Key Features

Overview

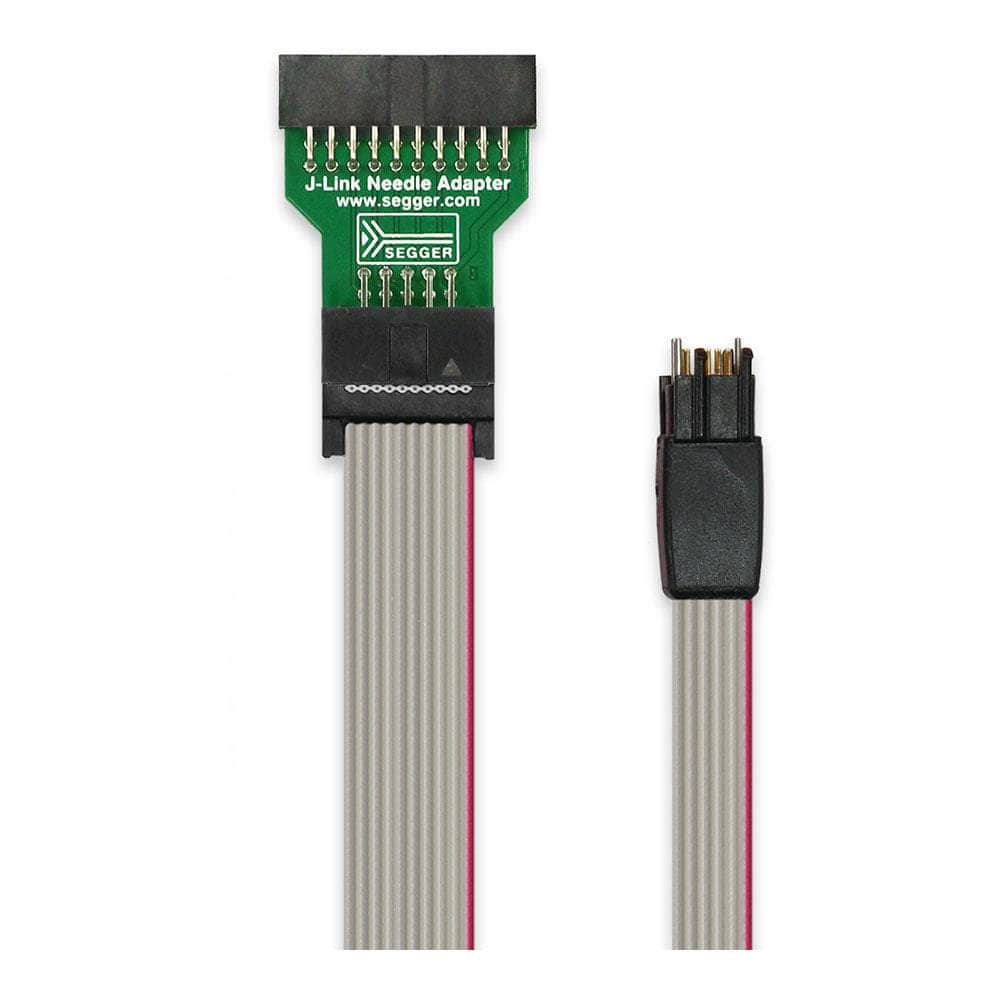

The SEGGER 10-Pin Needle Adapter represents a sophisticated solution for embedded developers seeking to eliminate bulky programming headers whilst maintaining full debug capabilities. This precision-engineered adapter bridges the gap between SEGGER's standard 20-pin debug interface and a minimal 10-pin needle footprint on your target PCB.

Unlike traditional headers that consume valuable PCB real estate and add component costs, this needle adapter contacts directly with copper pads through high-reliability spring pins. The innovative three-pin positioning system prevents incorrect connections whilst the robust spring contacts withstand over 100,000 programming cycles.

Engineers choose this solution for space-constrained designs, high-volume production runs, and anywhere connector costs impact project viability. The adapter supports both JTAG and SWD protocols with optional target power delivery, making it suitable for everything from initial prototype bring-up to final production programming. Compatible with the complete range of SEGGER J-Link debug probes and Flasher production tools, this adapter integrates seamlessly into existing development workflows.

Downloads

Why Engineers Choose The SEGGER 10-Pin Needle Adapter for J-Link Debug Programming

Eliminate Header Costs

Space-Constrained Designs

Production Reliability

Advanced Needle Adapter for Connector-Free Programming

The SEGGER 10-Pin Needle Adapter transforms how engineers connect J-Link and Flasher debug probes to target PCBs. This precision adapter eliminates the need for mounted connectors on your circuit boards whilst providing reliable spring-pin contact to a specialised footprint pattern.

Foolproof Connection Design

Three strategically positioned locating pins ensure the adapter can only connect in the correct orientation, preventing costly connection errors during development and production programming.

Technical Specifications

| Input Connector | 20-pin 0.1" (2.54mm) standard JTAG/SWD |

|---|---|

| Output Pattern | 10-pin 0.05" (1.27mm) needle pattern |

| Spring Pins | High-reliability, >100,000 cycle rating |

| PCB Footprint | Minimal space requirement with tri-pin keying |

| Target Power | Optional 5V supply via pin 9 (300mA max) |

Signal Mapping & Pinout

The adapter provides full JTAG and SWD signal access including:

- JTAG Signals: TCK, TDI, TDO, TMS, TRST

- SWD Signals: SWCLK, SWDIO, SWO

- Control: RESET, VTref, GND

- Power: 5V target supply (optional)

PCB Layout Requirements

Pad Specifications: - Contact pads: 0.8mm diameter minimum - Positioning holes: 0.7mm diameter - Solder mask: Must be clear of contact pads - No solder paste on needle contact areas - 0.5mm clearance from other tracesCompatible Debug Probes

Works seamlessly with all SEGGER debug tools including J-Link BASE, PLUS, PRO, ULTRA+, EDU, and Flasher series. The 20-pin standard interface ensures universal compatibility across the SEGGER ecosystem.

| General Information | |

|---|---|

Product Type |

Adapter

|

Part Number (SKU) |

8.06.04

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Warranty |

|

HS Code Customs Tariff code

|

|

EAN |

5055383614448

|

Frequently Asked Questions

Have a Question?

-

Does the adapter work with all SEGGER debug software?

Yes, the adapter is transparent to debug software. All SEGGER tools including J-Link Commander, Ozone debugger, and third-party IDEs work without modification.

-

How do I ensure reliable contact during automated testing?

The spring-loaded pins automatically adjust to slight PCB thickness variations. For production fixtures, ensure the adapter is held perpendicular to the PCB with consistent downward pressure.

-

What happens if I need to modify the cable or connector?

The adapter includes a fixed cable assembly. For custom modifications or different cable lengths, contact SEGGER directly or consider the 50-mil 10-pin patch adapter for custom wiring.

-

Can I use this for SWD debugging without JTAG signals?

Absolutely. The adapter supports both JTAG and SWD protocols through the same footprint. SWD uses SWCLK and SWDIO signals mapped to the needle pattern.

-

Is this adapter compatible with third-party debug probes?

The adapter uses SEGGER's proprietary needle footprint pattern. For universal compatibility, consider Tag-Connect TC2050 solutions which support multiple debugger brands.

-

How many programming cycles can I expect from the spring pins?

The high-reliability spring pins are rated for over 100,000 connection cycles, making them suitable for high-volume production programming without degradation.

-

What PCB layout rules must I follow for the needle footprint?

Contact pads require 0.8mm minimum diameter with clear solder mask. Position holes need 0.7mm diameter. Maintain 0.5mm clearance from other traces and never apply solder paste to contact areas.

-

How does the positioning system prevent incorrect connections?

Three precision-positioned locating pins mechanically key the adapter to your PCB footprint. The adapter physically cannot connect incorrectly, preventing damage from reverse or offset connections.

-

Can I power my target board through this adapter?

Yes, pin 9 provides 5V at up to 300mA for target power. This eliminates the need for separate power supplies during programming and debugging sessions.

-

What's the difference between this and the 6-pin needle adapter?

The 10-pin version provides full JTAG support (TDI, TDO, TCK, TMS) plus optional target power, whilst the 6-pin variant supports SWD debugging only. Choose 10-pin for maximum compatibility.