Overview

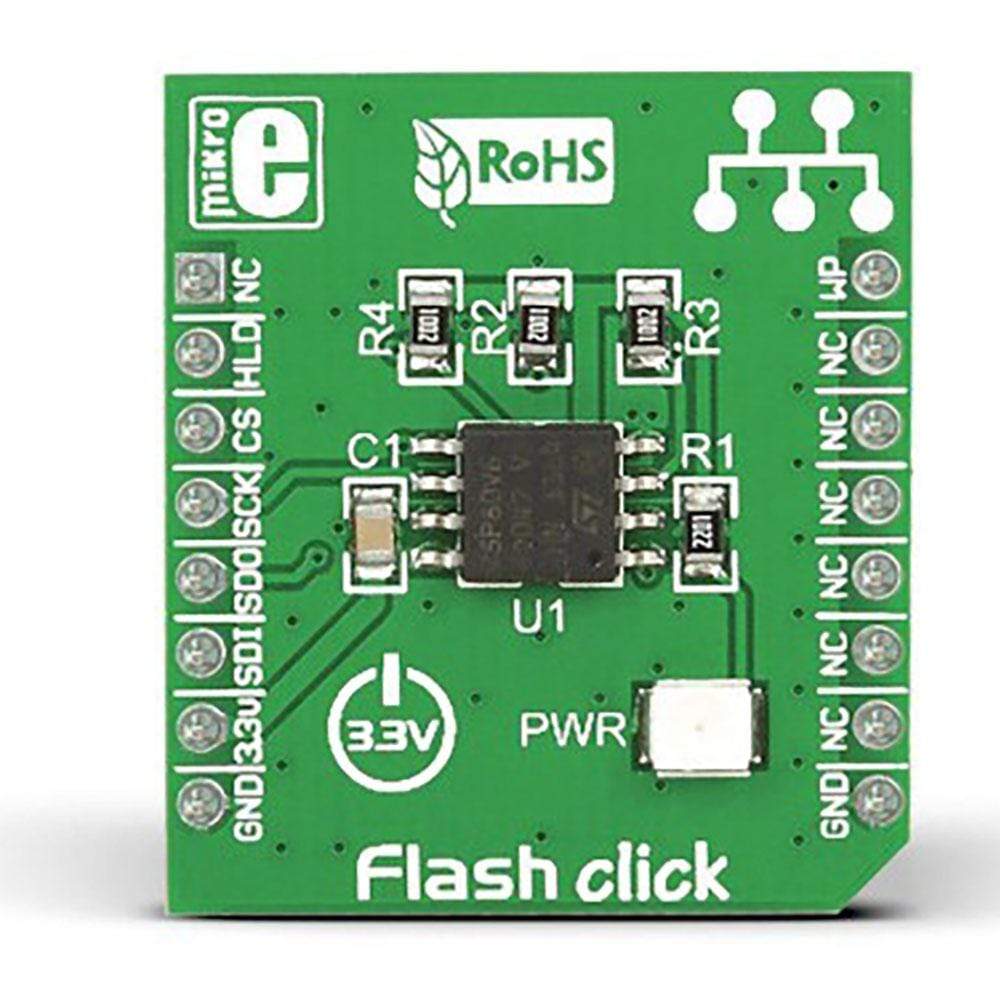

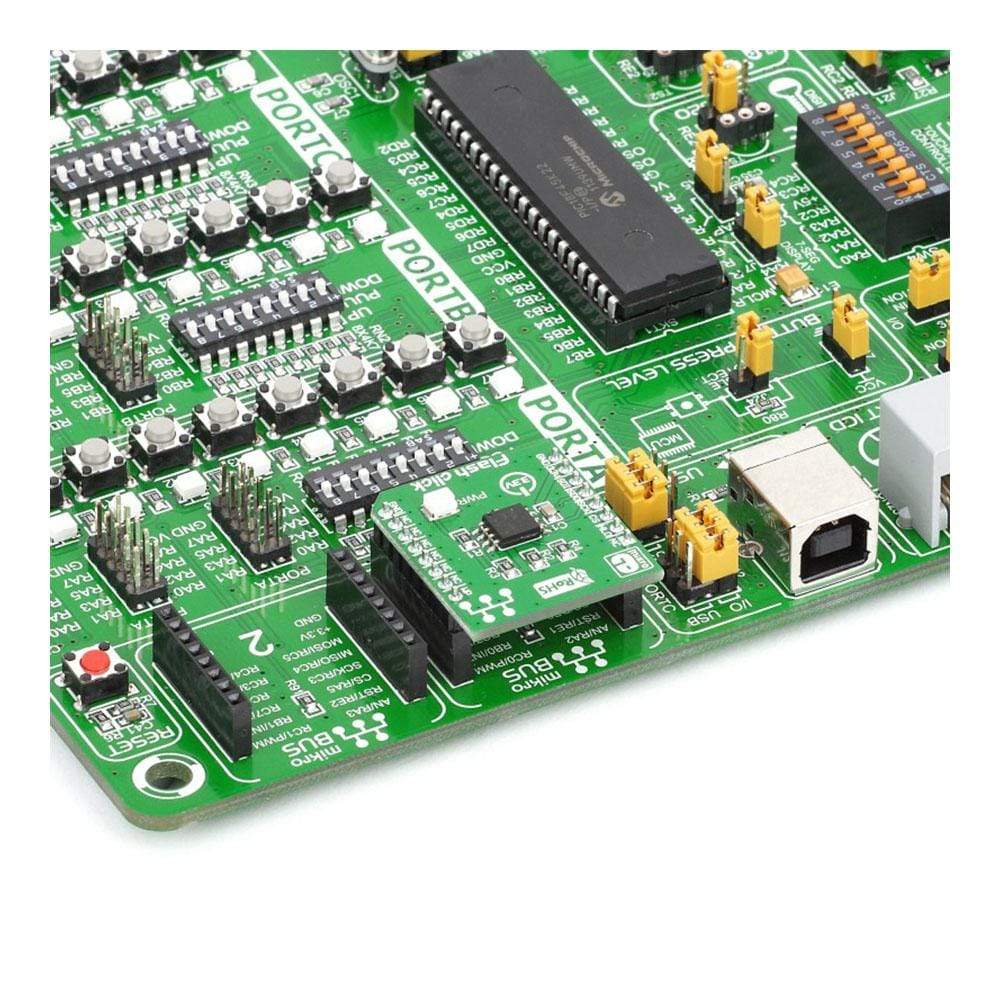

Introduce additional flash memory to your design with the Flash Click Board™. This small accessory board offers an easy and reliable solution for externally storing large amounts of data to be used in the project. The board features an EN25F80 8 megabit serial flash memory with uniform 4 Kbytes sector architecture. Designed for applications that need high performance and low power consumption, it supports clock frequency up to 75 MHz. EN25F80 module comes with software and hardware Write protection that enables the user to Write Protect all or portion of memory via software. The memory is divided into 16 sectors, each containing 256 pages; each page is 256 bytes wide. Flash Click Board™ communicates with the target board microcontroller through the SPI interface. The board is designed to use a 3.3V power supply only. The green LED diode denotes the power supply status.

The Flash Click Board™ is an ideal choice for a mass storage option in multimedia devices, drives, optical and printing devices.

Downloads

Introduisez une mémoire flash supplémentaire dans votre conception avec la carte Flash Click Board™ . Cette petite carte accessoire offre une solution simple et fiable pour stocker en externe de grandes quantités de données à utiliser dans le projet. La carte est dotée d'une mémoire flash série EN25F80 de 8 mégabits avec une architecture de secteur uniforme de 4 Ko. Conçue pour les applications nécessitant des performances élevées et une faible consommation d'énergie, elle prend en charge une fréquence d'horloge jusqu'à 75 MHz. Le module EN25F80 est fourni avec une protection en écriture logicielle et matérielle qui permet à l'utilisateur de protéger en écriture tout ou partie de la mémoire via un logiciel. La mémoire est divisée en 16 secteurs, chacun contenant 256 pages ; chaque page a une largeur de 256 octets. La carte Flash Click Board™ communique avec le microcontrôleur de la carte cible via l'interface SPI. La carte est conçue pour utiliser uniquement une alimentation 3,3 V. La diode LED verte indique l'état de l'alimentation.

Le Flash Click Board™ est un choix idéal pour une option de stockage de masse dans les appareils multimédias, les lecteurs, les périphériques optiques et d'impression.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-1199

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.03 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606015073941

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.