Overview

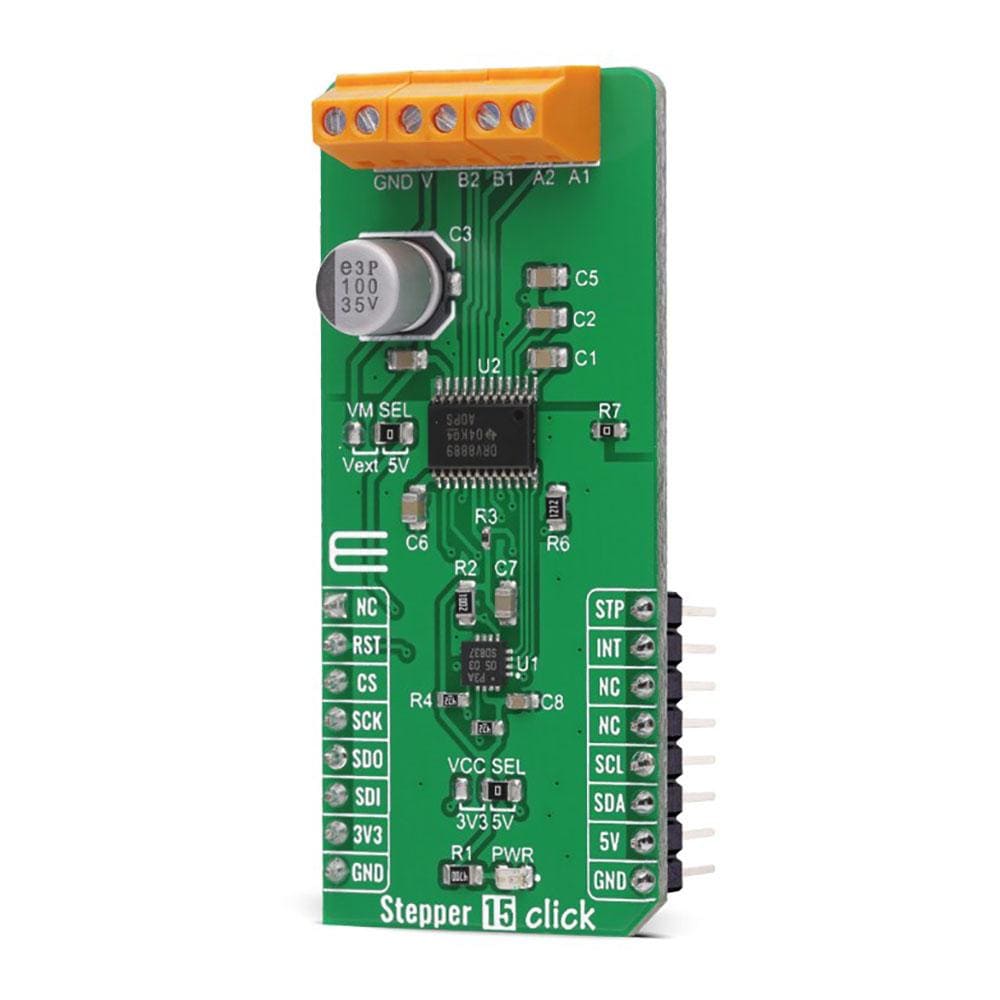

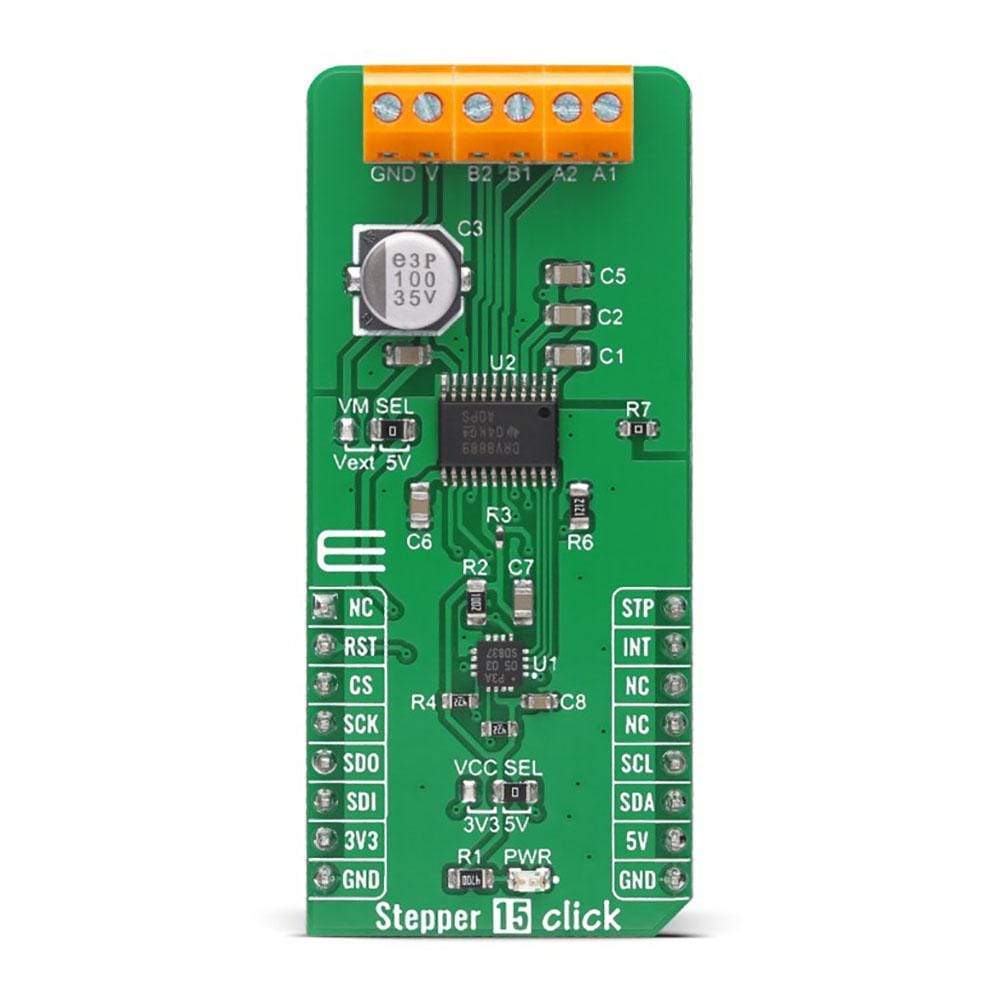

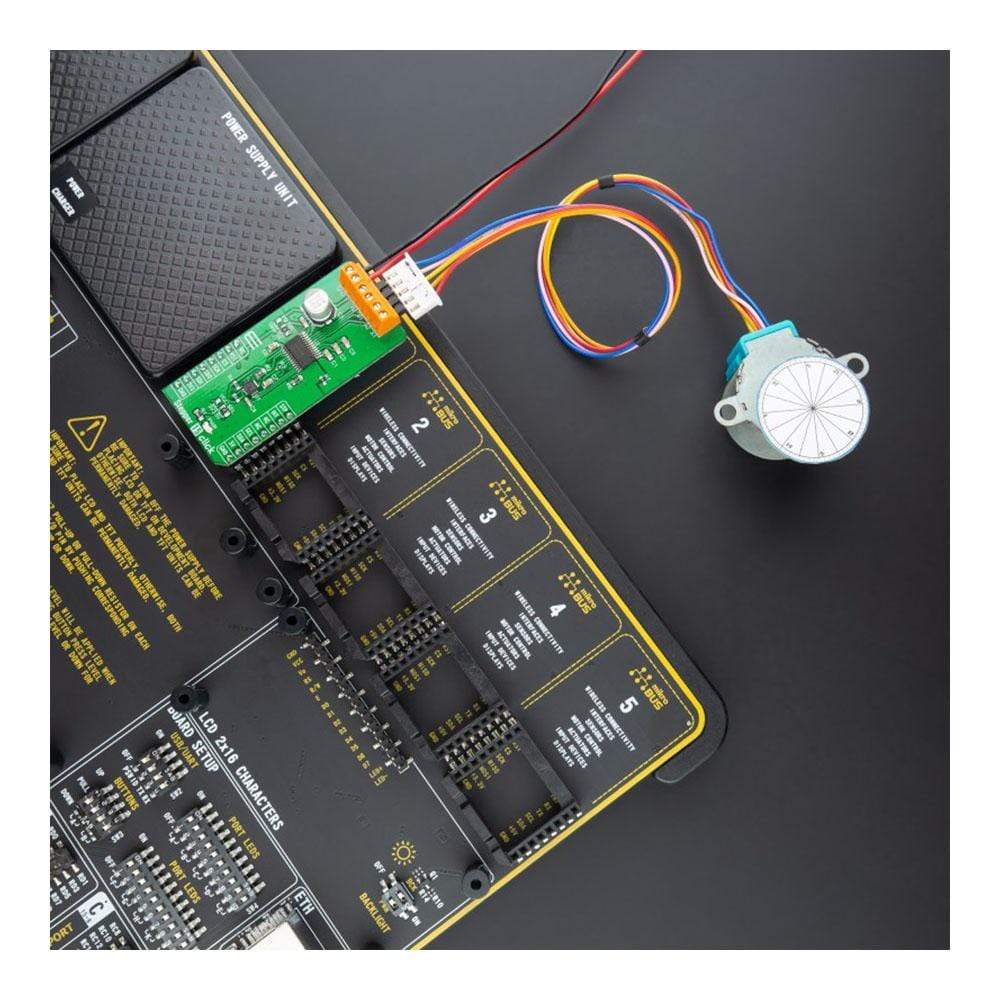

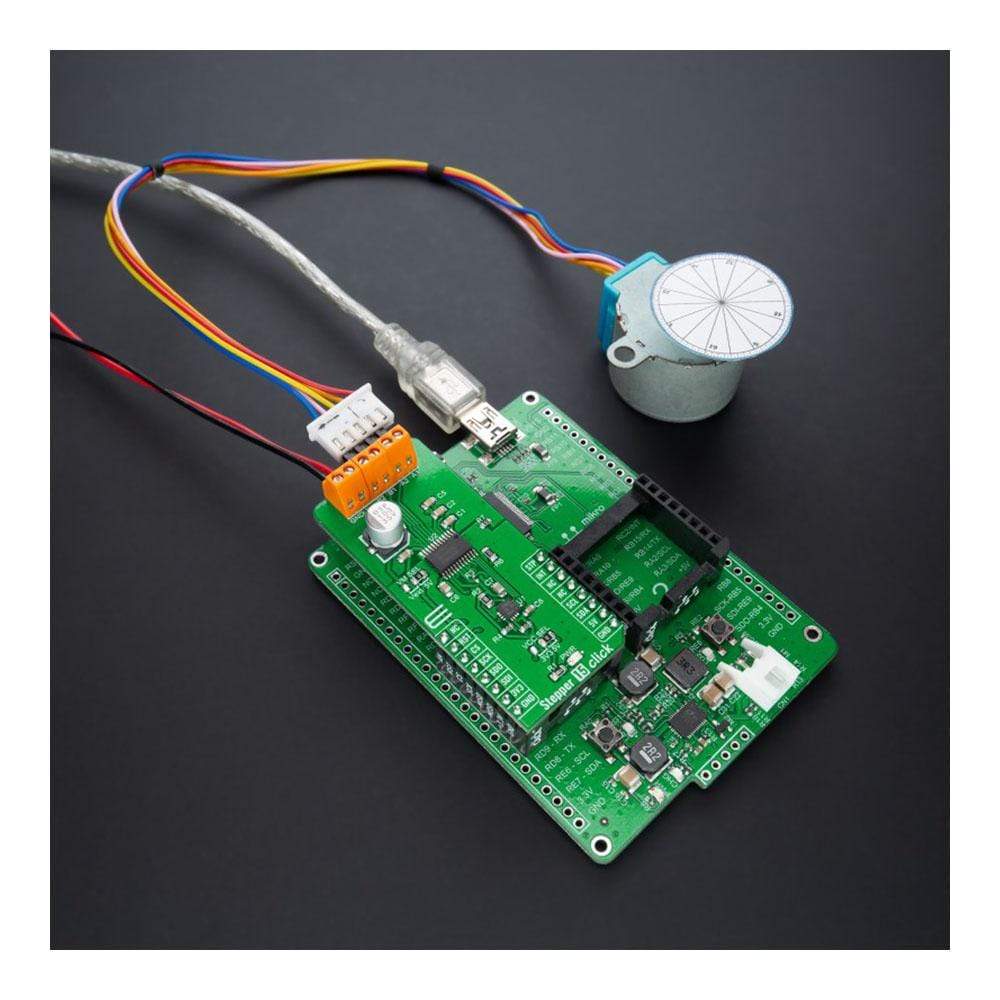

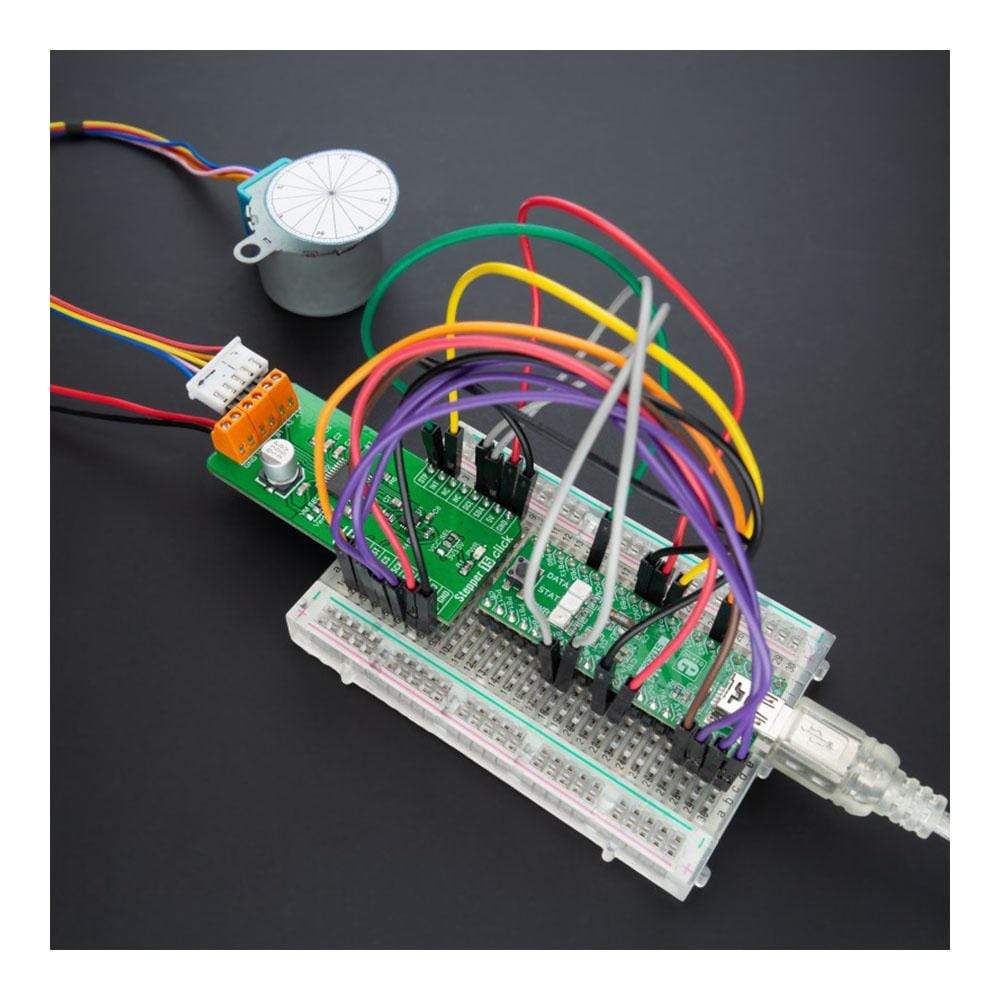

The Stepper 15 Click Board™ is a compact add-on board that contains a bipolar stepper motor driver. This board features the DRV8889A, an automotive stepper driver with integrated current sense and stall detection from Texas Instruments. It supports up to 1.5A full-scale current with an internal microstepping indexer, smart tune decay technology, advanced stall detection algorithm, and integrated current sensing, eliminating the need for power sense resistors. With a simple STEP/DIR interface, the device supports up to 1/256 levels of microstepping to enable a smooth motion profile. Also, an advanced stall detection algorithm allows users to detect if the motor stopped and take action as needed, improving efficiency and reducing noise. This Click Board™ is suitable for driving motors in any application that demands a precise and safe step motor driver.

The Stepper 15 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a thoroughly tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Le Stepper 15 Click Board™ est une carte complémentaire compacte qui contient un pilote de moteur pas à pas bipolaire. Cette carte comprend le DRV8889A, un pilote de moteur pas à pas automobile avec détection de courant et de calage intégrée de Texas Instruments. Il prend en charge jusqu'à 1,5 A de courant pleine échelle avec un indexeur de micropas interne, une technologie de décroissance de réglage intelligent, un algorithme avancé de détection de calage et une détection de courant intégrée, éliminant ainsi le besoin de résistances de détection de puissance. Avec une interface STEP/DIR simple, l'appareil prend en charge jusqu'à 1/256 niveaux de micropas pour permettre un profil de mouvement fluide. De plus, un algorithme avancé de détection de calage permet aux utilisateurs de détecter si le moteur s'est arrêté et de prendre les mesures nécessaires, améliorant ainsi l'efficacité et réduisant le bruit. Ce Click Board™ convient à la commande de moteurs dans toute application qui exige un pilote de moteur pas à pas précis et sûr.

Le Stepper 15 Click Board™ est pris en charge par une bibliothèque compatible mikroSDK, qui comprend des fonctions qui simplifient le développement logiciel. Cette Click Board™ est un produit entièrement testé, prêt à être utilisé sur un système équipé du socket mikroBUS™.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4639

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027382543

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.