Key Features

Overview

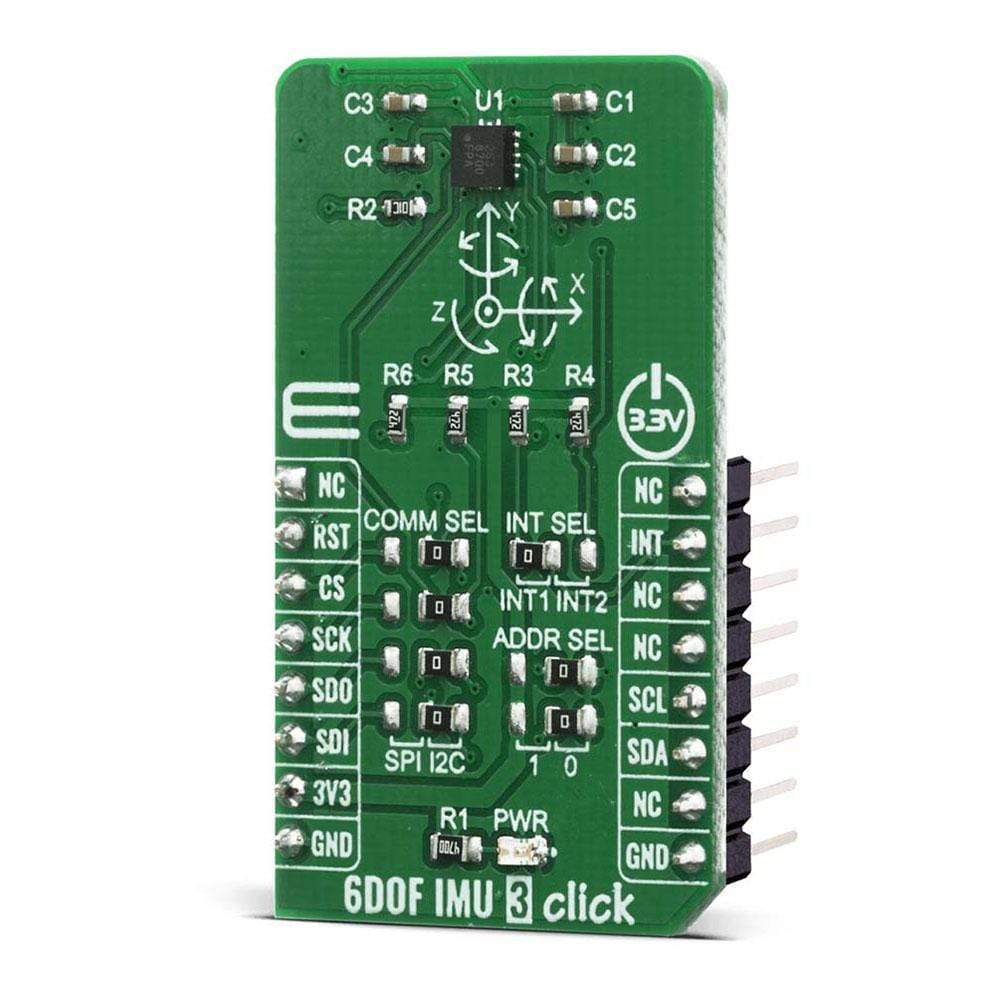

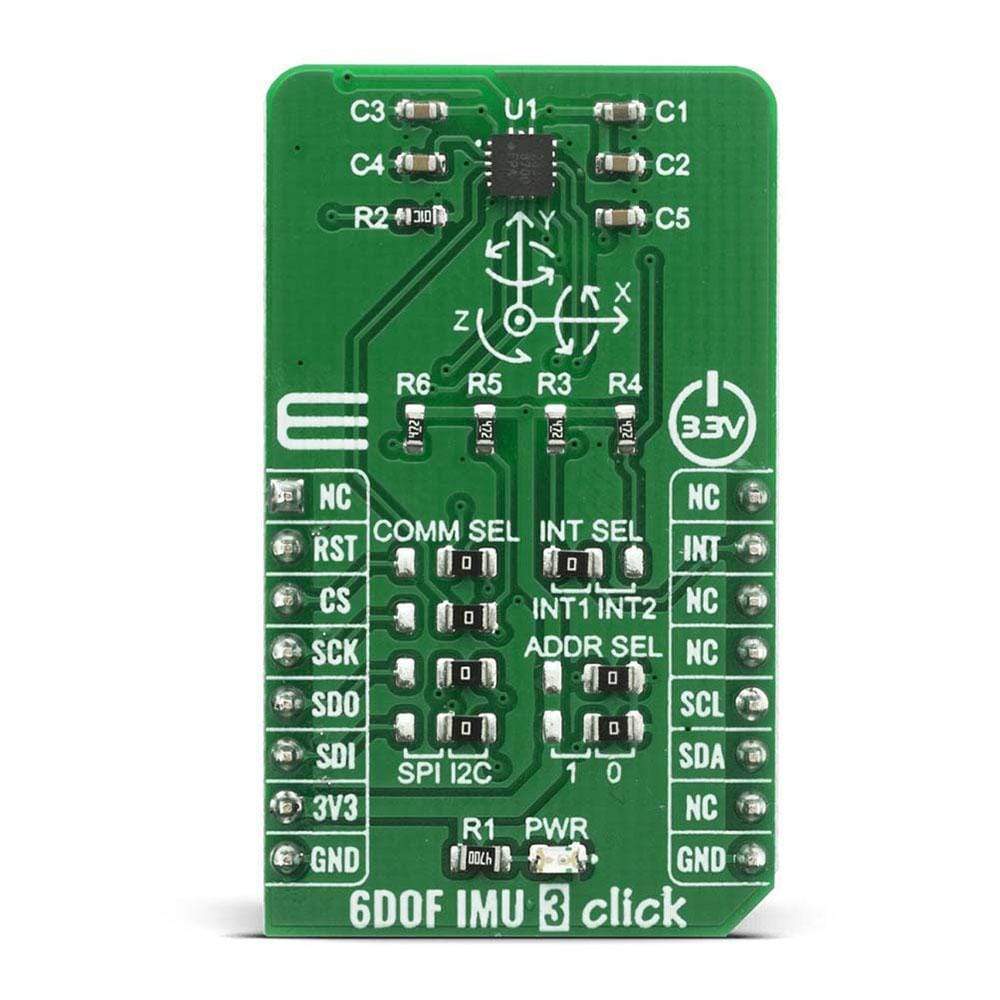

The 6DOF IMU 3 Click Board™ is a complete 6-axis detection development board suitable for movement and position tracking devices. This Click Board™ board features the compact FXOS8700CQ motion sensor from NXP, an integrated 3-axis linear accelerometer and a 3-axis magnetometer combined in one package.

The device supports a selectable I2C or point-to-point SPI serial interface with a 14-bit accelerometer and 16-bit magnetometer which are combined with a high-performance ASIC to enable an eCompass solution capable of a typical orientation resolution of 0.1° and sub-5° compass heading accuracy for many applications.

Downloads

La carte Click Board™ 6DOF IMU 3 est une carte de développement de détection 6 axes complète adaptée aux dispositifs de suivi de mouvement et de position. Cette carte Click Board™ comprend le capteur de mouvement compact FXOS8700CQ de NXP, un accéléromètre linéaire 3 axes intégré et un magnétomètre 3 axes combinés dans un seul boîtier.

L'appareil prend en charge une interface série I2C ou SPI point à point sélectionnable avec un accéléromètre 14 bits et un magnétomètre 16 bits qui sont combinés à un ASIC hautes performances pour permettre une solution eCompass capable d'une résolution d'orientation typique de 0,1° et d'une précision de cap de boussole inférieure à 5° pour de nombreuses applications.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4086

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.017 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018717286

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.