Overview

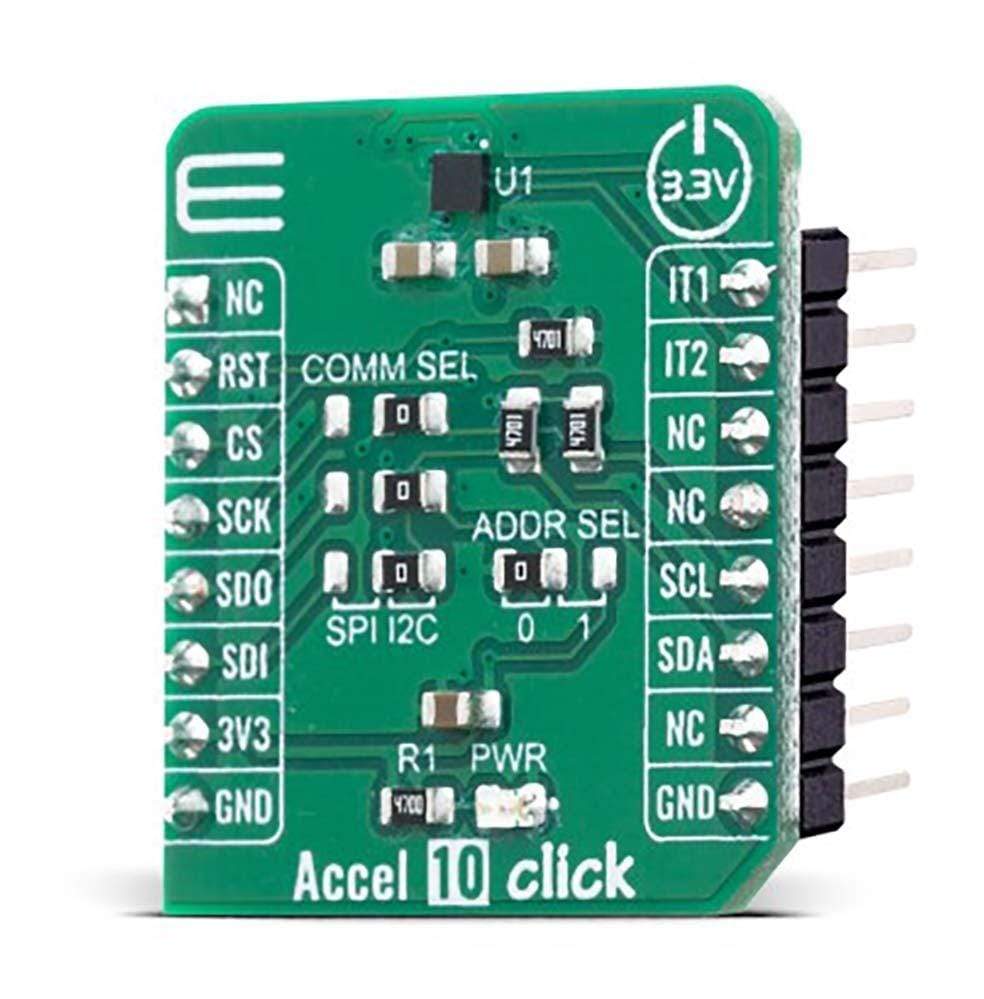

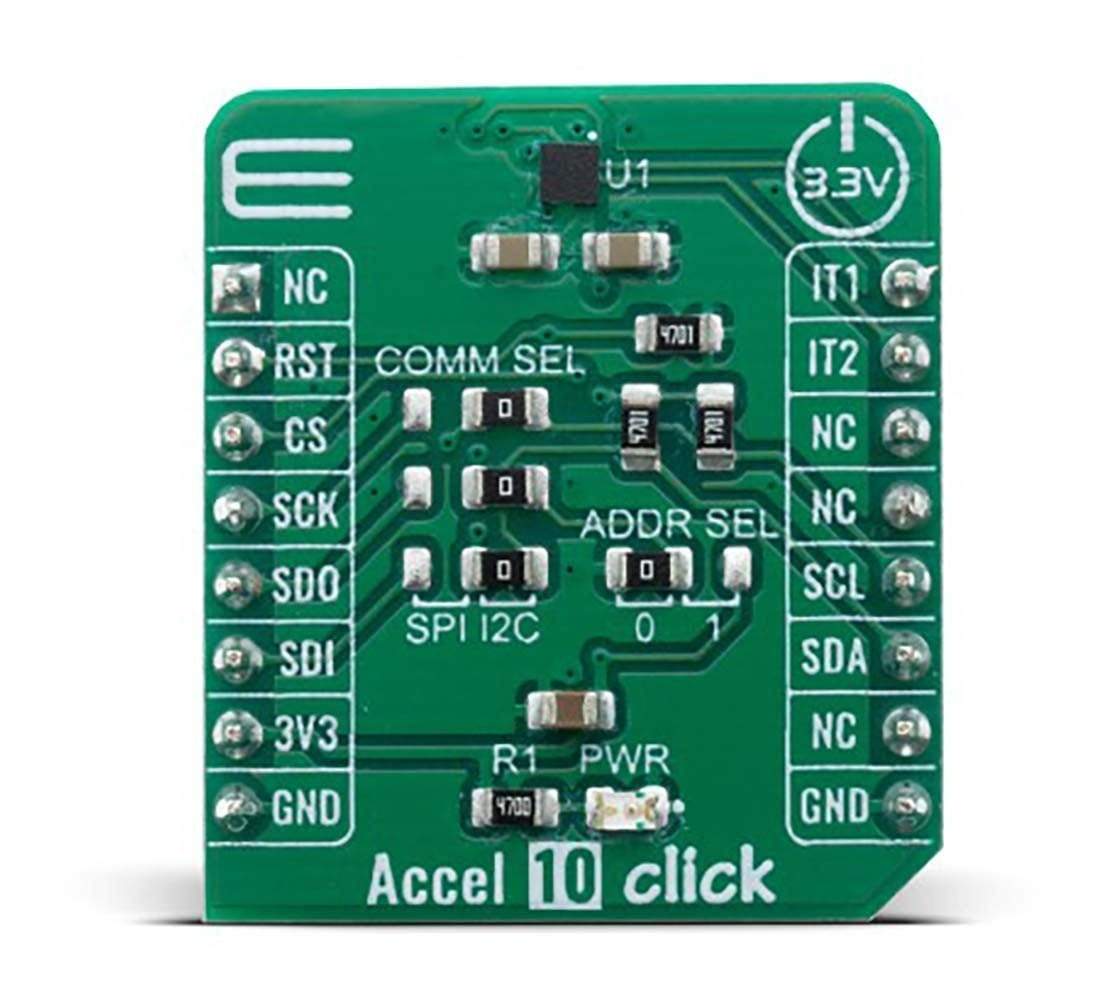

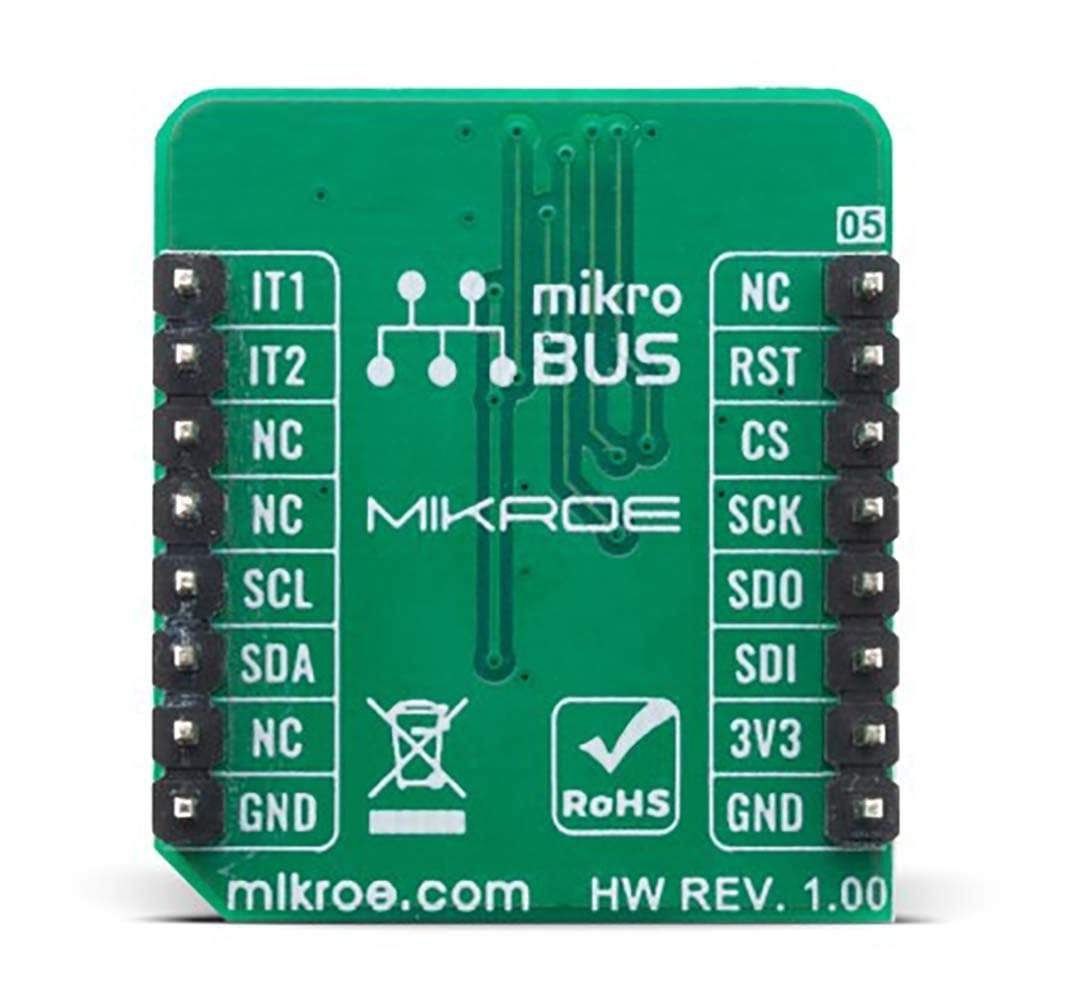

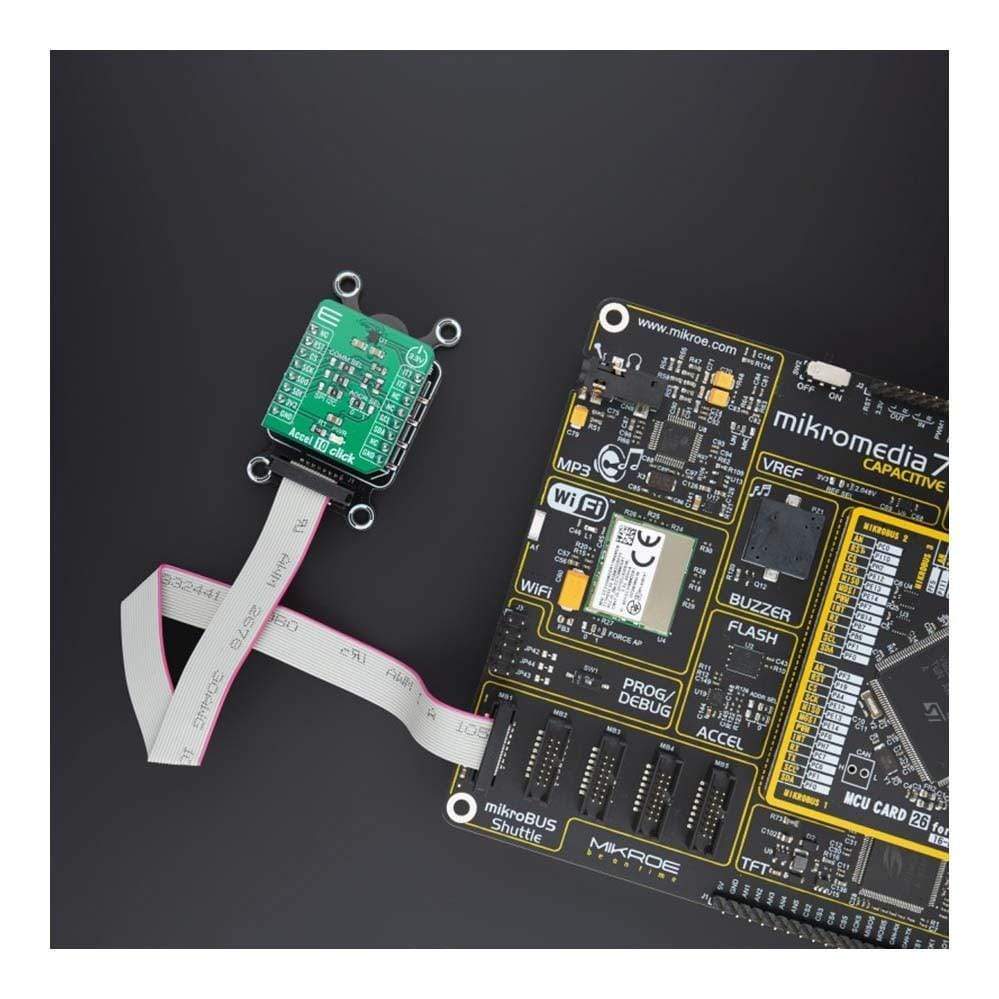

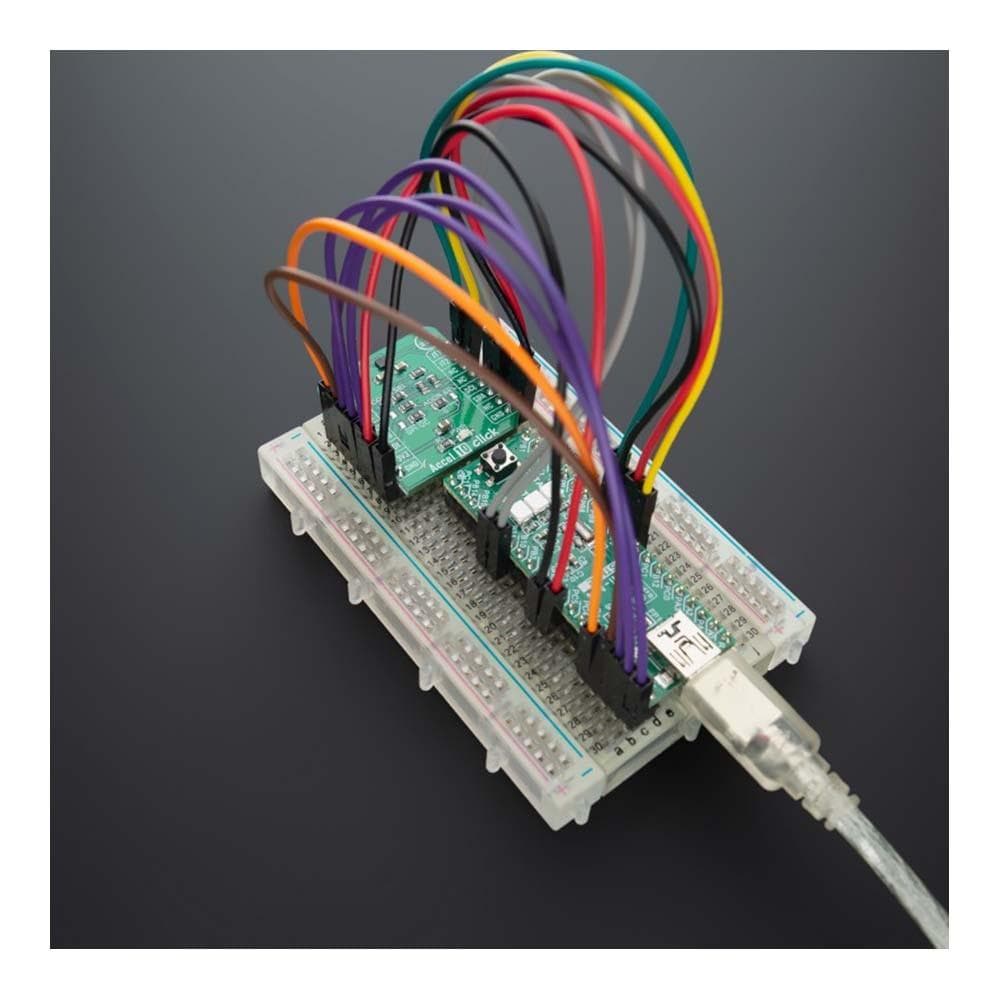

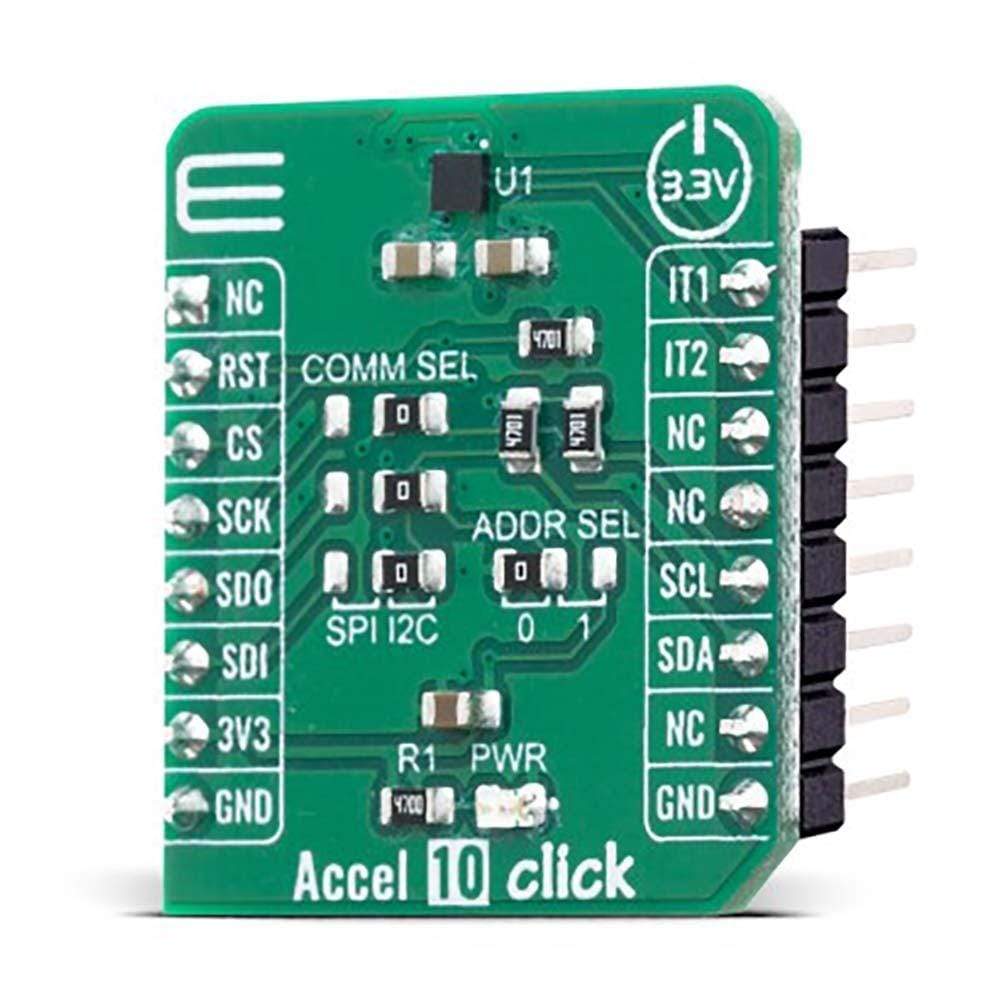

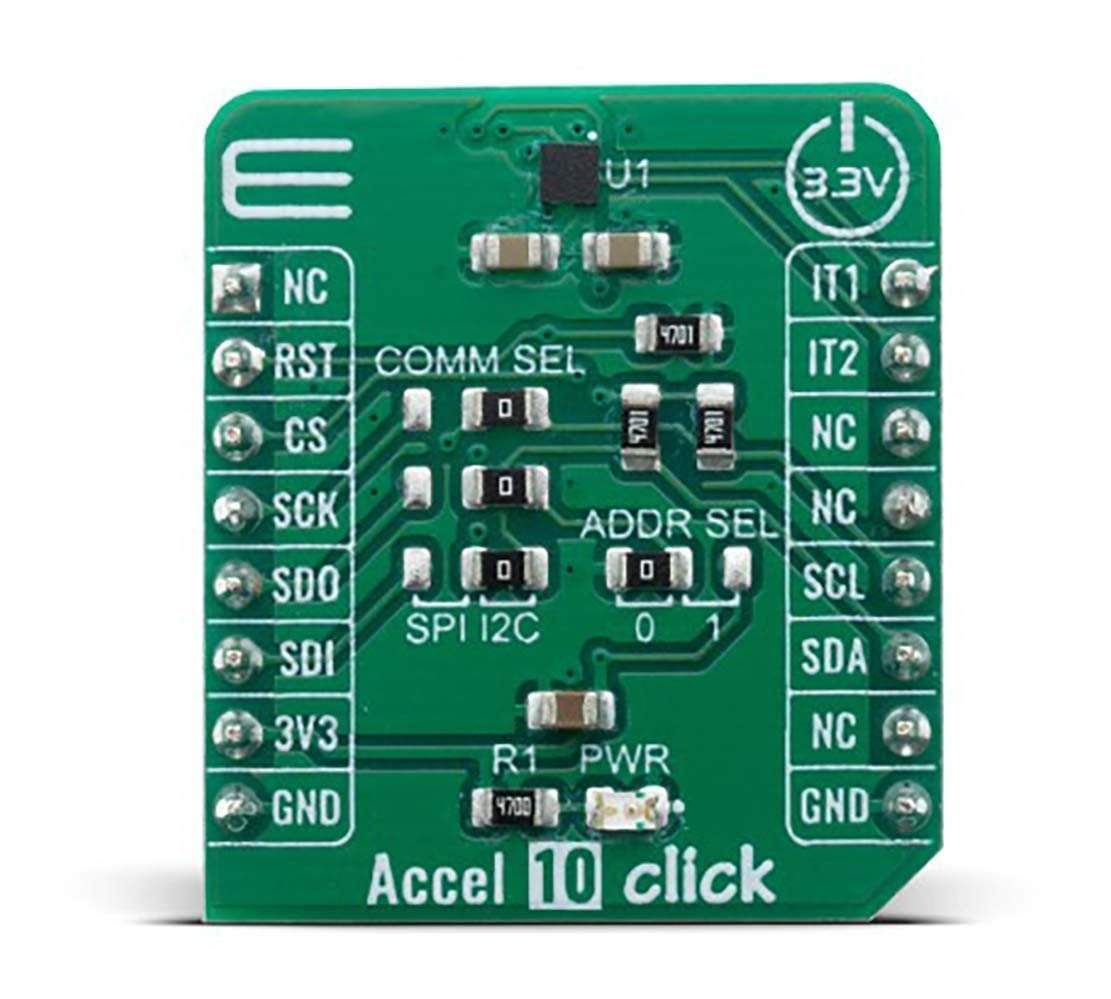

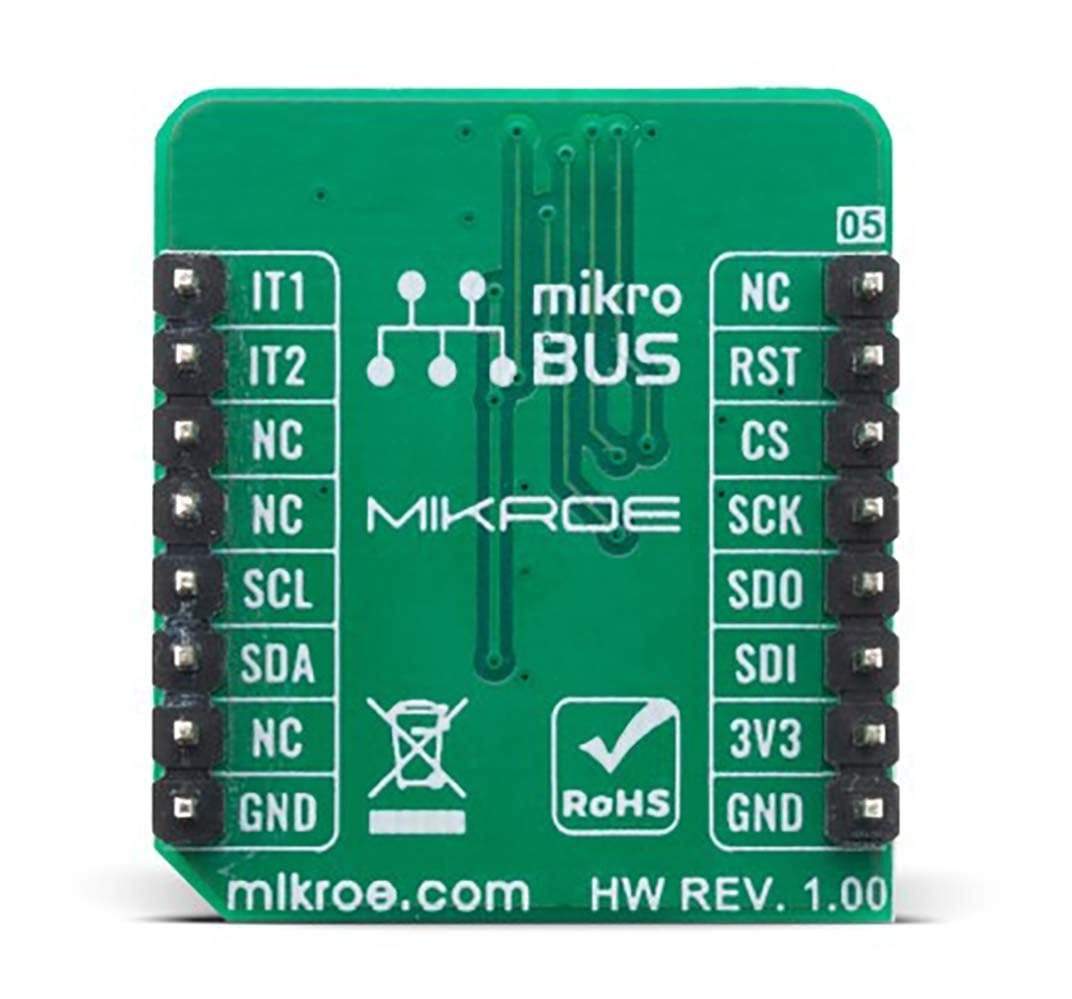

The Accel 10 Click Board™ features an ultra-low power triaxial "Femto" accelerometer sensor with embedded intelligence, labelled as the LIS2DW12TR. This Click Board™ allows linear motion and gravitational force measurements in ranges of ±2 g, ±4 g, ±8, and ±16 g in three perpendicular axes. This smart sensor allows the Accel 10 Click to detect many different events, including tap, double-tap, free-fall detection, and more, making it well suited for using it in handheld or wearable devices. It features onboard data processing, offering the acceleration data directly, over the standard I2C or SPI interface.

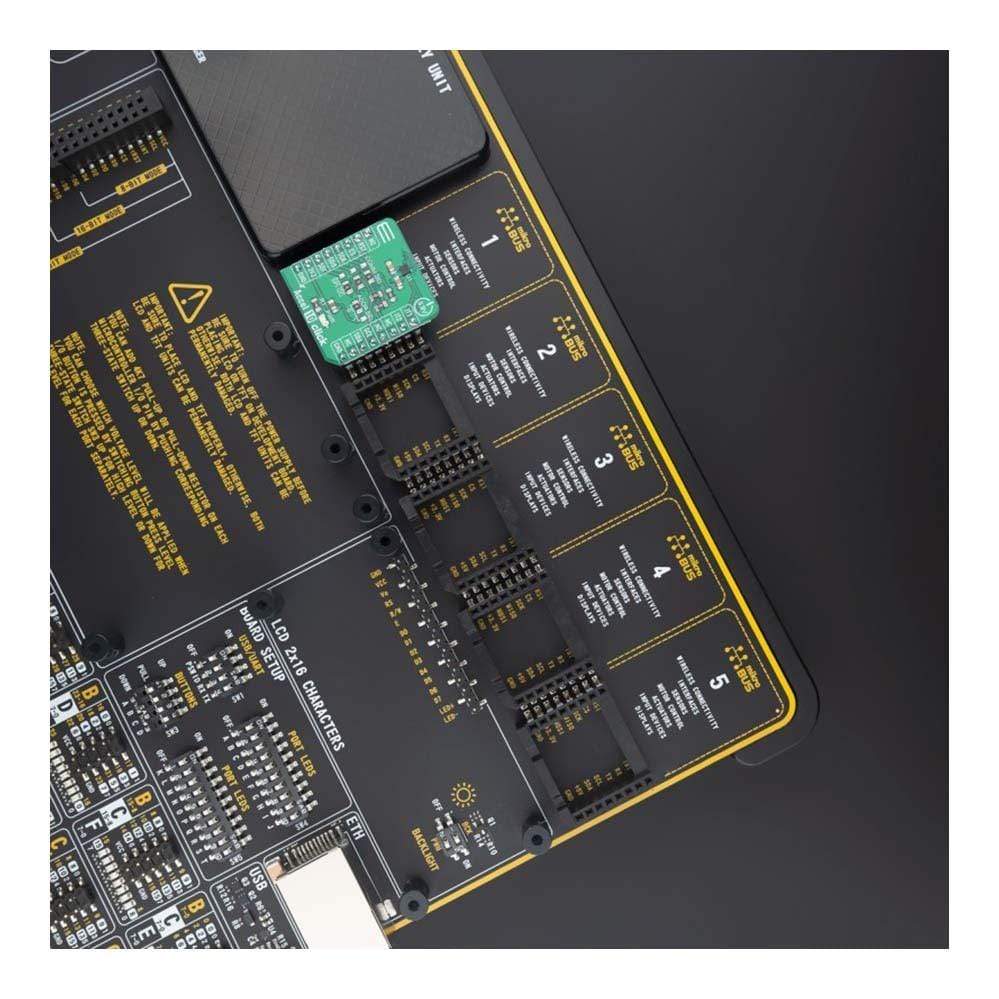

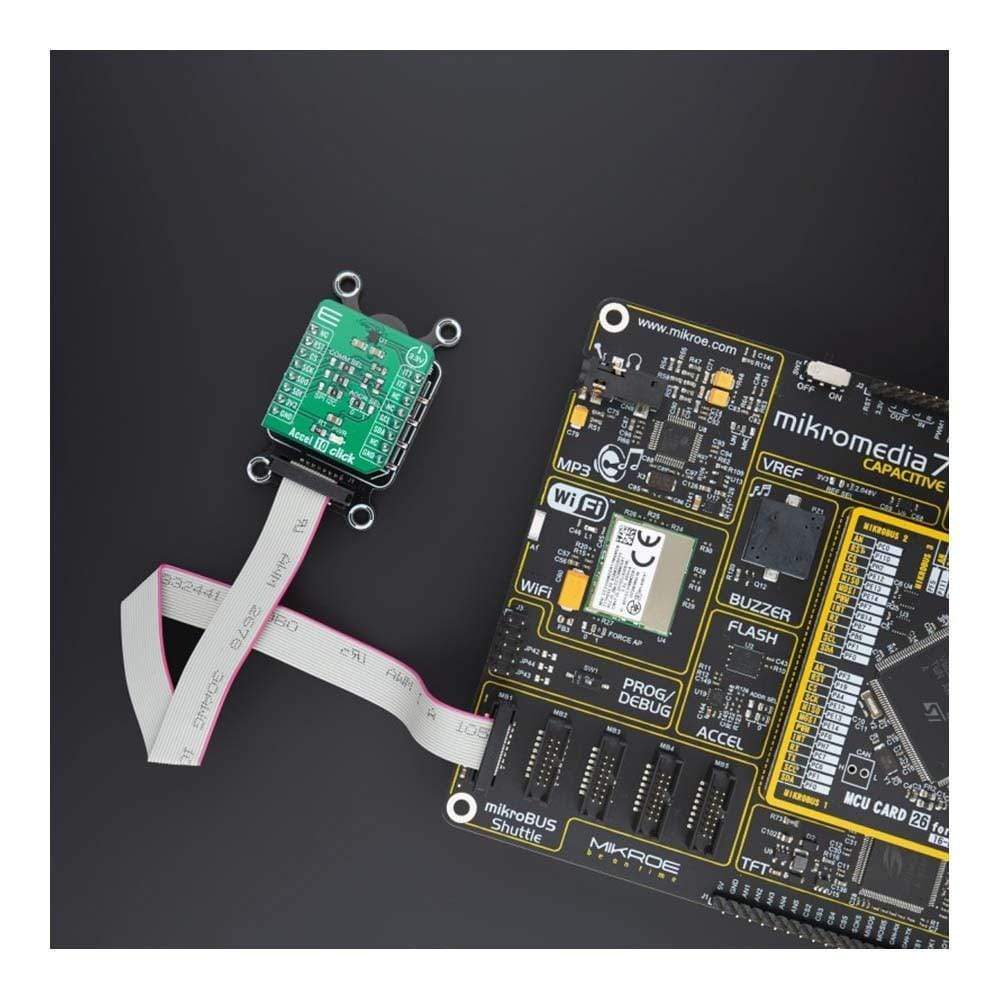

The Accel 10 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

The sensor can use any of its two interrupt pins to report a detected event.

Downloads

L' Accel 10 Click Board™ est doté d'un capteur accéléromètre triaxial « Femto » à très faible consommation d'énergie avec intelligence intégrée, étiqueté LIS2DW12TR. Ce Click Board™ permet des mesures de mouvement linéaire et de force gravitationnelle dans des plages de ±2 g, ±4 g, ±8 et ±16 g sur trois axes perpendiculaires. Ce capteur intelligent permet à l'Accel 10 Click de détecter de nombreux événements différents, notamment les tapotements, les doubles tapotements, la détection de chute libre, etc., ce qui le rend parfaitement adapté à une utilisation dans des appareils portables ou portables. Il dispose d'un traitement de données intégré, offrant les données d'accélération directement, via l'interface I2C ou SPI standard.

L' Accel 10 Click Board™ est supportée par une bibliothèque compatible mikroSDK, qui comprend des fonctions qui simplifient le développement logiciel. Cette Click Board™ est un produit entièrement testé, prêt à être utilisé sur un système équipé du socket mikroBUS™.

Le capteur peut utiliser l’une de ses deux broches d’interruption pour signaler un événement détecté.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4112

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.015 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018717422

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.