Overview

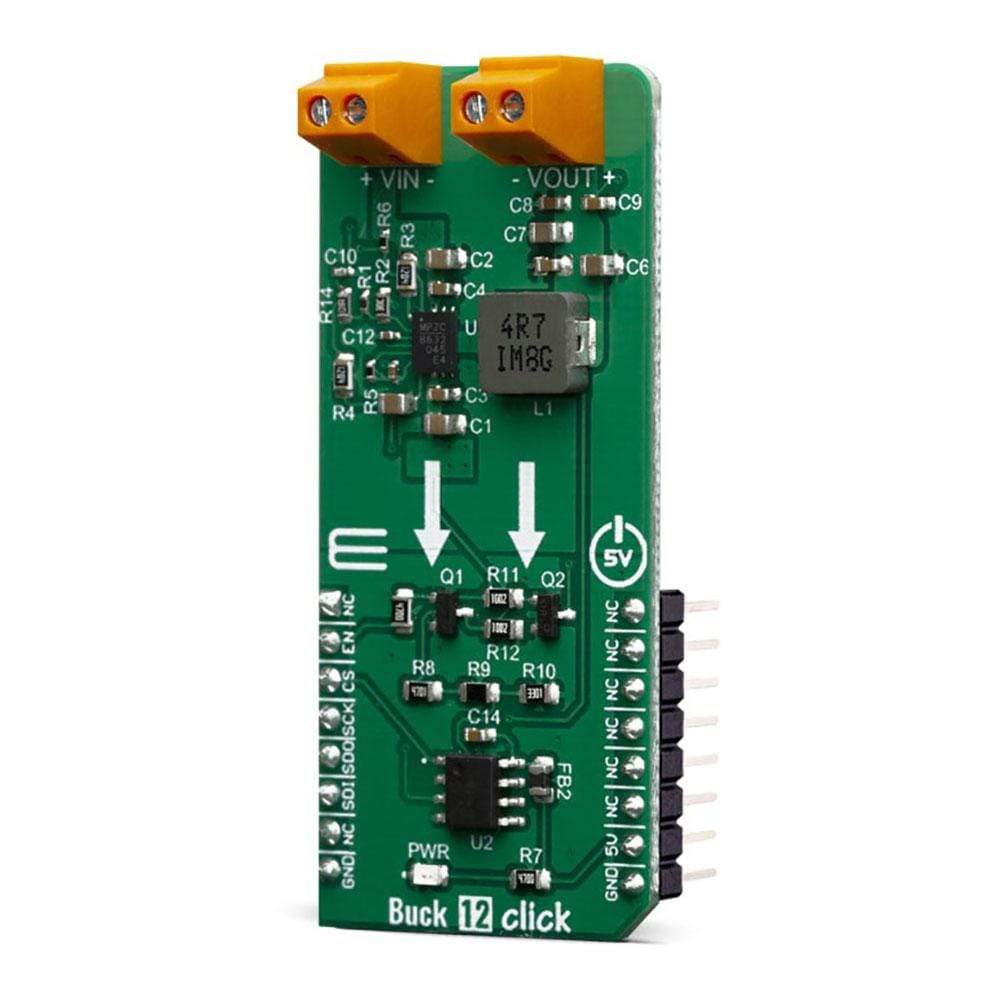

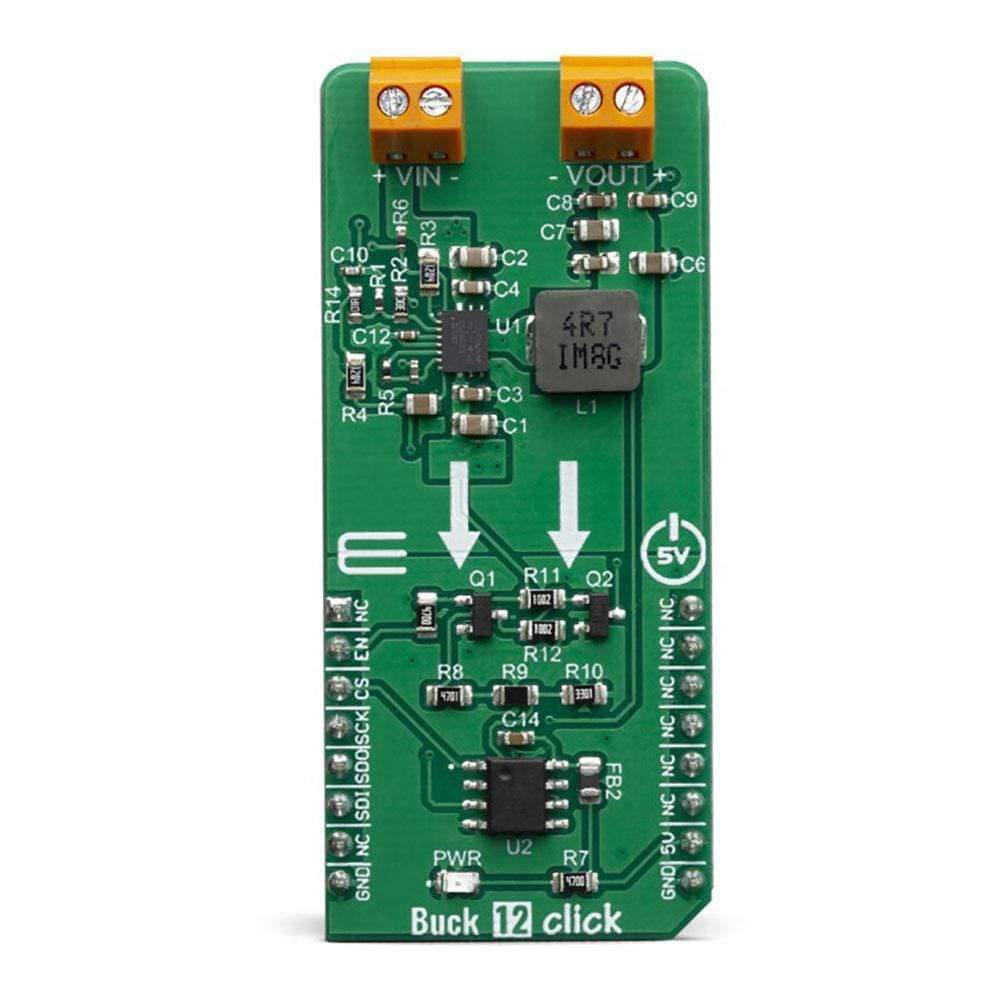

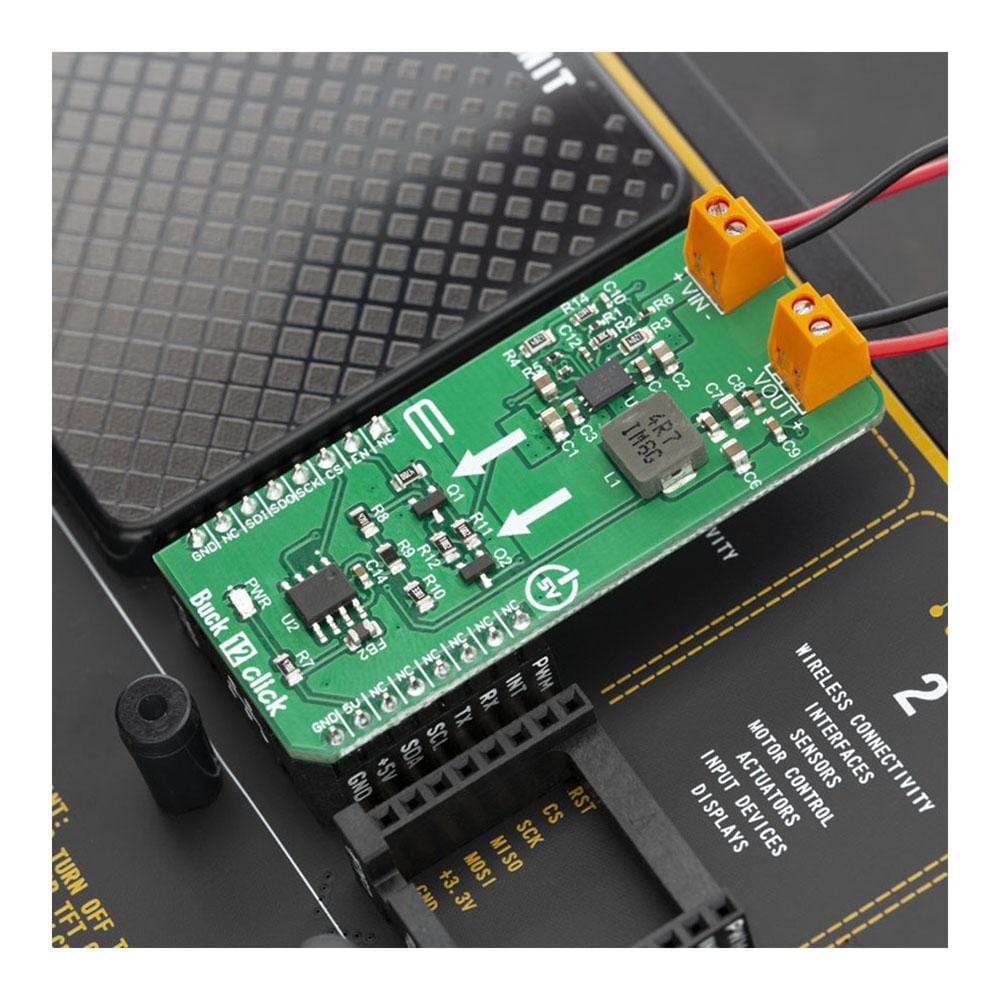

The Buck 12 Click Board™ is a high-efficiency step-down converter that provides 3.3V on its output, derived from the connected power supply voltage, in the range from 4.2V to 18V. Buck 12 Click Board™ is based on the MPQ8632, a highly efficient DC-DC step-down converter. In addition, the Buck 12 Click Board™ offers to monitor the input and output voltage stability by employing an additional A/D converter circuit. Due to its high efficiency, MPQ8632 allows the Click Board™ to efficiently deliver up to 4A of current. It features a package that enables a low noise performance, high efficiency, and very compact size while maintaining compatibility with higher current ICs from the family.

Downloads

Das Buck 12 Click Board™ ist ein hocheffizienter Abwärtswandler, der an seinem Ausgang 3,3 V liefert, abgeleitet von der angeschlossenen Versorgungsspannung im Bereich von 4,2 V bis 18 V. Das Buck 12 Click Board™ basiert auf dem MPQ8632, einem hocheffizienten DC-DC-Abwärtswandler. Darüber hinaus bietet das Buck 12 Click Board™ die Möglichkeit, die Stabilität der Eingangs- und Ausgangsspannung durch den Einsatz einer zusätzlichen A/D-Wandlerschaltung zu überwachen. Aufgrund seines hohen Wirkungsgrads ermöglicht MPQ8632 dem Click Board™, effizient bis zu 4 A Strom zu liefern. Es verfügt über ein Gehäuse, das eine geräuscharme Leistung, einen hohen Wirkungsgrad und eine sehr kompakte Größe ermöglicht und gleichzeitig die Kompatibilität mit ICs mit höherem Strom aus der Familie beibehält.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3652

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018716395

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.