Overview

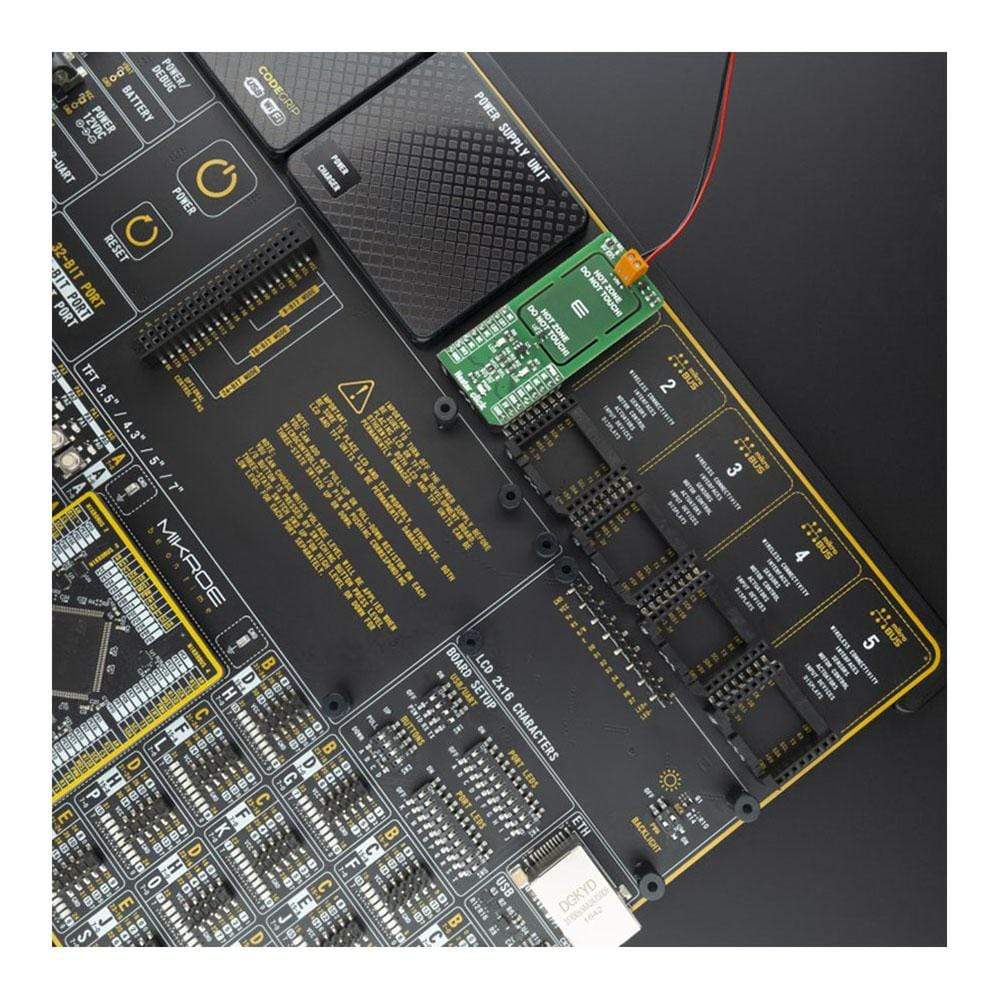

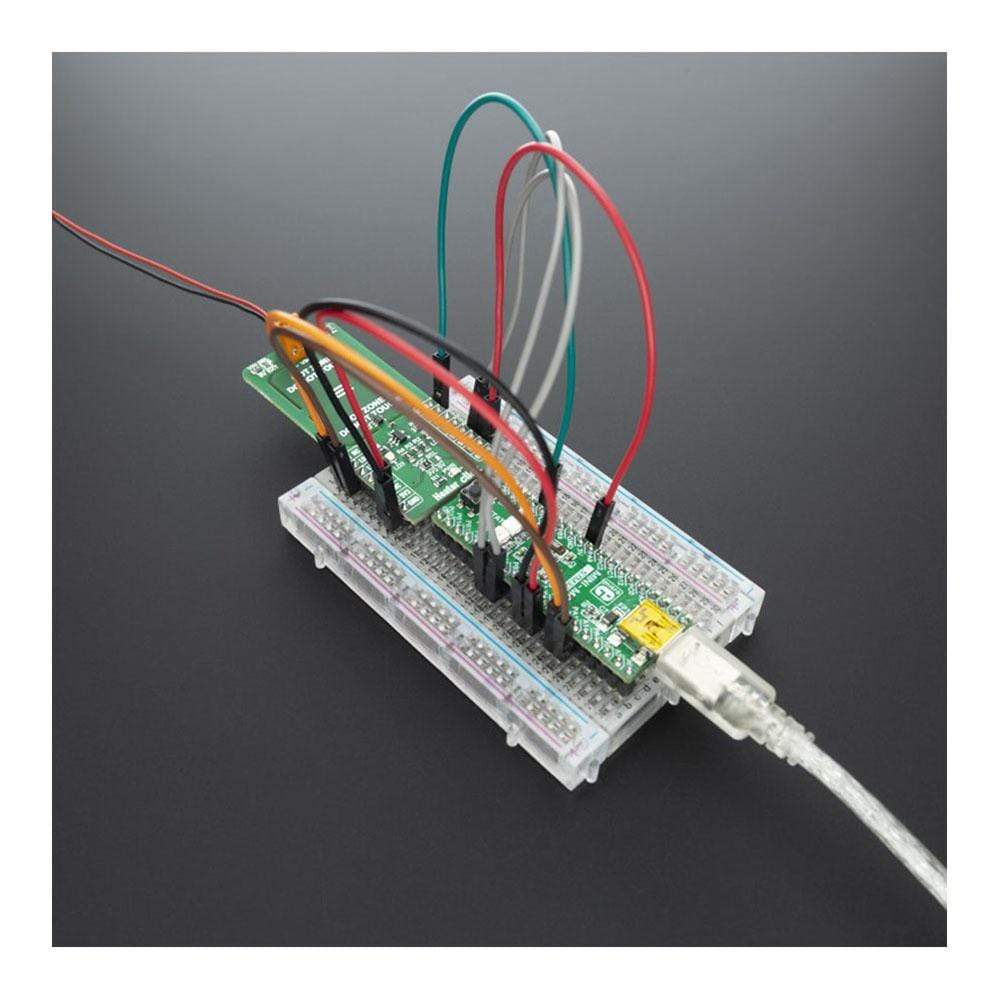

The Heater Click Board™ is designed with intention of PCB heater concept testing and a useful tool for heating complete casing where staying in a specified temperature range is crucial. The exact PCB temperature can be set and controlled using a TMP235 onboard temperature sensor from Texas Instruments. Heater Click is a useful tool for some projects and products that require some kind of heating, whether to prevent electronics from becoming too cold, to help control humidity, to heat up a substance, or even to prevent one material from sticking to another.

The Heater Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

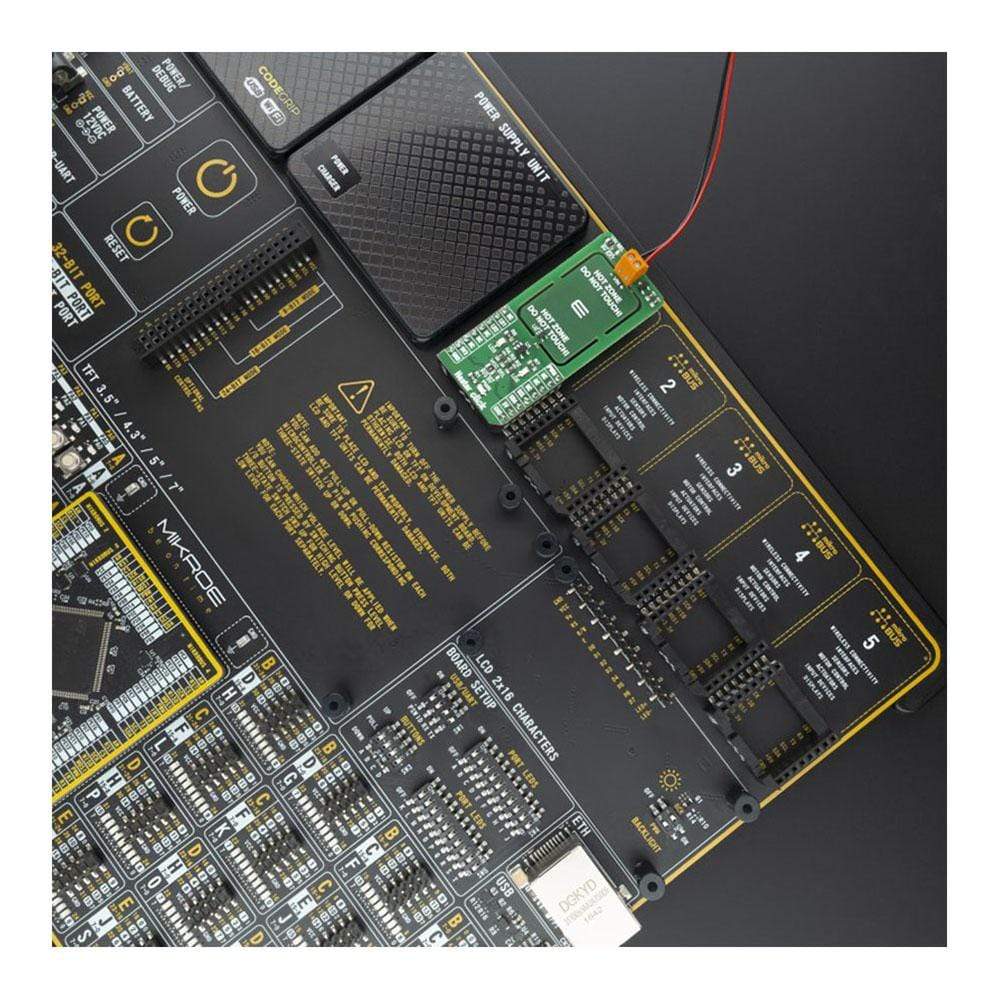

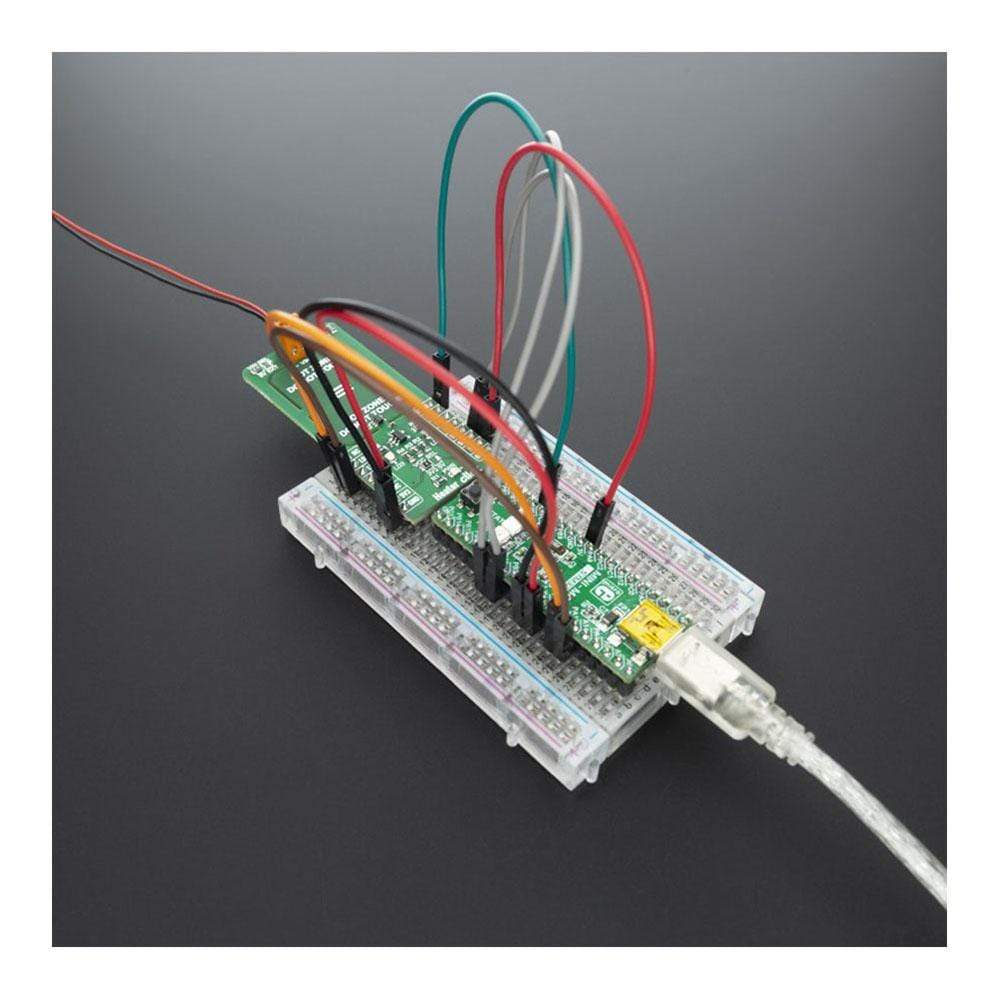

Das Heater Click Board™ wurde zum Testen von PCB-Heizkonzepten entwickelt und ist ein nützliches Werkzeug zum Heizen kompletter Gehäuse, bei denen es entscheidend ist, in einem bestimmten Temperaturbereich zu bleiben. Die genaue PCB-Temperatur kann mit einem integrierten Temperatursensor TMP235 von Texas Instruments eingestellt und gesteuert werden. Heater Click ist ein nützliches Werkzeug für einige Projekte und Produkte, die eine Art von Heizung benötigen, sei es, um zu verhindern, dass Elektronik zu kalt wird, um die Luftfeuchtigkeit zu kontrollieren, um eine Substanz zu erhitzen oder sogar um zu verhindern, dass ein Material an einem anderen klebt.

Das Heater Click Board™ wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3996

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.019 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018718399

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.