Overview

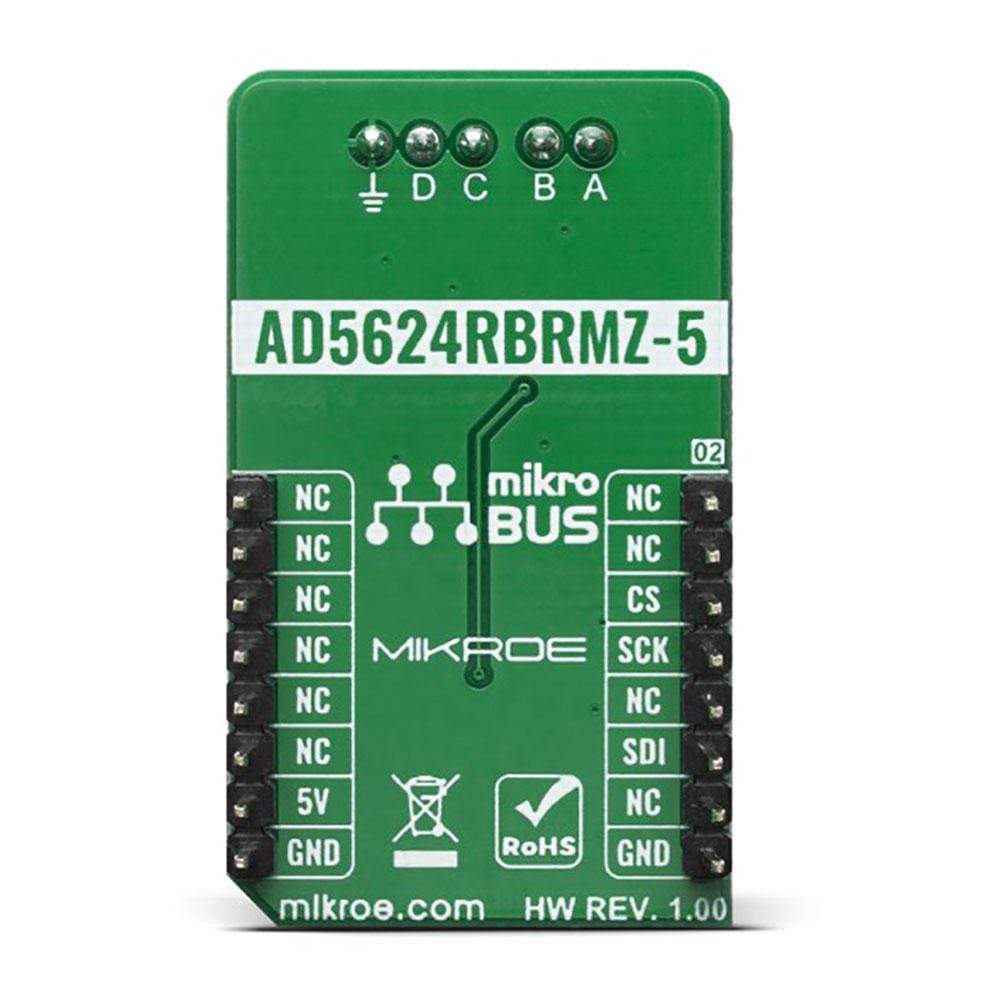

The DAC 7 Click Board™ carries the AD5624R, a low-power four-channel, 12-bit buffered Digital-to-Analog Converter. AD5624R converts the digital value to the corresponding voltage level using an external voltage reference. This will help you convert digital information from the mainboard to four analogue outputs on the DAC 7 Click Board™. For that purpose, DAC 7 Click Board™ uses MCP1541, which is a low-dropout precision voltage reference with a 4.096V output voltage.

With all those possibilities on board, DAC 7 Click Board™ makes a perfect choice for an accurate and simple generation of analogue signals for various purposes, such as programmable Power Supplies, Laser Drivers, Projectors, IP Network cameras, autofocus digital still camera lens, and more

Downloads

Le DAC 7 Click Board™ est équipé de l'AD5624R, un convertisseur numérique-analogique à quatre canaux et 12 bits à faible consommation. L'AD5624R convertit la valeur numérique au niveau de tension correspondant à l'aide d'une référence de tension externe. Cela vous aidera à convertir les informations numériques de la carte mère vers quatre sorties analogiques sur le DAC 7 Click Board™ . À cette fin, le DAC 7 Click Board™ utilise le MCP1541, qui est une référence de tension de précision à faible chute de tension avec une tension de sortie de 4,096 V.

Avec toutes ces possibilités à bord, le DAC 7 Click Board™ constitue un choix parfait pour une génération précise et simple de signaux analogiques à des fins diverses, telles que les alimentations programmables, les pilotes laser, les projecteurs, les caméras réseau IP, les objectifs d'appareil photo numérique autofocus, etc.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3886

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.019 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018719273

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.