Overview

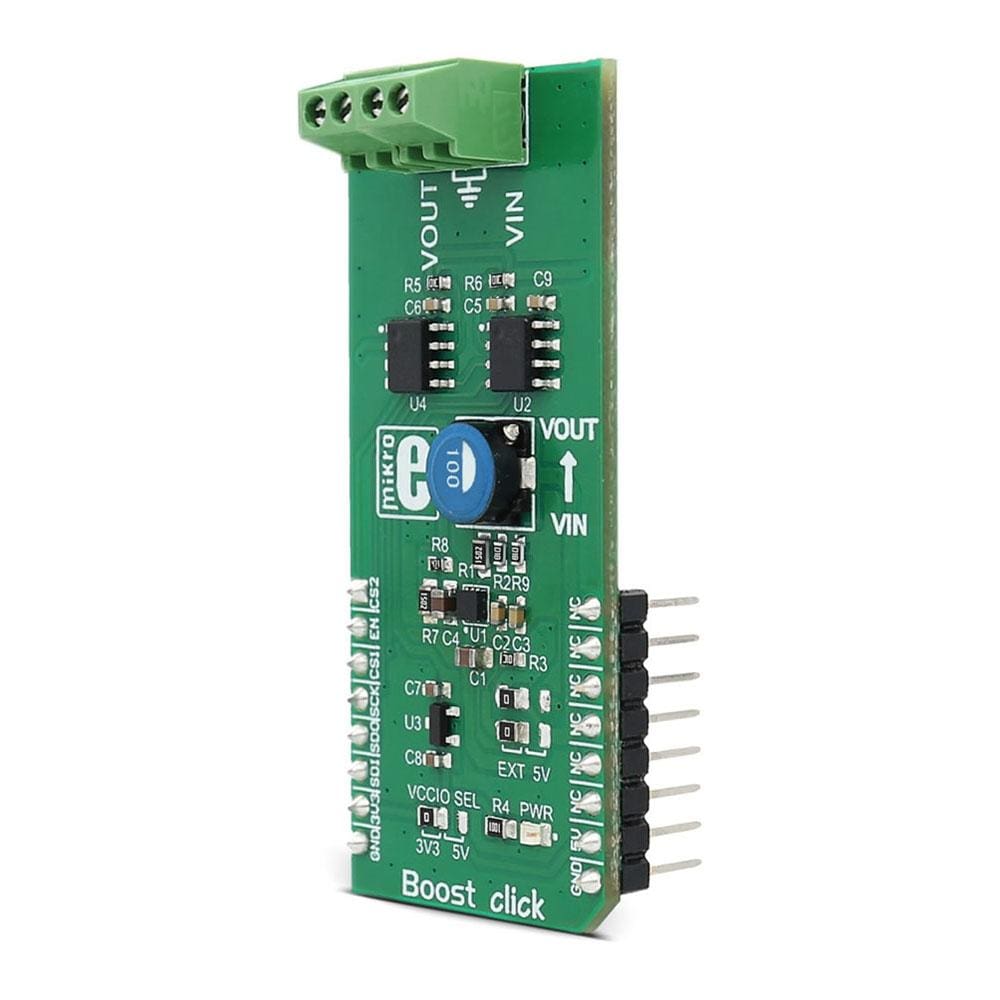

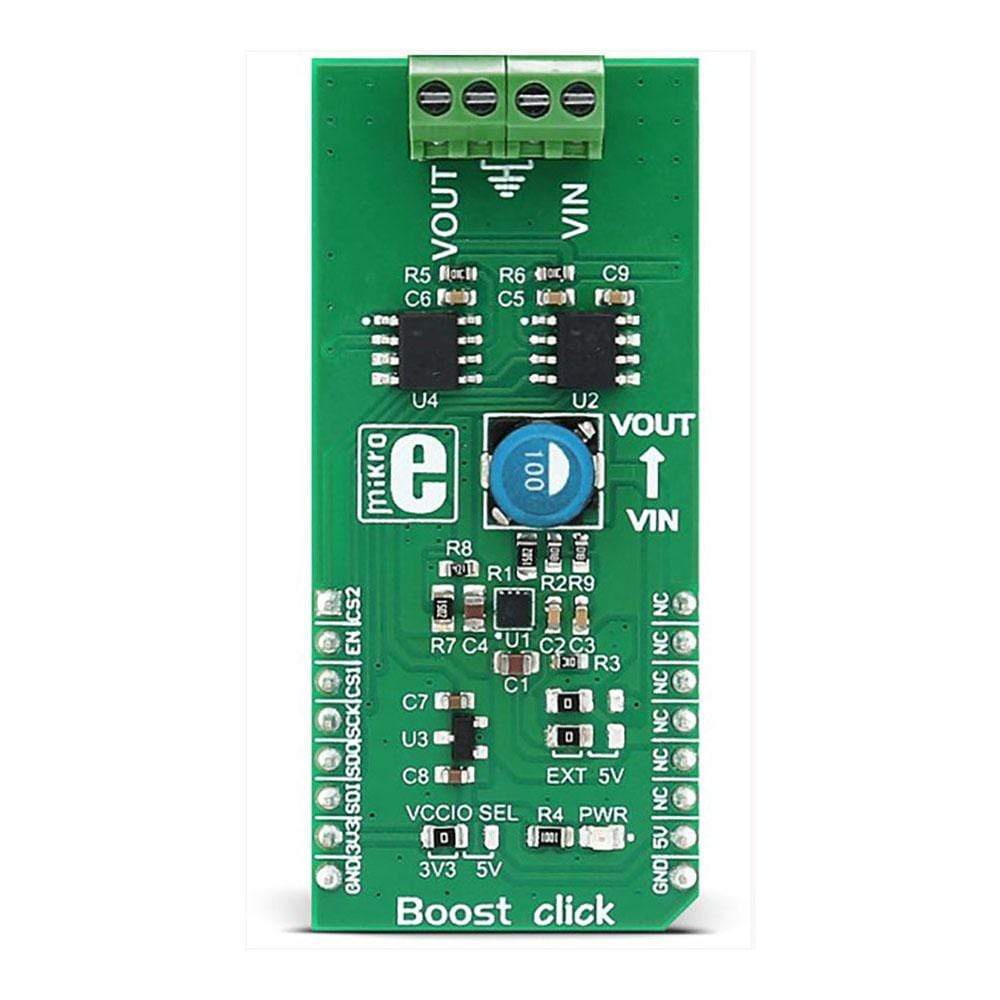

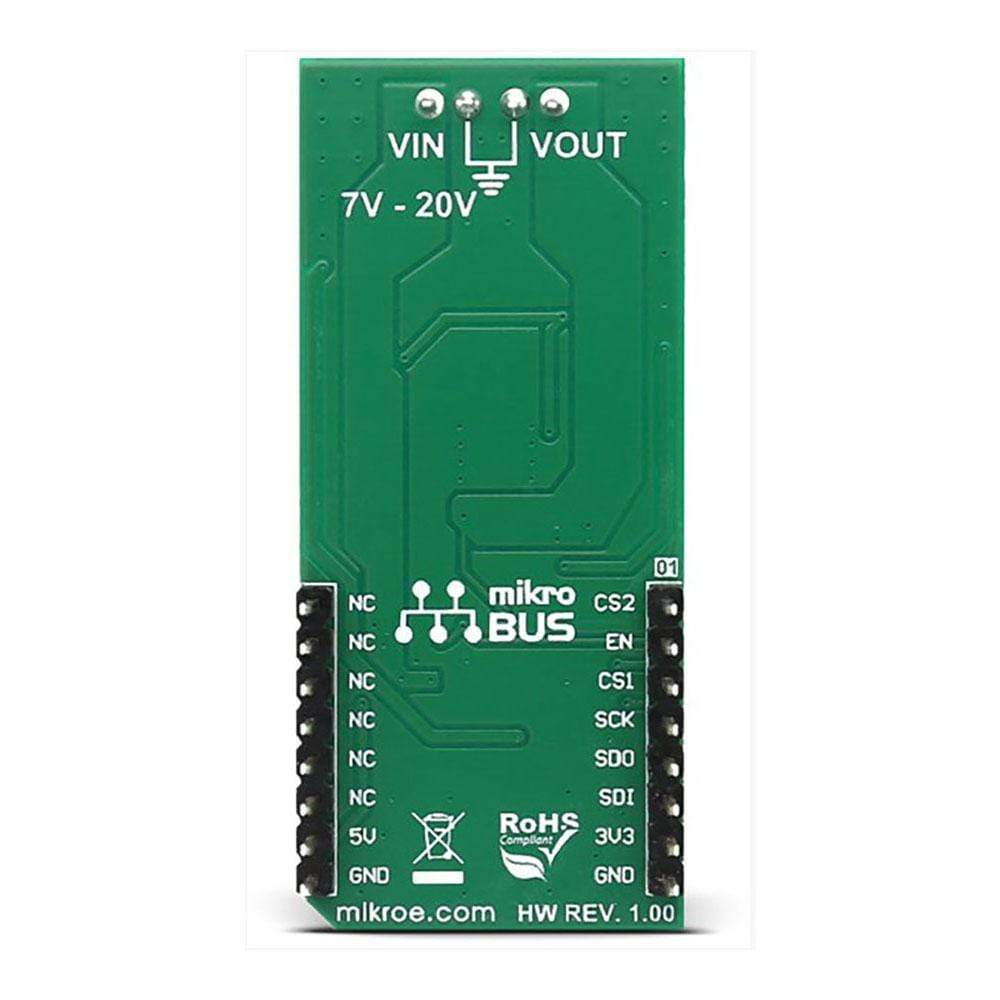

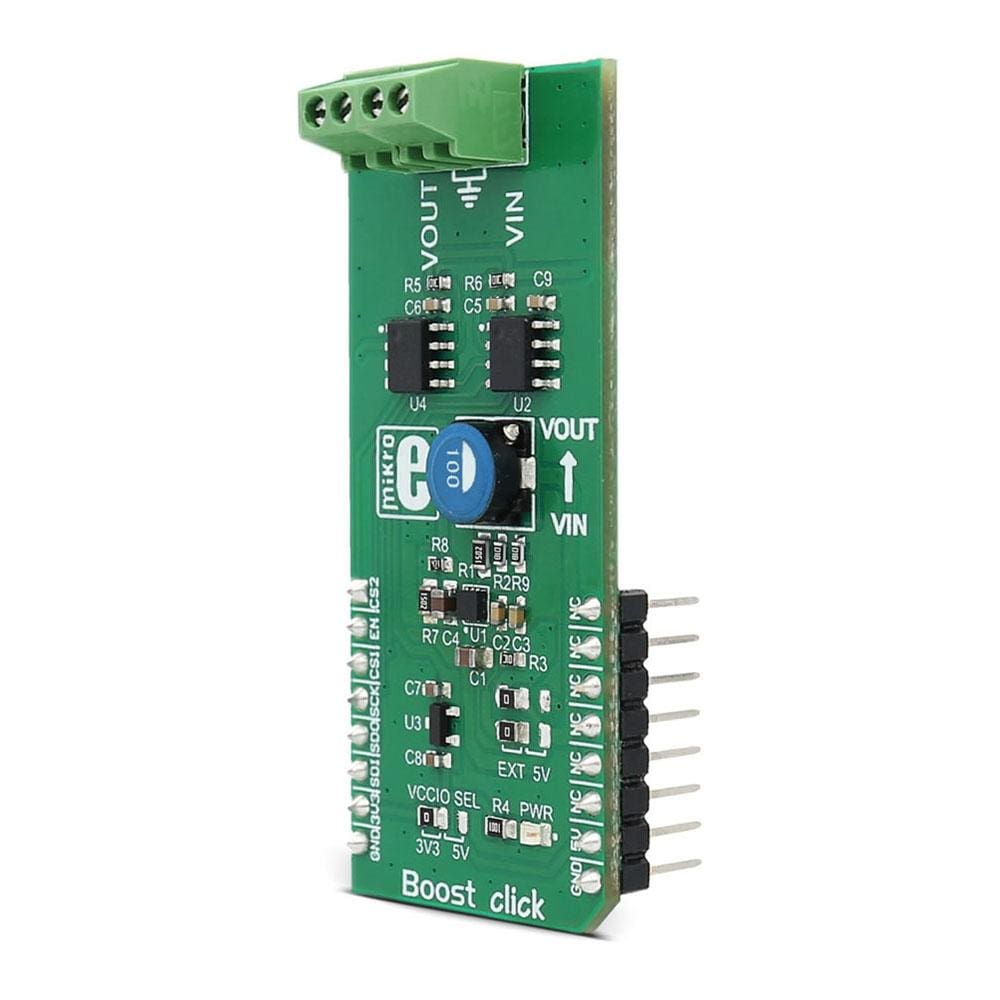

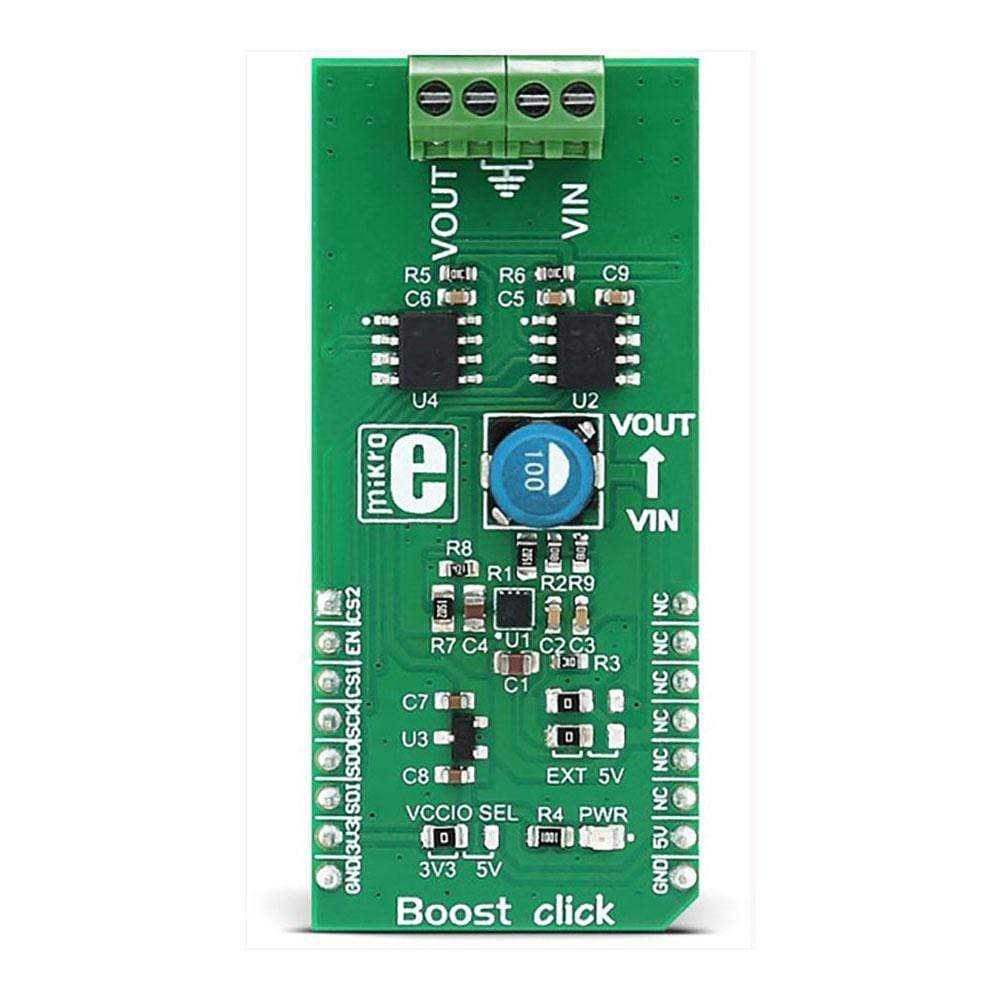

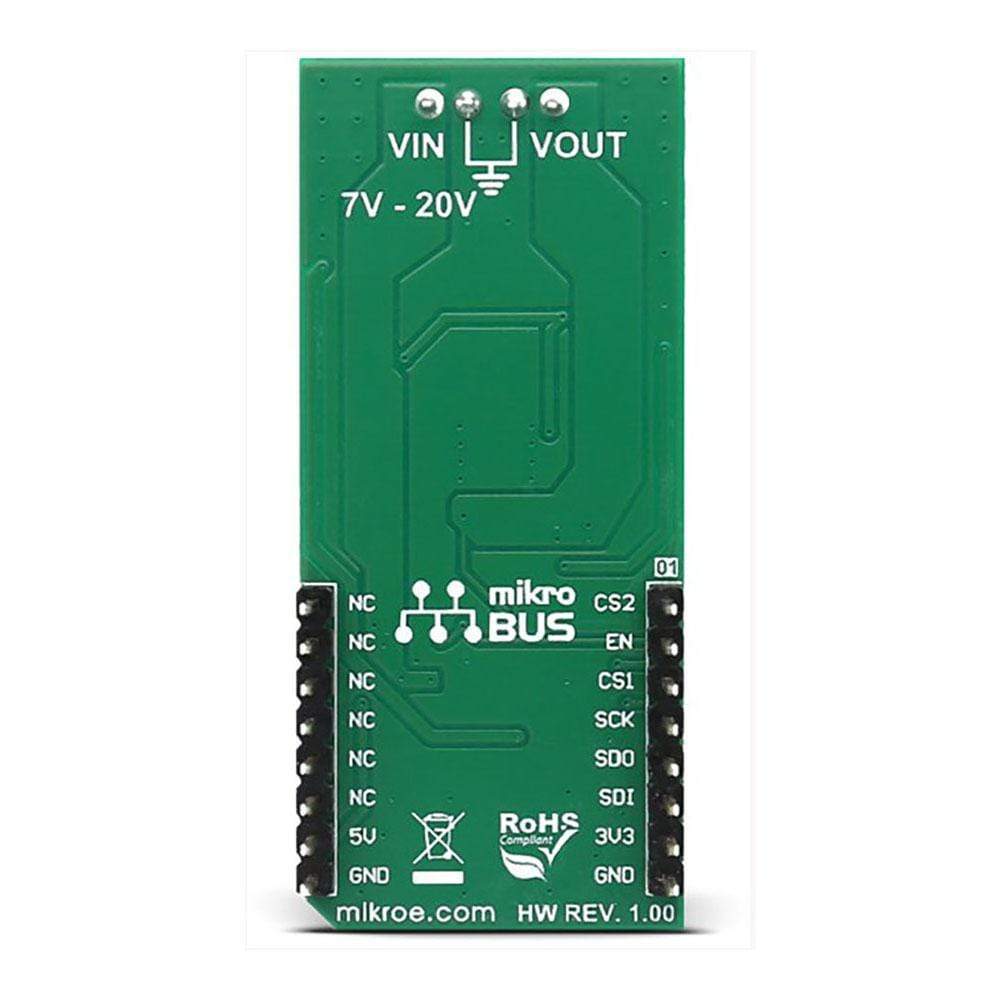

The Boost Click Board™ is based on Microchip's MIC2606, a 2MHz, PWM DC/DC boost switching regulator available in a 2mm x 2mm MLF package.

The Boost Click Board™ provides an adjustable output voltage through the onboard DAC that drives the FB pin of the MIC2606 to set the desired output voltage. The Click Board™ also has an onboard ADC that converts output voltage and sends its digital value through SPI pins of mikroBUS to the microcontroller.

Downloads

Le Boost Click Board™ est basé sur le MIC2606 de Microchip, un régulateur de commutation boost DC/DC PWM 2 MHz disponible dans un boîtier MLF de 2 mm x 2 mm.

La carte Boost Click Board™ fournit une tension de sortie réglable via le DAC intégré qui pilote la broche FB du MIC2606 pour définir la tension de sortie souhaitée. La carte Click Board™ dispose également d'un ADC intégré qui convertit la tension de sortie et envoie sa valeur numérique via les broches SPI du mikroBUS au microcontrôleur.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2780

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.025 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018711611

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.