Overview

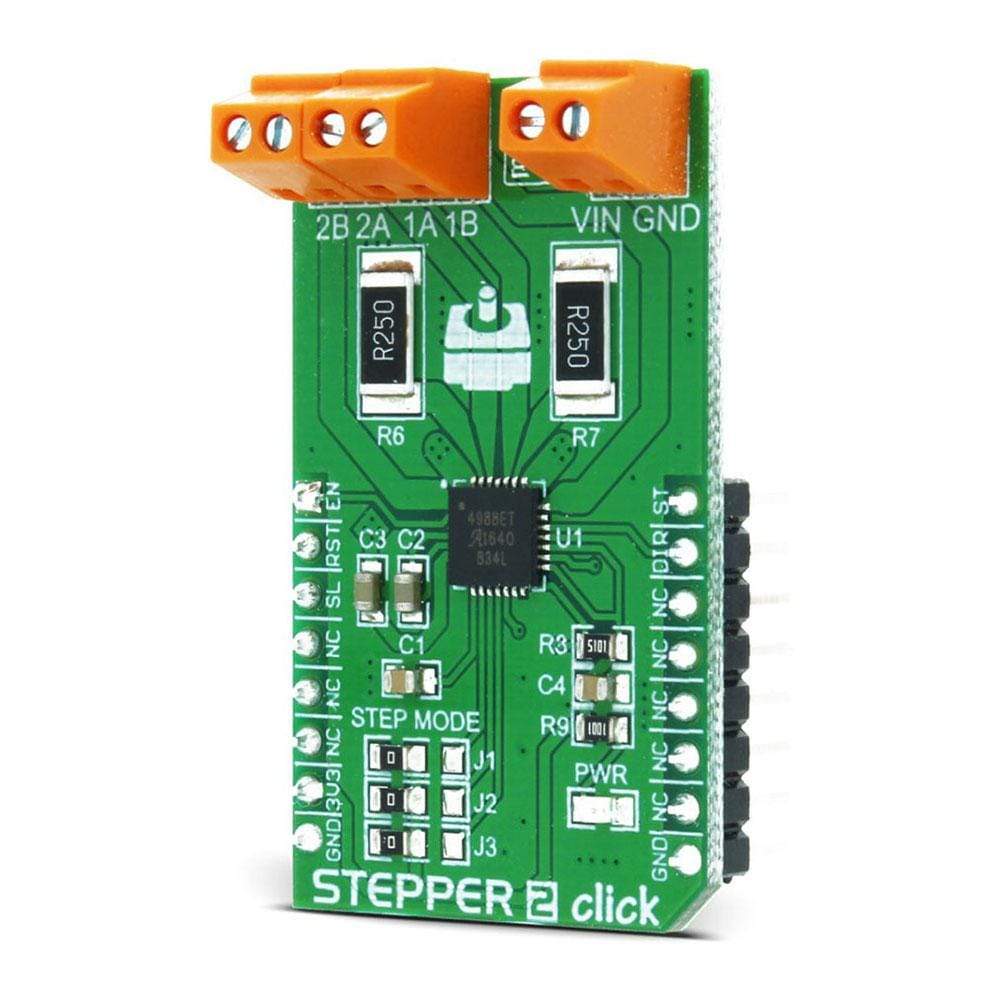

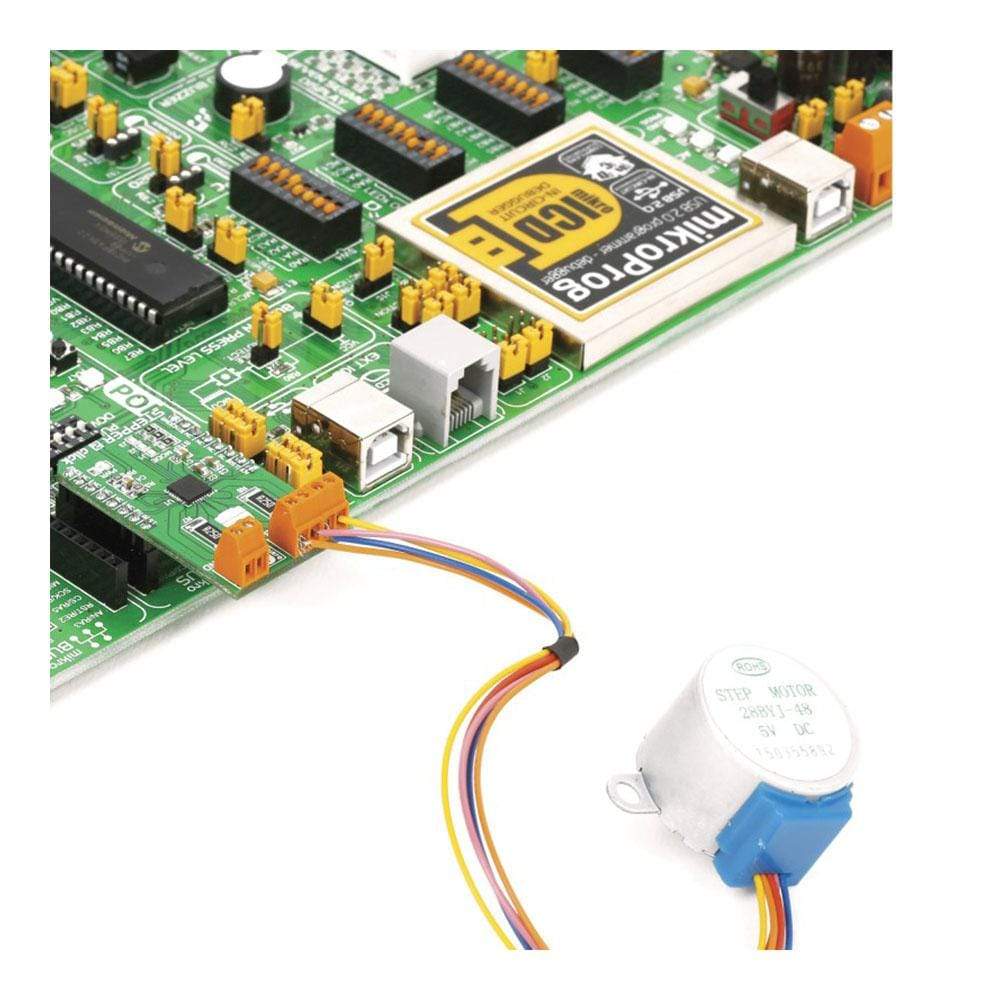

An improvement over its predecessor, the Stepper 2 Click Board™ from MikroE is another addition in the range of motor driver Click Boards™. Complete with an A4988 microstepping motor driver, the Stepper 2 Click Board™ surpasses the original Stepper Click Board™ with an output drive capability of up to 35V and 2A.

Not just power, the new version is designed to offer users more control (precision). It can go down to 1/16th of a step to drive the motor. The board features three pairs of onboard screw terminals for secure connectivity. The first two (2B, 2A; 1A, 1B) are for connecting the motor while the third pair (VIN and GND) is for an external power supply (minimum 7V).

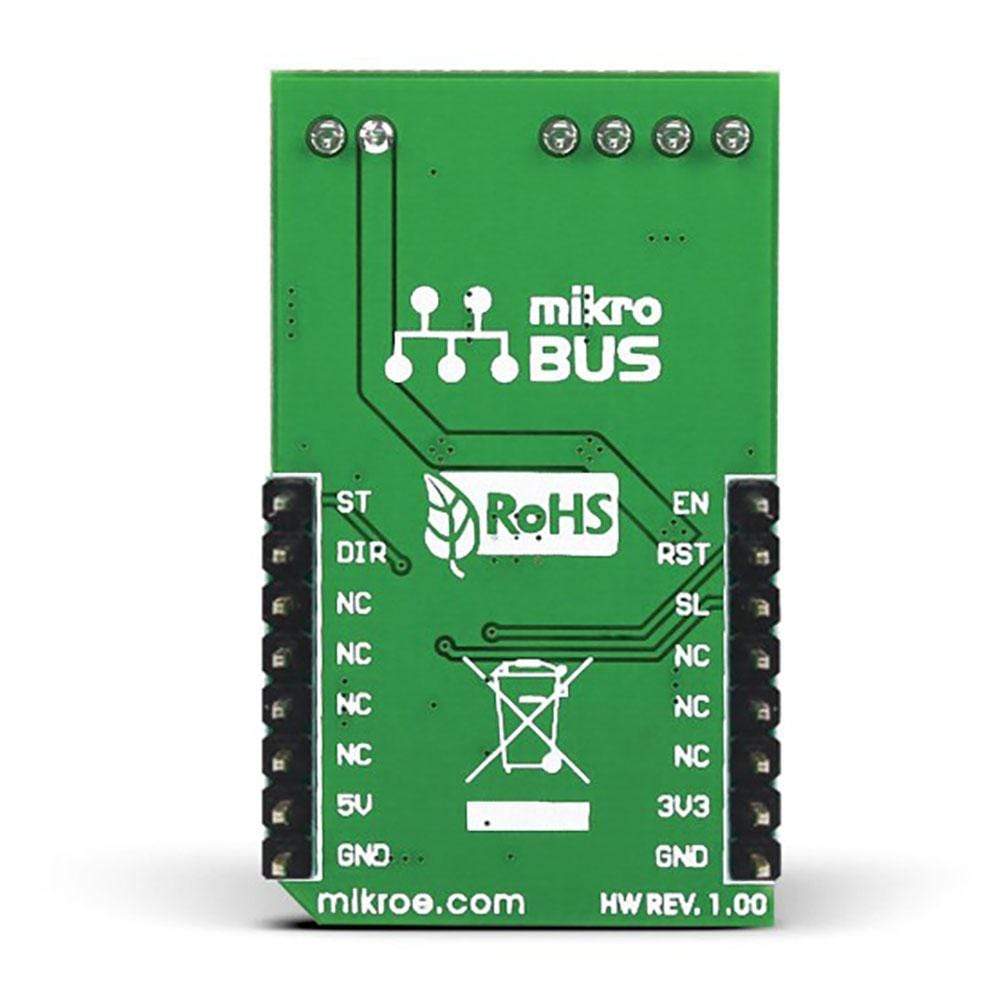

The Stepper 2 Click Board™ is intended to operate bipolar stepper motors in full-, half-, quarter-, eighth-, and sixteenth-step modes. The user can select between the different stepping modes (steps and micro-steps) using a set of three (J1-J3) onboard jumpers. Stepper 2 Click Board™ uses MikroBUS EN, RST, SL, ST and DIR pins to communicate with the target board microcontroller. It is designed to work with a 3.3V power supply but is also compatible with a 5V logic level.

Downloads

Das Stepper 2 Click Board™ von MikroE ist eine Verbesserung gegenüber seinem Vorgänger und eine weitere Ergänzung im Bereich der Motortreiber Click Boards™. Ausgestattet mit einem A4988-Mikroschrittmotortreiber übertrifft das Stepper 2 Click Board™ das ursprüngliche Stepper Click Board™ mit einer Ausgangsantriebsleistung von bis zu 35 V und 2 A.

Die neue Version bietet dem Benutzer nicht nur Leistung, sondern auch mehr Kontrolle (Präzision). Der Motor kann bis auf 1/16 eines Schritts heruntergefahren werden. Die Platine verfügt über drei Paare integrierter Schraubklemmen für eine sichere Verbindung. Die ersten beiden (2B, 2A; 1A, 1B) dienen zum Anschluss des Motors, während das dritte Paar (VIN und GND) für eine externe Stromversorgung (mindestens 7 V) vorgesehen ist.

Das Stepper 2 Click Board™ ist für den Betrieb bipolarer Schrittmotoren im Voll-, Halb-, Viertel-, Achtel- und Sechzehntelschrittmodus vorgesehen. Der Benutzer kann mithilfe eines Satzes von drei (J1-J3) integrierten Jumpern zwischen den verschiedenen Schrittmodi (Schritte und Mikroschritte) wählen. Das Stepper 2 Click Board™ verwendet MikroBUS EN-, RST-, SL-, ST- und DIR-Pins zur Kommunikation mit dem Mikrocontroller der Zielplatine. Es ist für den Betrieb mit einer 3,3-V-Stromversorgung ausgelegt, ist aber auch mit einem 5-V-Logikpegel kompatibel.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-1926

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.028 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606015076997

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.