Overview

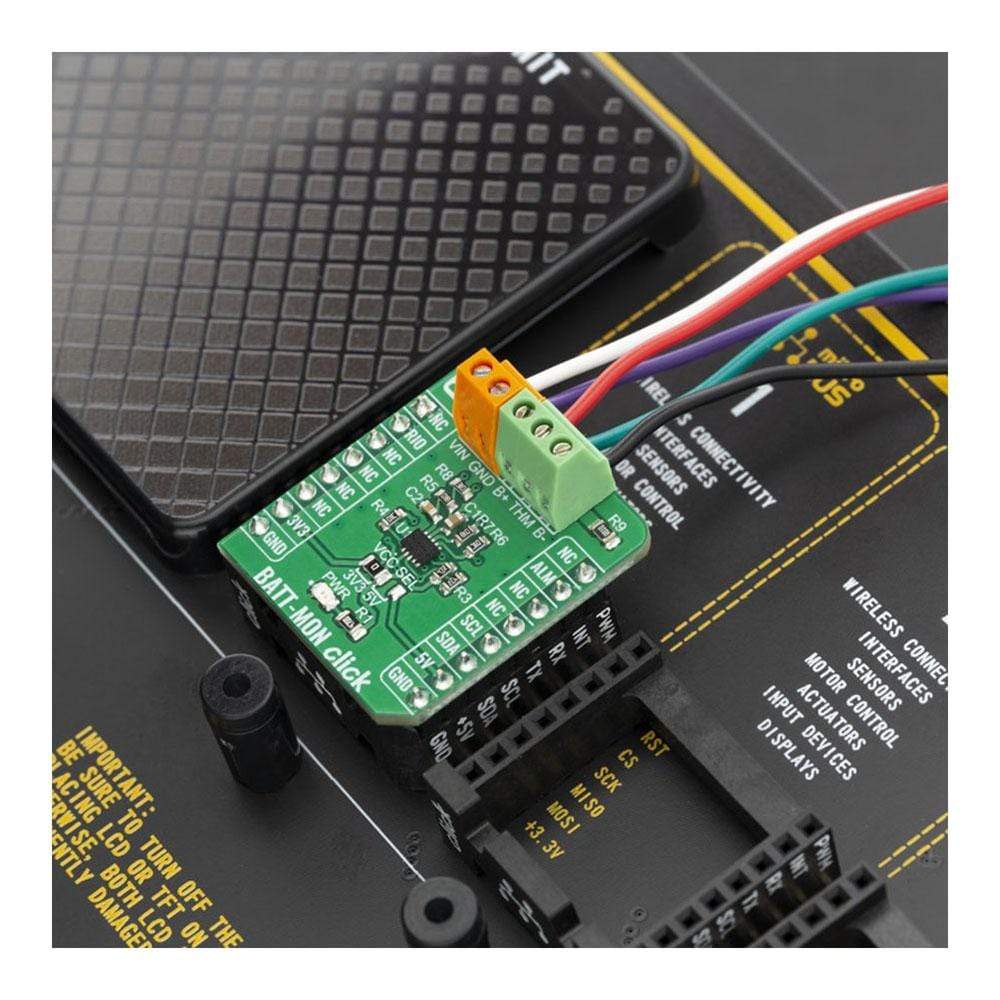

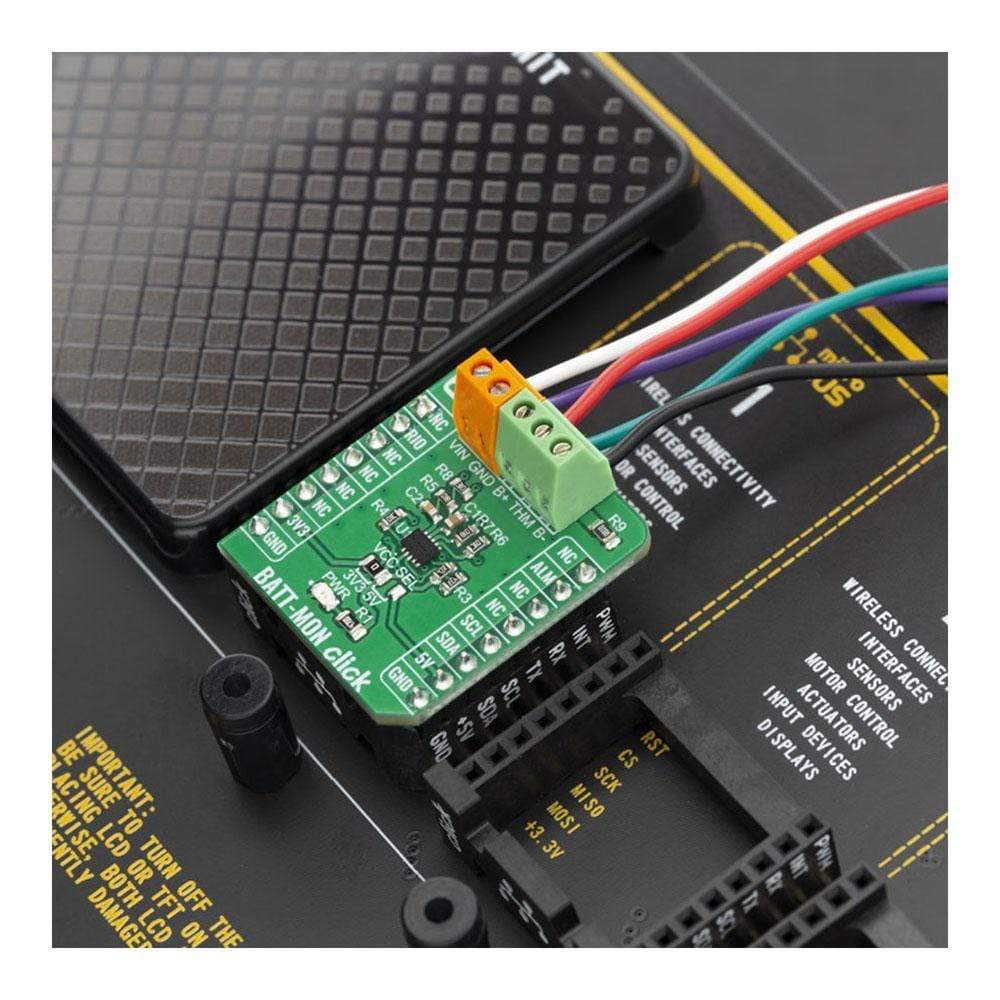

The BATT-MON Click Board™ is a very versatile, high accuracy, multiple-chemistry battery gauge for applications of single-cell batteries. It can be used for various applications, ranging from smartphones, notebooks/laptops, power tools, vacuums, to energy storage systems (ESS), while providing the output voltage at the same time. The interesting feature of this device is that it can provide additional current to the connected load if the current provided from the mikroBUS™ socket is not enough. This is possible by utilizing the connected battery and by employing intelligent power routing algorithms of the BATT-MON Click Board™.

Downloads

Features like the OptimGaugeTM algorithm, 0.25% accuracy battery voltage monitoring, Coulomb counter, and voltage-mode gas gauge operations make the BATT-MON click specialized battery gauge IC, used to provide battery depletion data via the I2C interface, the BATT-MON Click Board™ can be used to charge and monitorLiPo/Li-Ion batteries for a wide range of applications that can benefit from reliable and efficient LiPo/Li-Ion battery charger, like the mobile phones, multimedia players, digital cameras, portable medical equipment, and many more.

How Does The BATT-MON Click Board™ Work?

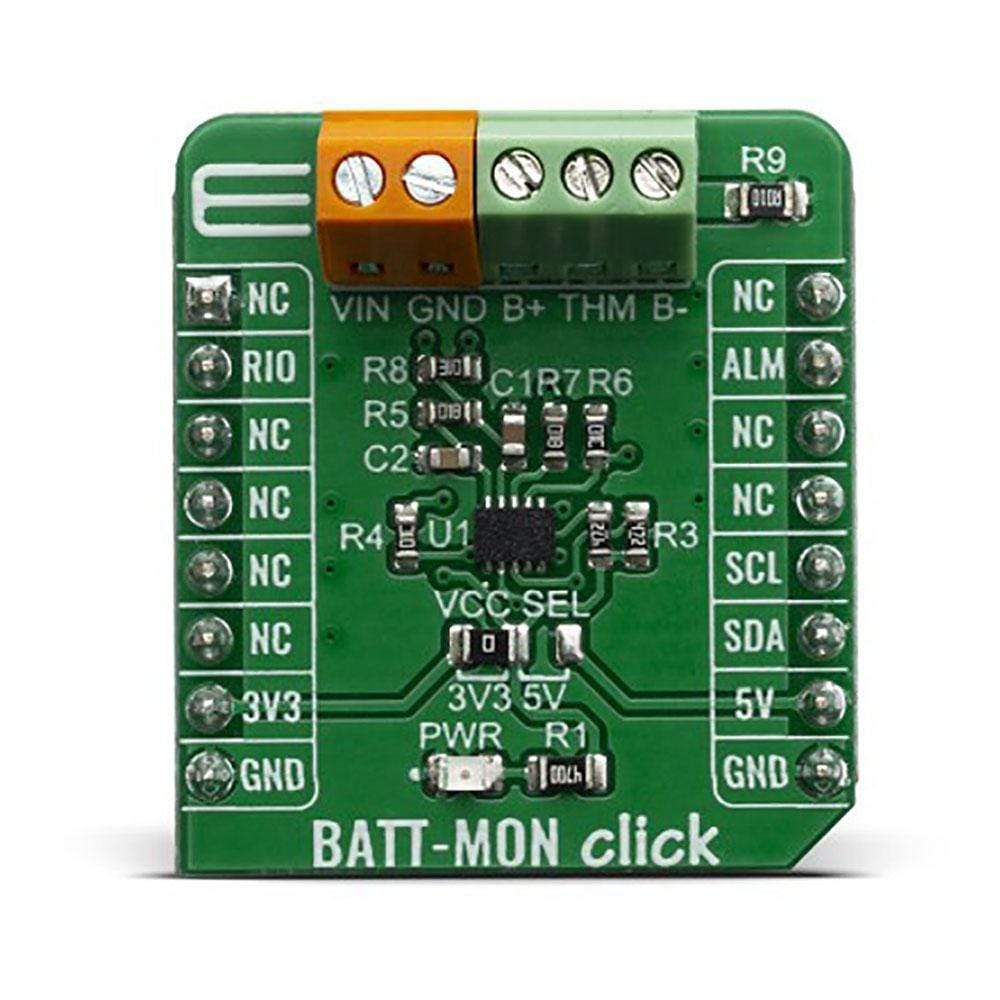

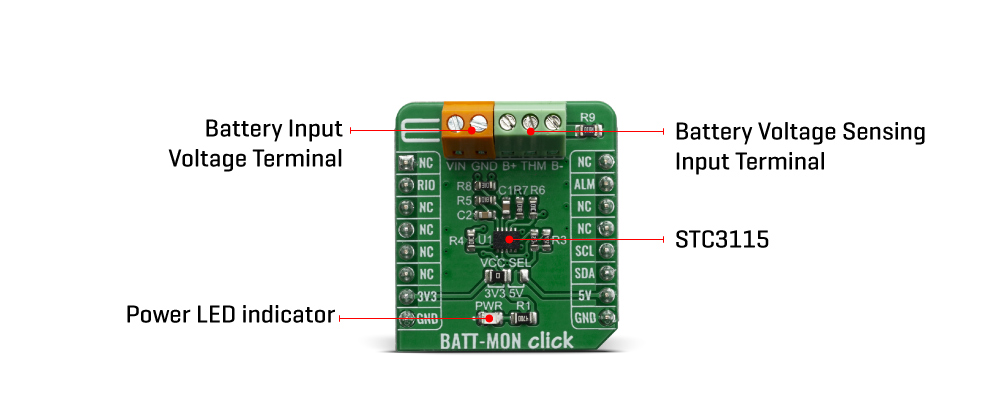

The core component of the BATT-MON Click Board™ is the STC3115, a high-precision battery gas gauge IC with alarm output for handheld applications, from STMicroelectronics. It includes all necessary components for the STC3115 to ensure the proper functionality of the Click board™ and maintain the monitoring precision.

The monitoring functions include the measurement of battery voltage, current, and temperature. A Coulomb counter is available to track the SOC when the battery is charging or discharging at a high rate. A sigma-delta A/D converter is used to measure the voltage, current, and temperature. The STC3115 can operate in two different modes with different power consumption. Mode selection is made by the VMODE bit in register 0. For more information about registers and operating modes, refer to modes STC3115 datasheet.

Battery voltage is measured by using one conversion cycle of the A/D converter every 4 s. The conversion cycle takes 8192 clock cycles, which means that when the the internal 32768 Hz clock is used, the conversion cycle time is 250 ms. The voltage range is 0 to 4.5 V and resolution is 2.20 mV. Accuracy of the voltage measurement is ±0.5% over the temperature range. This allows accurate SOC information from the battery open-circuit voltage

For current sensing, the voltage drop across the sense resistor (R9) is measured with the internal 14-bit sigma-delta A/D converter. Using the 32768 Hz internal clock, the conversion cycle time is 500 ms for a 14-bit resolution. The LSB value is 5.88 μV. The A/D converter output is in two's complement format. When a conversion cycle is completed, the result is added to the Coulomb counter accumulator and the number of conversions is incremented in a 16-bit counter. The current register is updated only after the conversion closest to the voltage conversion (that is: once per 4-s measurement cycle). The result is stored in the REG_CURRENT register (see Table 12).

The voltage range which can be used to power up the BATT-MON Click Board™, allows for it to work with both 3.3V and 5V capable MCUs. It can be selected by soldering a small SMD jumper, labeled as VCC SEL to the correct position.

SPECIFICATIONS

| Type | Battery charger |

| Applications | The BATT-MON Click Board™ can be used for smartphones development, notebook / laptops, power tools, vacuums, to energy storage systems (ESS). |

| On-board modules | STC3115, a high-precision battery gas gauge IC with alarm output for handheld applications, from STMicroelectronics |

| Key Features | The BATT-MON Click Board™ features OptimGaugeTM algorithm, 0.25% accuracy battery voltage monitoring, Coulomb counter, and voltage-mode gas gauge operations |

| Interface | GPIO,I2C |

| Compatibility | mikroBUS |

| Click board size | S (28.6 x 25.4 mm) |

| Input Voltage | 3.3V or 5V |

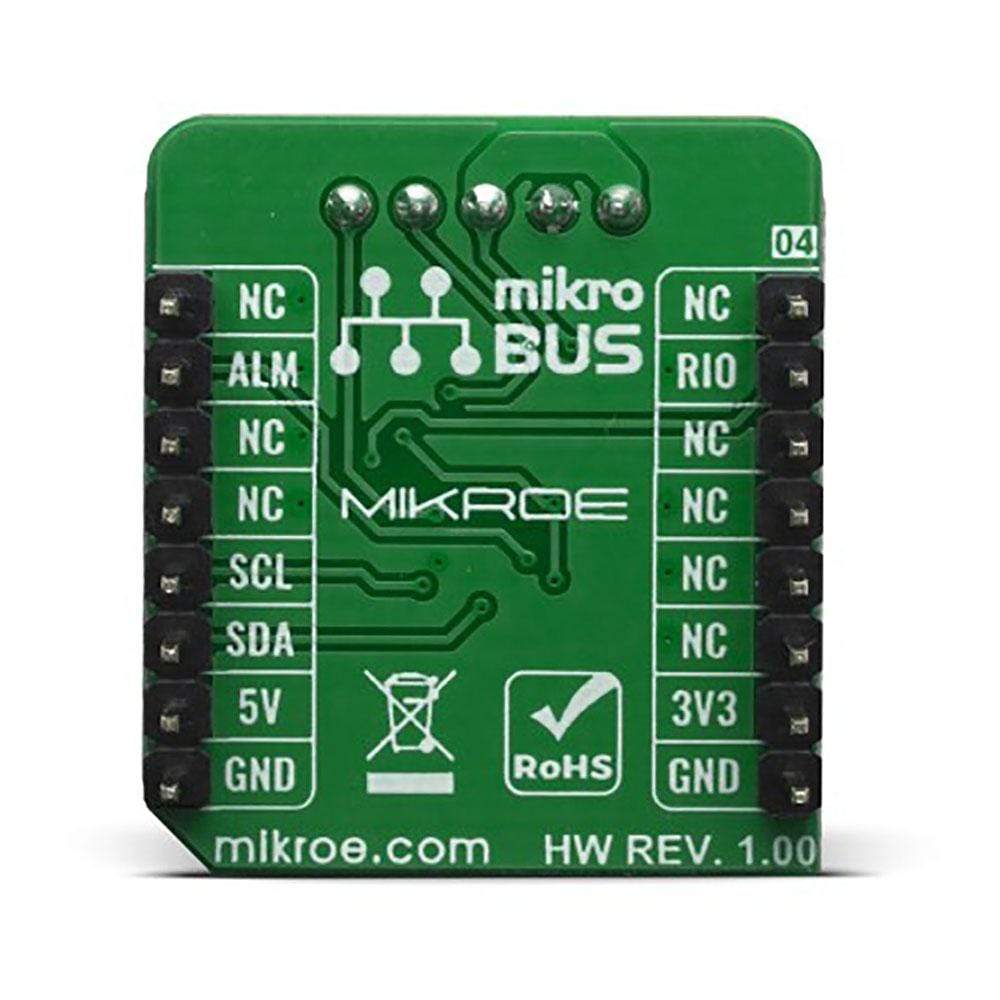

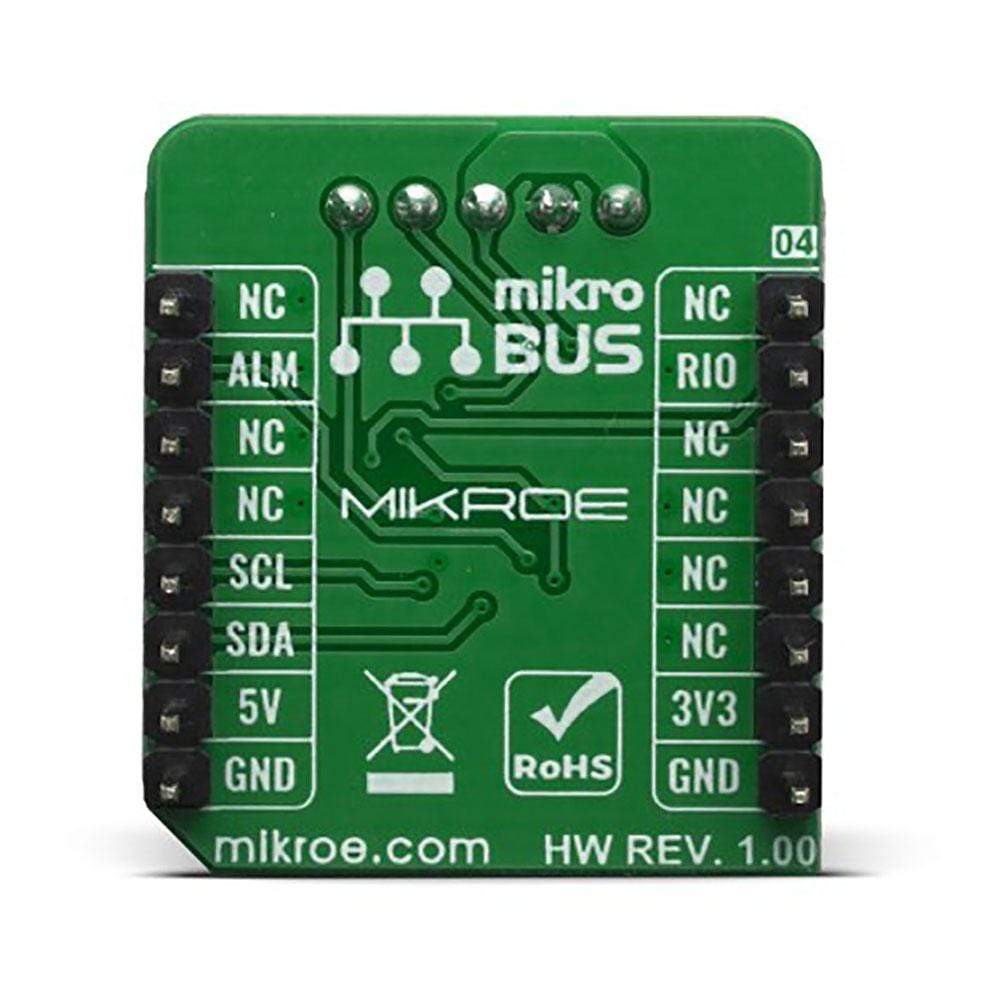

Pinout Diagram

This table shows how the pinout of the BATT-MON Click Board™ corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | NC | ||

| Reset sense input & reset control output | RIO | 2 | RST | INT | 15 | ALM | Alarm Out |

| NC | 3 | CS | RX | 14 | NC | ||

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | SCL | I2C Clock | |

| NC | 6 | MOSI | SDA | 11 | SDA | I2C Data | |

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | 5V | Power Supply |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

ONBOARD SETTINGS AND INDICATORS

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| JP1 | VCC SEL | Left | Enables switching regulator output, left position 3V3, right position 5V |

| TB1 | TB1 | - | Battery voltage In/Out |

| TB2 | TB2 | - | Battery connection terminal |

BATT-MON CLICK ELECTRICAL SPECIFICATIONS

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Operating current consumption | - | 45 | 60 | µA |

| Current consumption in standby | - | - | 2 | µA |

| Current sensing AD converter granularity | - | 5.88 | - | µA |

| Battery Voltage measurement granularity | - | 2.20 | - | µA |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3741

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018716890

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.