Overview

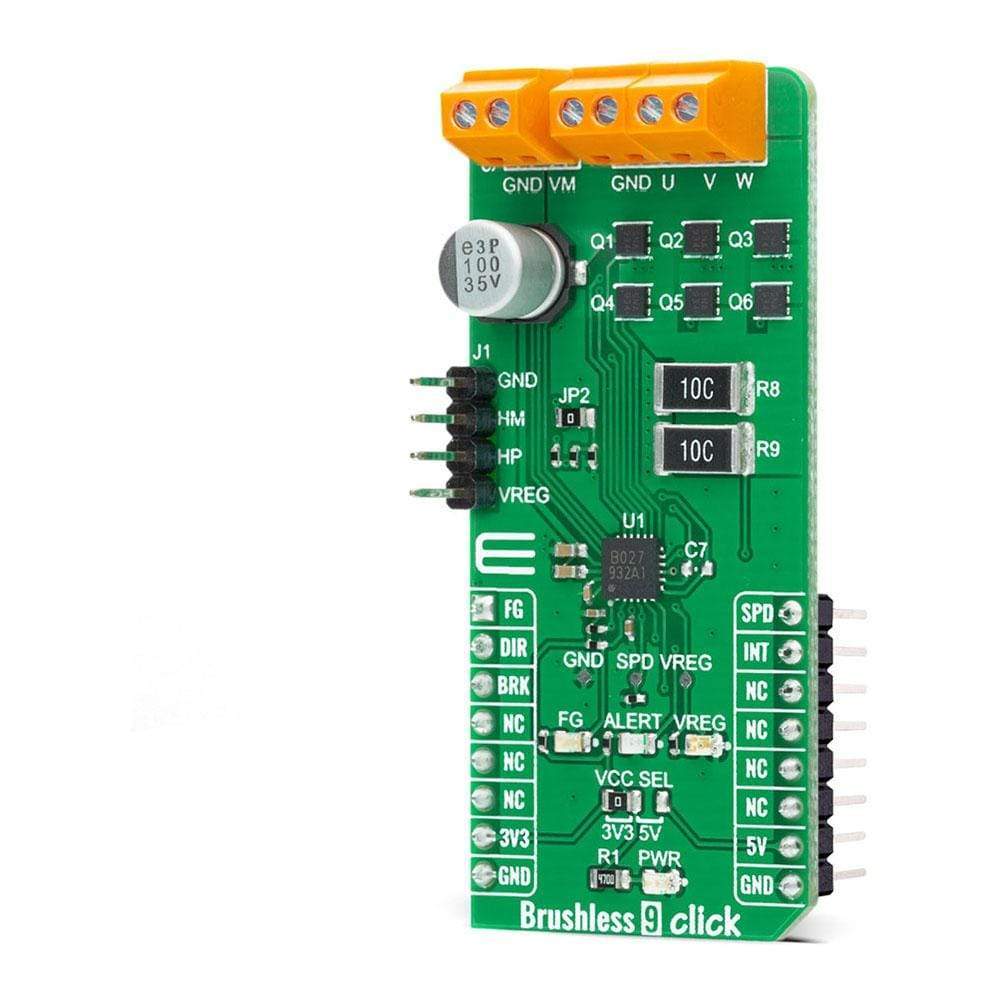

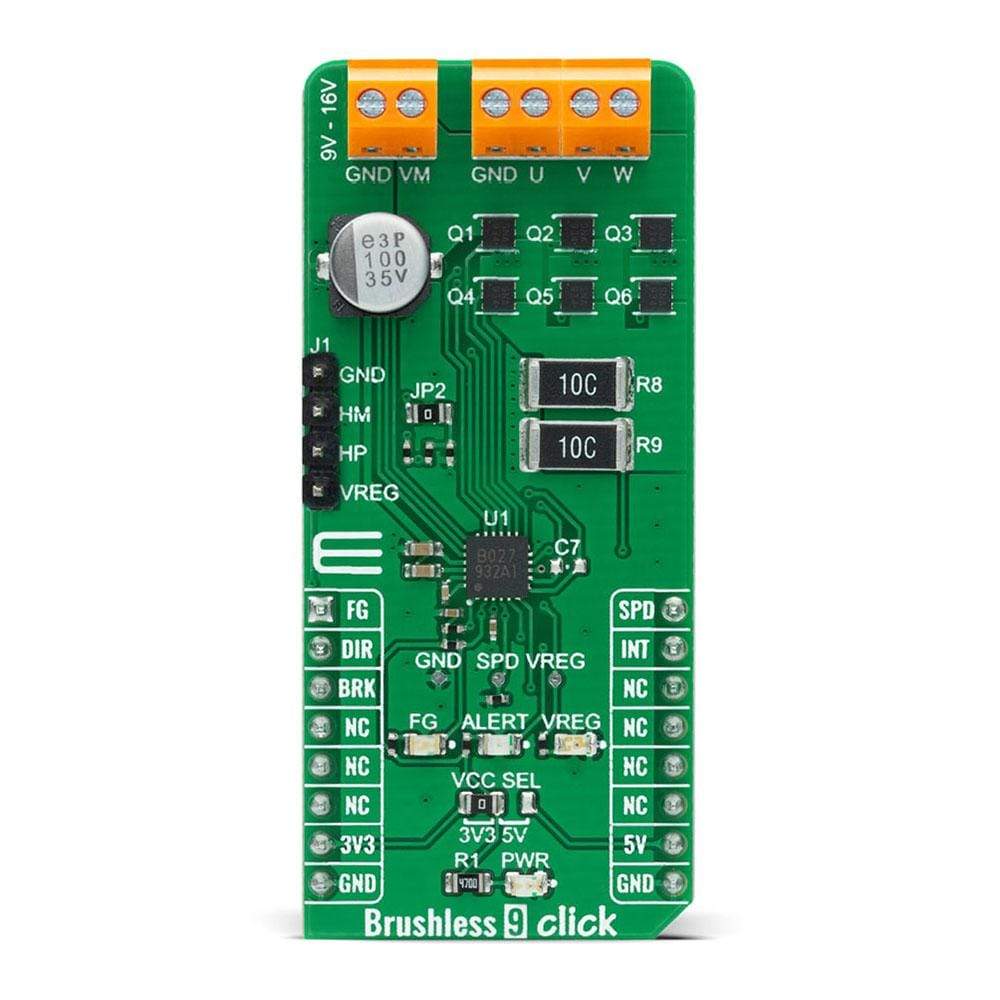

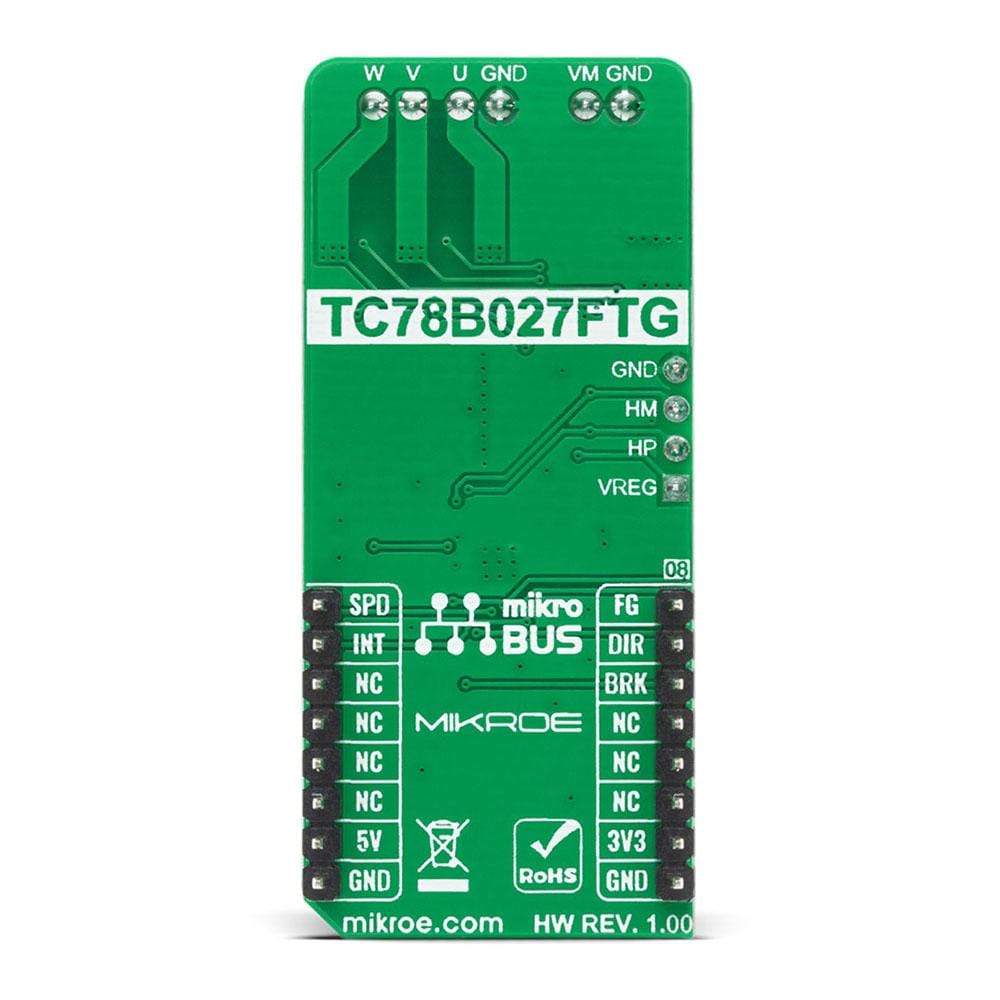

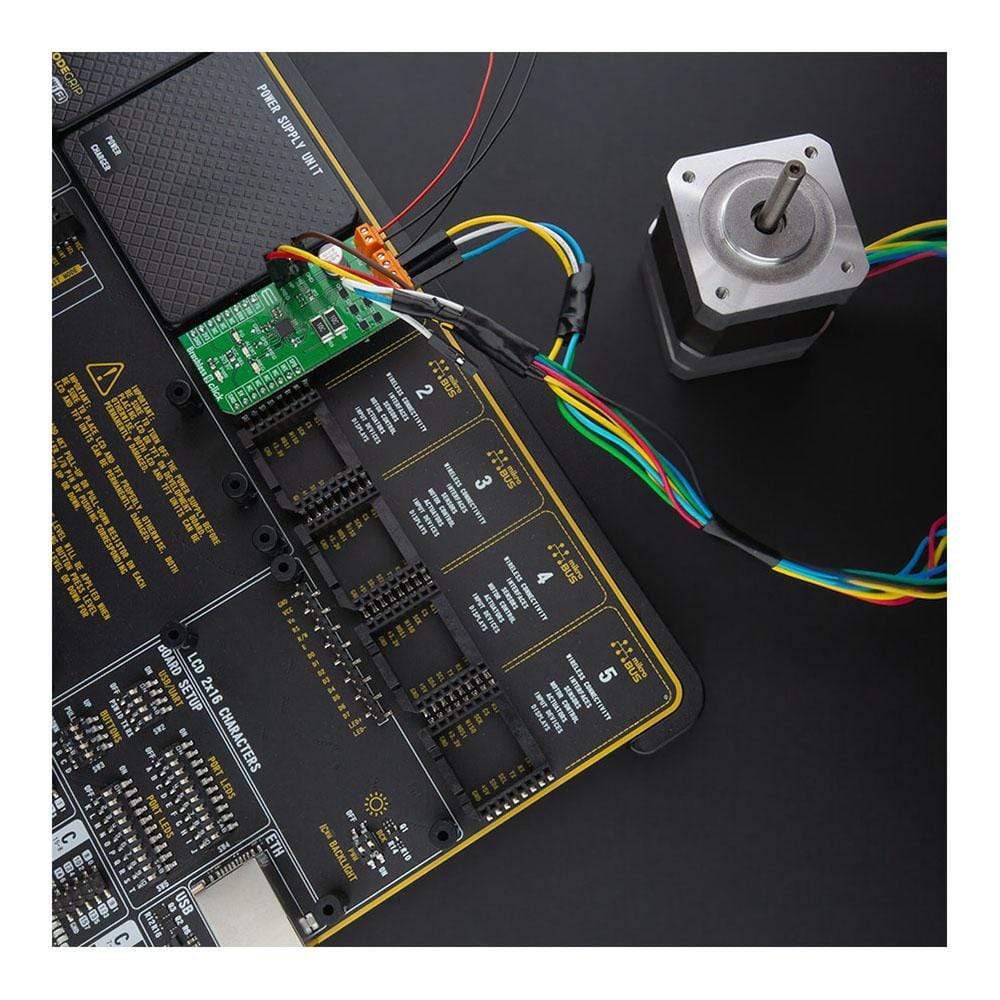

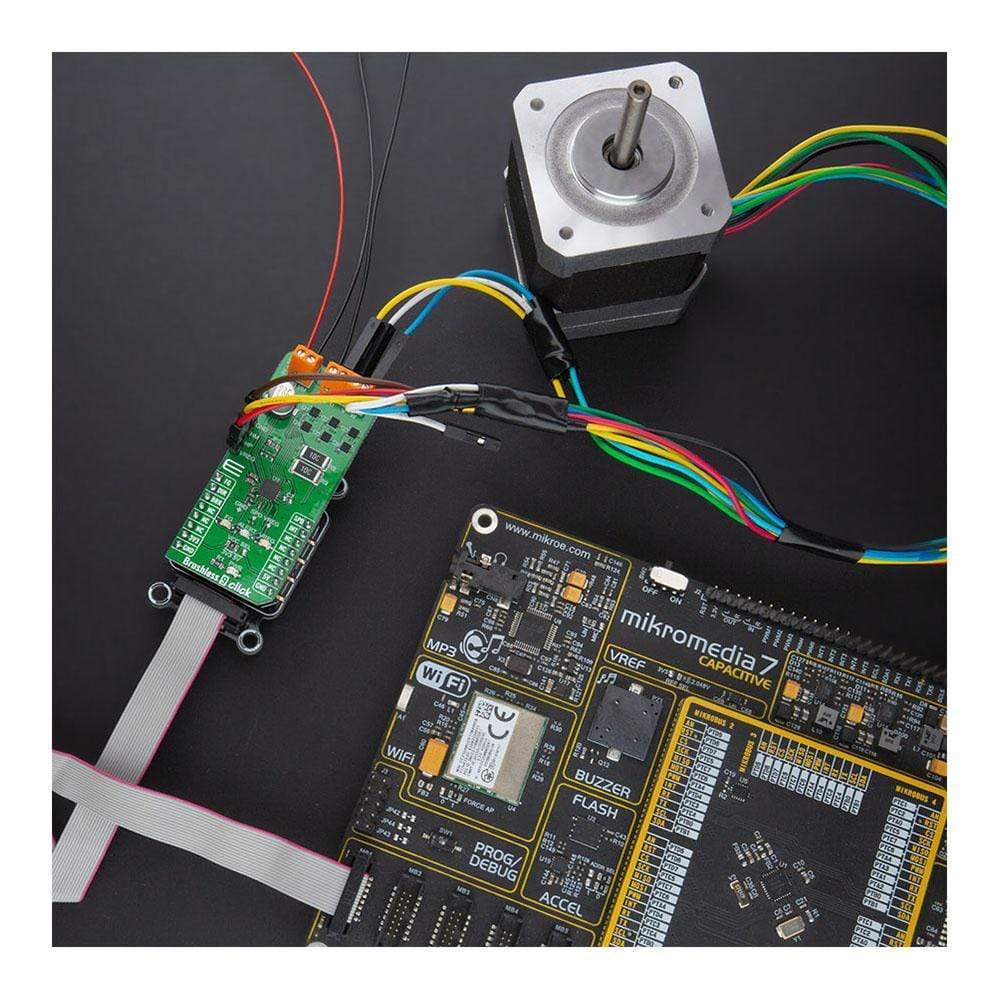

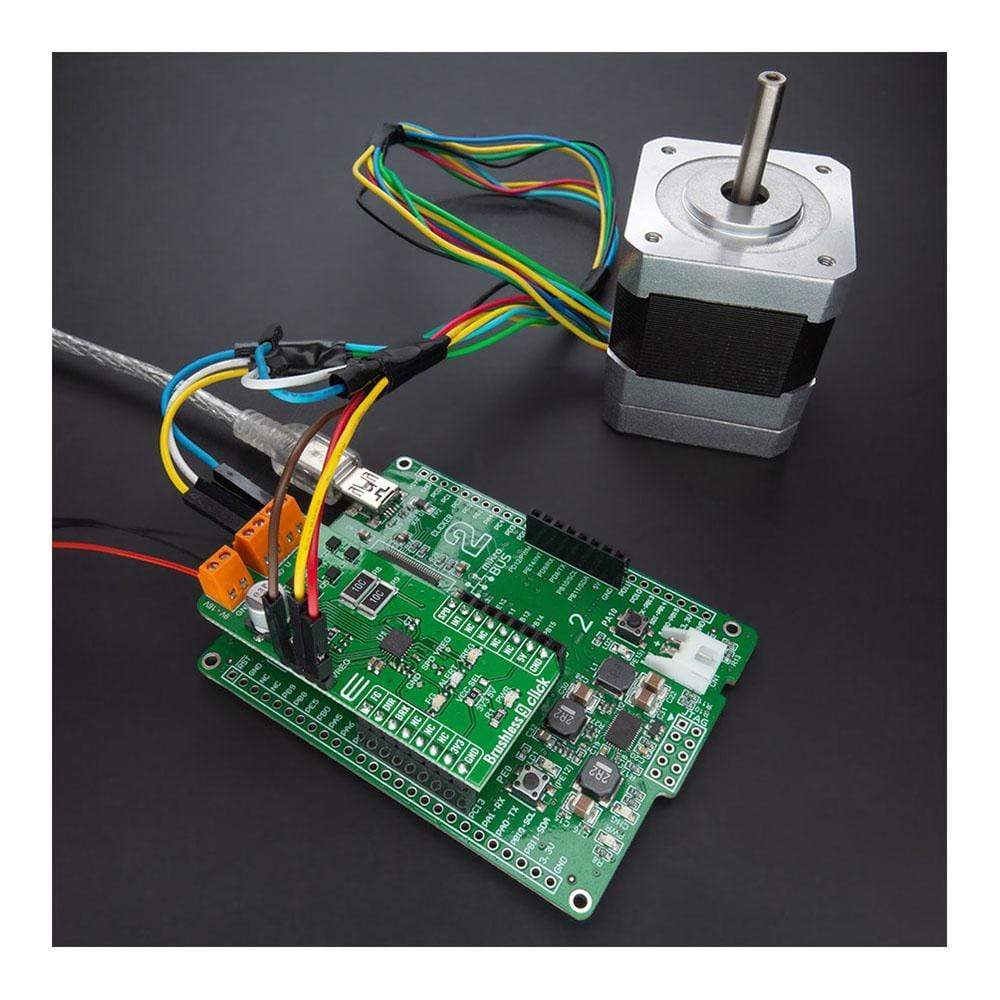

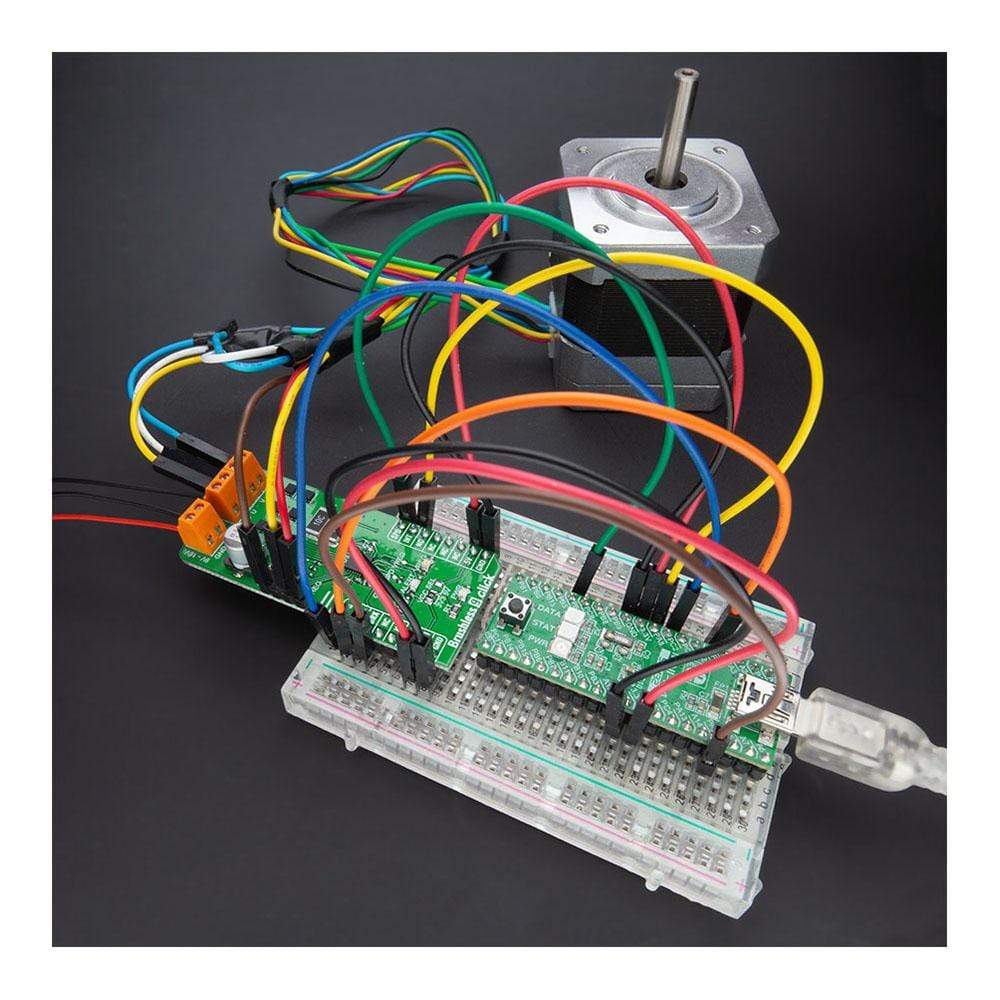

The Brushless 9 Click Board™ is a compact add-on board that controls BLDC motors with any MCU. This board features the TC78B027FTG, a 1-Hall sine-wave PWM controller for three-phase brushless DC motors from Toshiba Semiconductor. It simplifies the motor selection by using only one Hall sensor input that can be used with either a single Hall sensor motor or the more conventional 3 Hall sensor motors. Besides, it offers energy-saving and quiet motor operation, incorporating non-volatile memory and a closed-loop speed control function. This Click Board™ provides optimum operating efficiency in applications such as high-velocity server fans, blowers, and pumps.

The Brushless 9 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Das Brushless 9 Click Board™ ist eine kompakte Zusatzplatine, die BLDC-Motoren mit jedem MCU steuert. Diese Platine verfügt über den TC78B027FTG, einen 1-Hall-Sinus-PWM-Controller für dreiphasige bürstenlose Gleichstrommotoren von Toshiba Semiconductor. Es vereinfacht die Motorauswahl durch die Verwendung von nur einem Hall-Sensor-Eingang, der entweder mit einem einzelnen Hall-Sensor-Motor oder den konventionelleren 3 Hall-Sensor-Motoren verwendet werden kann. Darüber hinaus bietet es einen energiesparenden und leisen Motorbetrieb, der einen nichtflüchtigen Speicher und eine Drehzahlregelungsfunktion mit geschlossenem Regelkreis umfasst. Dieses Click Board™ bietet optimale Betriebseffizienz in Anwendungen wie Hochgeschwindigkeits-Serverlüftern, Gebläsen und Pumpen.

Das Brushless 9 Click Board™ wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4387

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.022 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027381478

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.