Overview

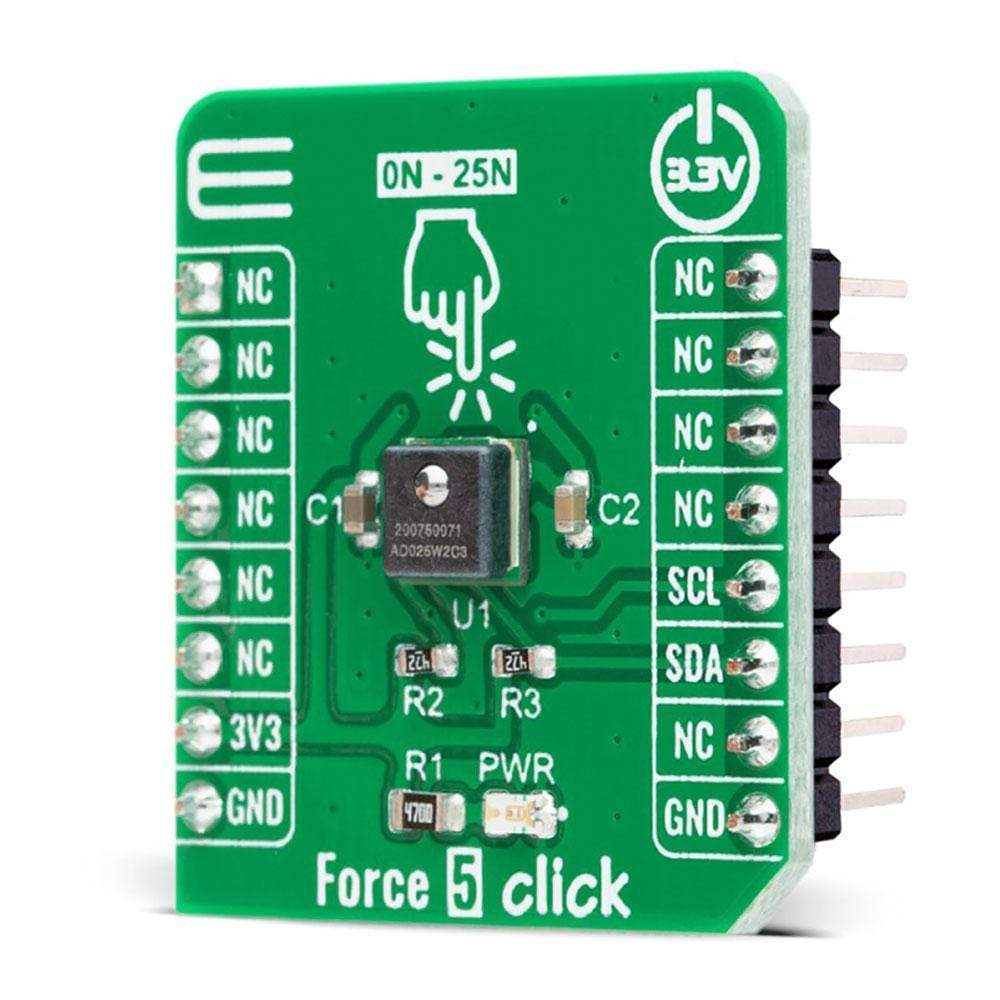

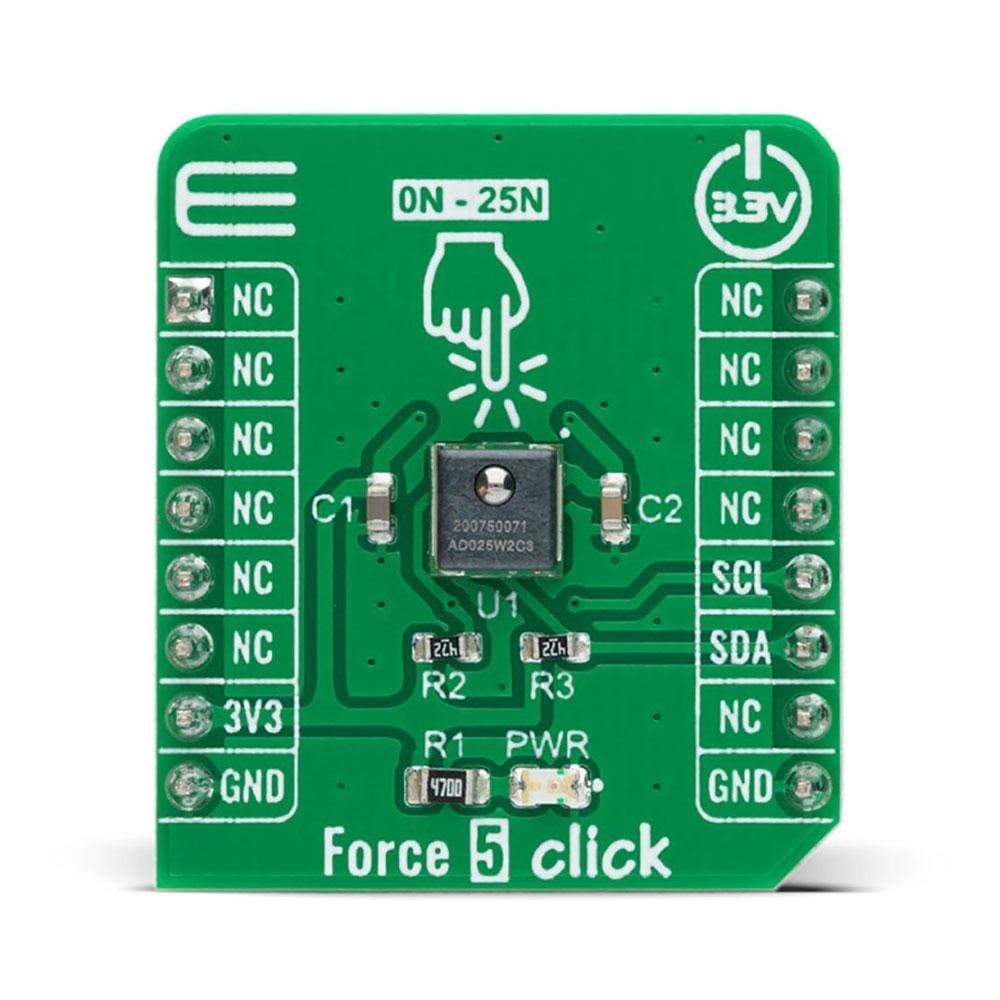

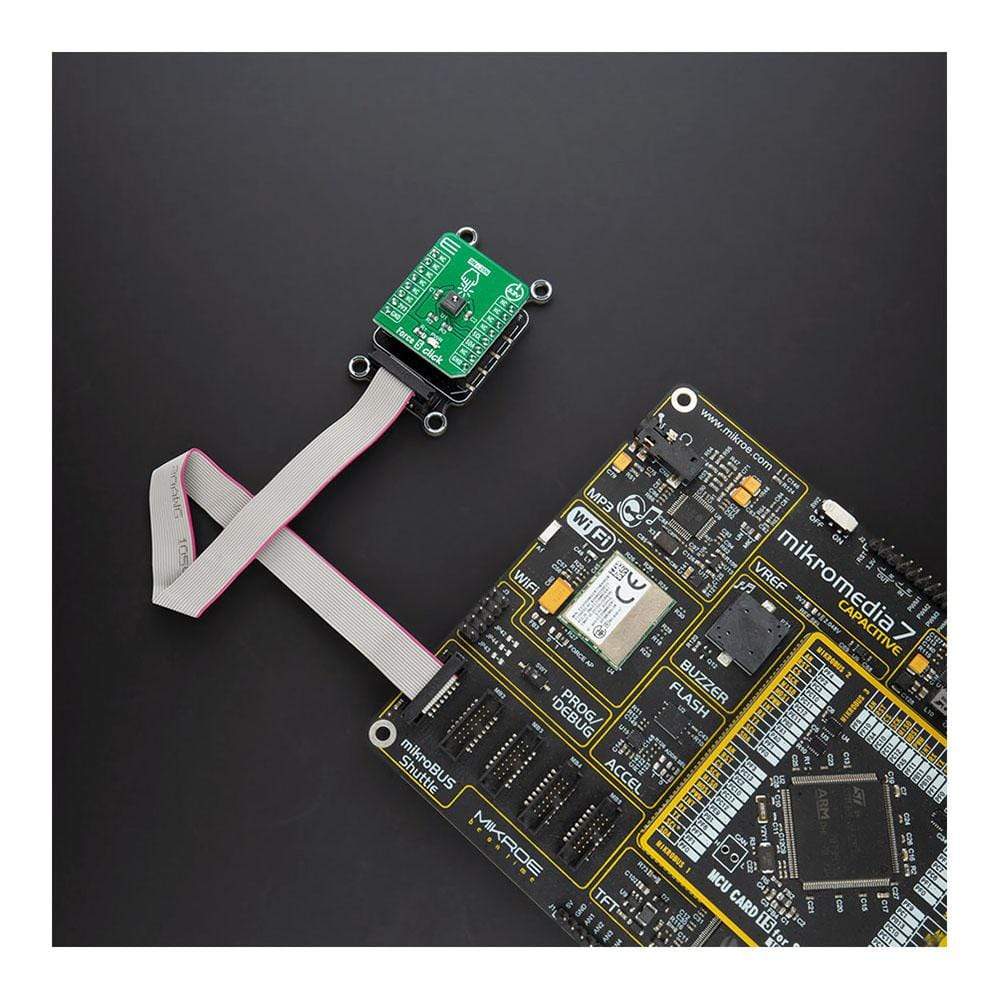

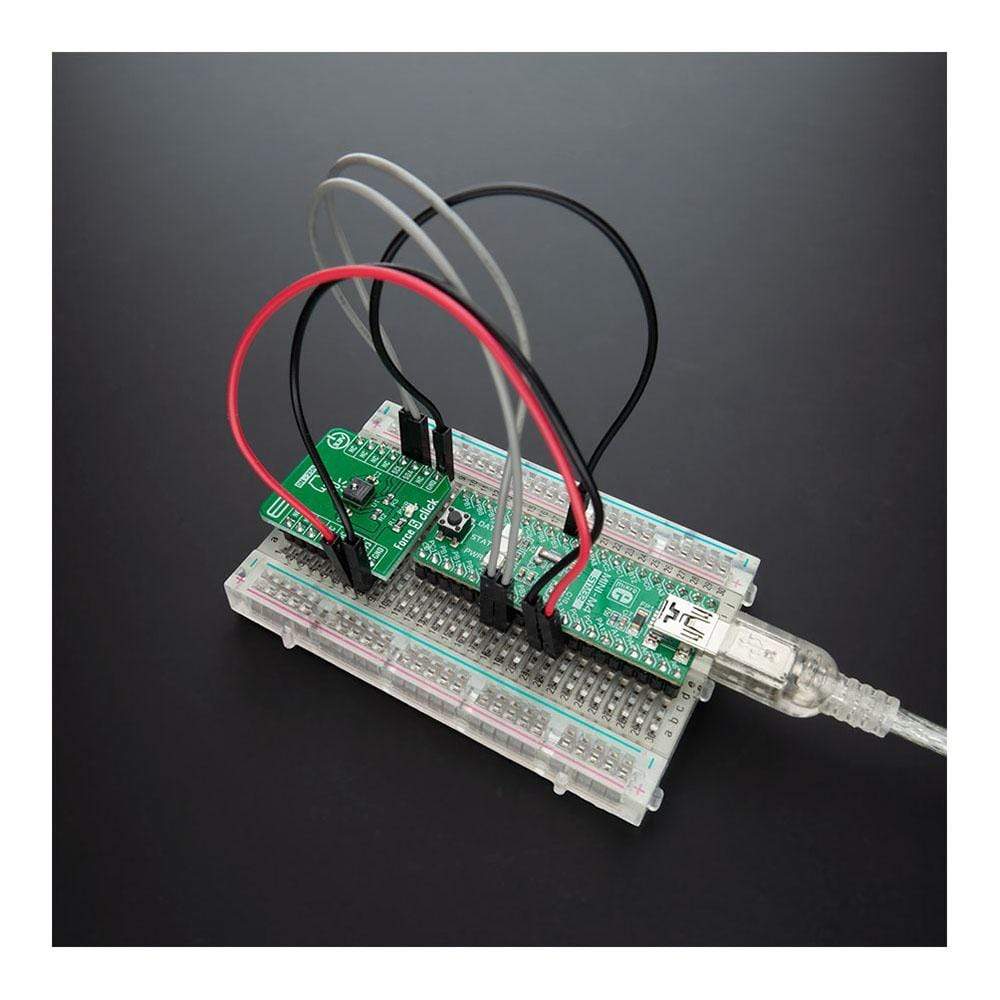

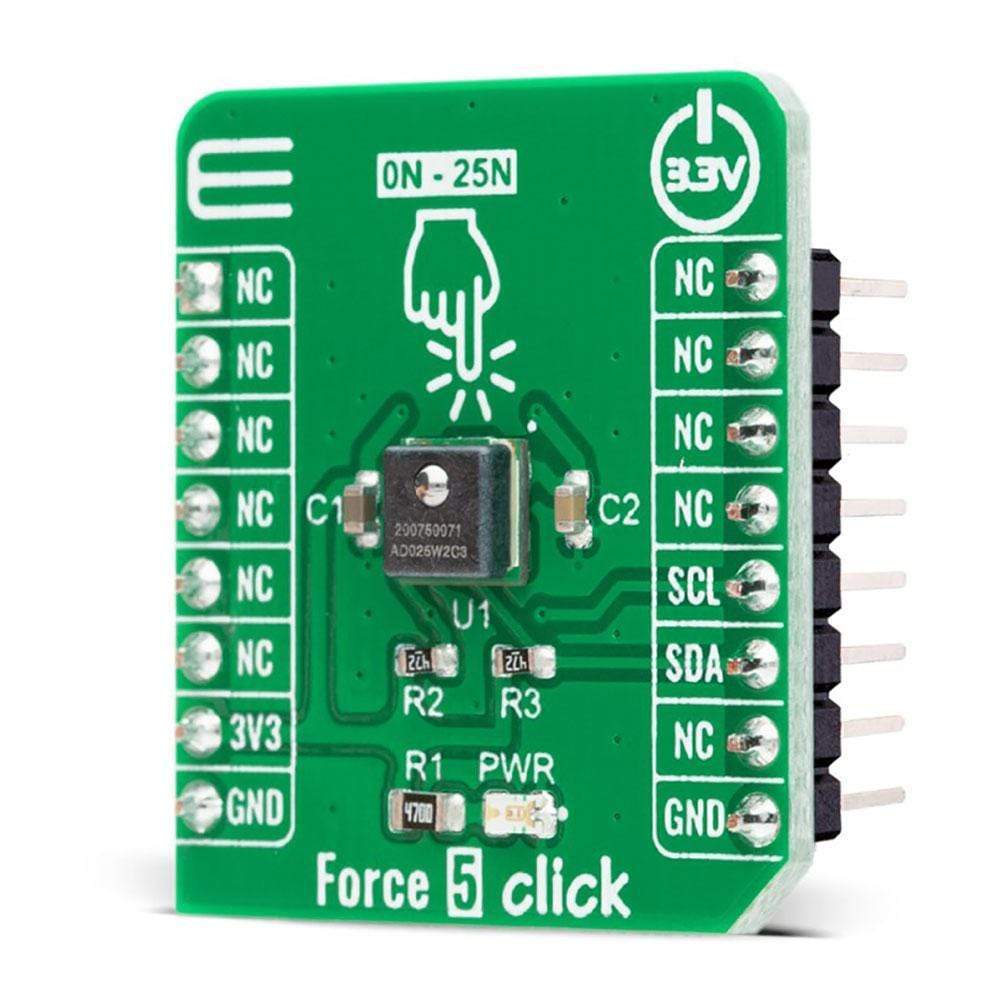

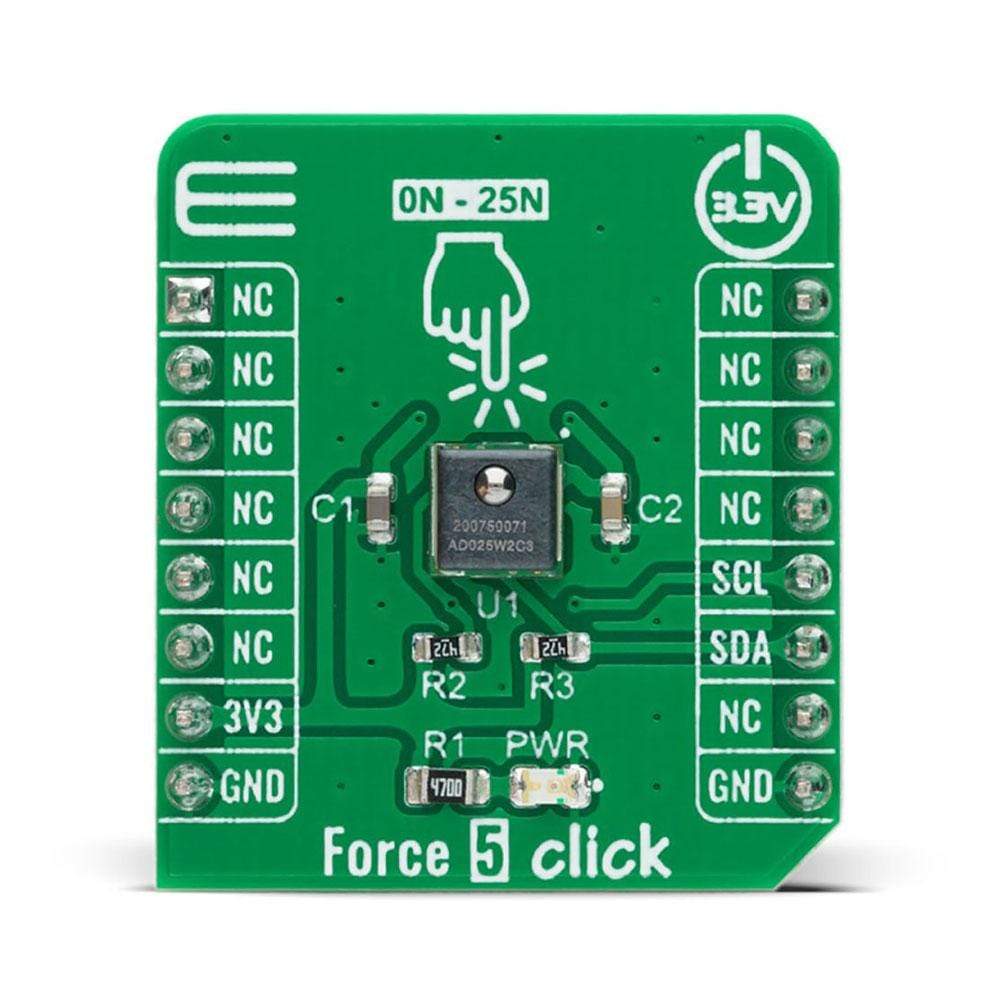

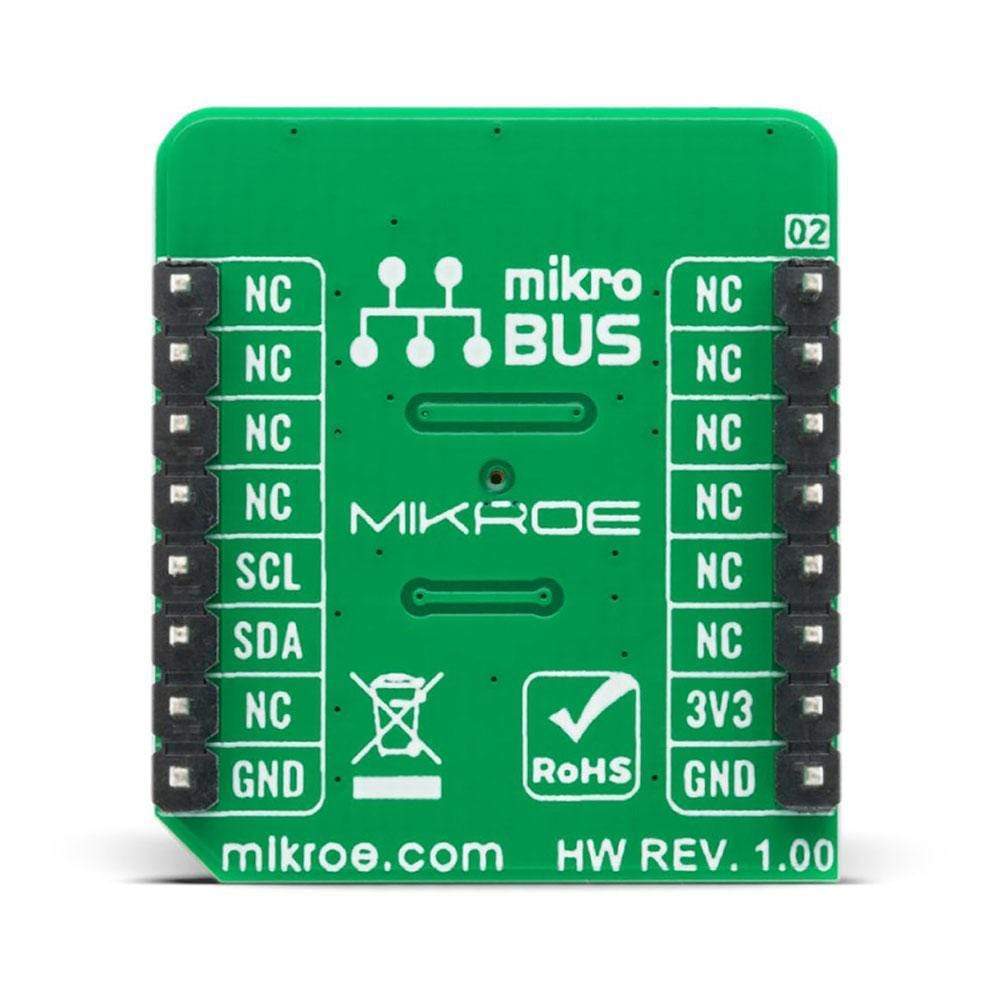

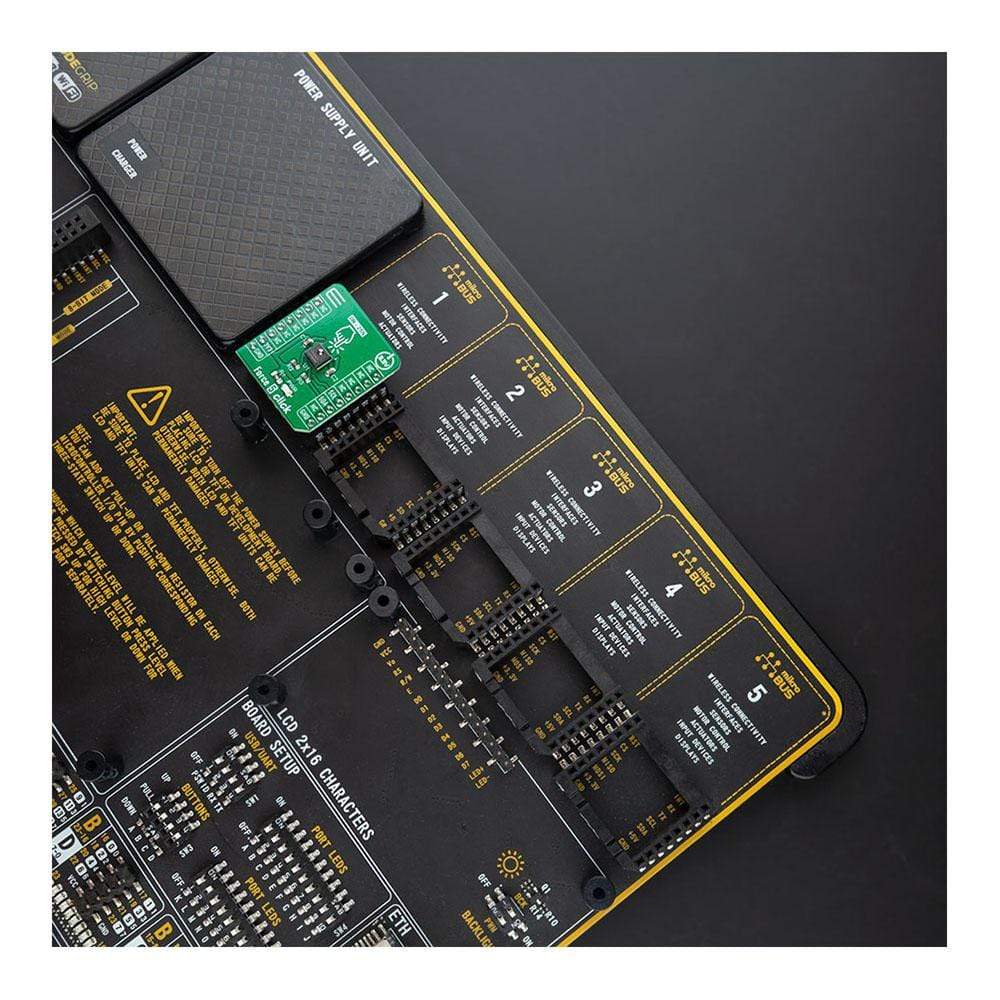

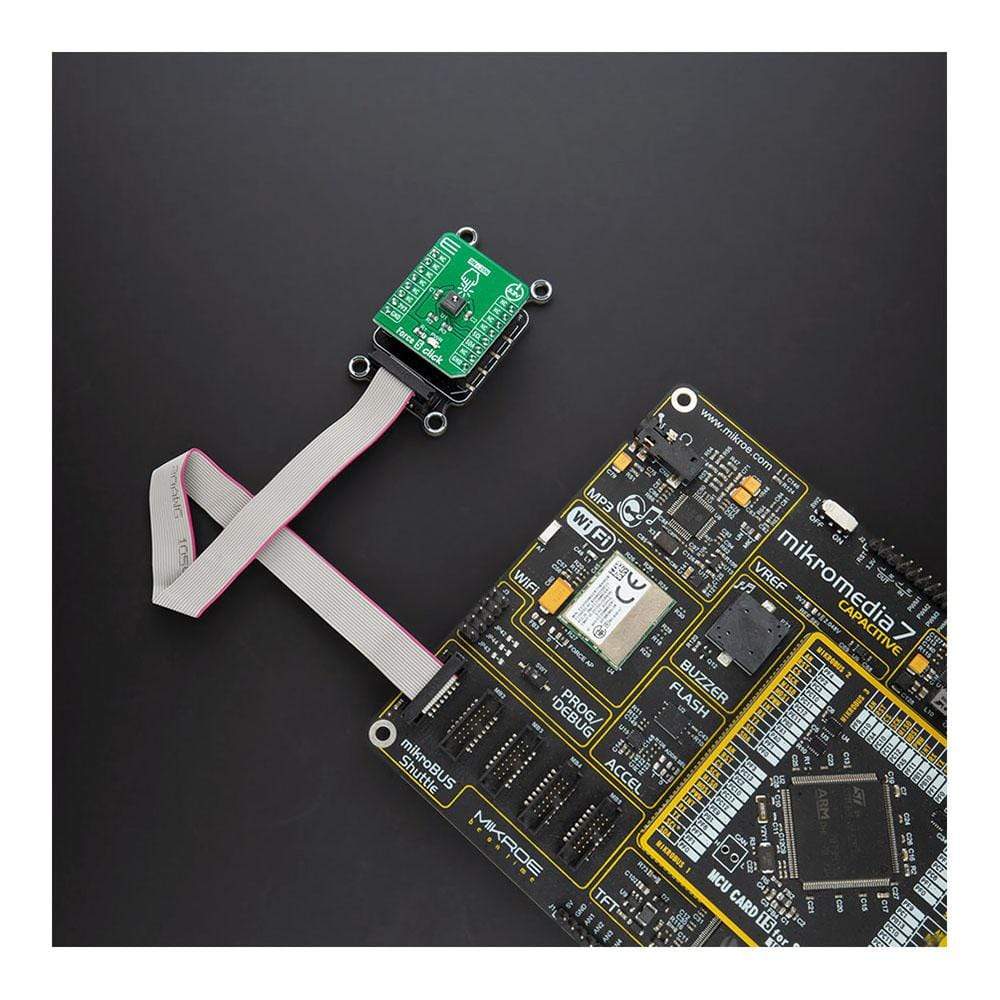

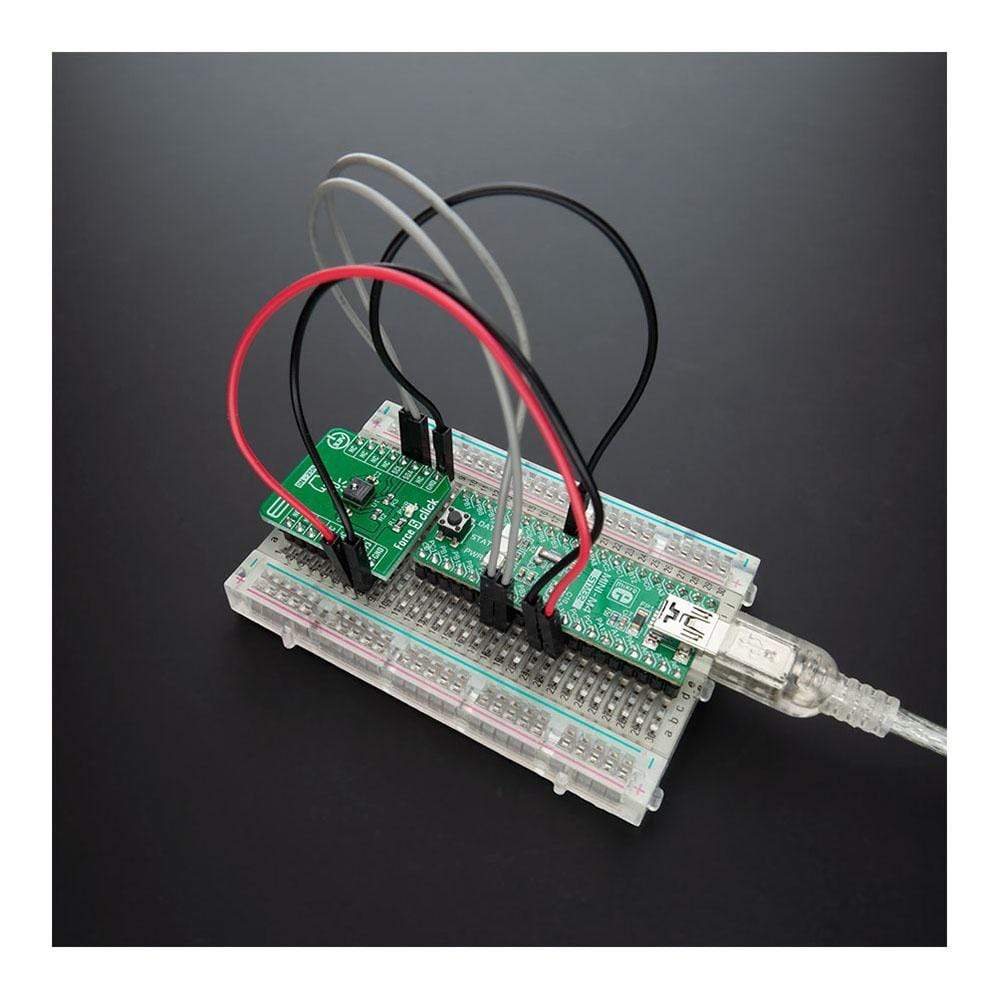

The Force 5 Click Board™ is a compact add-on board that contains a stable and flexible compensated/amplified micro force sensor. This board features the FMAMSDXX025WC2C3, a piezoresistive-based force sensor offering a digital output for reading force over the specified full-scale force span and a temperature range from Honeywell Sensing and Productivity Solutions. The very stable digital output that is directly proportional to the force applied to the mechanically coupled sphere, enhanced accuracy, and reduced total error band that enhances system performance are just some of the good features that this sensor has. This Click Board™ is suitable for industrial applications such as force/grip measuring equipment, load and compression sensing, robotics, and more.

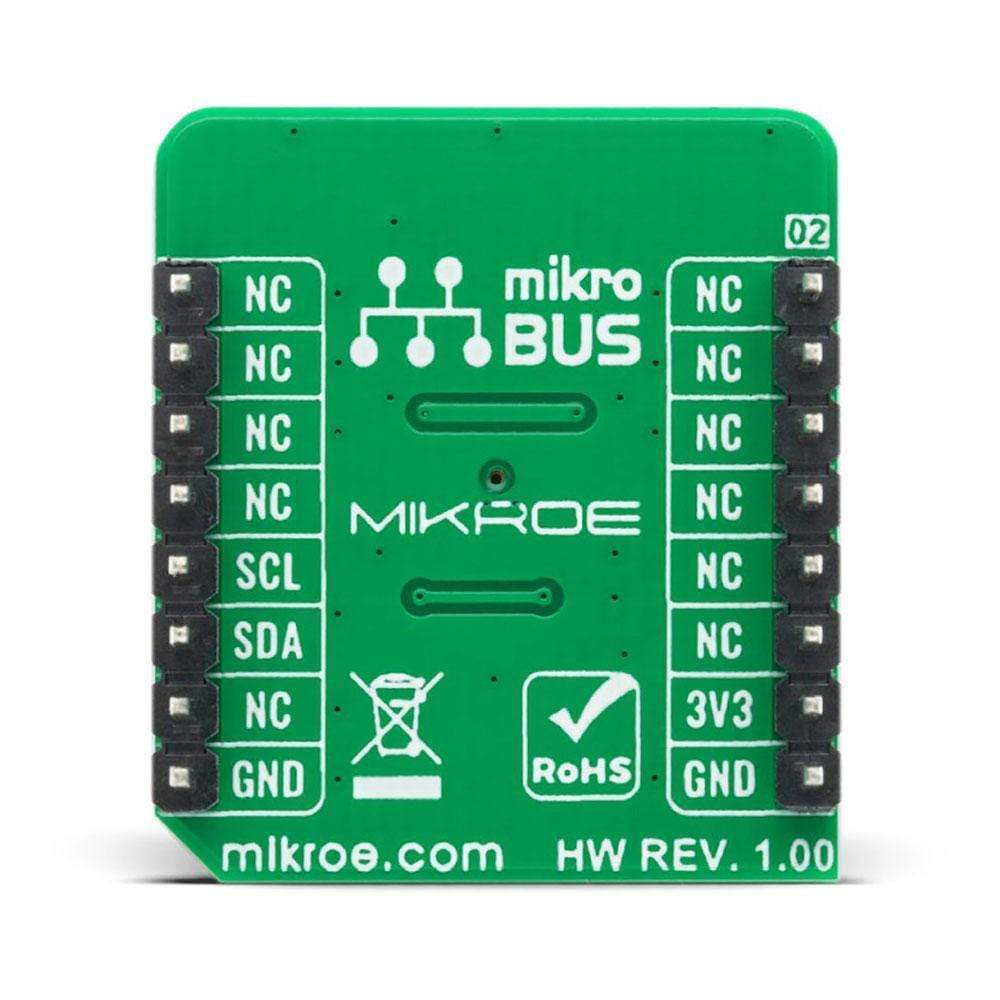

Force 5 Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Das Force 5 Click Board™ ist eine kompakte Zusatzplatine, die einen stabilen und flexiblen kompensierten/verstärkten Mikrokraftsensor enthält. Diese Platine verfügt über den FMAMSDXX025WC2C3, einen piezoresistiven Kraftsensor mit einem digitalen Ausgang zum Ablesen der Kraft über den angegebenen vollen Kraftbereich und einen Temperaturbereich von Honeywell Sensing and Productivity Solutions. Der sehr stabile digitale Ausgang, der direkt proportional zur auf die mechanisch gekoppelte Kugel ausgeübten Kraft ist, die verbesserte Genauigkeit und das reduzierte Gesamtfehlerband, das die Systemleistung verbessert, sind nur einige der guten Eigenschaften dieses Sensors. Dieses Click Board™ ist für industrielle Anwendungen wie Kraft-/Griffmessgeräte, Last- und Kompressionssensoren, Robotik und mehr geeignet.

Force 5 Click wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4305

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.016 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027380891

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.