Overview

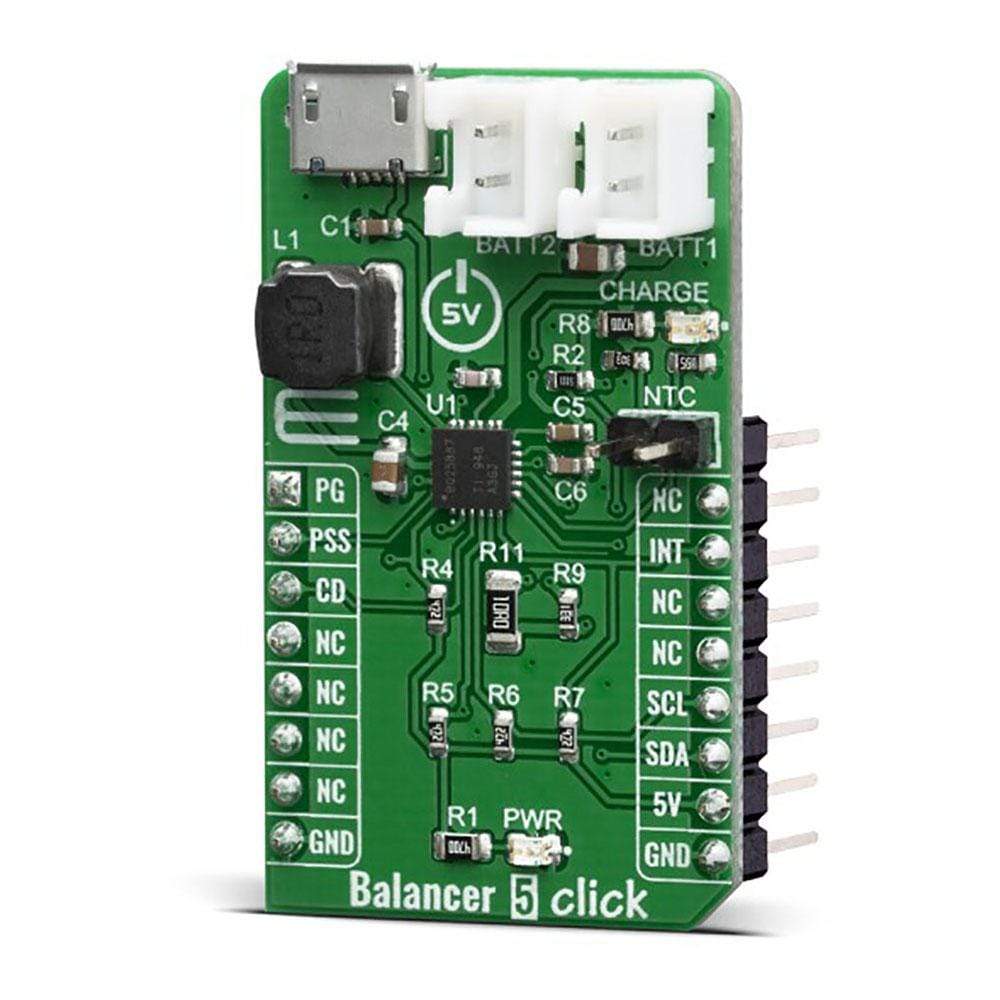

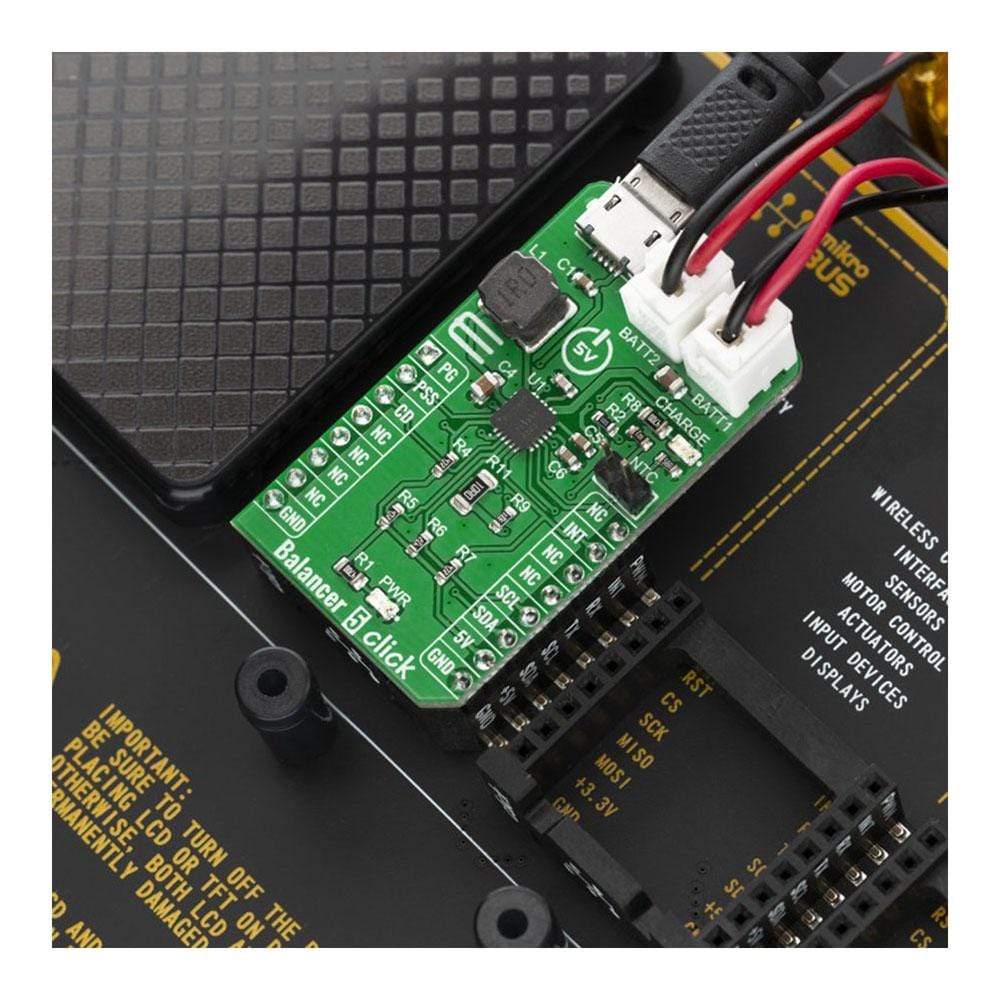

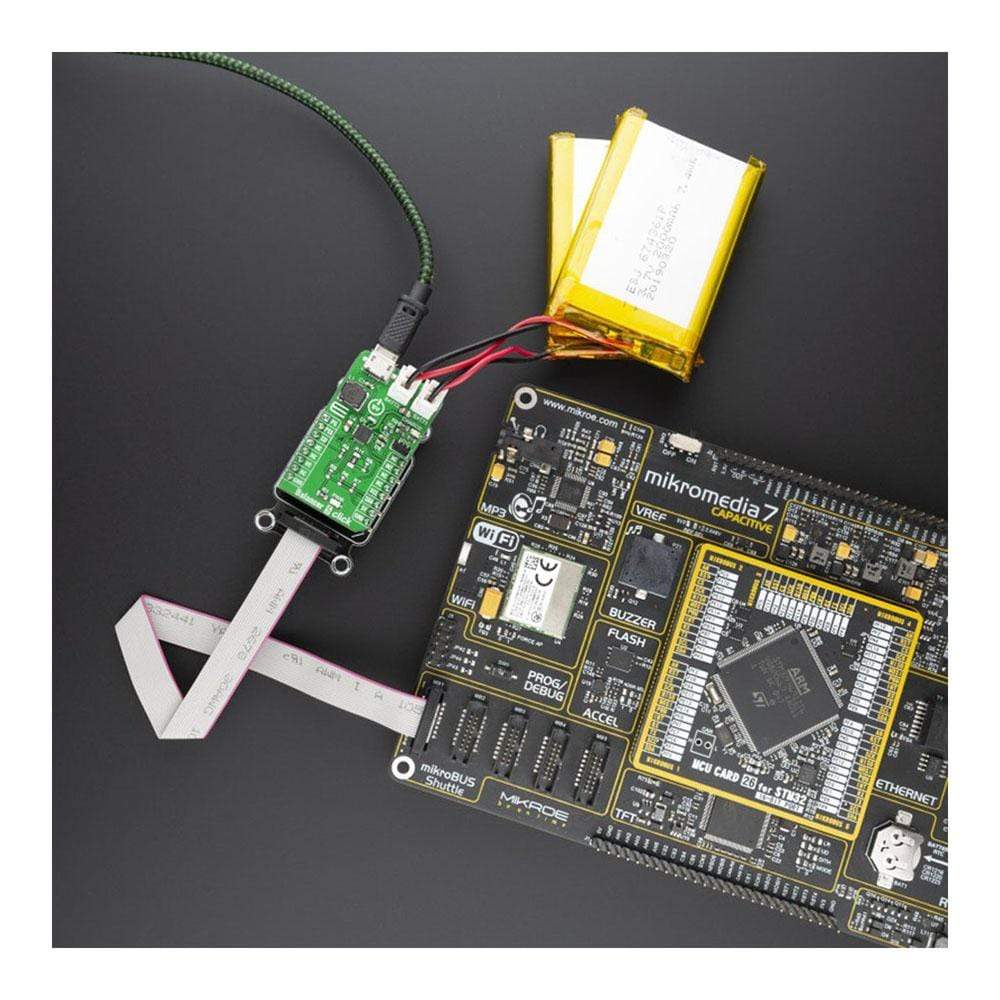

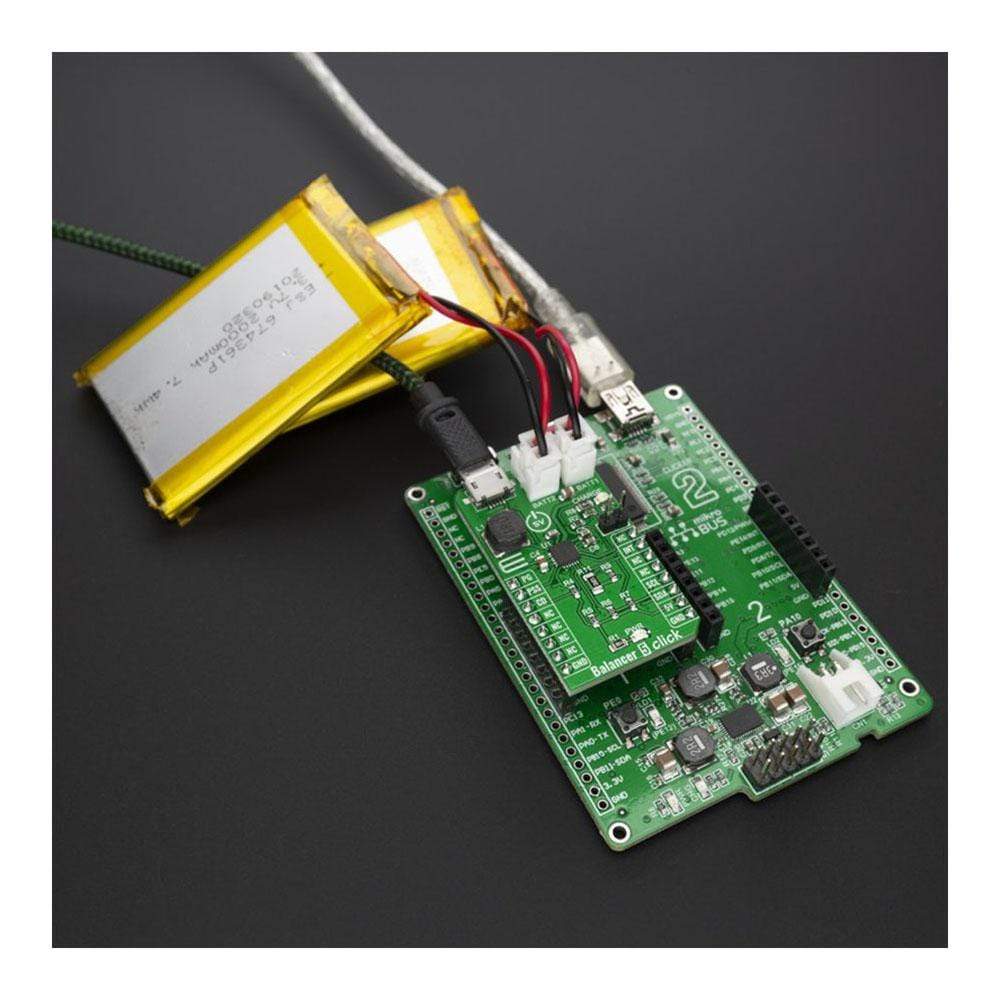

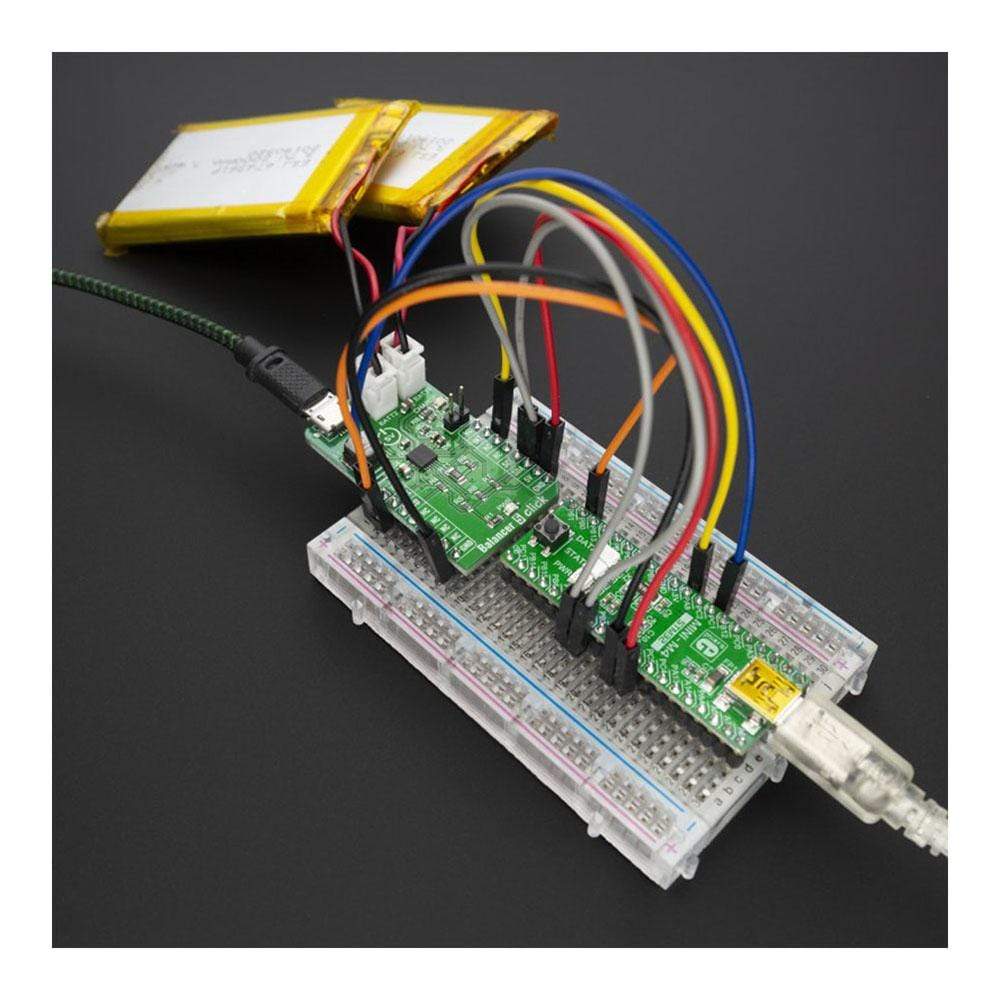

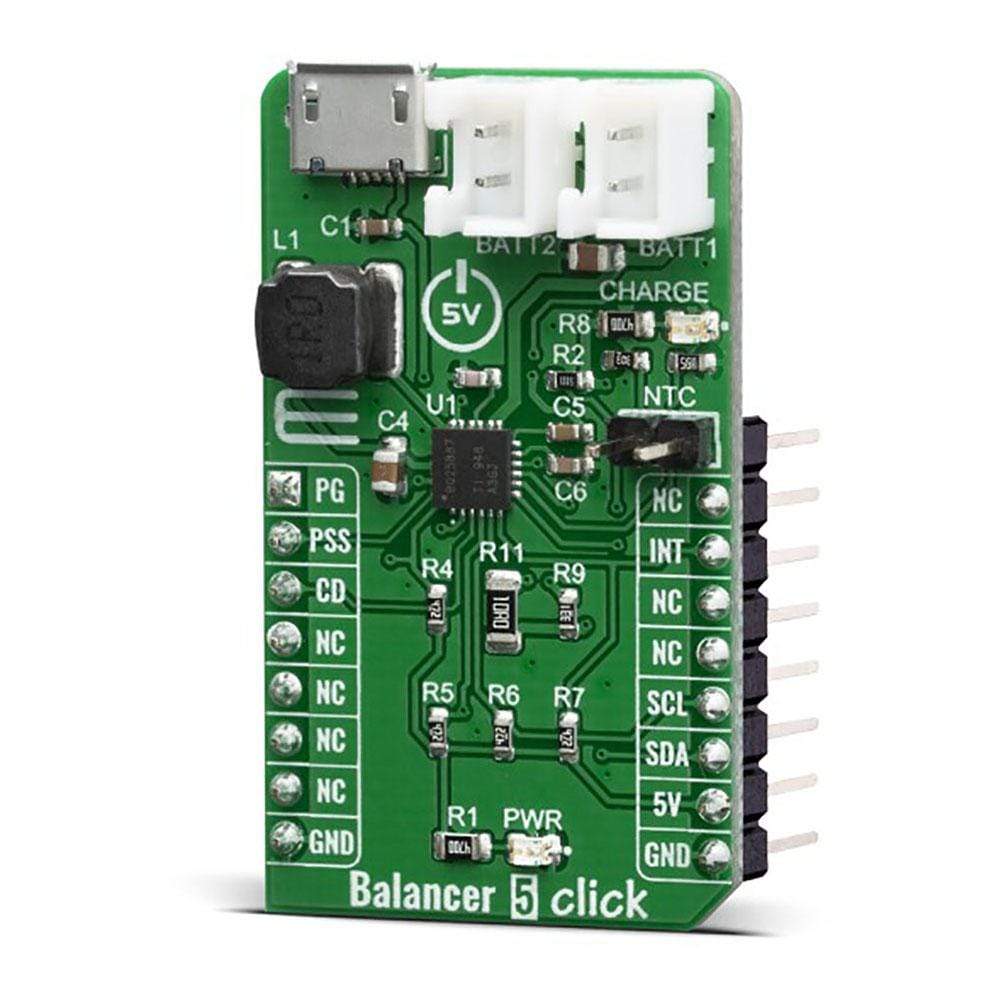

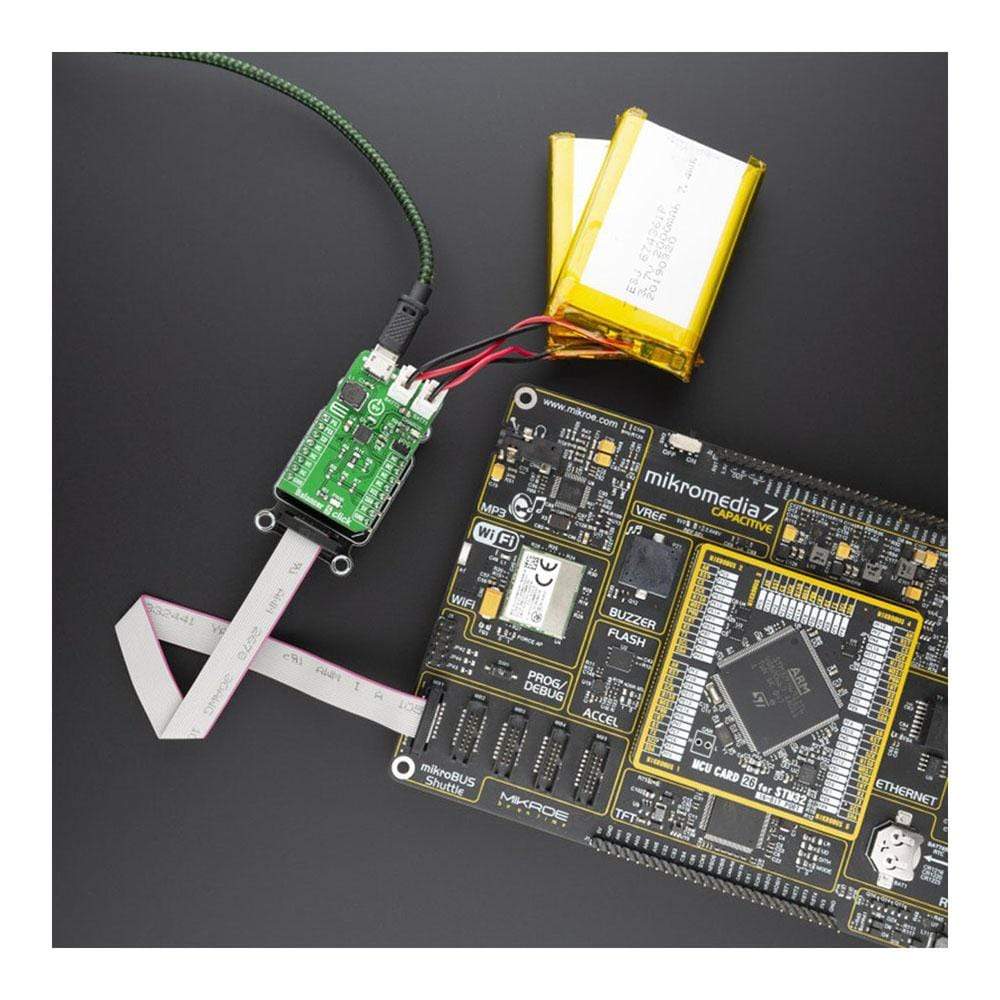

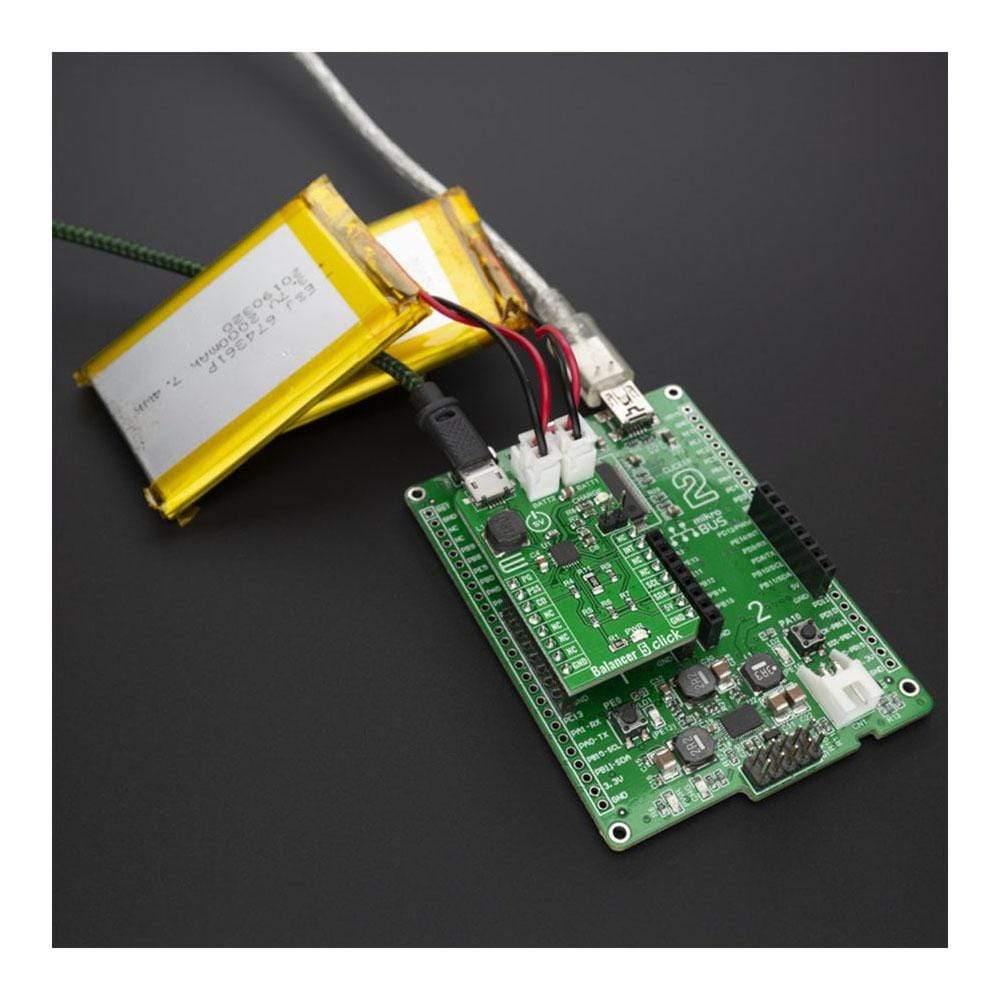

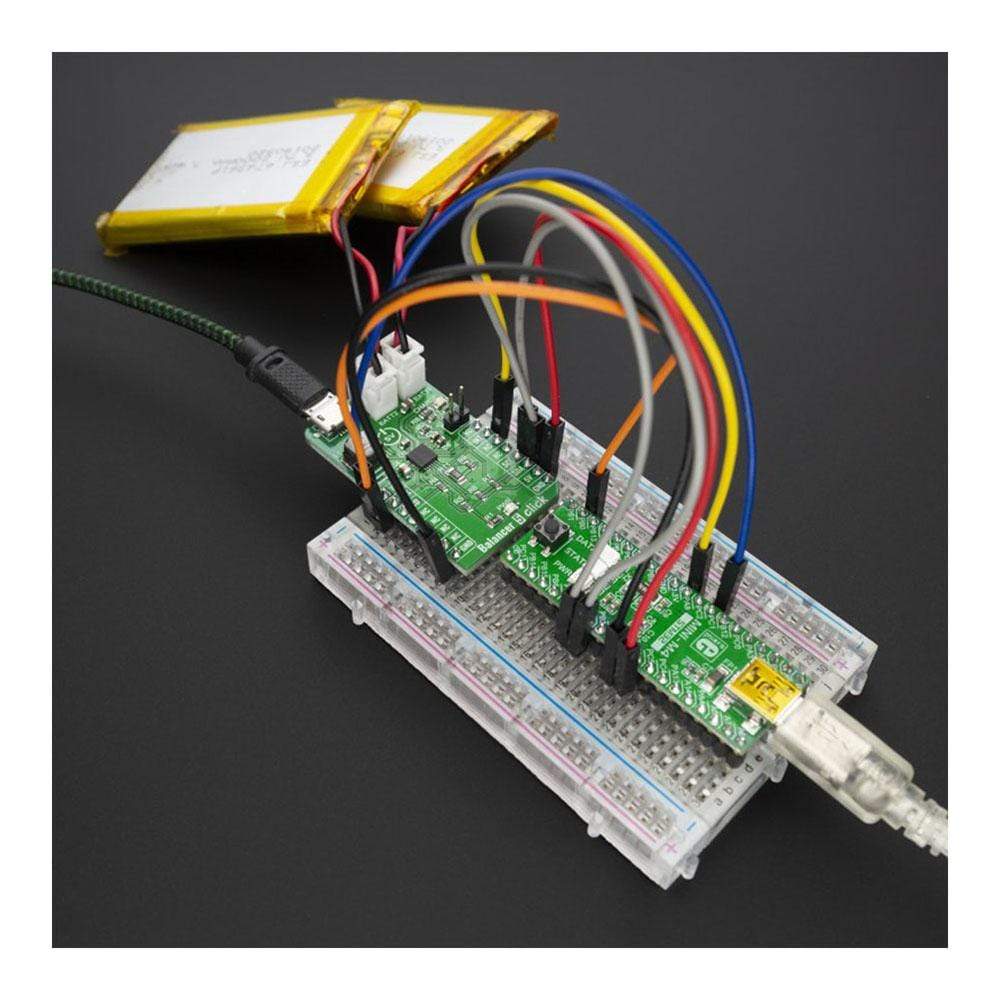

The Balancer 5 Click Board™ is an intelligent 2-cell Li-Ion battery charger, system power manager, and battery fuel gauge Click Board™.

The Balancer 5 Click Board™ is based on a BQ25887 controller which has some extra features enabling charging without too much hassle. As a system power distributor, it can supply up to 3.3A to a connected battery. By utilizing an externally connected USB power supply, it can charge a 2-cell Li-Ion battery. A dedicated power management IC with optimized smart power control allows very efficient management of the available power.

Downloads

Le Balancer 5 Click Board™ est un chargeur de batterie Li-Ion intelligent à 2 cellules, un gestionnaire d'alimentation système et une jauge de carburant de batterie Click Board™.

Le Balancer 5 Click Board™ est basé sur un contrôleur BQ25887 qui possède quelques fonctionnalités supplémentaires permettant une charge sans trop de tracas. En tant que distributeur d'alimentation système, il peut fournir jusqu'à 3,3 A à une batterie connectée. En utilisant une alimentation USB connectée en externe, il peut charger une batterie Li-Ion à 2 cellules. Un circuit intégré de gestion de l'alimentation dédié avec un contrôle intelligent de l'alimentation optimisé permet une gestion très efficace de l'énergie disponible.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3853

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018719495

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.