Overview

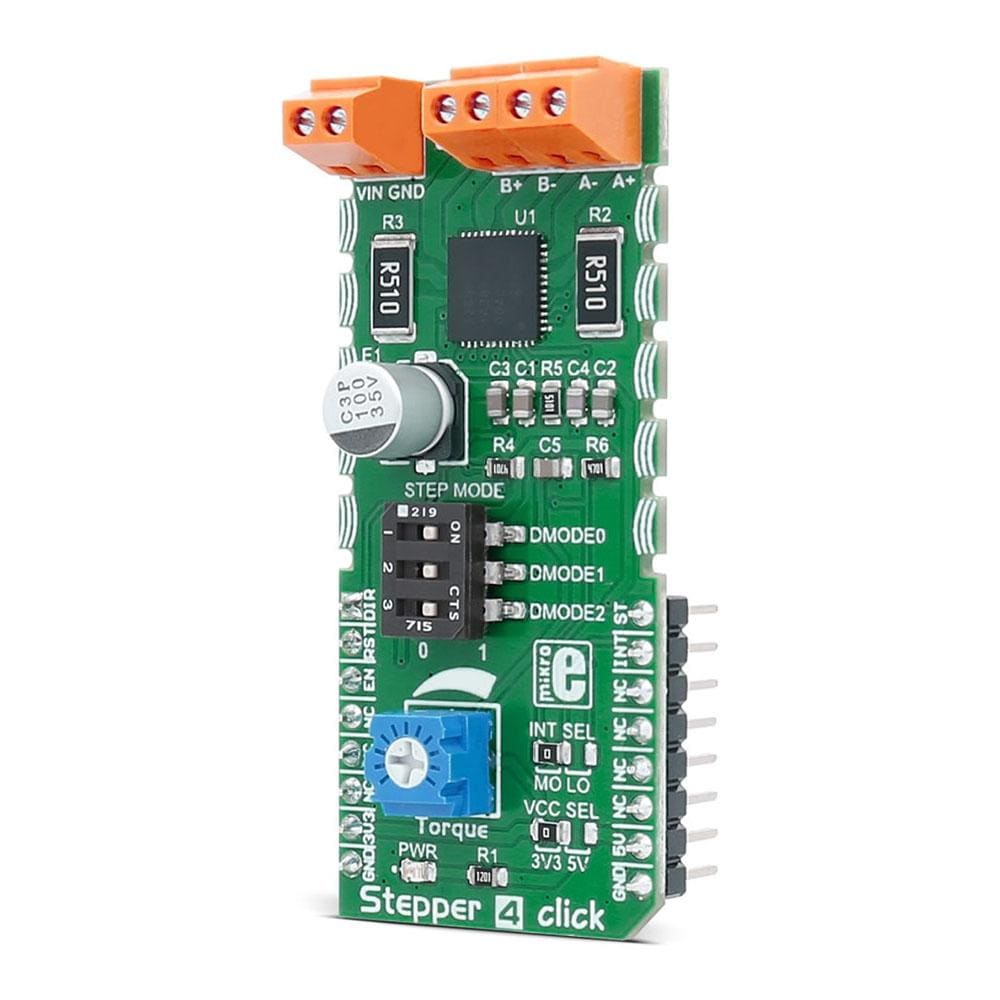

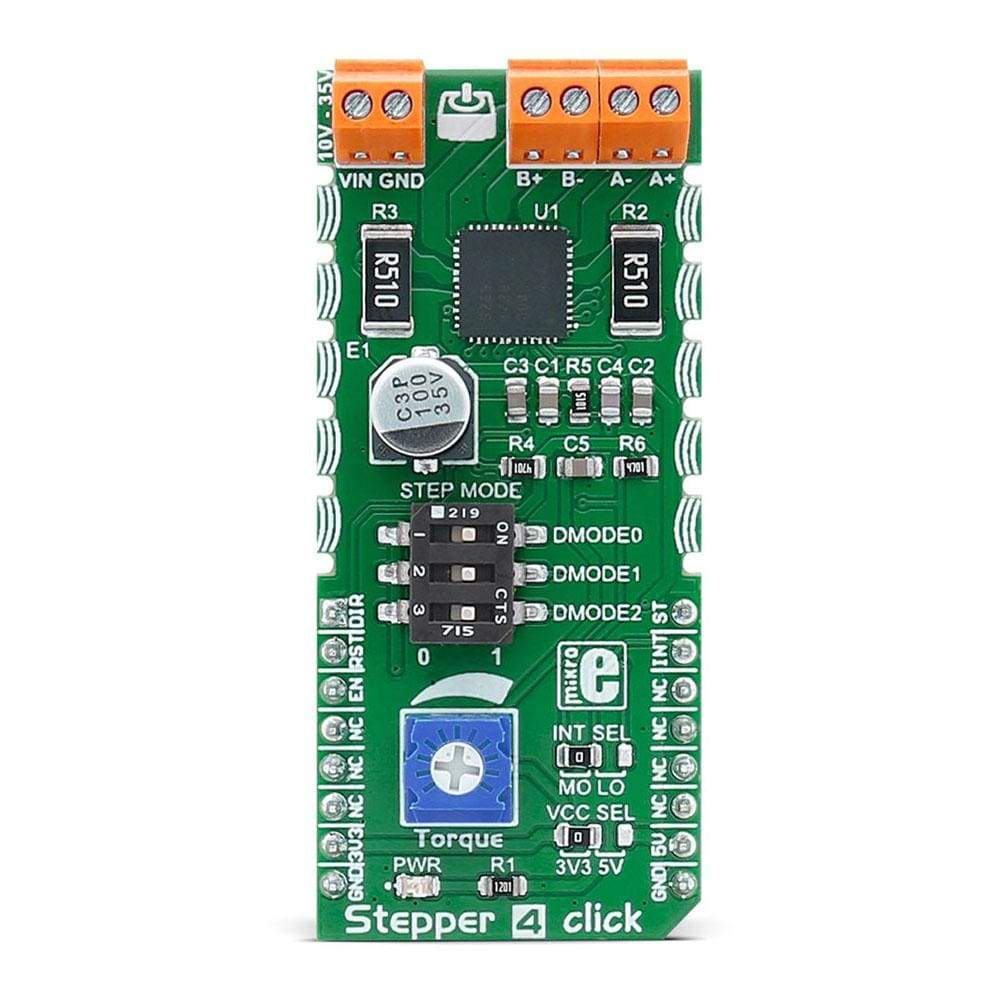

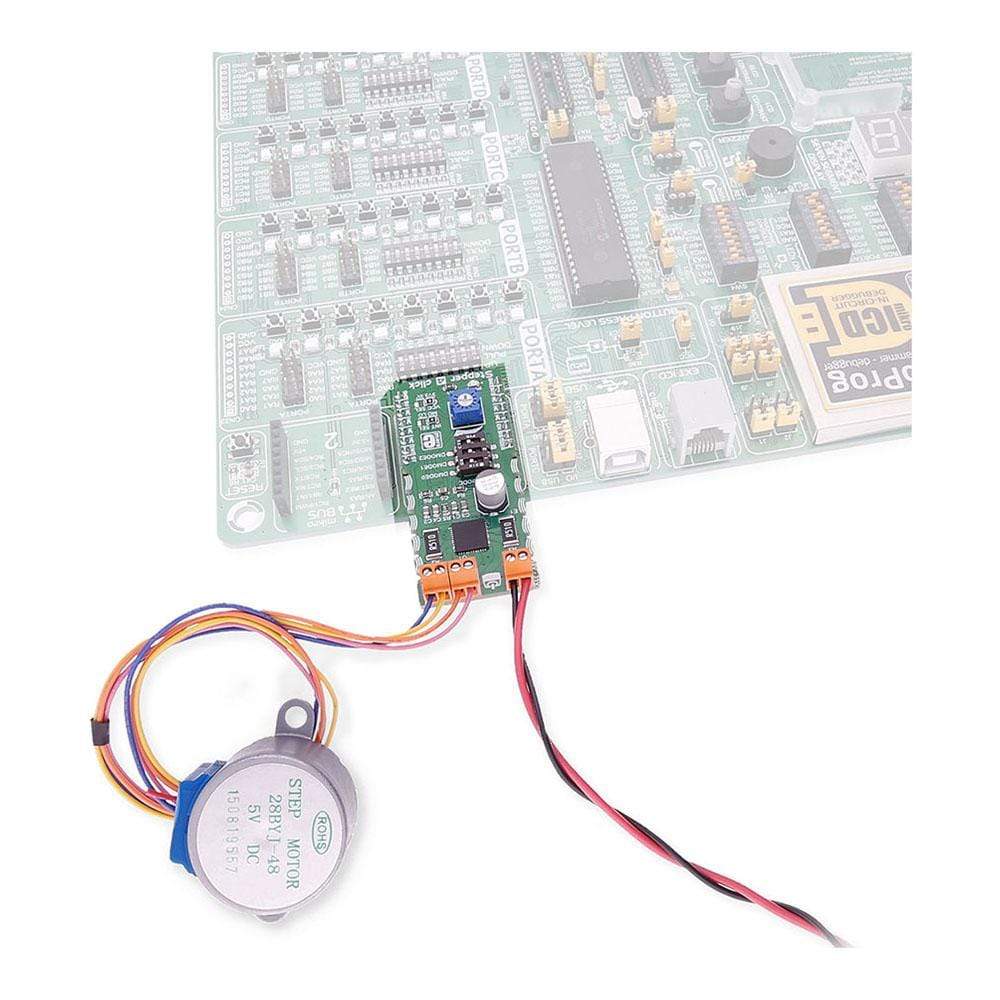

The Stepper 4 Click Board™ can be used for driving a stepper motor and controlling its step resolution, rotation direction, and time between the steps. It has an output drive capability of 2A.

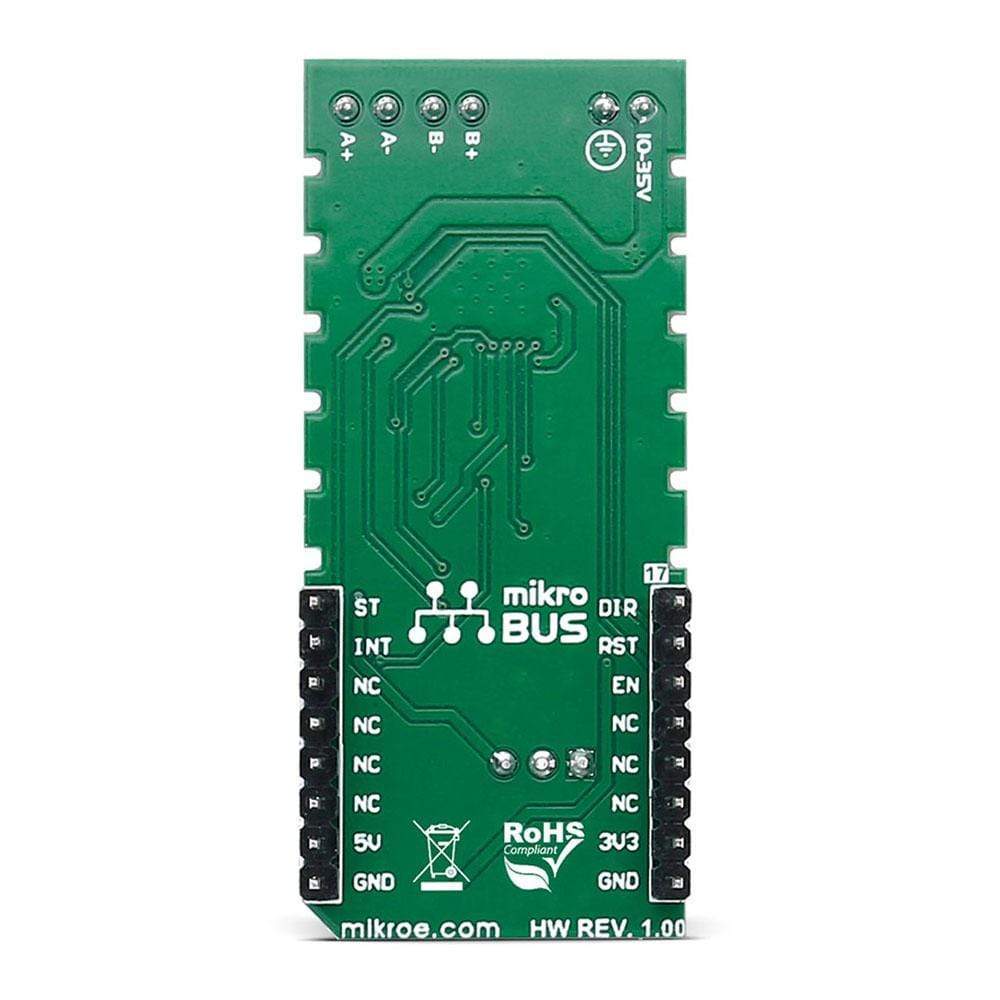

The Click Board™ carries TB67S269FTG, a two-phase bipolar stepping motor driver from Toshiba. Stepper 4 Click Board™ is designed to run on either 3.3V or 5V power supply. It communicates with the target microcontroller over the following pins on the MikroBUSline: AN, RST, CS, PWM, INT.

Downloads

Le Stepper 4 Click Board™ peut être utilisé pour piloter un moteur pas à pas et contrôler sa résolution de pas, son sens de rotation et le temps entre les pas. Il a une capacité de sortie de 2 A.

Le Click Board™ est équipé du TB67S269FTG, un pilote de moteur pas à pas bipolaire à deux phases de Toshiba. Le Stepper 4 Click Board™ est conçu pour fonctionner sur une alimentation 3,3 V ou 5 V. Il communique avec le microcontrôleur cible via les broches suivantes sur la ligne MikroBUS : AN, RST, CS, PWM, INT.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2748

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.024 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018711352

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.