Overview

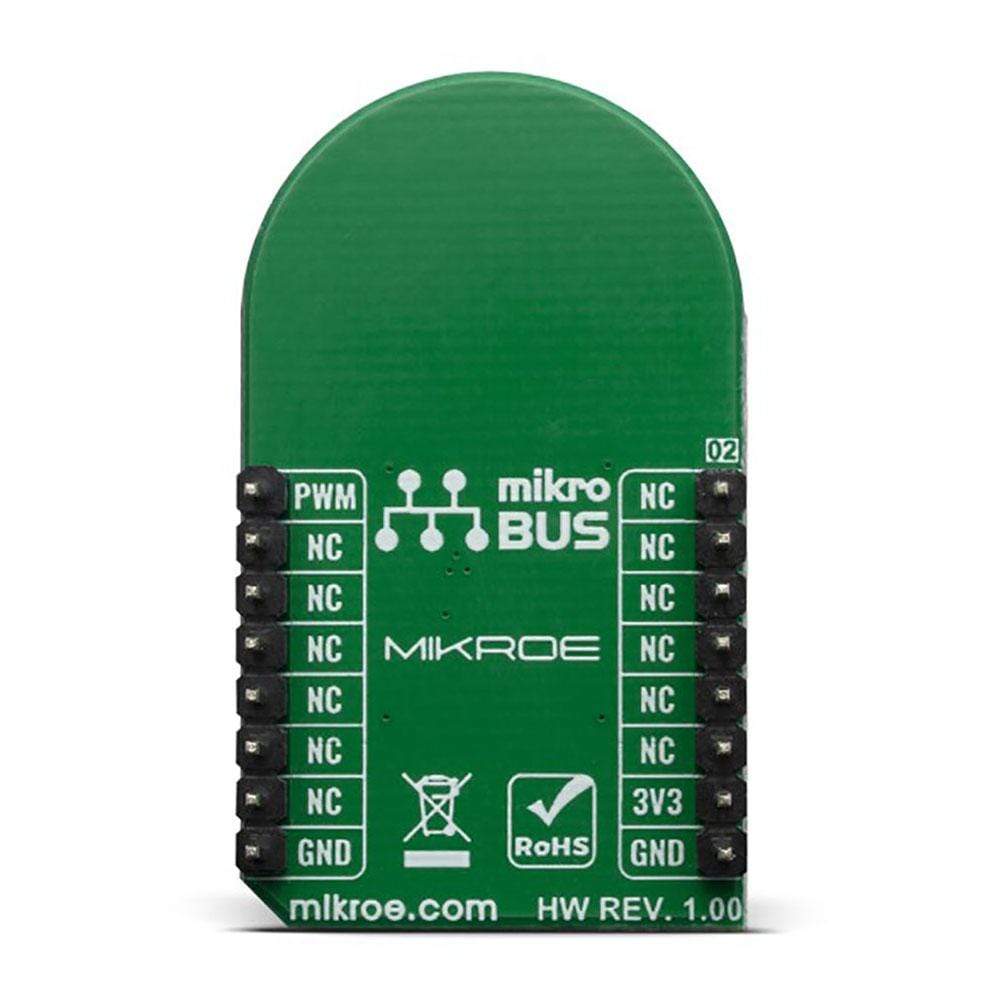

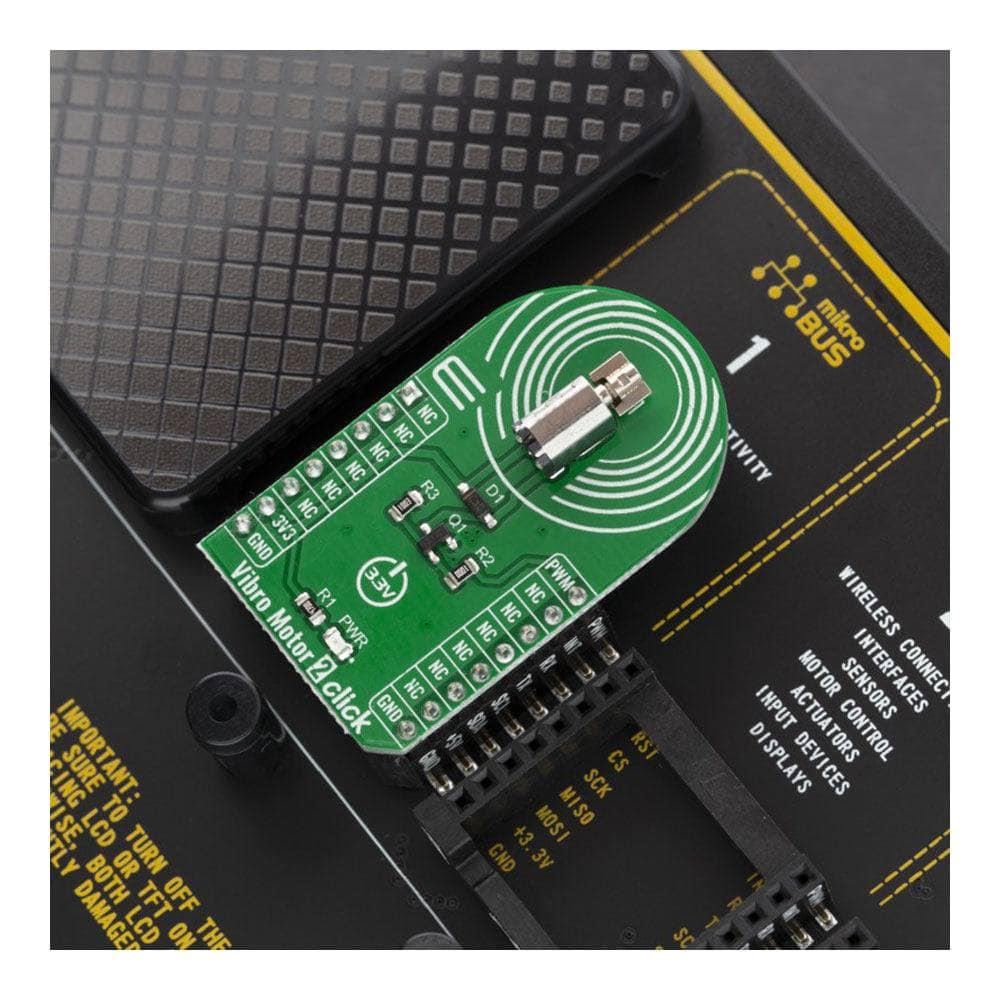

The Vibro Motor 2 Click Board™ features a compact size Eccentric Rotating Mass (ERM) motor, labelled as Z4FC1B1301781 as well as DMG3420U MOSFET to drive the ERM motor since the MCU itself cannot provide enough power for the motor driving. This type of motor is often used for haptic feedback on many small handheld devices, such as cellphones, pagers, RFID scanners and similar devices. This motor contains a small eccentric weight on its rotor, so while rotating it also produces a vibration effect. This kind of motor is sometimes referred to as a coin motor, due to its shape.

Besides the vibration motor, the click is also equipped with the DMG3420U, a small MOSFET, which is used to drive the motor. The Vibro Motor 2 Click Board™ is an ideal solution for adding simple, one pin-driven haptic feedback to any design.

Downloads

Le moteur vibro 2 Click Board™ Le moteur à masse rotative excentrique (ERM) de taille compacte, étiqueté Z4FC1B1301781, ainsi que le MOSFET DMG3420U pour entraîner le moteur ERM, car le microcontrôleur lui-même ne peut pas fournir suffisamment de puissance pour l'entraînement du moteur. Ce type de moteur est souvent utilisé pour le retour haptique sur de nombreux petits appareils portables, tels que les téléphones portables, les téléavertisseurs, les scanners RFID et les appareils similaires. Ce moteur contient un petit poids excentrique sur son rotor, de sorte qu'il produit également un effet de vibration lors de sa rotation. Ce type de moteur est parfois appelé moteur à pièces, en raison de sa forme.

Outre le moteur de vibration, le Click est également équipé du DMG3420U, un petit MOSFET, qui sert à piloter le moteur. Le Vibro Motor 2 Click Board™ est une solution idéale pour ajouter un retour haptique simple, piloté par une seule broche, à n'importe quelle conception.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3713

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.019 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018716715

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.