Overview

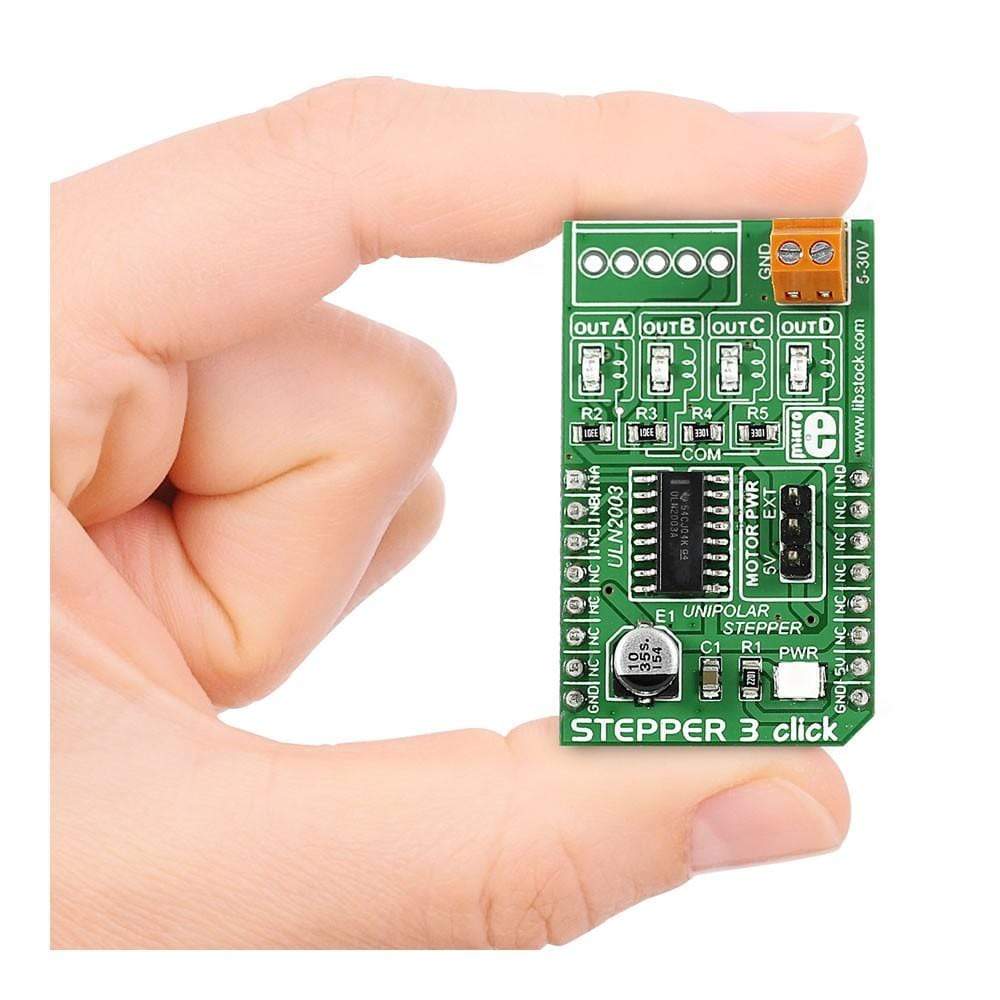

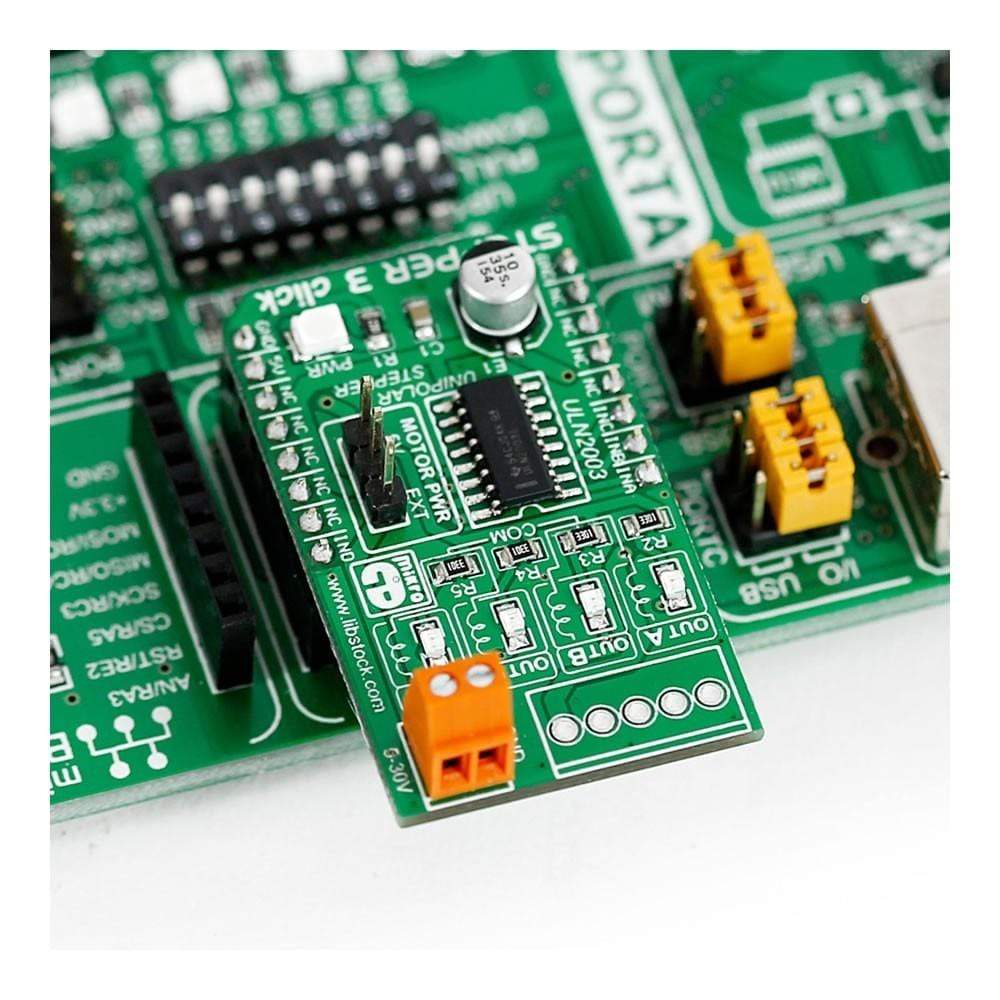

The Stepper 3 Click Board™ is designed to drive unipolar stepper motors, with a supply voltage applied to the common wire. The current flows through the common wire and the motor coil, via the activated current sink driver, to the ground. This Click Board™ uses the ULN2003A, a high voltage and current Darlington transistors array IC, as the sink driver. This IC is an ideal solution for this purpose, as it has seven high power Darlington output stages, activated by TTL/CMOS logic level signals, applied to the control pins. This allows driving unipolar stepper motors with up to 30V and 500mA per coil.

Downloads

Das Stepper 3 Click Board™ ist für den Antrieb unipolarer Schrittmotoren ausgelegt, wobei eine Versorgungsspannung an den gemeinsamen Draht angelegt wird. Der Strom fließt durch den gemeinsamen Draht und die Motorspule über den aktivierten Stromsenkentreiber zur Erde. Dieses Click Board™ verwendet den ULN2003A, einen Hochspannungs- und Hochstrom-Darlington-Transistor-Array-IC, als Senkentreiber. Dieser IC ist eine ideale Lösung für diesen Zweck, da er über sieben Hochleistungs-Darlington-Ausgangsstufen verfügt, die durch TTL/CMOS-Logikpegelsignale aktiviert werden, die an die Steuerstifte angelegt werden. Dies ermöglicht den Antrieb unipolarer Schrittmotoren mit bis zu 30 V und 500 mA pro Spule.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2035

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018717989

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.