Key Features

Overview

The TC2050-CLIP provides a simple, effective solution for maintaining stable connections between TC2050-NL "no legs" programming cables and target PCBs during debugging and programming operations. This precision-manufactured clip attaches to the cable's alignment pins from beneath the PCB, creating a secure mechanical retention that enables hands-free debugging sessions.

Designed for engineers working with space-constrained designs, the TC2050-CLIP works exclusively with Tag Connect's minimal-footprint TC2050-NL connector system. The clip accommodates PCB thicknesses up to standard 1.6mm whilst maintaining reliable spring-pin contact pressure for consistent electrical connections.

The clip's compact design ensures it doesn't interfere with surrounding components whilst providing the mechanical stability required for extended programming sessions, production testing, or firmware development activities.

Downloads

Why Engineers Choose The Tag Connect TC2050-CLIP Retaining Clip for TC2050-NL Cables

Hands-Free Debugging

Production Efficiency

Space Conservation

Hands-Free Programming and Debugging Solution

The TC2050-CLIP is a precision-engineered retaining clip designed to securely hold TC2050-NL ("No Legs") cables in place on target PCBs during programming, debugging, and testing operations. This compact solution addresses the challenge of maintaining stable connections when using Tag Connect's space-saving no-legs connector footprint.

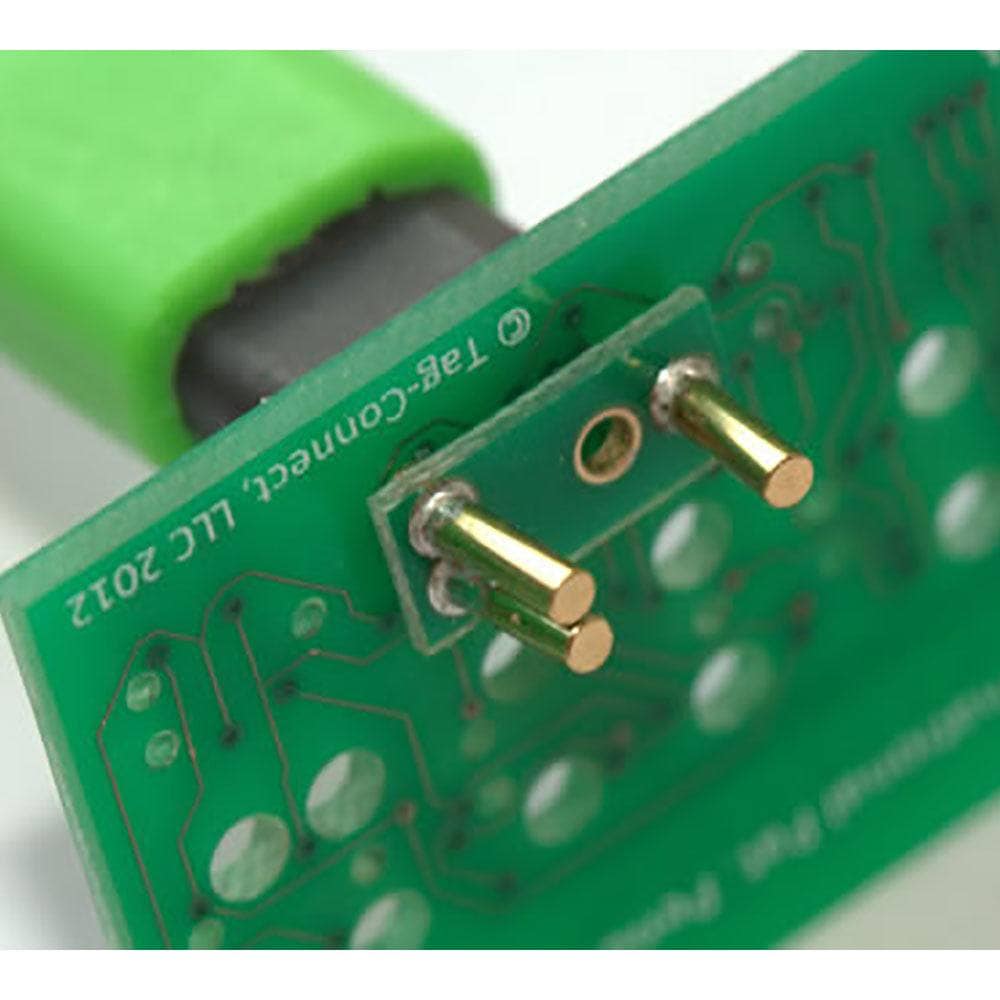

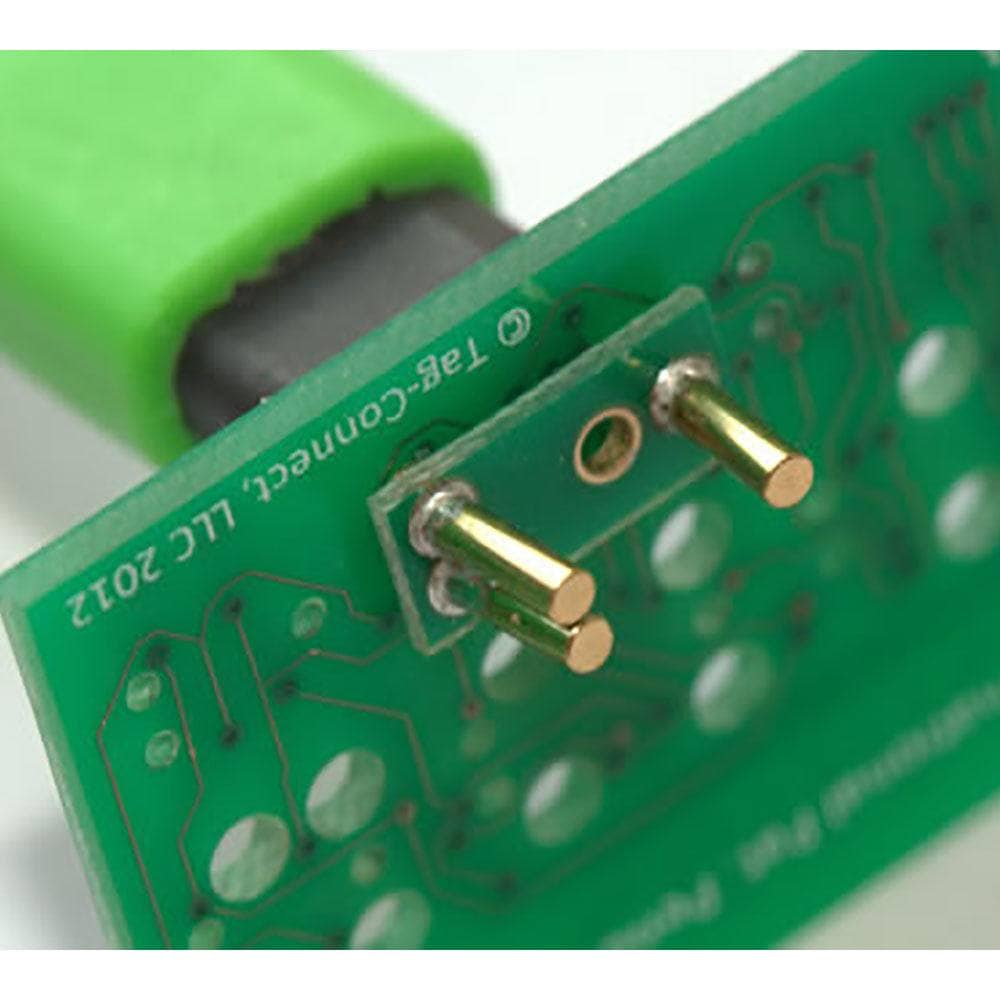

Key Operating Principle

The TC2050-CLIP operates by attaching to the alignment pins of the TC2050-NL cable from underneath the target PCB. Once pressed onto the alignment pins, it provides mechanical retention that keeps the cable securely connected during extended debugging sessions, allowing engineers to work hands-free whilst maintaining reliable electrical connections.

Wiring Quick-Start

Installation requires no soldering or permanent modifications to your target board:

1. Connect TC2050-NL cable to target PCB footprint 2. Align TC2050-CLIP with cable alignment pins from PCB underside 3. Press clip firmly onto alignment pins until secured 4. Verify stable connection with gentle cable movement test 5. Begin programming or debugging operation PCB Footprint Requirements

The clip works with the standard TC2050-NL footprint, which requires only 0.03 square inches of PCB space - equivalent to two or three SMT resistors. The footprint consists of ten contact pads arranged in two rows of five, plus two alignment holes for the cable's positioning pins.

| Parameter | Specification |

|---|---|

| Footprint Size | 0.43" x 0.20" (10.9mm x 5.1mm) |

| Contact Pad Diameter | 0.04" (1.0mm) |

| Alignment Hole Diameter | 0.04" (1.0mm) |

| Pin Pitch | 0.05" (1.27mm) |

| Row Spacing | 0.1" (2.54mm) |

Compatibility Matrix

The TC2050-CLIP is specifically designed for use with Tag Connect's TC2050-NL series cables and their compatible adapters:

| Cable Model | Connector Type | Compatibility |

|---|---|---|

| TC2050-IDC-NL | 10-pin ribbon (0.1") | ✓ Full compatibility |

| TC2050-IDC-NL-050 | 10-pin ribbon (0.05") | ✓ Full compatibility |

| TC2050-IDC-NL-430 | MSP430 RJ12 | ✓ Full compatibility |

| TC2050-IDC | 10-pin legged | ✗ Not compatible |

Production Programming Applications

The TC2050-CLIP excels in production environments where rapid, repeated connections are required. The clip enables automated test equipment to maintain consistent connections during high-volume programming cycles whilst eliminating the need for expensive custom fixtures or pogo pin assemblies.

Frequently Asked Questions

Have a Question?

-

Can the TC2050-CLIP interfere with nearby PCB components?

The TC2050-CLIP has a compact design specifically engineered to minimise interference with surrounding components. Its low profile ensures it doesn't obstruct nearby parts whilst providing secure cable retention.

-

What happens if I lose my TC2050-CLIP during development?

Individual replacement clips are available from Debug Store. Tag Connect also offers TC2050-CLIP-3PACK containing three clips, which many engineers prefer to ensure spares are always available during development work.

-

Is the TC2050-CLIP reusable across different projects?

Yes, the TC2050-CLIP is fully reusable. However, Tag Connect recommends keeping spare clips available as they can be easily misplaced during bench work and may lose grip strength after extended use.

-

What debuggers and programmers work with TC2050-CLIP setups?

The TC2050-CLIP works with any debugger or programmer compatible with TC2050-NL cables, including SEGGER J-Link, ST-LINK/V2, ARM Keil ULINK, and many others when used with appropriate adapters like the TC2050-ARM2010.

-

How do I install the TC2050-CLIP on my setup?

Installation is straightforward: first connect your TC2050-NL cable to the target PCB footprint, then align the TC2050-CLIP with the cable's alignment pins from underneath the PCB, and press firmly until the clip is secured onto the pins.

-

Can I use the TC2050-CLIP for production programming?

Yes, the TC2050-CLIP is well-suited for production programming applications. It enables automated test equipment to maintain consistent connections during high-volume programming cycles without requiring expensive custom fixtures.

-

What PCB thickness does the TC2050-CLIP support?

The TC2050-CLIP is designed to work with standard PCB thicknesses up to 1.6mm (0.063"). This accommodates the majority of embedded system PCB designs using standard stackups.

-

Does the TC2050-CLIP require any modifications to my PCB?

No, the TC2050-CLIP requires no soldering or permanent modifications to your target PCB. It simply clips onto the TC2050-NL cable's alignment pins from the underside of the board, providing temporary mechanical retention.

-

Which Tag Connect cables are compatible with the TC2050-CLIP?

The TC2050-CLIP is compatible with all TC2050-NL series cables, including TC2050-IDC-NL, TC2050-IDC-NL-050, TC2050-IDC-NL-050-ALL, and TC2050-IDC-NL-430. It is not compatible with the "legged" versions like TC2050-IDC.

-

What is the TC2050-CLIP and how does it work?

The TC2050-CLIP is a retaining clip that securely holds TC2050-NL "no legs" programming cables in place on target PCBs. It attaches to the cable's alignment pins from underneath the PCB, providing mechanical retention for hands-free debugging and programming operations.