Overview

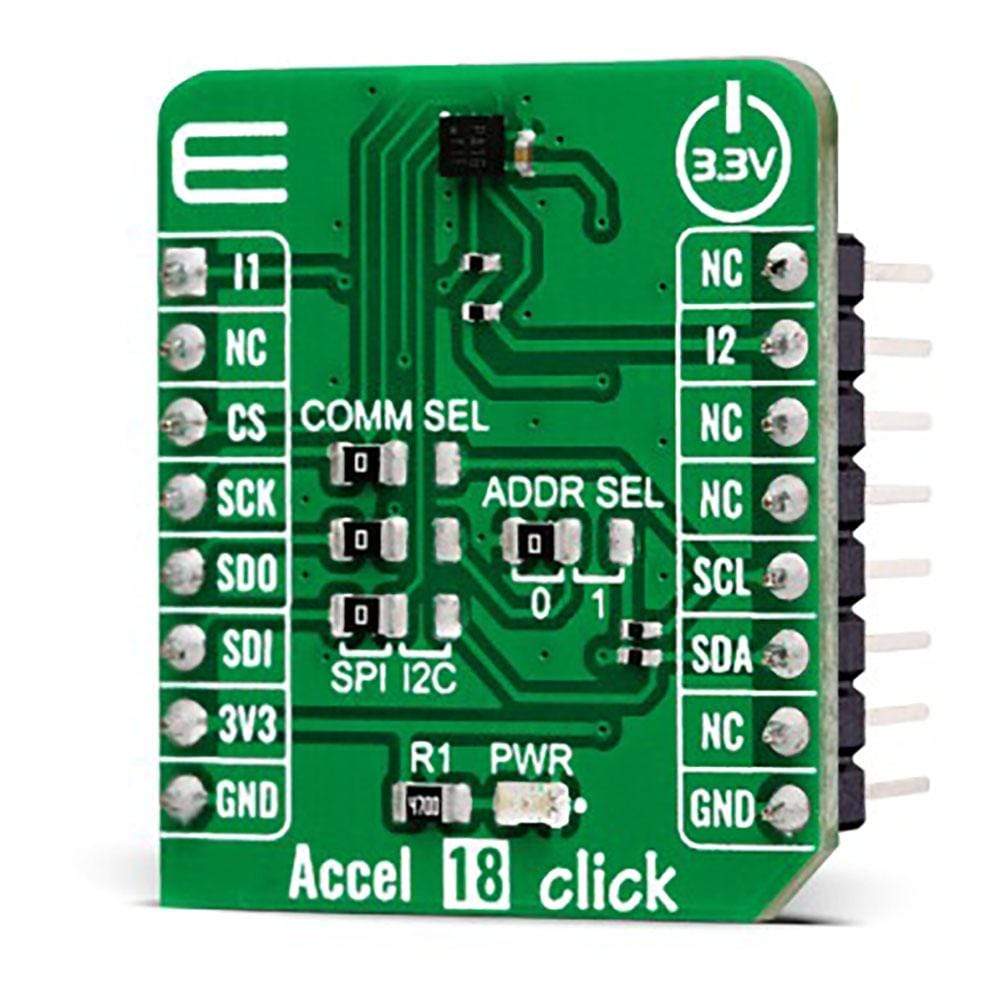

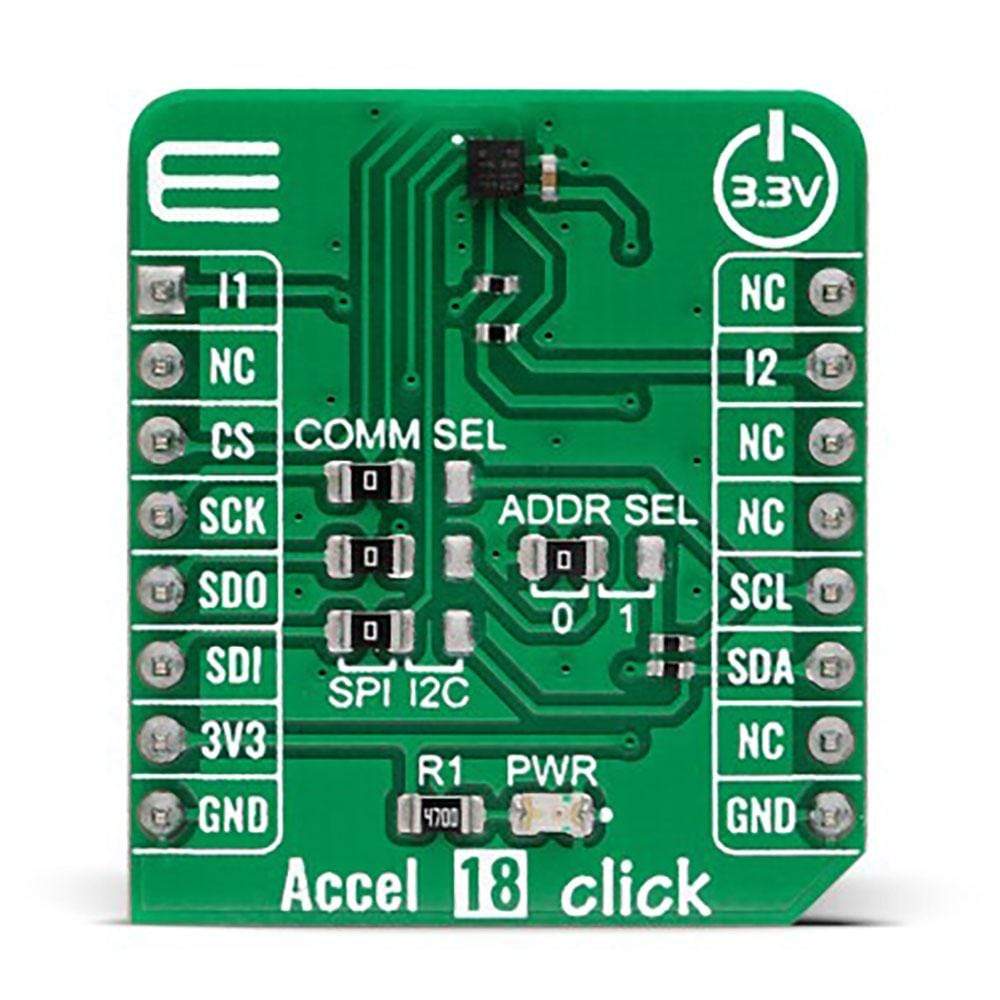

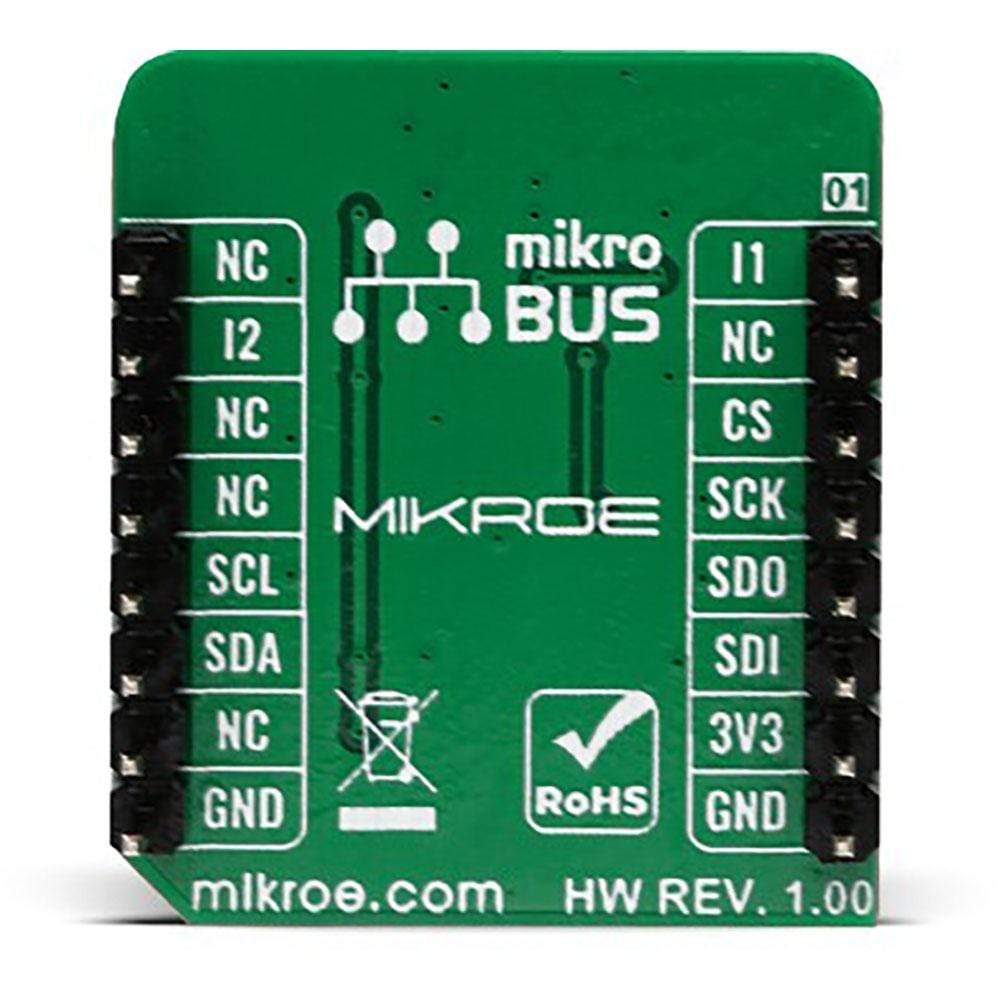

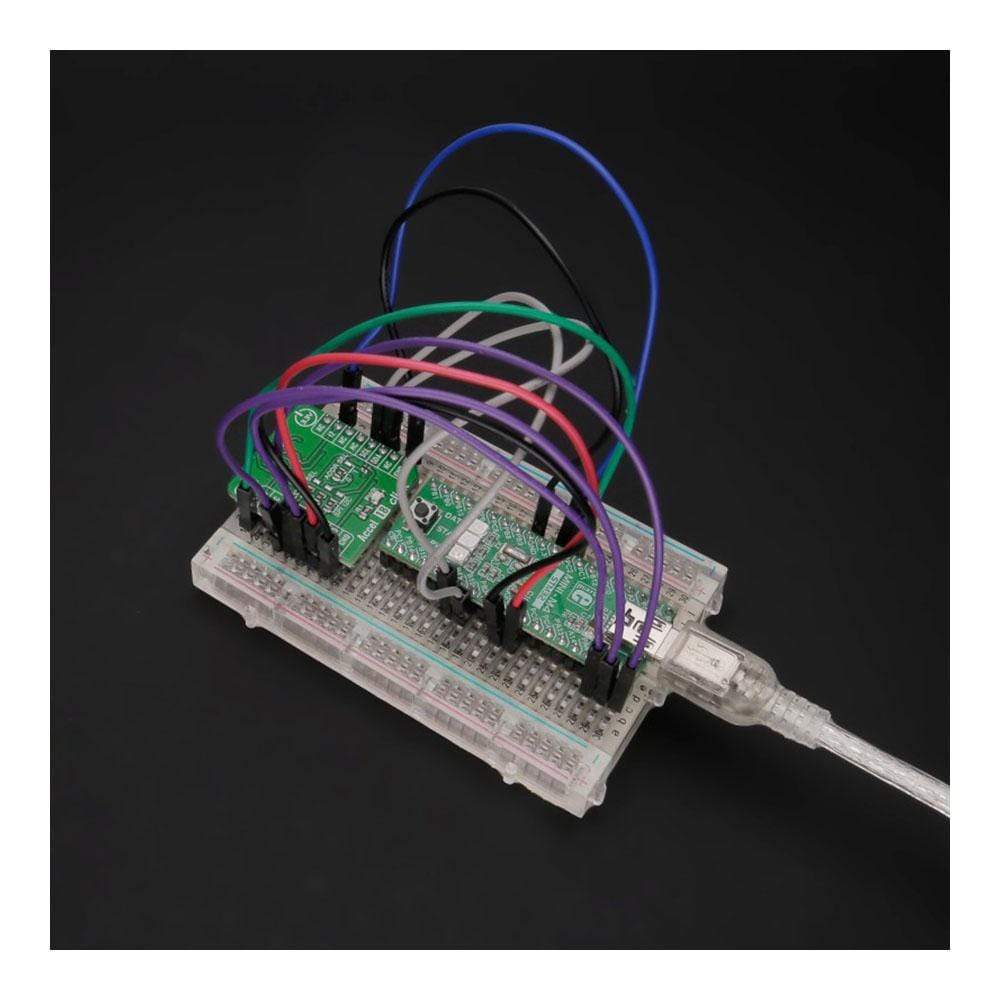

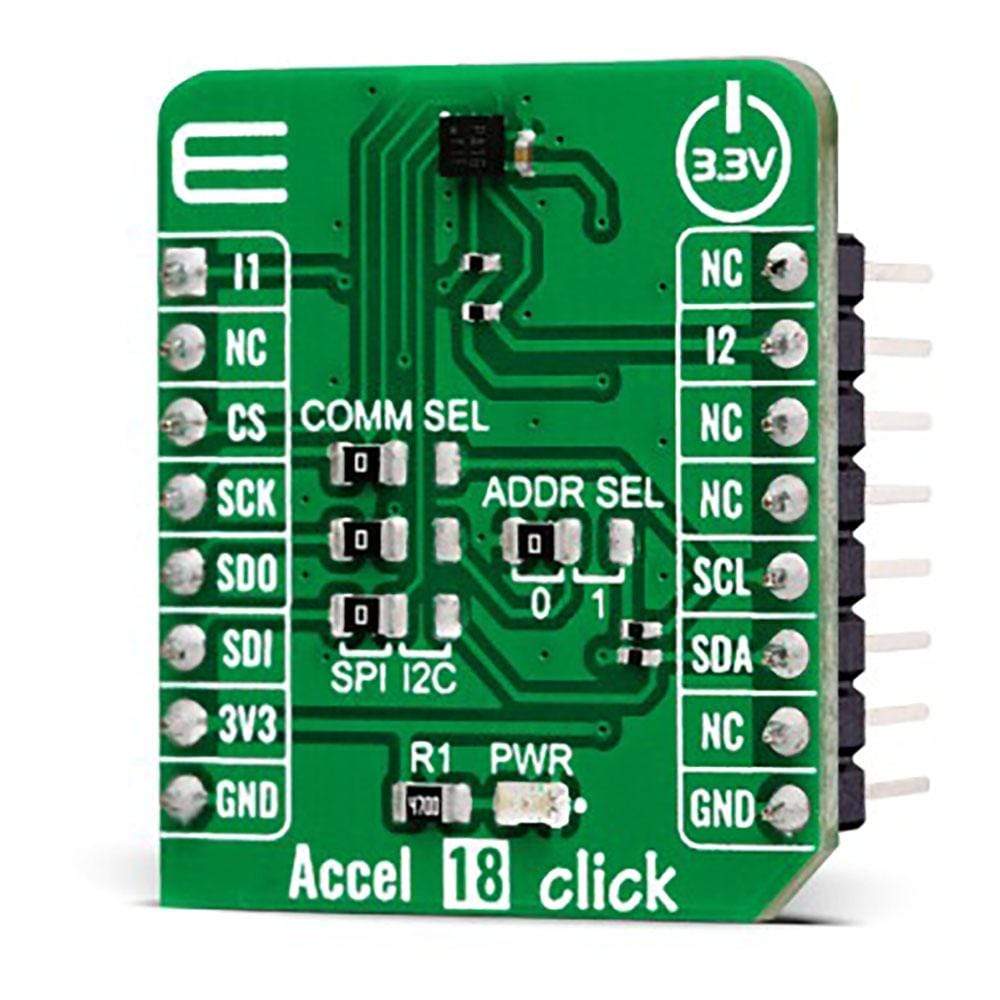

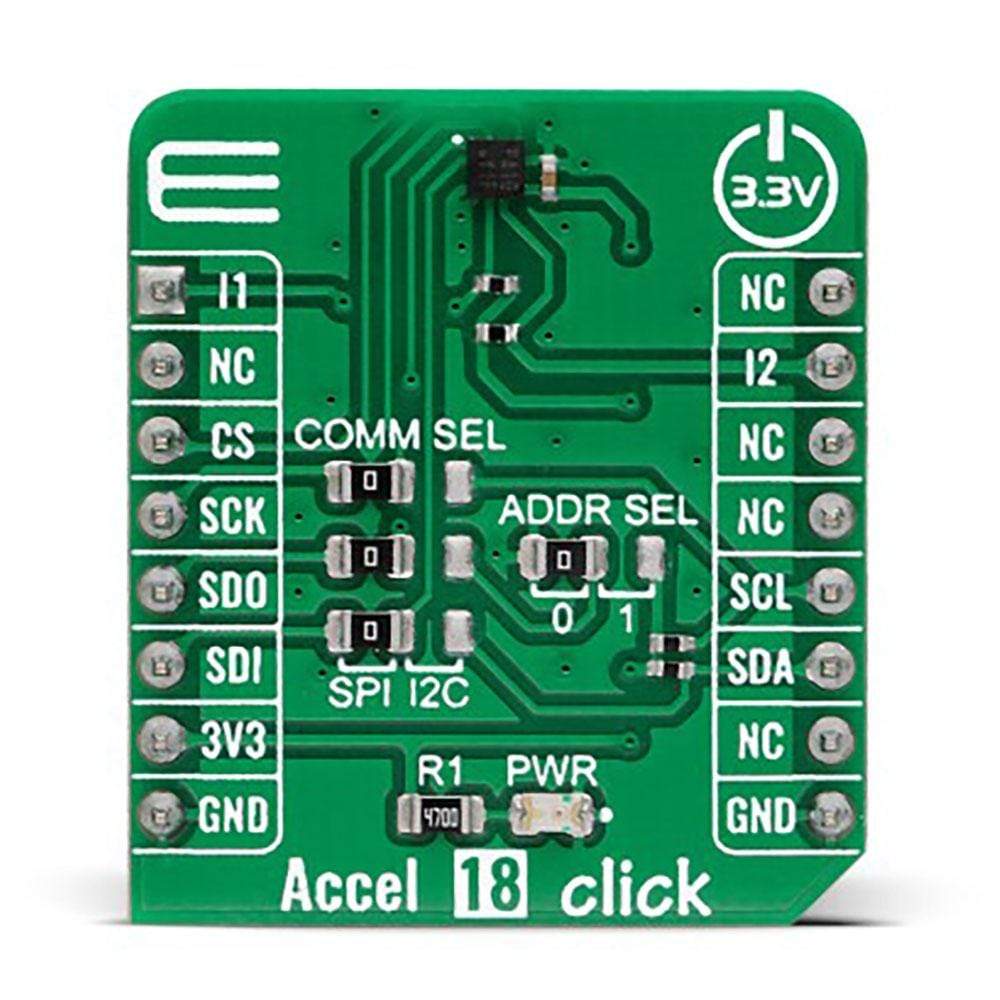

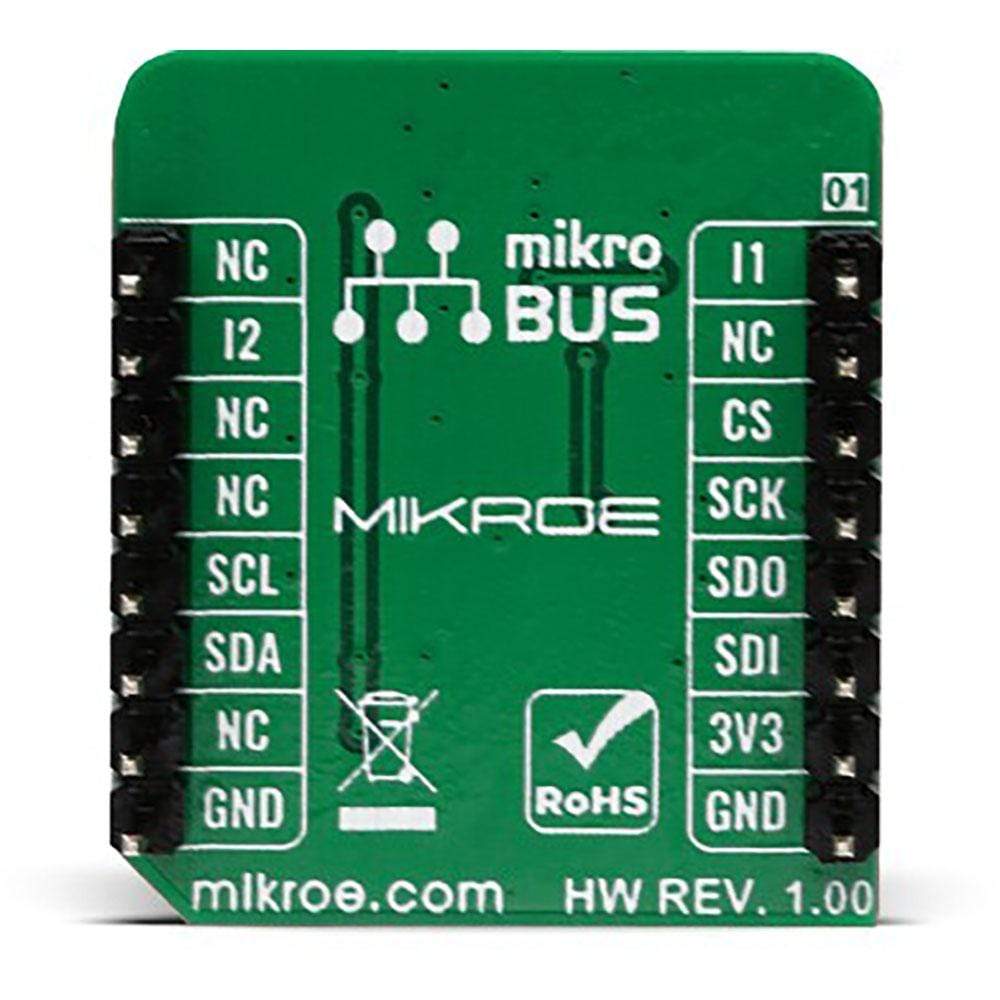

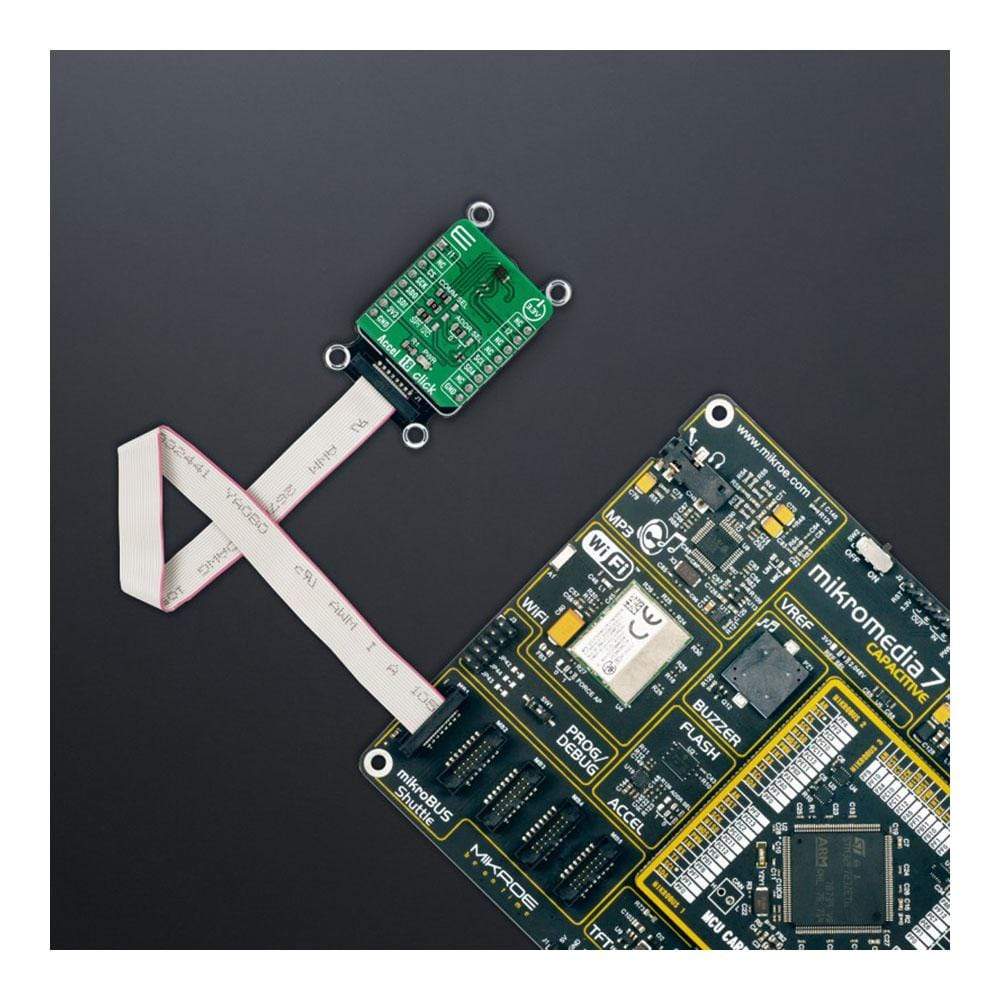

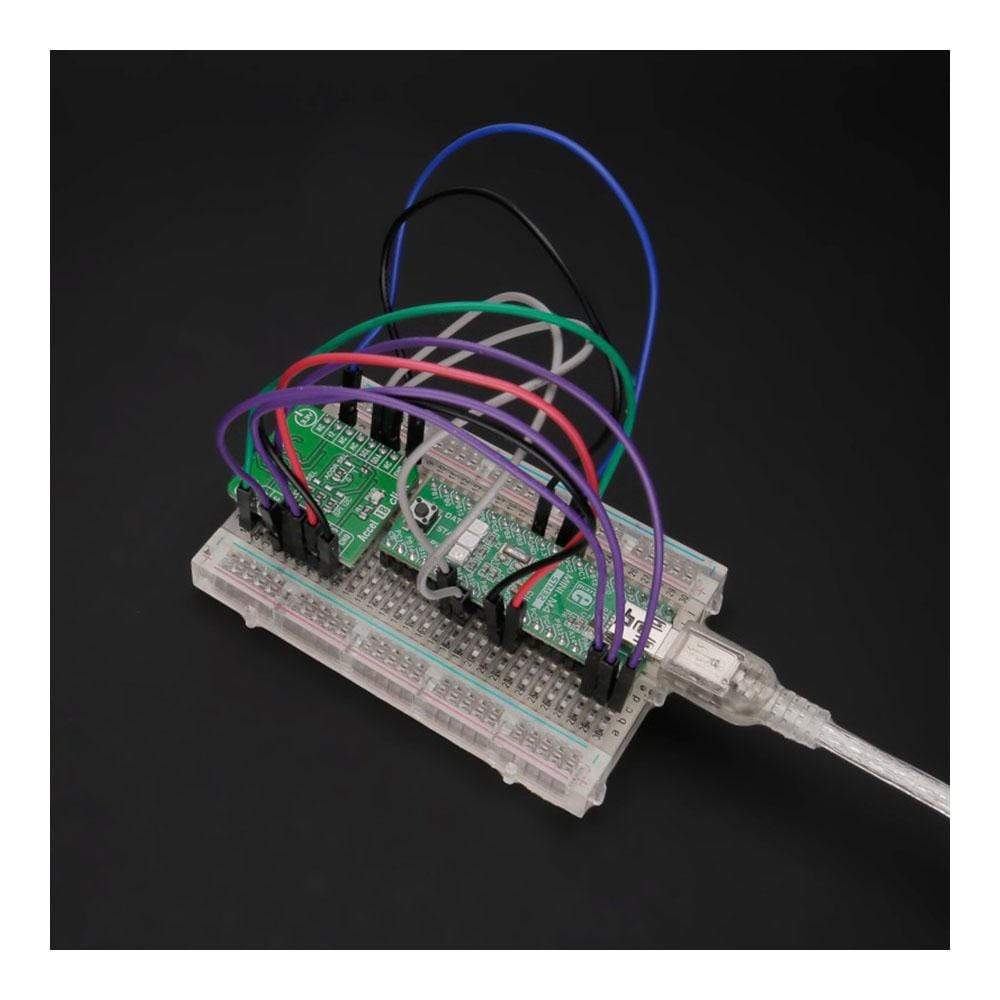

The Accel 18 Click Board™ is a compact add-on board that contains an acceleration sensor. This board features the MC3419, a digital output 3-axis accelerometer with a feature set optimized for consumer product motion sensing from MEMSIC. It allows selectable full-scale acceleration measurements in ranges of ±2g, ±4g, ±8g, and ±16g in three axes with a configurable host interface that supports both SPI and I2C serial communication. The MC3419 also features a dedicated motion block that implements algorithms to support any motion and shake detection, tilt/flip and tilt 35 position detection. This Click Board™ is suitable for various applications such as vibration and condition monitoring, test and measurements, predictive maintenance, and more.

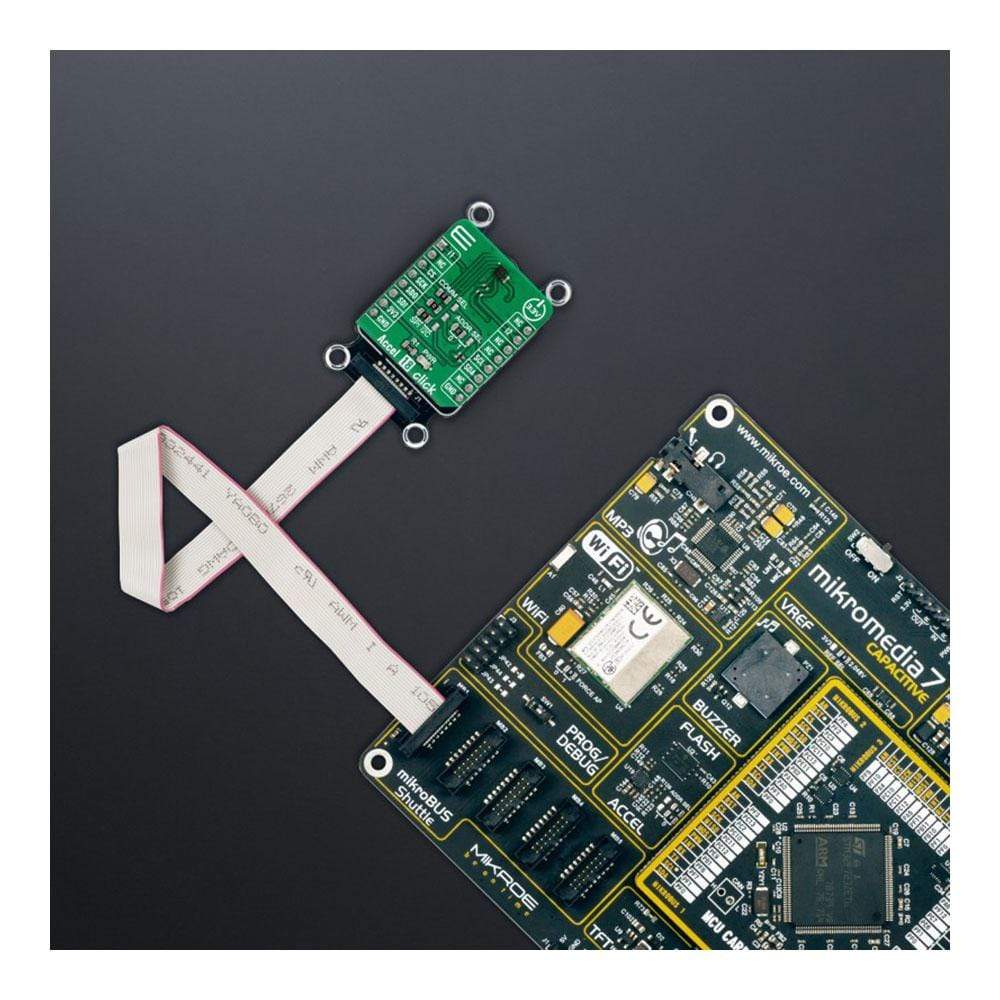

The Accel 18 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Der Accel 18 Click Board™ ist eine kompakte Zusatzplatine, die einen Beschleunigungssensor enthält. Diese Platine verfügt über den MC3419, einen 3-Achsen-Beschleunigungsmesser mit digitalem Ausgang und einem für die Bewegungserkennung von Verbraucherprodukten optimierten Funktionssatz von MEMSIC. Es ermöglicht wählbare Beschleunigungsmessungen im vollen Maßstab in den Bereichen ±2 g, ±4 g, ±8 g und ±16 g in drei Achsen mit einer konfigurierbaren Hostschnittstelle, die sowohl SPI- als auch I2C-Seriellkommunikation unterstützt. Der MC3419 verfügt außerdem über einen dedizierten Bewegungsblock, der Algorithmen zur Unterstützung von Bewegungs- und Schüttelerkennung, Neigungs-/Umdrehungs- und Neigungspositionserkennung implementiert. Dieses Click Board™ eignet sich für verschiedene Anwendungen wie Vibrations- und Zustandsüberwachung, Tests und Messungen, vorausschauende Wartung und mehr.

Das Accel 18 Click Board™ wird durch eine mikroSDK-kompatible Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4826

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027383816

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.