Overview

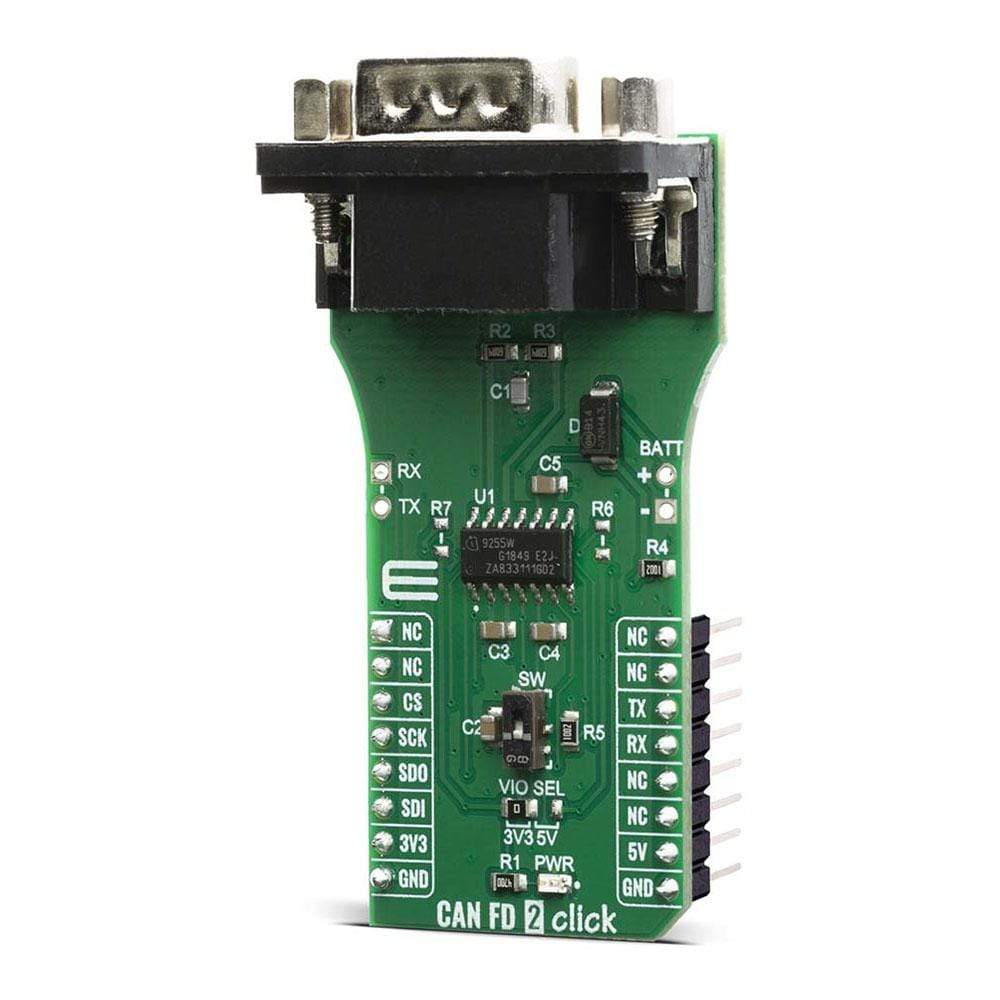

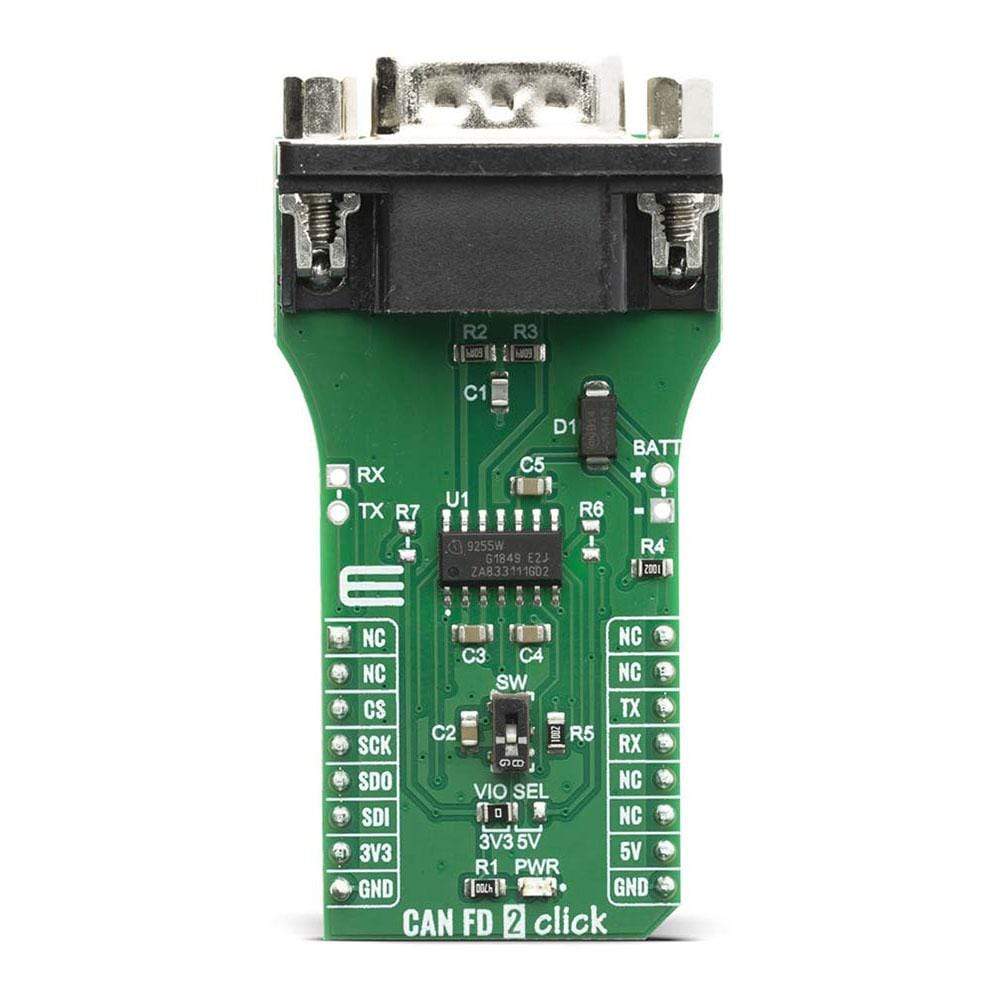

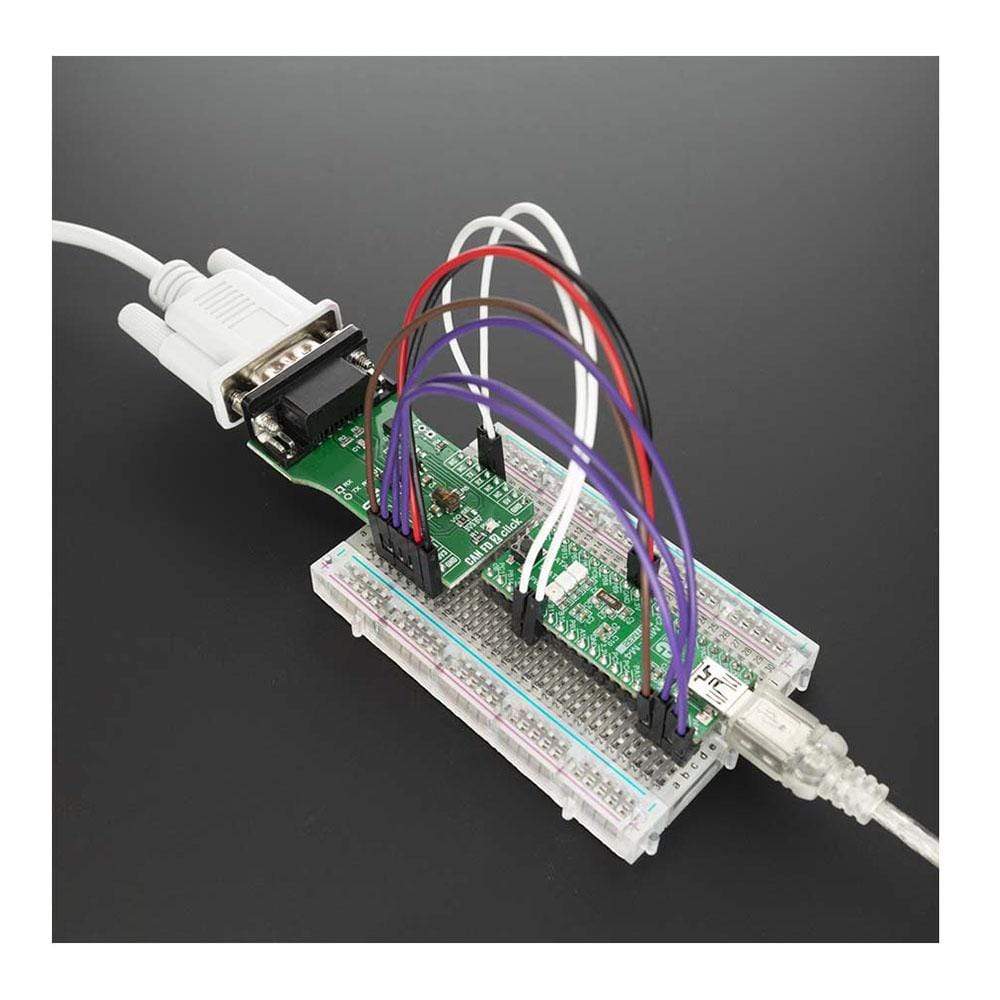

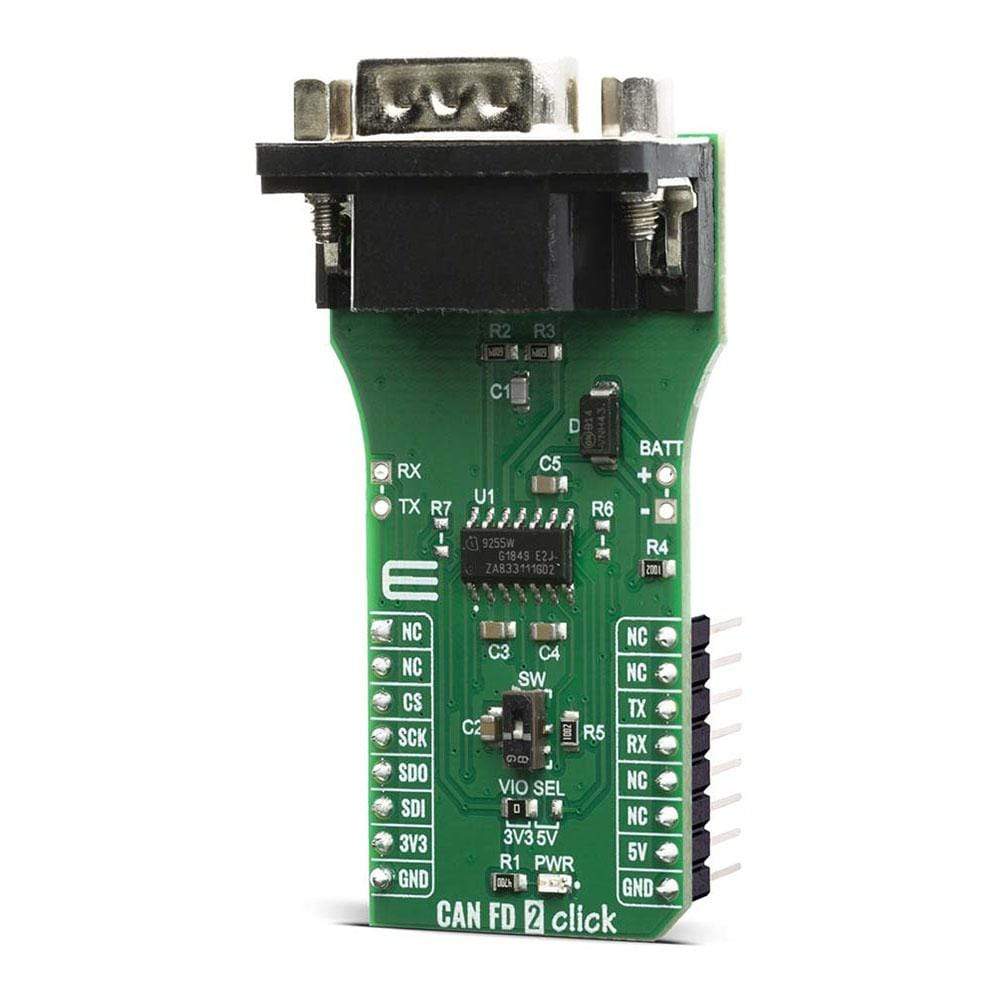

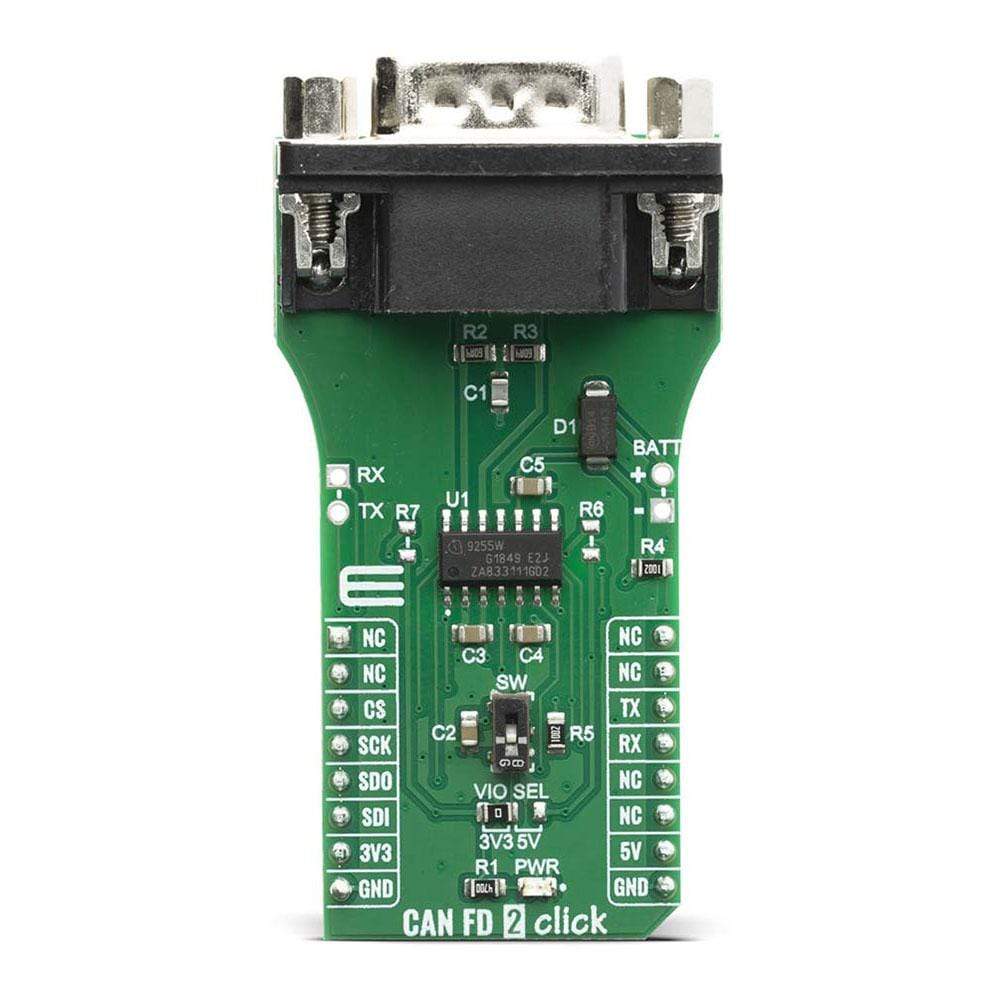

The CAN FD 2 Click Board™ is an HS CAN transceiver add on board, suitable for the evaluation of the TLE9255W CAN network transceiver from Infineon. The transceiver itself drives the signals to the CAN bus and protects the microcontroller from interference generated within the CAN network. Based on the high symmetry of the CANH and CANL signals, the TLE9255W provides a very low level of electromagnetic emission within a wide frequency range, allowing the operation of the TLE9255W without a common mode choke in automotive and industrial applications.

Downloads

Das CAN FD 2 Click Board™ ist eine HS CAN-Transceiver-Zusatzplatine, die für die Evaluierung des TLE9255W CAN-Netzwerk-Transceivers von Infineon geeignet ist. Der Transceiver selbst leitet die Signale an den CAN-Bus weiter und schützt den Mikrocontroller vor Störungen, die im CAN-Netzwerk entstehen. Basierend auf der hohen Symmetrie der CANH- und CANL-Signale bietet das TLE9255W eine sehr geringe elektromagnetische Emission innerhalb eines weiten Frequenzbereichs, was den Betrieb des TLE9255W ohne Gleichtaktdrossel in Automobil- und Industrieanwendungen ermöglicht.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4062

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018717194

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.