Overview

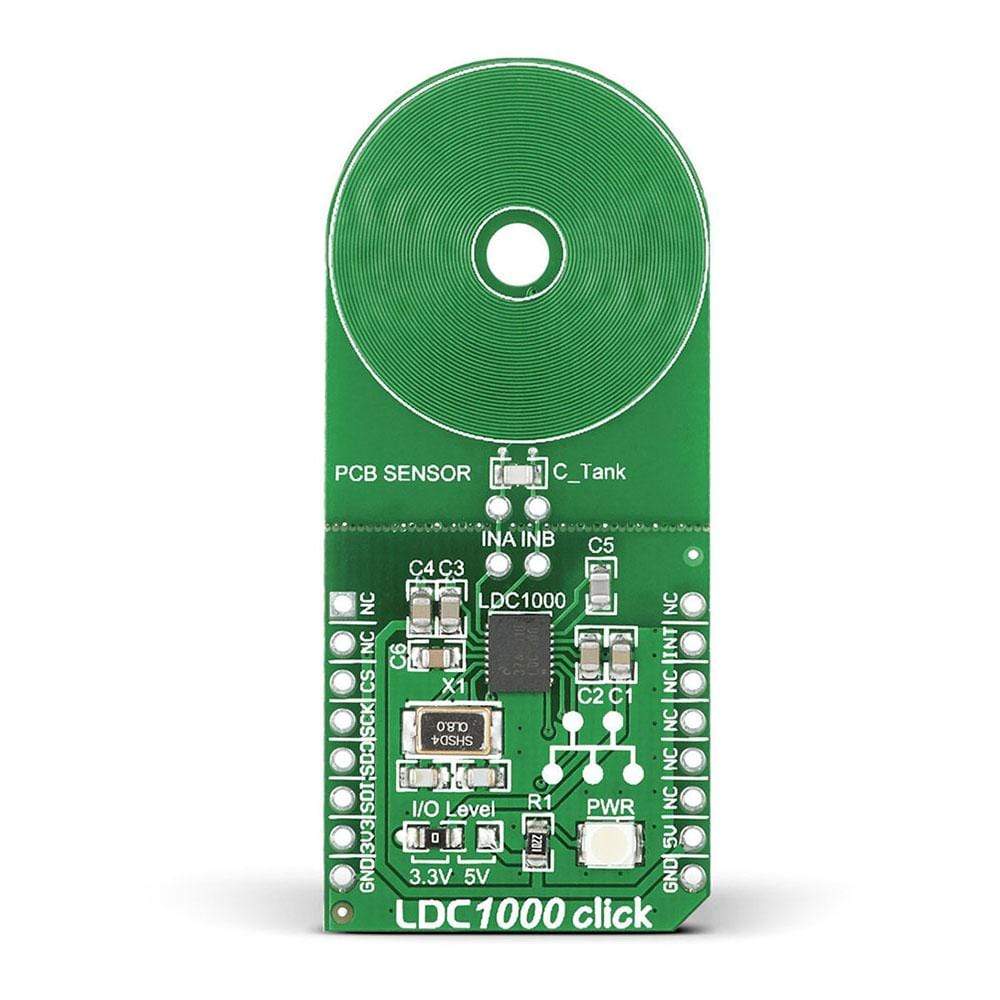

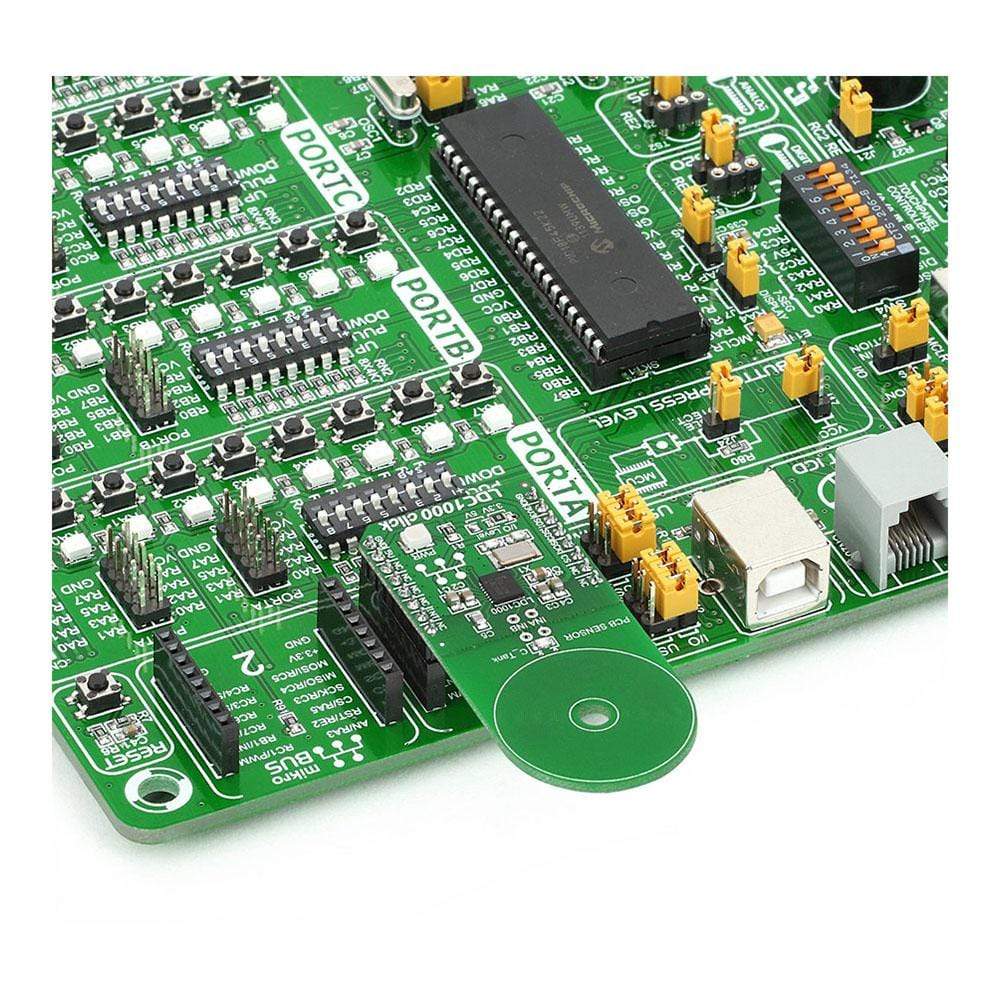

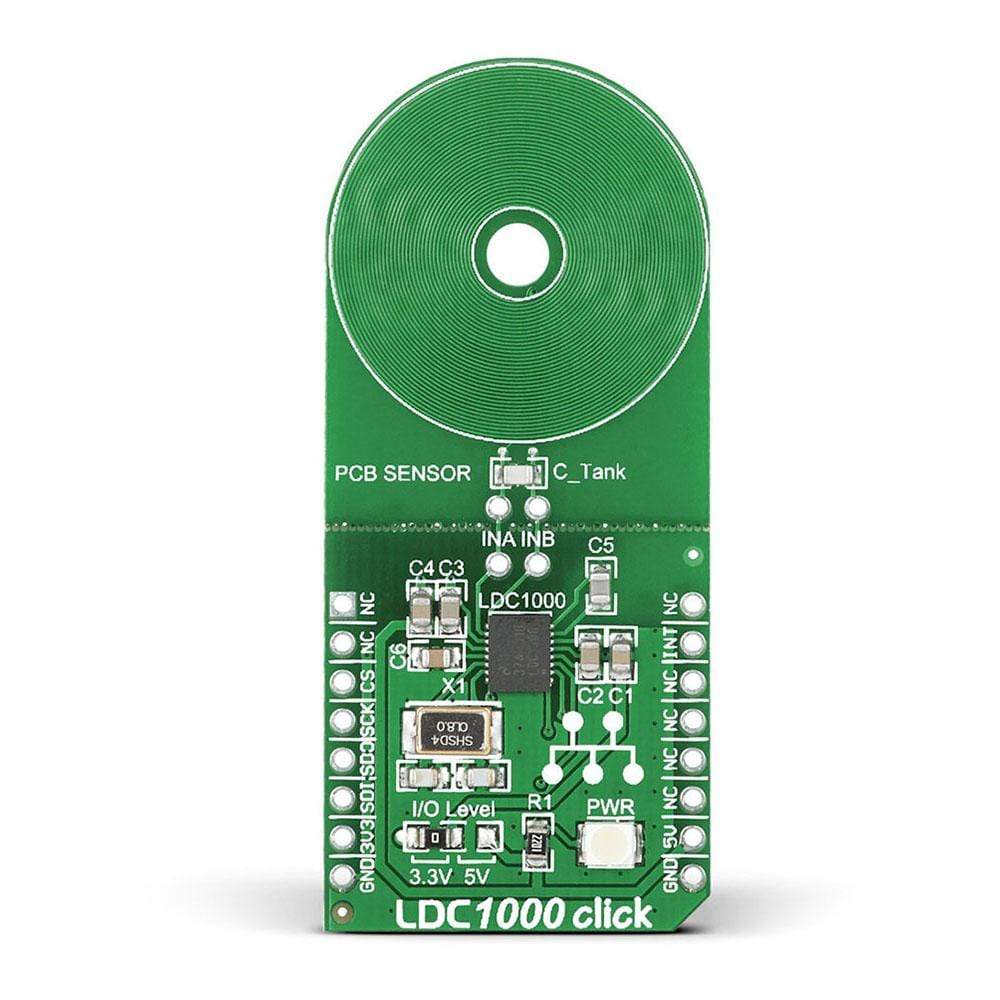

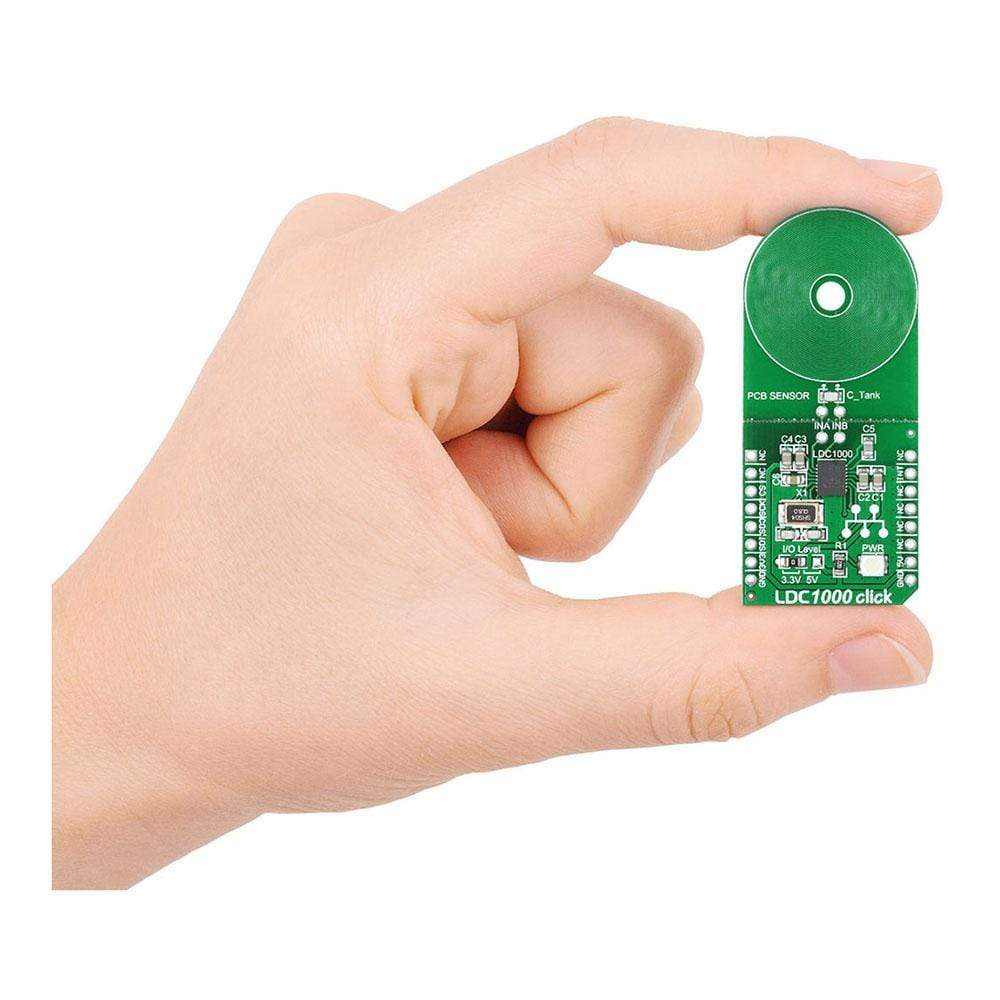

Equip your design with the first inductance-to-digital converter IC by using the LDC1000 Click Board™. The board also features a detachable PCB sensor, which comprises a 36-turn PCB coil and a 100pF 1% NPO capacitor. LDC1000 Click Board™ also allows the user to experiment with different sensors by breaking off the original and soldering it to the onboard INA and INB pins.

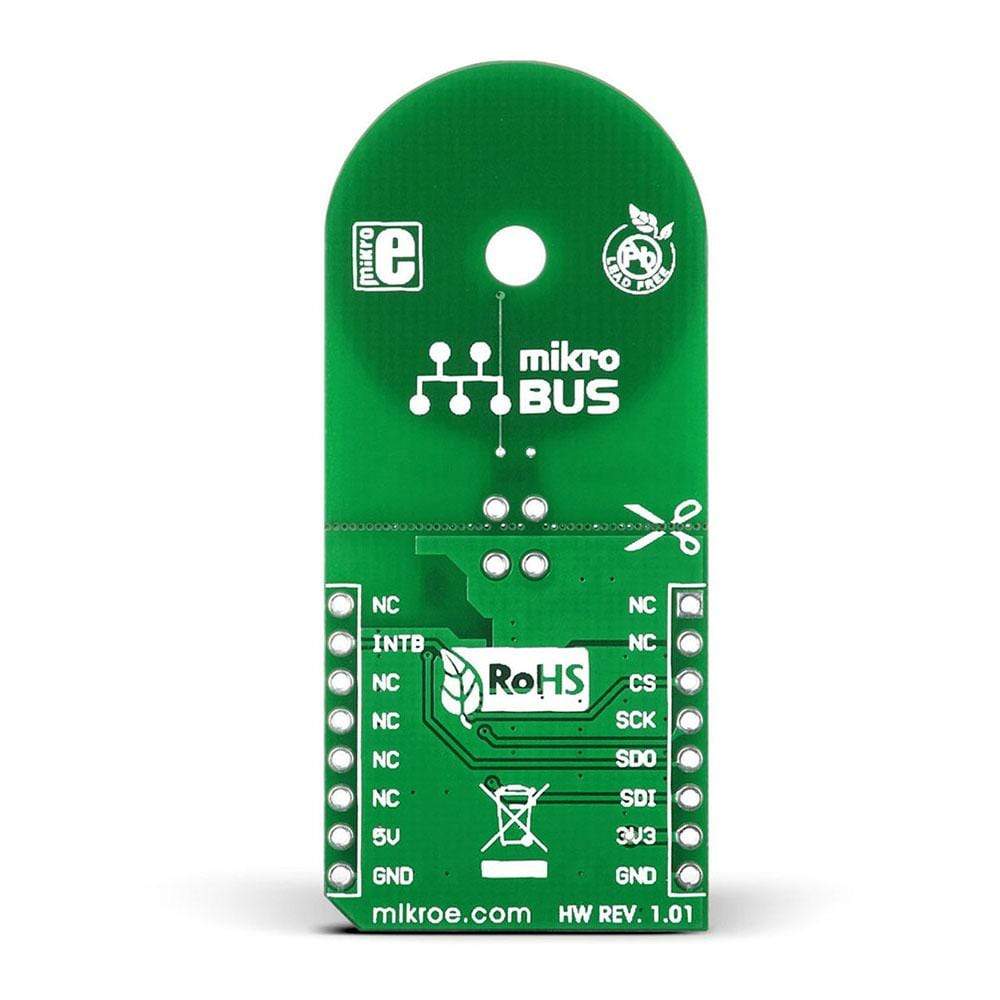

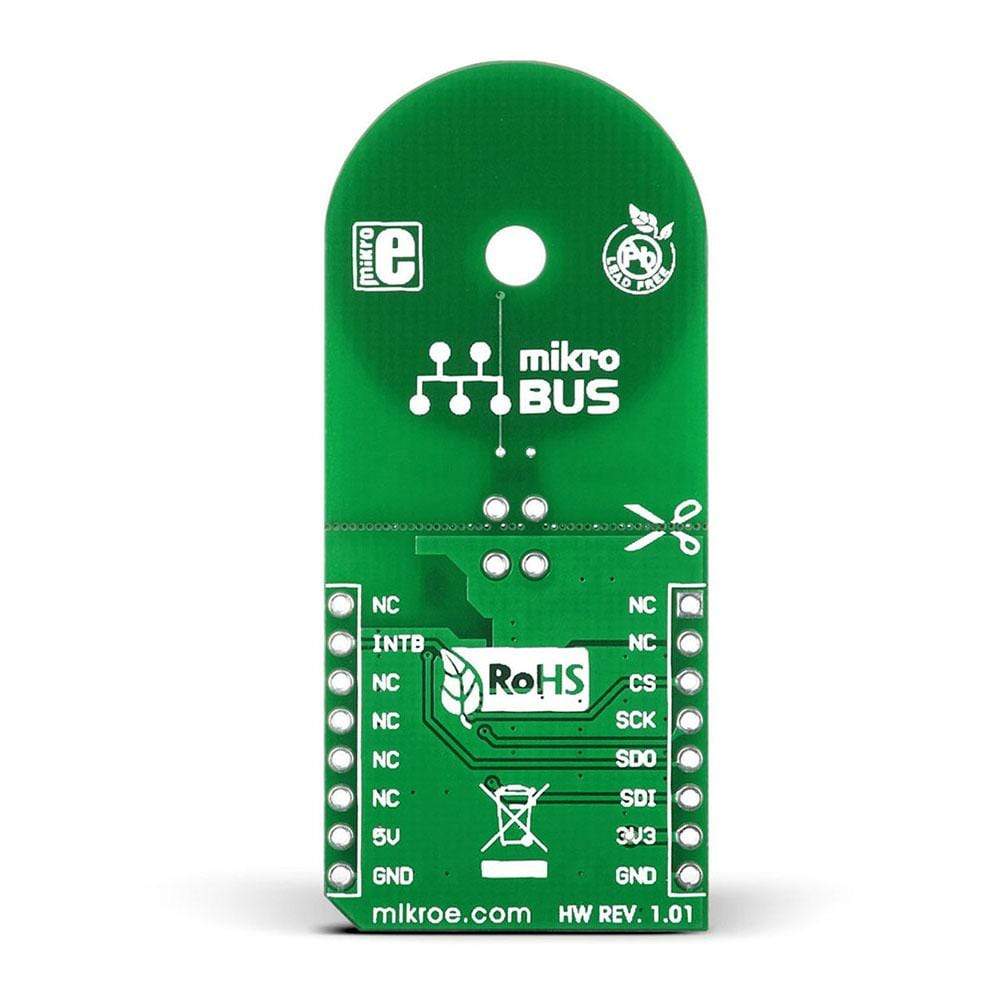

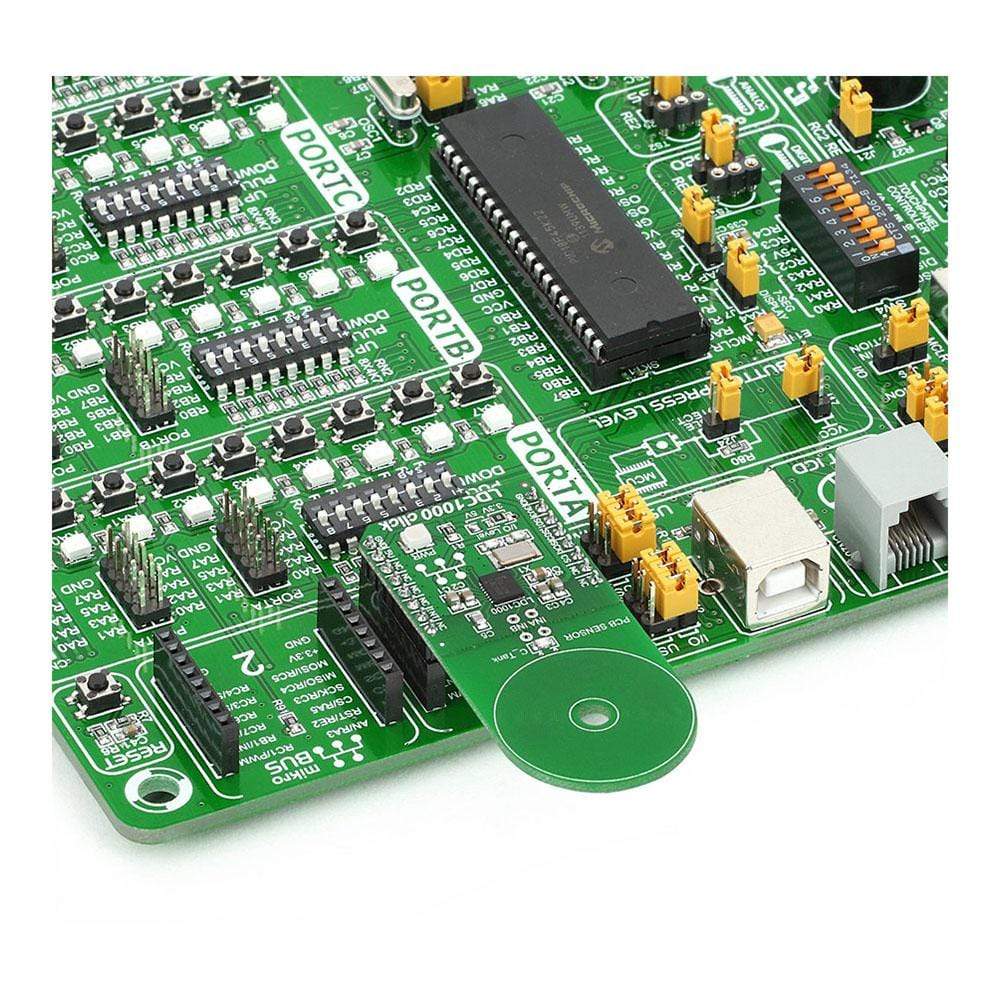

The onboard INA and INB pins enable the user to replace the offered detachable sensor and solder its own. LDC1000 Click Board™ communicates via MikroBUS SPI (CS, SCK, MISO, MOSI) and INT lines with the target board MCU. It supports either a 3.3V or 5V power supply.

In short-range applications, the LDC1000 features a sub-micron resolution, which makes LDC1000 Click Board™ an ideal choice for very precise short-range measurements of the position, motion or composition of conductive targets. Based on a contactless, magnet-free inductive sensing technology, LDC1000 Click Board™ offers steadfast performance even in hostile environments like, in the presence of dust, dirt, oil, moisture, etc.

Downloads

IC/Module: LDC1000 Inductance-to-Digital Converter

Known to be the worlds first inductance-to-digital converter IC, the LDC1000 Click Board™ is a high resolution inductive sensing technology based IC that offers the benefits of inductive sensing in a low-power, small-footprint solution.

Inductive Sensing

LDC1000 Click Board™ is based on a contactless, magnet-free inductive sensing technology with huge potential in embedded design. Designed for tough conditions, it provides better performance and high reliability at lower cost. It enables the user for enables accurate measurement of linear and angular position, displacement, motion, compression, vibration, metal composition, and several other applications.

Detachable PCB Sensor

The LDC1000 Click Board™ features a detachable PCB sensor, which is an LC tank that includes a 36-turn PCB coil and a 100pF 1% NPO capacitor. The user can try out using different sensors, to attain a low-cost solution, by breaking off the original, and soldering the new sensor to the on-board INA and INB pins.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-1583

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.03 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606015075327

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.