Overview

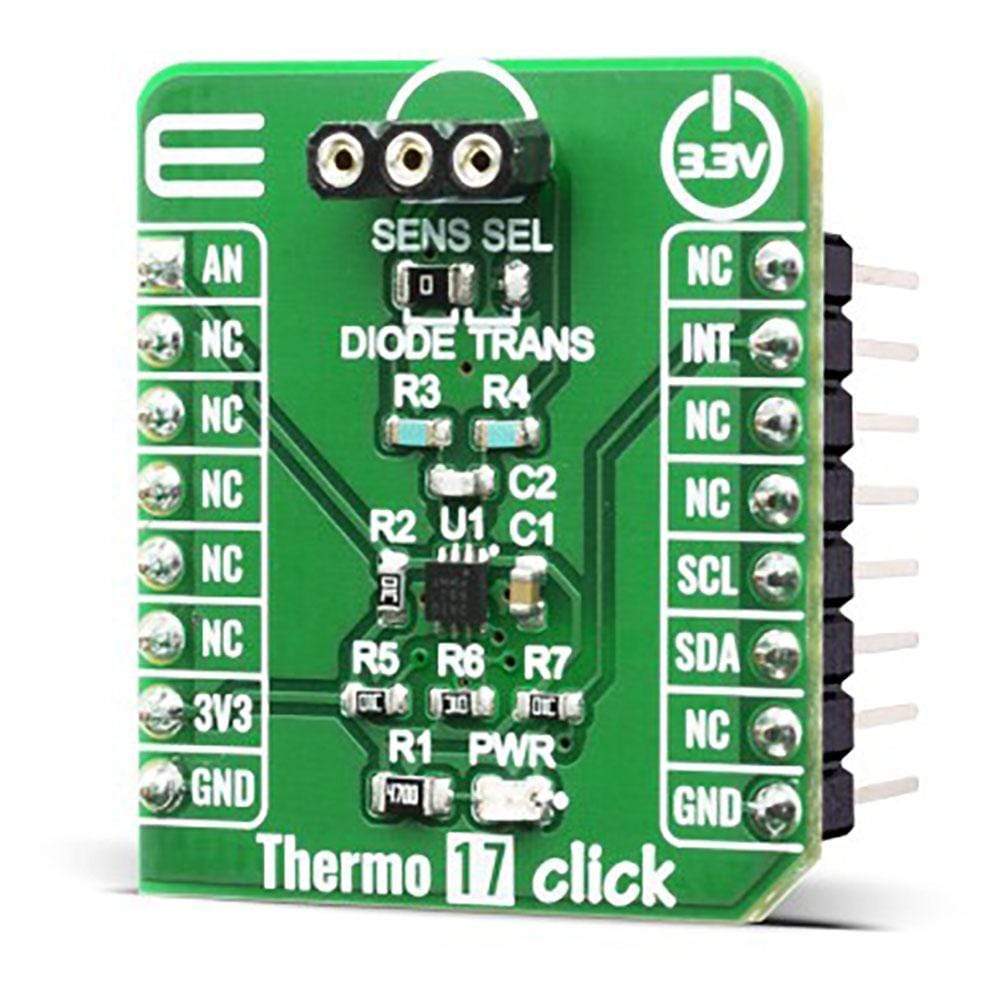

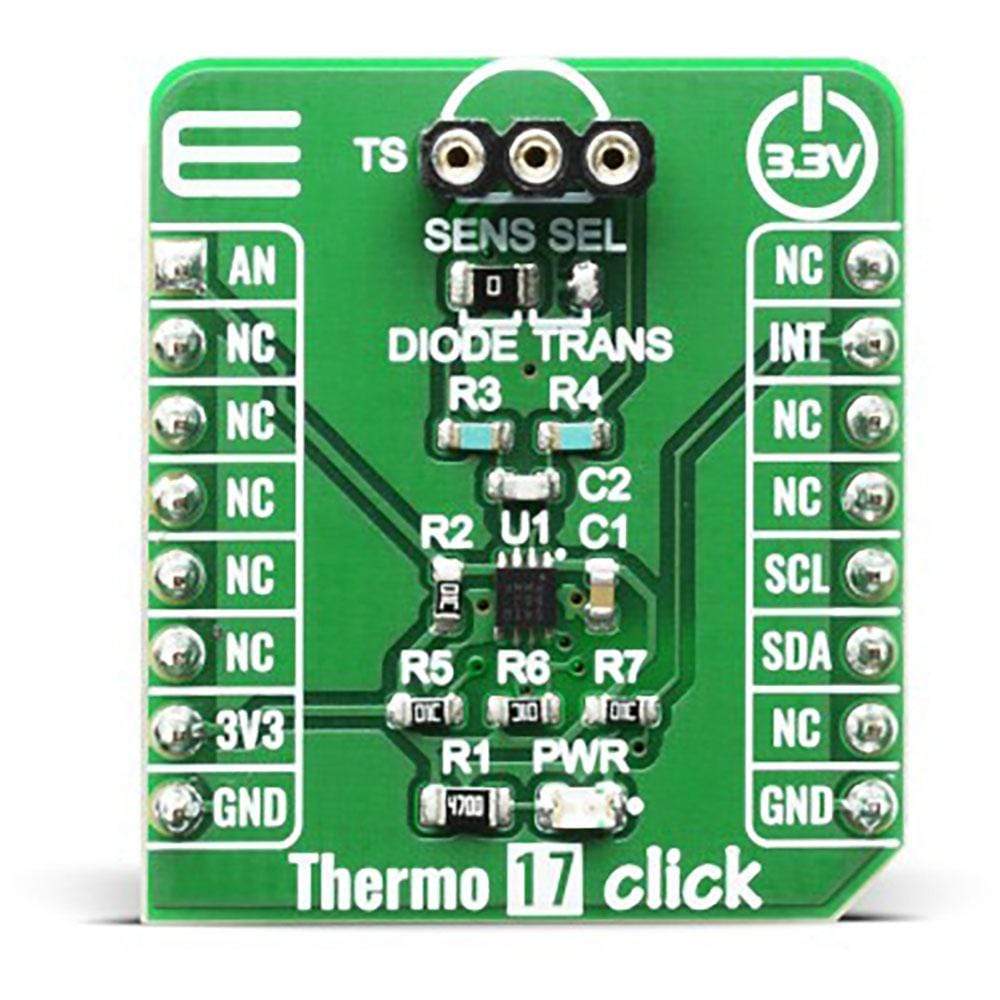

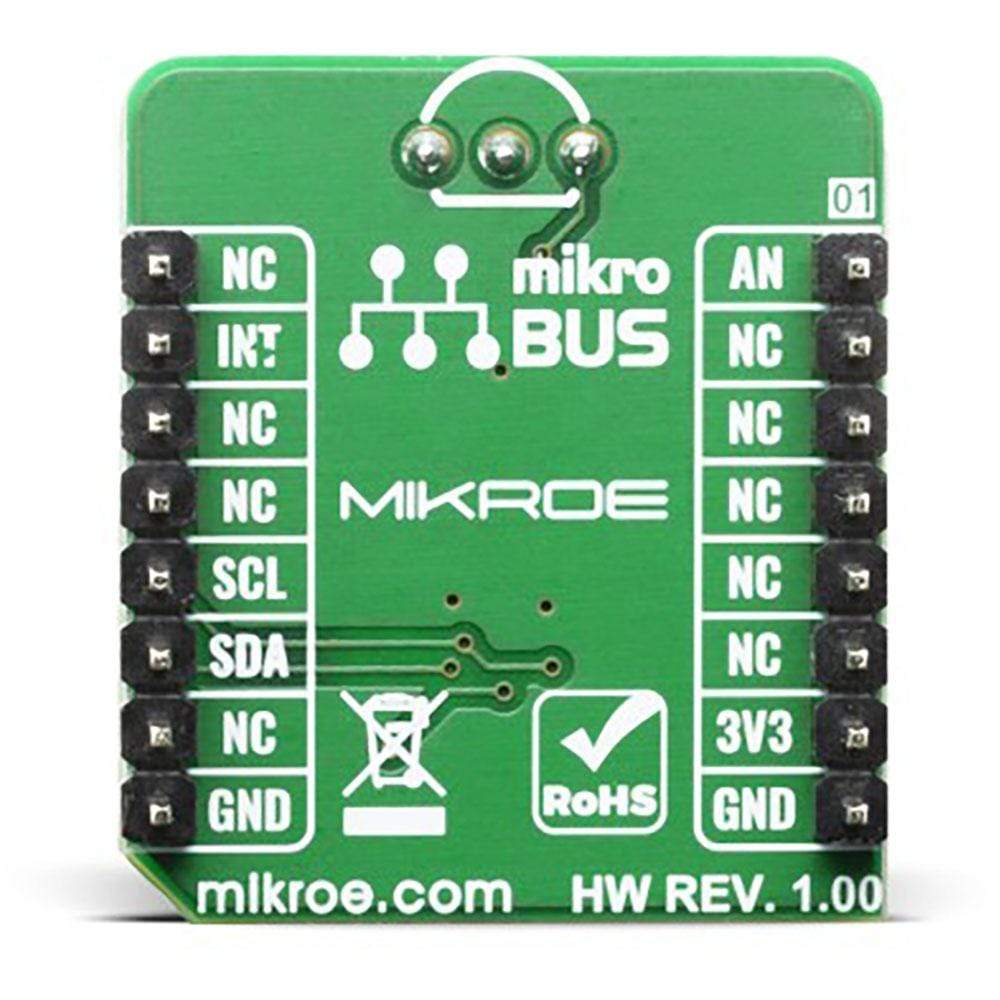

The Thermo 17 Click Board™is based on the TMP451-Q1, a high-accuracy, low-power remote temperature sensor monitor with a built-in local temperature sensor from Texas Instruments. Because of its main features, this Click Board™ is perfect for automotive infotainment systems, ECU processor temperature monitoring, TCM processor temperature monitoring, BCM processor temperature monitoring and LED headlight thermal control.

The Thermo 17 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Das Thermo 17 Click Board™ basiert auf dem TMP451-Q1, einem hochpräzisen, stromsparenden Remote-Temperatursensormonitor mit integriertem lokalen Temperatursensor von Texas Instruments. Aufgrund seiner Hauptfunktionen ist dieses Click Board™ perfekt für Kfz-Infotainmentsysteme, ECU-Prozessortemperaturüberwachung, TCM-Prozessortemperaturüberwachung, BCM-Prozessortemperaturüberwachung und thermische Steuerung von LED-Scheinwerfern geeignet.

Das Thermo 17 Click Board™ wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3994

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.016 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018718412

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.