Overview

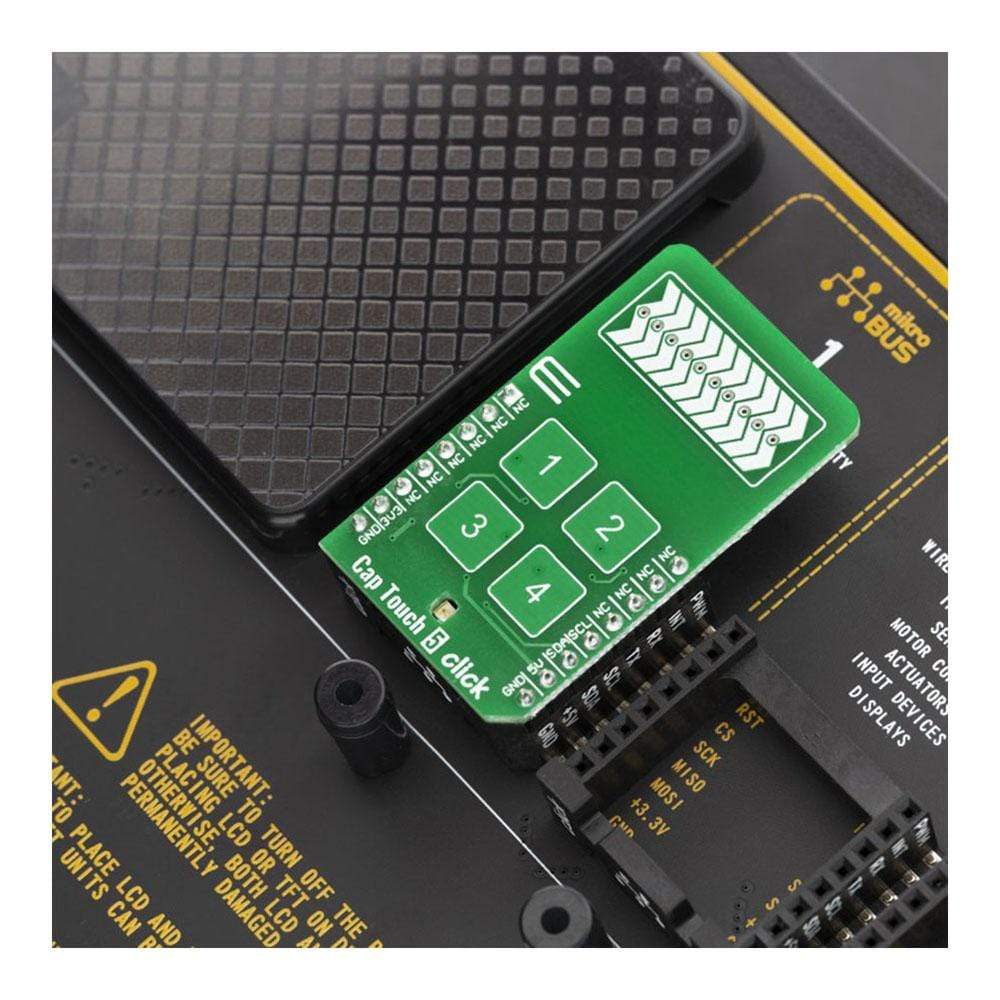

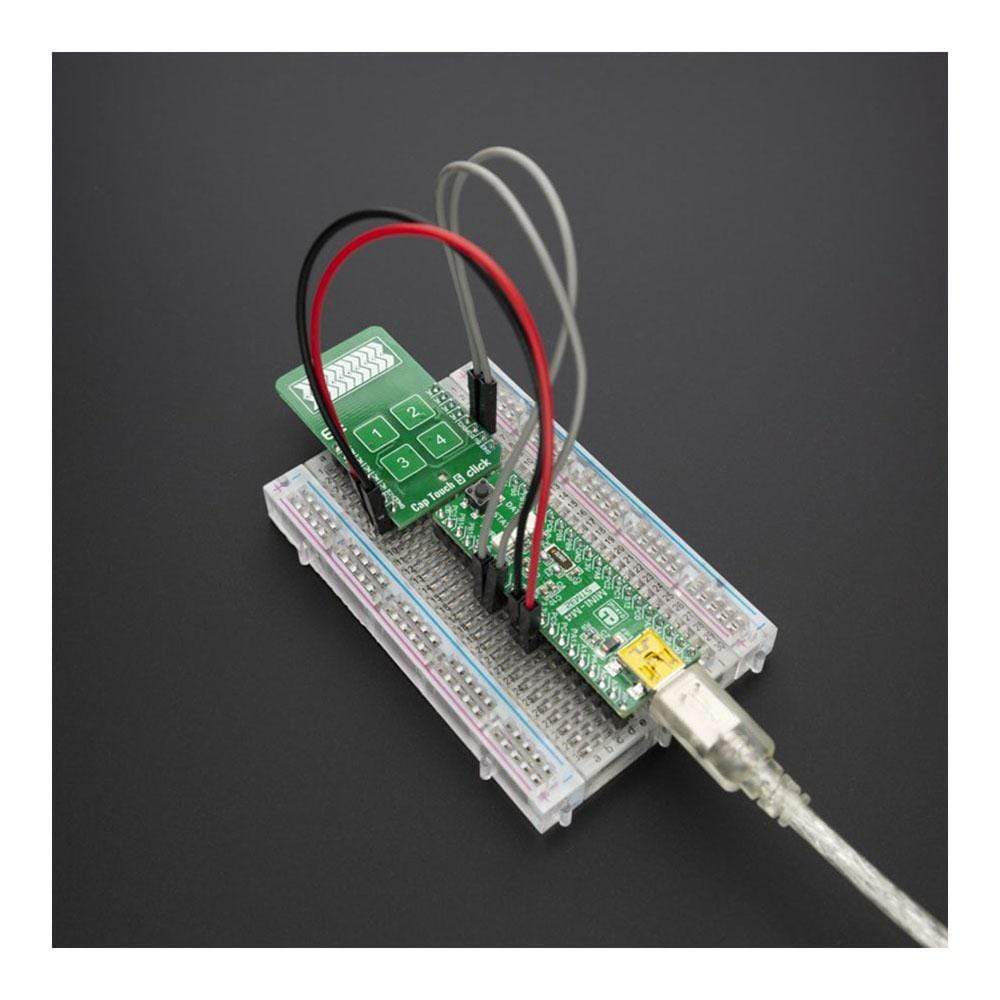

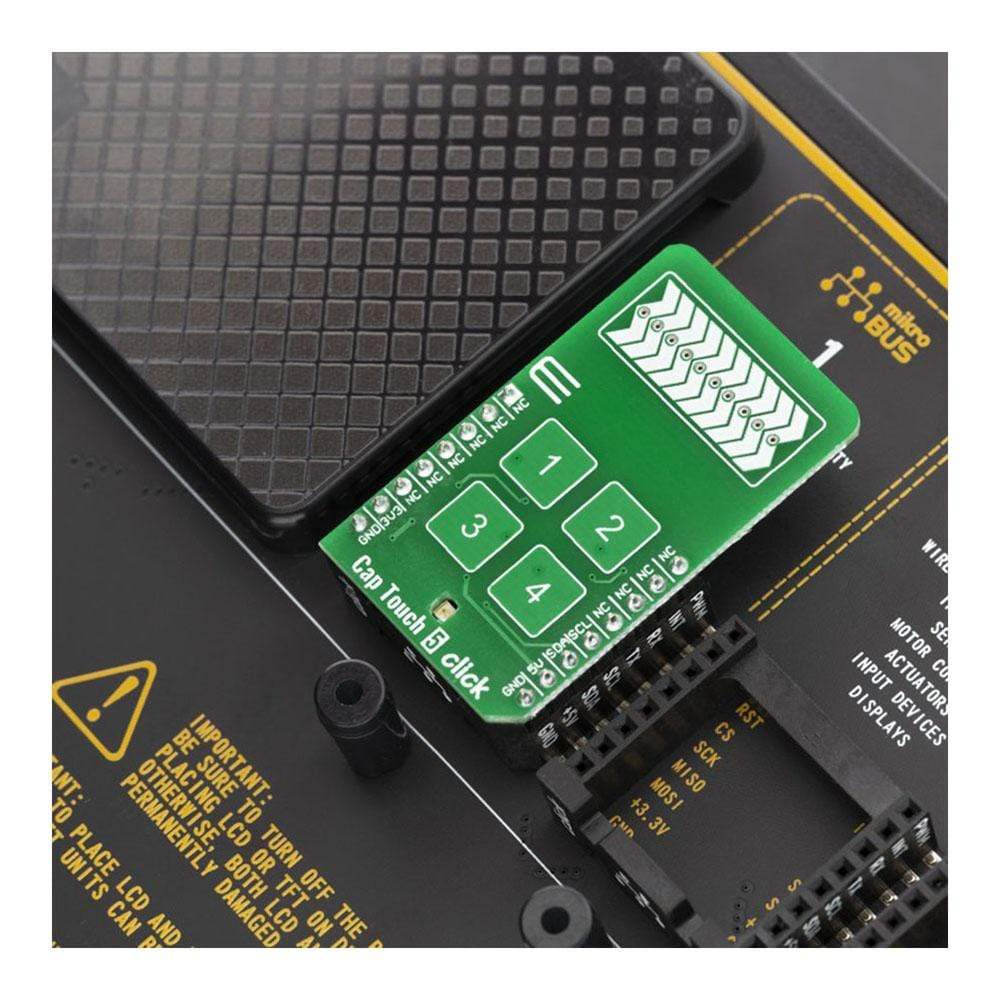

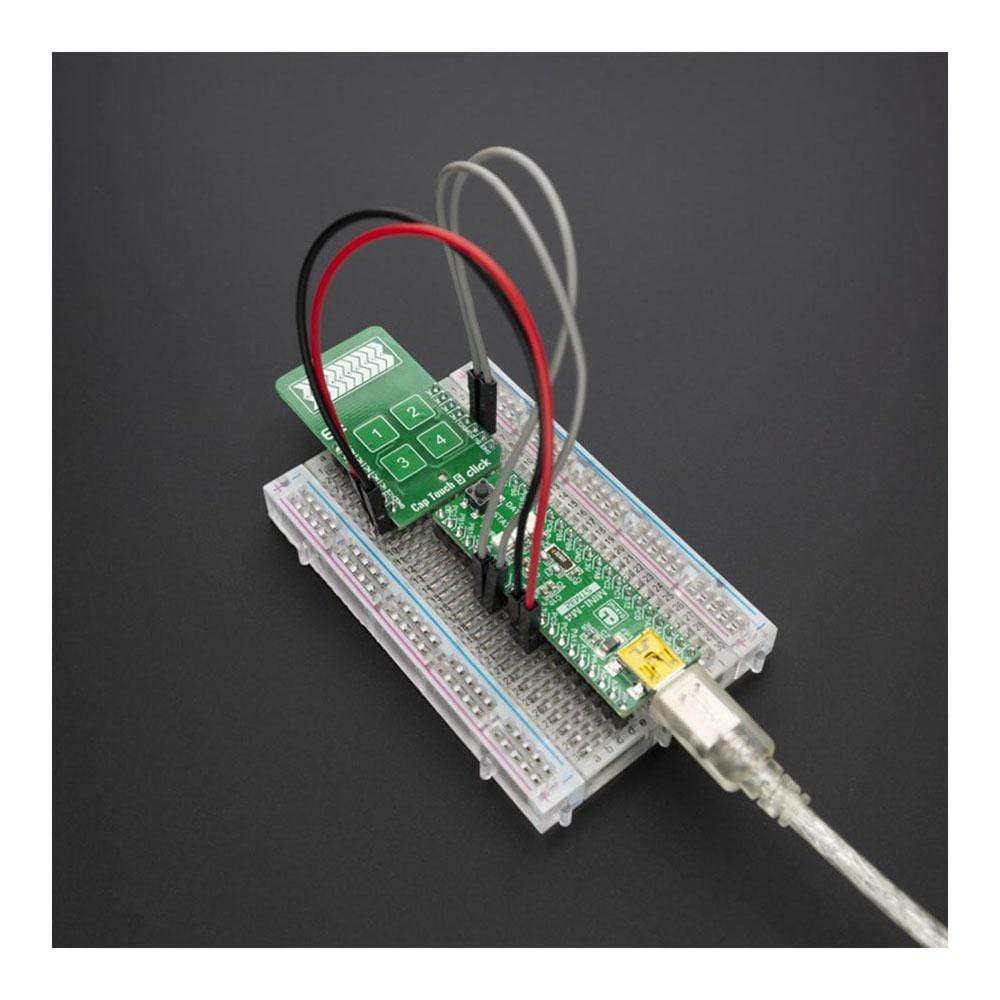

The Cap Touch 5 Click Board™ is a capacitive touch sensing Click Board™ that features the CY8CMBR3106S-LQXI CapSense® Express™ controller which enables advanced, yet easy-to-implement, capacitive touch sensing user interface solutions. It supports up to 16 capacitive sensing inputs, eliminates time-consuming firmware development. This controller is ideal for implementing capacitive buttons, sliders, and proximity sensing solutions with minimal development-cycle times.

The Cap Touch 5 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Le Cap Touch 5 Click Board™ est un Click Board™ à détection tactile capacitive doté du contrôleur CapSense® Express™ CY8CMBR3106S-LQXI qui permet des solutions d'interface utilisateur à détection tactile capacitive avancées, mais faciles à mettre en œuvre. Il prend en charge jusqu'à 16 entrées de détection capacitive, éliminant ainsi le développement fastidieux du micrologiciel. Ce contrôleur est idéal pour la mise en œuvre de boutons capacitifs, de curseurs et de solutions de détection de proximité avec des temps de cycle de développement minimes.

Le Cap Touch 5 Click Board™ est pris en charge par une bibliothèque compatible mikroSDK, qui comprend des fonctions qui simplifient le développement logiciel. Ce Click Board™ est un produit entièrement testé, prêt à être utilisé sur un système équipé du socket mikroBUS™.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3786

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.017 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018719907

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.