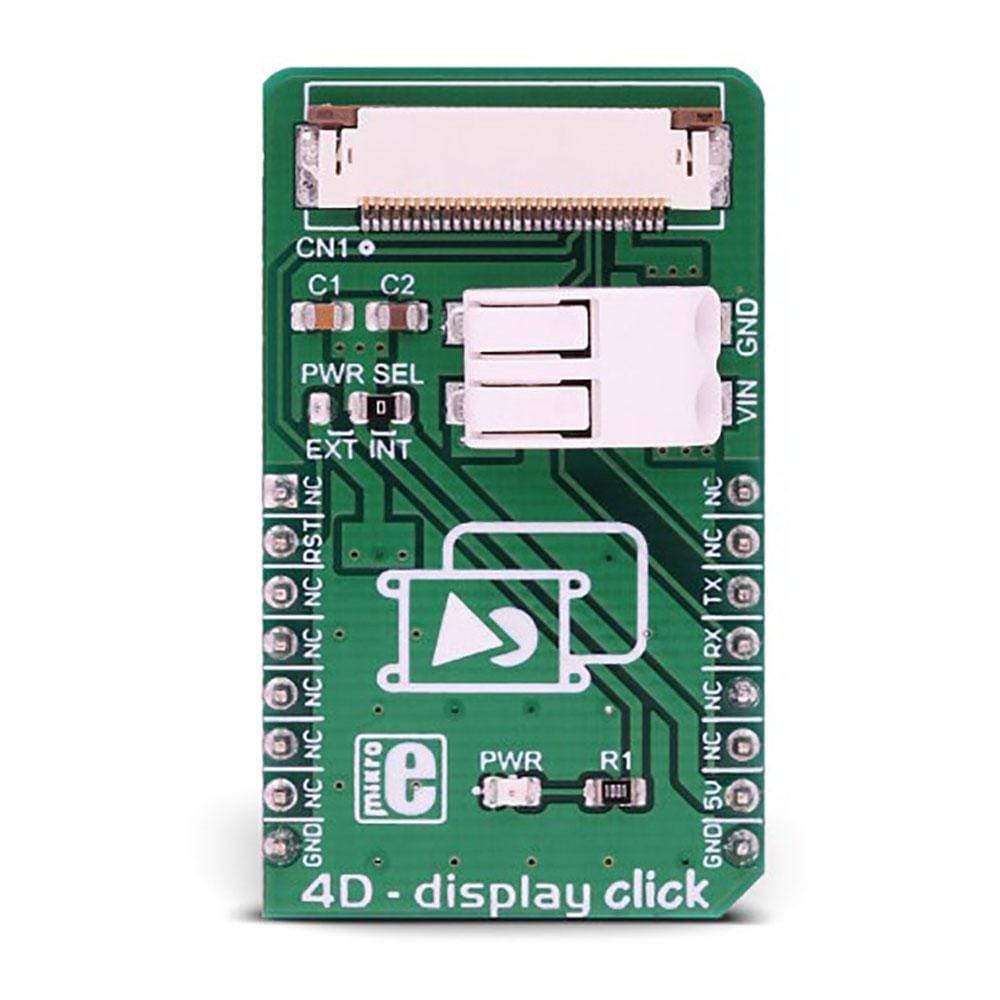

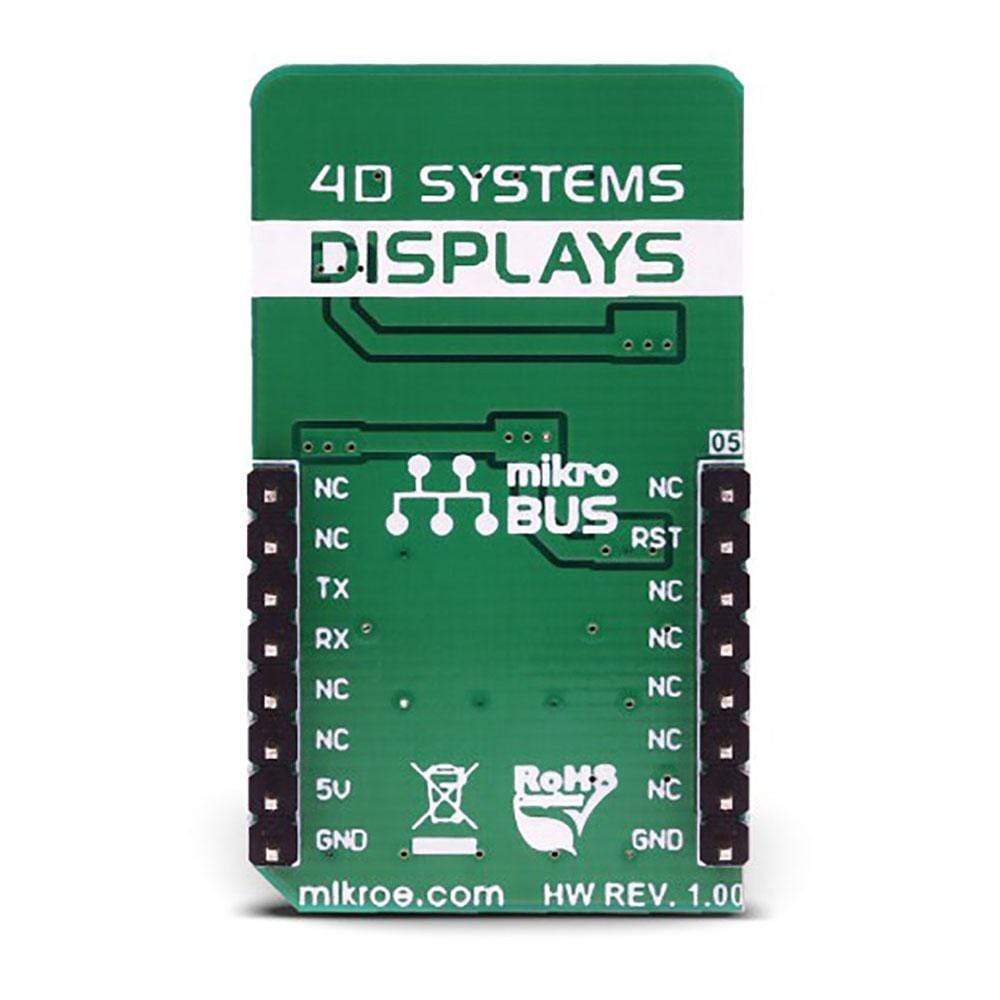

The 4D - Display Click Board™ is an adapter Click Board™ that offers a mikroBUS interface for controlling 4D Systems gen4 Series intelligent Display Modules. 4D Systems designs and manufactures a wide range of Intelligent Display Modules equipped with powerful graphics processors. Their displays allow graphical objects control by exchanging specifically formatted messages with the external microcontroller (MCU) over the UART.

By utilizing the 4D - Display Click Board™, it is possible to develop an MCU firmware application that can interact with the graphic objects on the 4D Intelligent Display Module over the mikroBUS. This significantly simplifies the application design, while reducing the processing load on the host MCU, allowing amazing graphically based applications to be created, even with slower 8-bit MCUs.

Downloads

Le 4D - Display Click Board™ est un adaptateur Click Board™ qui offre une interface mikroBUS pour contrôler les modules d'affichage intelligents de la série gen4 de 4D Systems. 4D Systems conçoit et fabrique une large gamme de modules d'affichage intelligents équipés de puissants processeurs graphiques. Leurs écrans permettent de contrôler des objets graphiques en échangeant des messages spécifiquement formatés avec le microcontrôleur externe (MCU) via l'UART.

En utilisant le 4D - Display Click Board™ , il est possible de développer une application de micrologiciel MCU capable d'interagir avec les objets graphiques du module d'affichage intelligent 4D via le mikroBUS. Cela simplifie considérablement la conception de l'application, tout en réduisant la charge de traitement sur le MCU hôte, ce qui permet de créer des applications graphiques étonnantes, même avec des MCU 8 bits plus lents.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3044

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.019 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713080

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.