Key Features

Overview

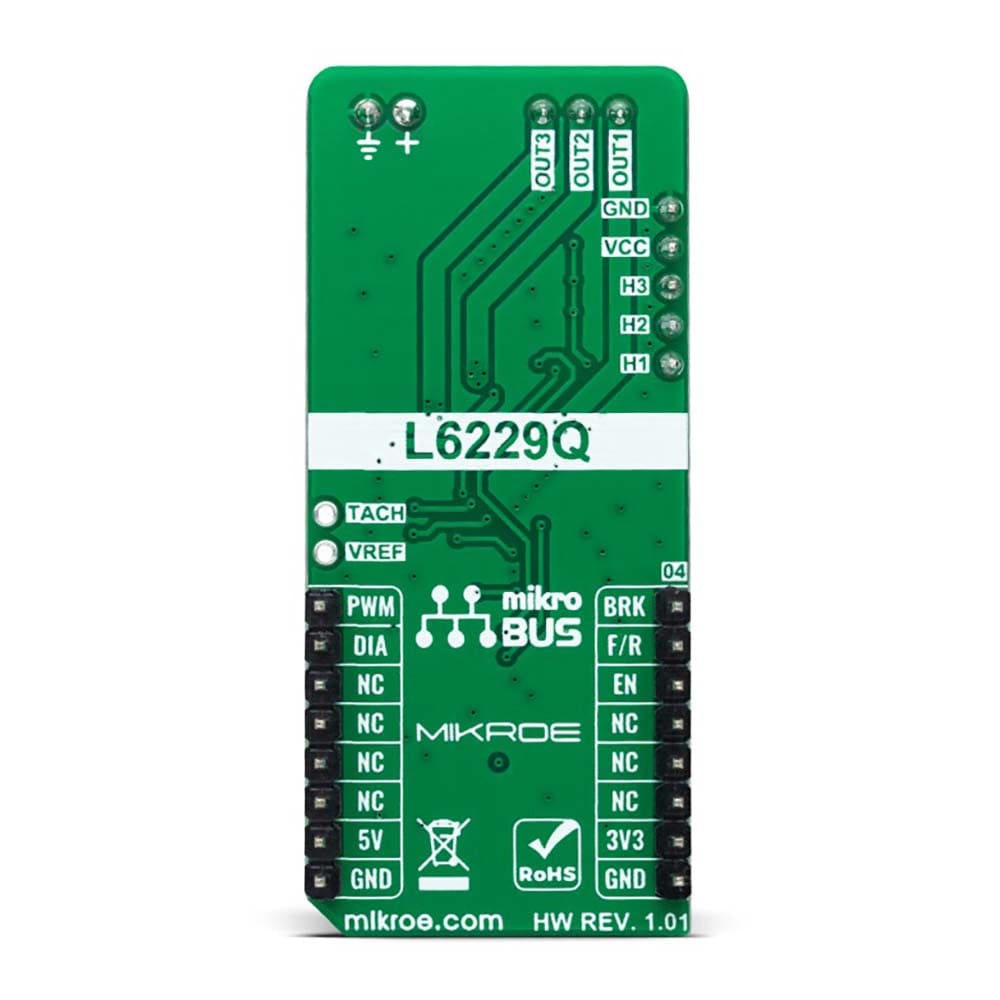

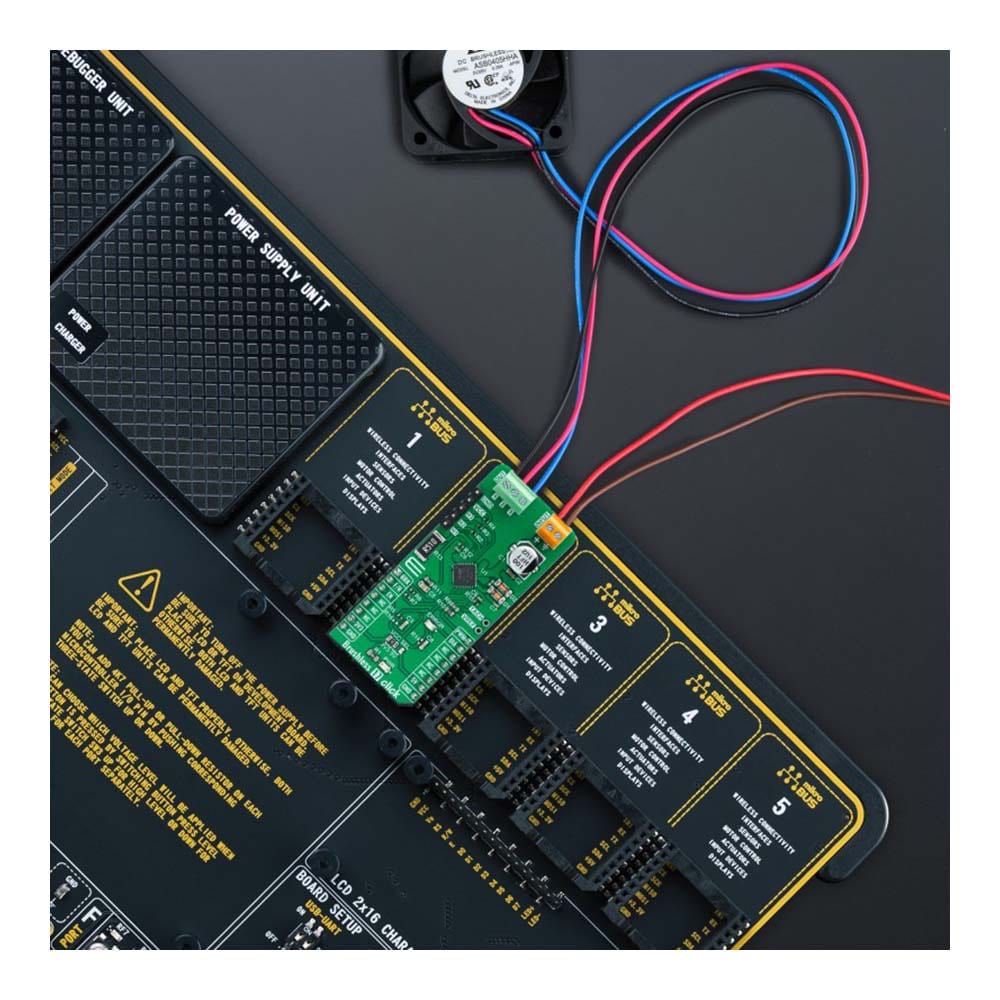

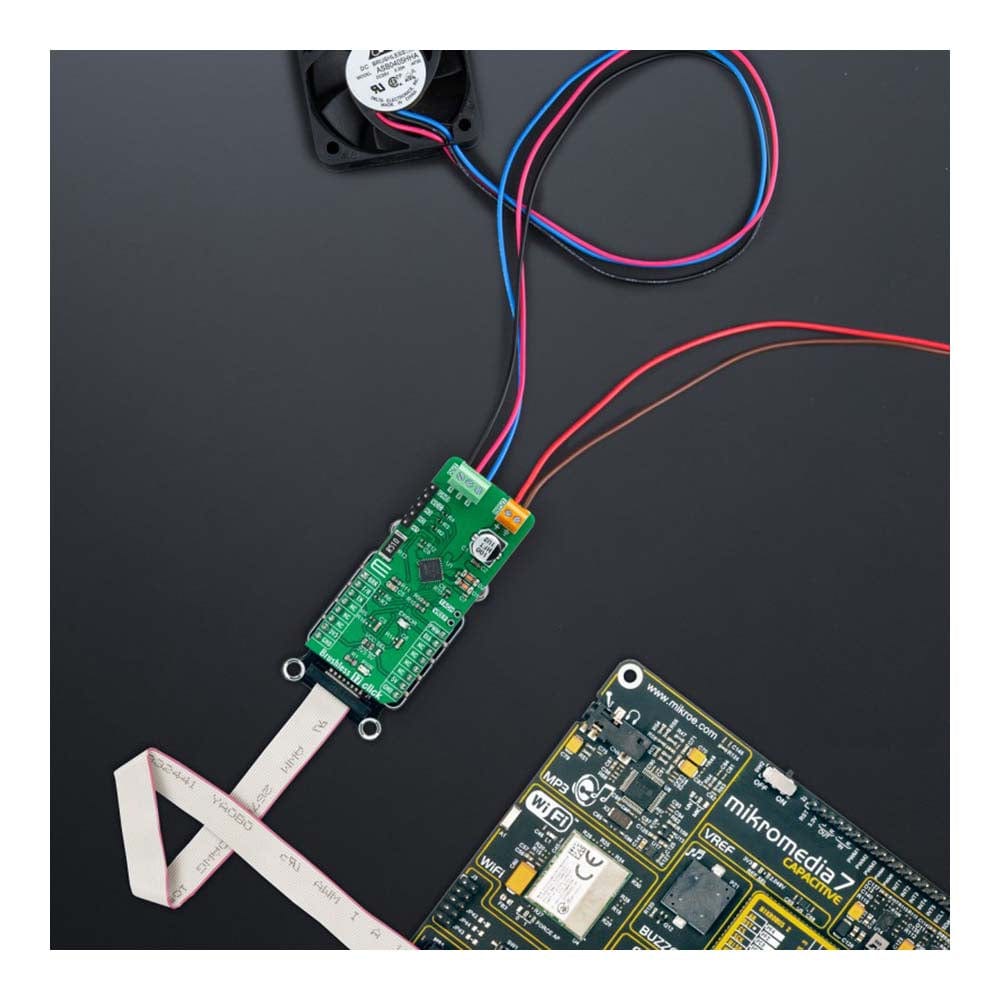

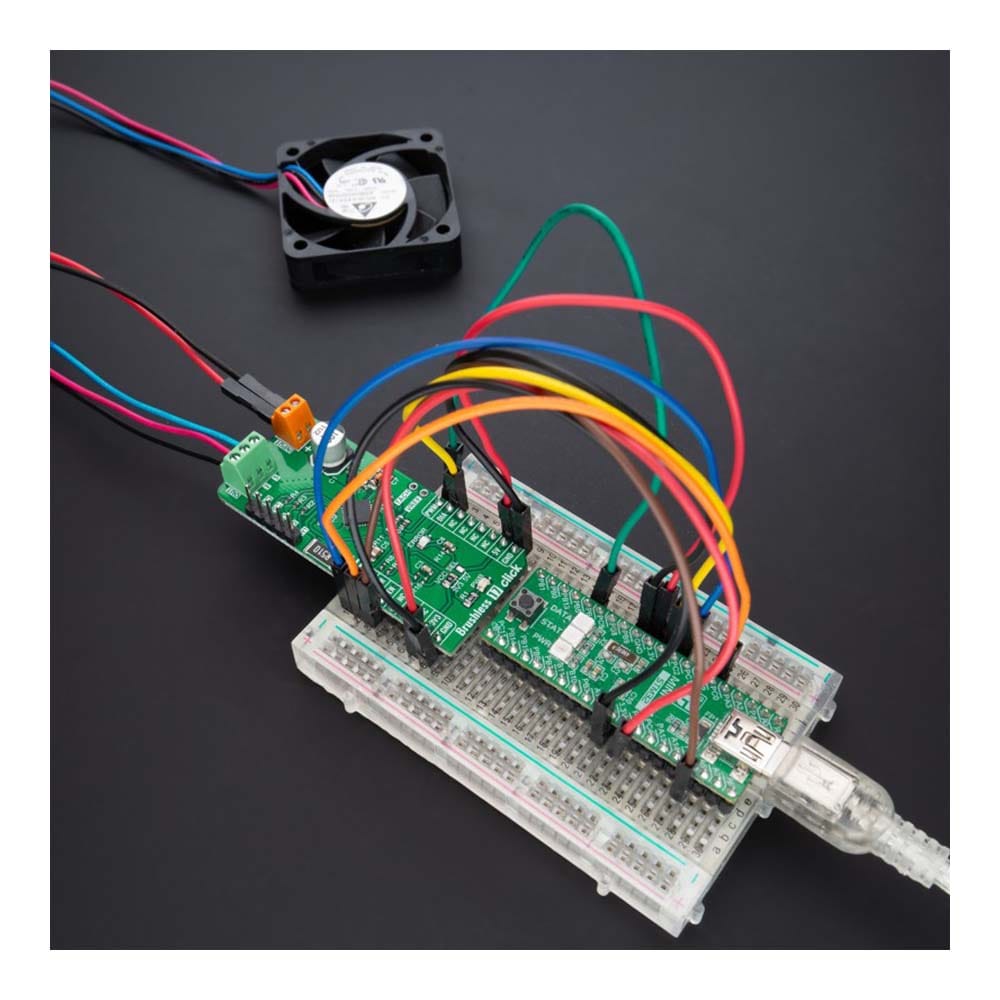

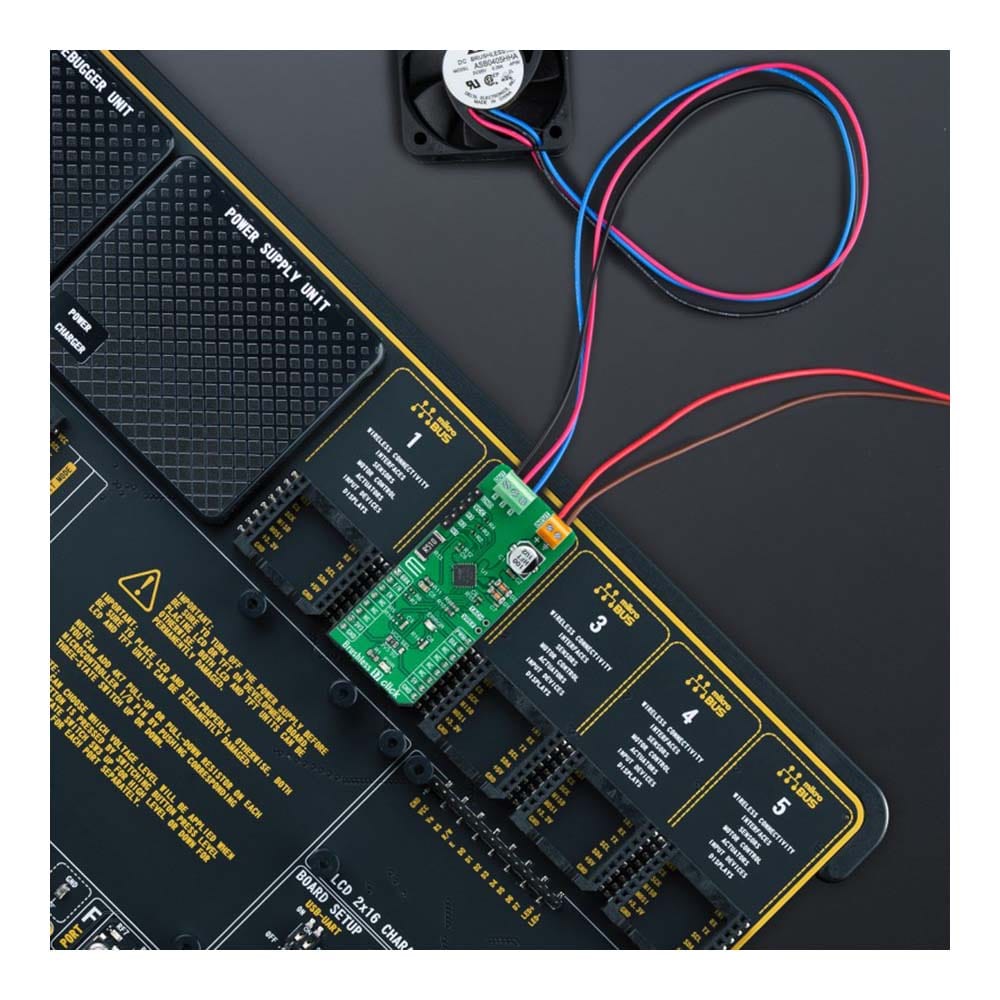

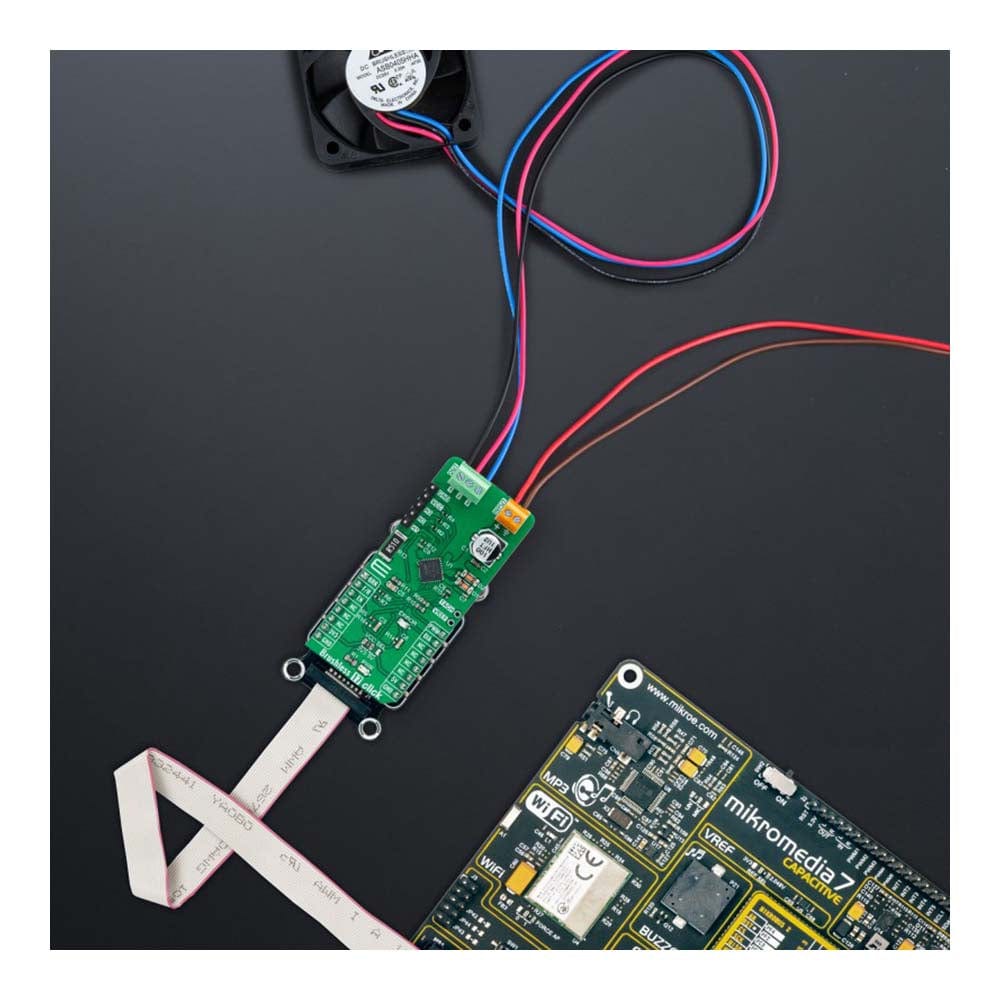

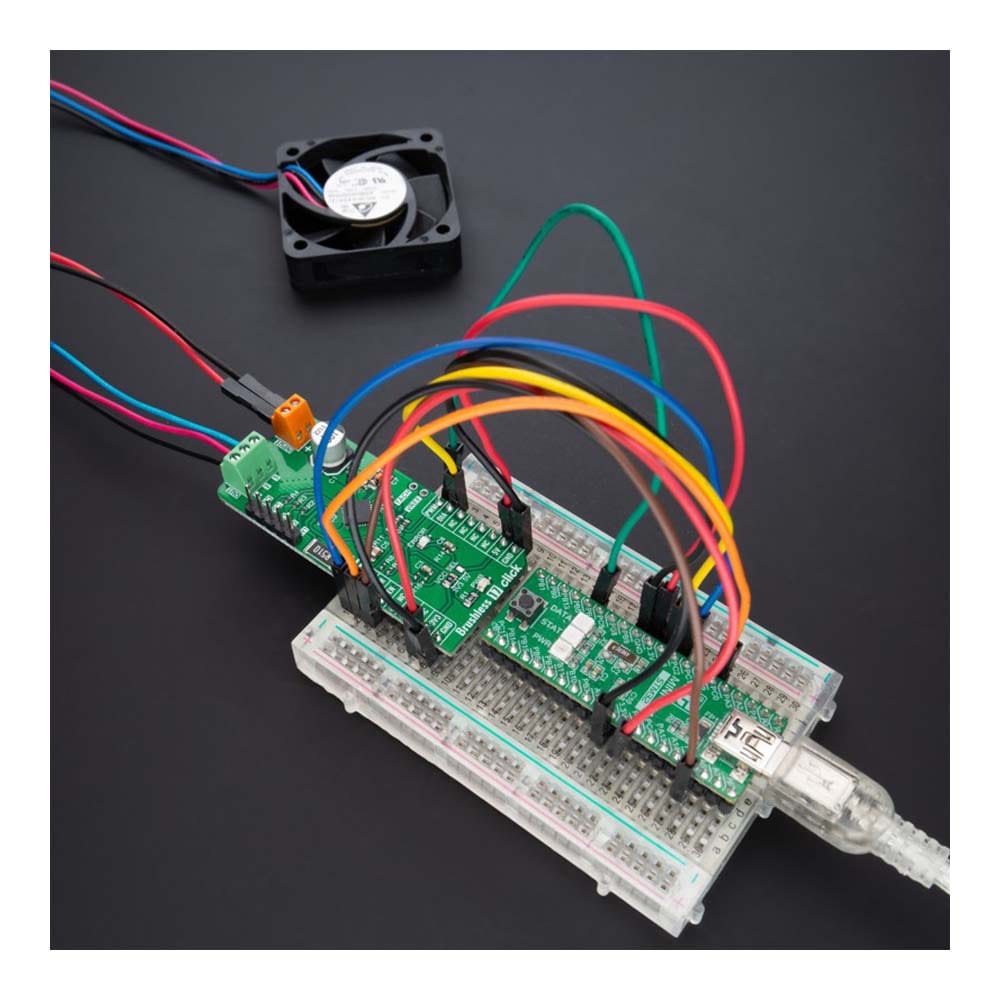

The Brushless 17 Click Board™ is a compact add-on board suitable for controlling brushless DC (BLDC) motors with any MCU. This board features the L6229Q, DMOS fully integrated three-phase BLDC motor driver with overcurrent protection from STMicroelectronics. This motor driver combines isolated DMOS power transistors with CMOS and bipolar circuits on the same chip, realized in BCD (Bipolar-CMOS-DMOS) multipower technology. It includes all the circuitry for a three-phase BLDC motor drive, including a three-phase DMOS bridge, a constant off-time PWM current controller, and the decoding logic for single-ended hall sensors that generate the required sequence for the power stage. This Click board™ makes the perfect solution for driving three-phase brushless DC motors with currents up to 1A DC.

The Brushless 17 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Das Brushless 17 Click Board™ ist eine kompakte Zusatzplatine, die sich zur Steuerung bürstenloser Gleichstrommotoren (BLDC) mit jedem MCU eignet. Diese Platine verfügt über den vollständig integrierten dreiphasigen BLDC-Motortreiber L6229Q, DMOS mit Überstromschutz von STMicroelectronics. Dieser Motortreiber kombiniert isolierte DMOS-Leistungstransistoren mit CMOS- und bipolaren Schaltkreisen auf demselben Chip, realisiert in BCD-Multipower-Technologie (Bipolar-CMOS-DMOS). Es umfasst die gesamte Schaltung für einen dreiphasigen BLDC-Motorantrieb, einschließlich einer dreiphasigen DMOS-Brücke, eines PWM-Stromreglers mit konstanter Ausschaltzeit und der Dekodierungslogik für einseitige Hallsensoren, die die erforderliche Sequenz für die Leistungsstufe erzeugen. Dieses Click Board™ ist die perfekte Lösung zum Antrieb dreiphasiger bürstenloser Gleichstrommotoren mit Strömen bis zu 1 A DC.

Das Brushless 17 Click Board™ wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-5000

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027388620

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.