Overview

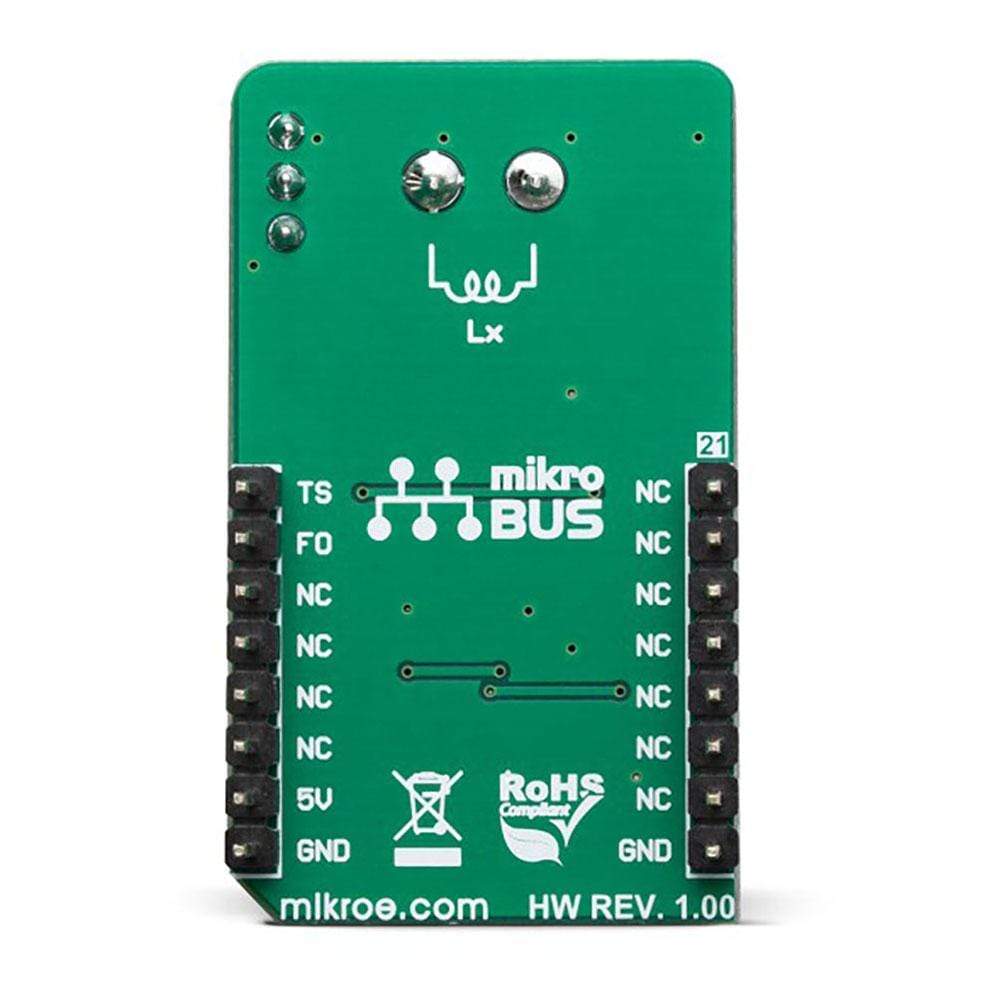

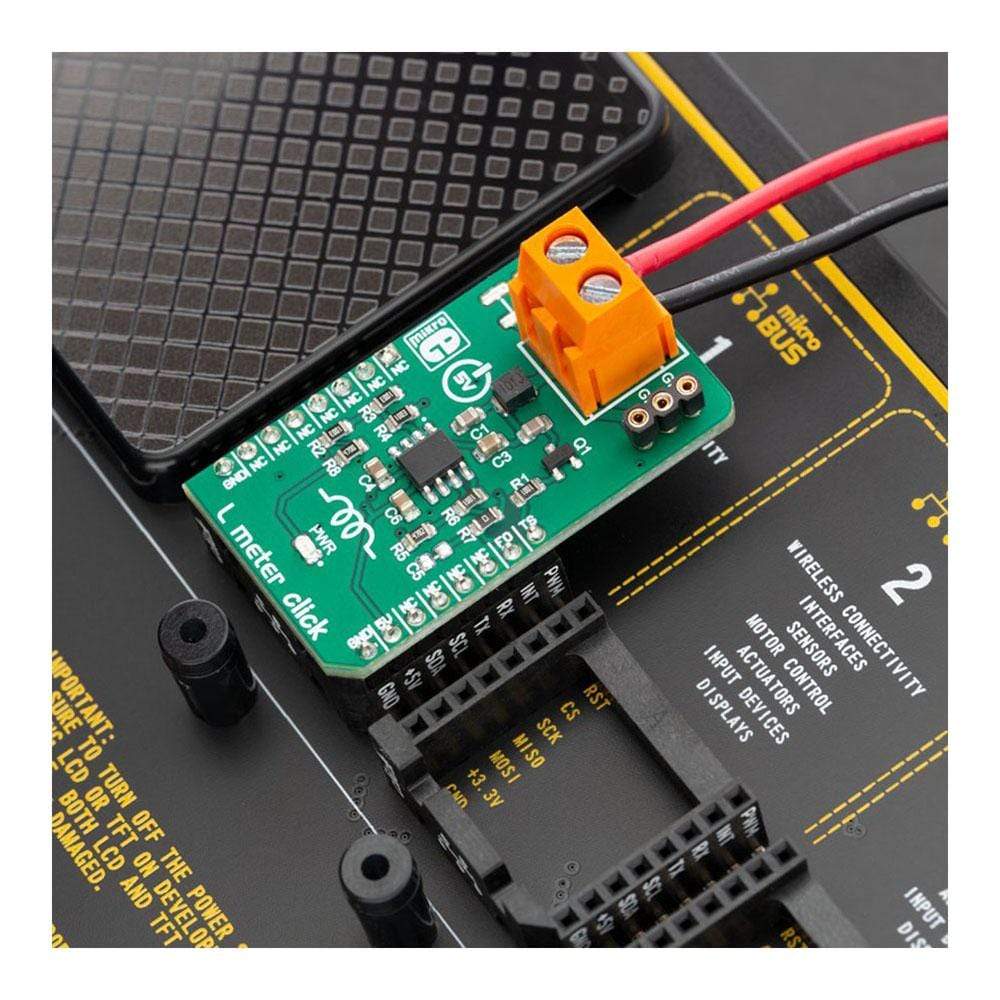

The L Meter Click Board™ is a compact and accurate Click Board™, capable of measuring and monitoring the inductance of the external component. The board can be used to measure a wide range of inductance. The design is based on a single high-speed voltage comparator LM311 by which the frequency of the oscillating LC circuit is measured and, based on the known value of capacitance, measures the unknown inductance value.

The L Meter Click Board™ can be used to measure inductance as well as to check the accuracy and precision of the coil.

Downloads

Das L Meter Click Board™ ist ein kompaktes und genaues Click Board™, das die Induktivität der externen Komponente messen und überwachen kann. Die Platine kann zum Messen eines breiten Induktivitätsbereichs verwendet werden. Das Design basiert auf einem einzelnen Hochgeschwindigkeits-Spannungskomparator LM311, mit dem die Frequenz des oszillierenden LC-Schaltkreises gemessen wird und der basierend auf dem bekannten Kapazitätswert den unbekannten Induktivitätswert misst.

Das L Meter Click Board™ kann zum Messen der Induktivität sowie zum Überprüfen der Genauigkeit und Präzision der Spule verwendet werden.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3505

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018715077

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.