Overview

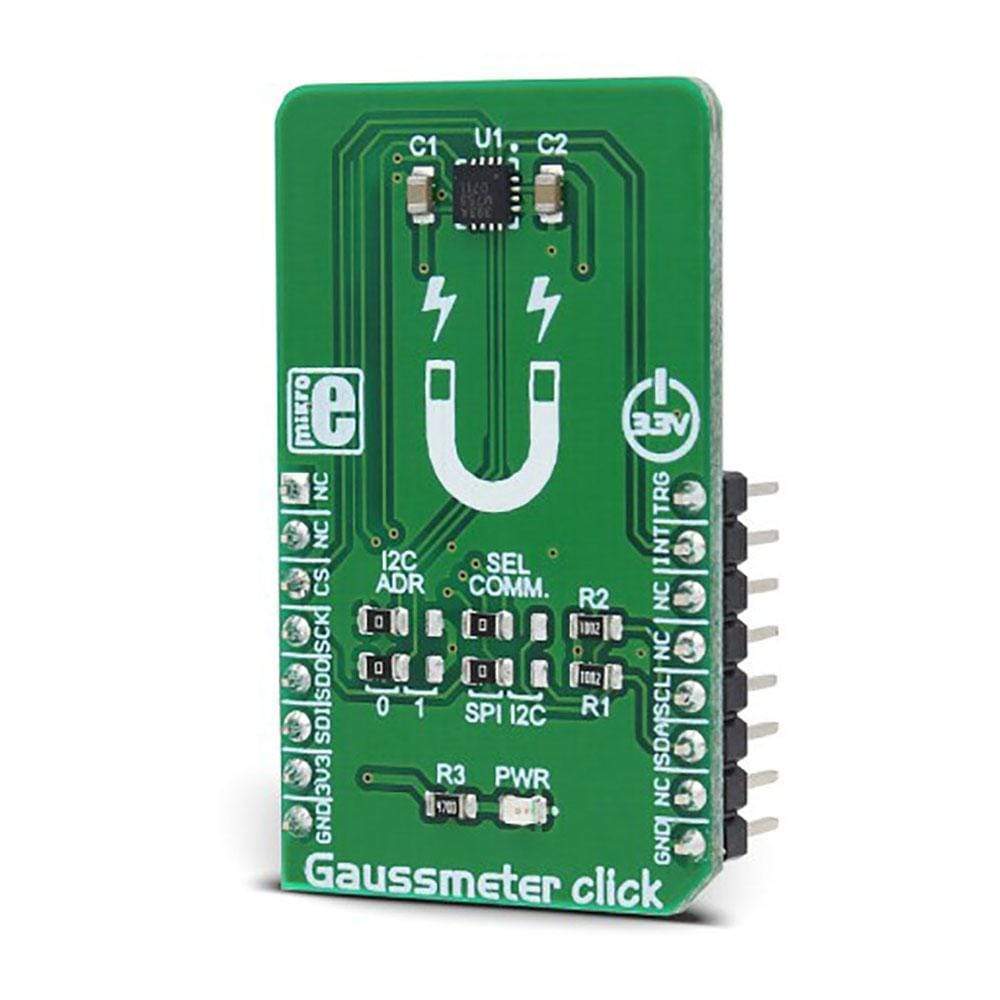

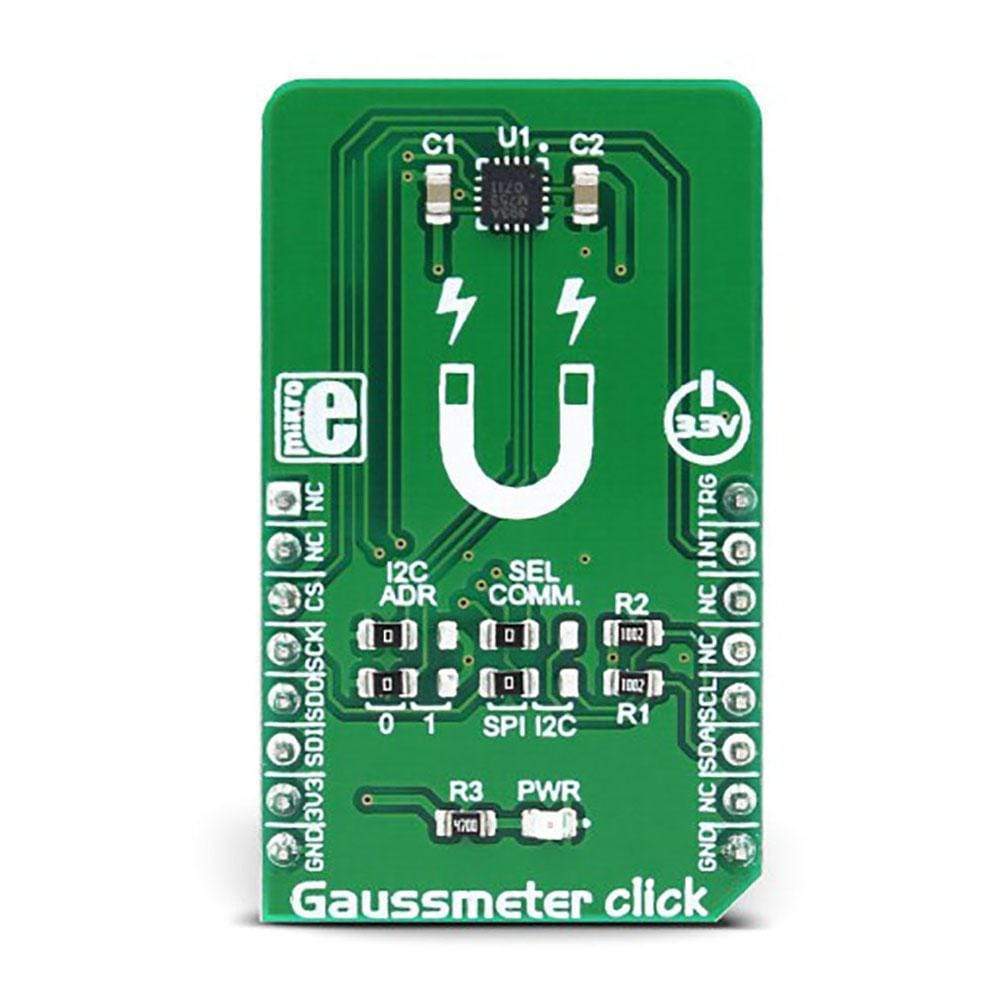

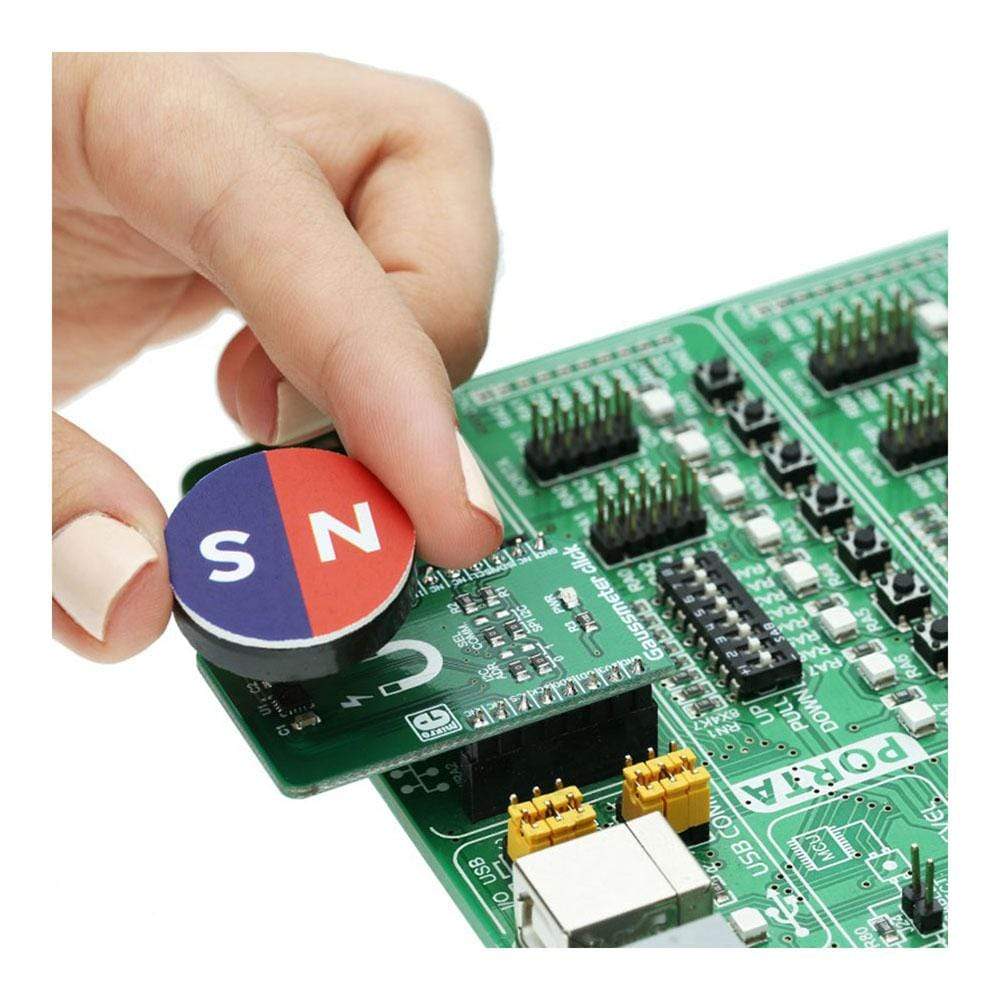

The Gaussmeter Click Board™ is a device that is used for measuring the magnetic field in X, Y and Z axes. This Click Board™ features the MLX90393, a micropower magnetometer based on the proprietary Triaxis' technology, from Melexis. It can detect the magnetic field down to 0.8 µT (8 mG) thanks to this technology. The integrated temperature sensor provides data for the thermal compensation, while the on-chip non-volatile memory can store the various working and compensation parameters, so they can be reused after the Power ON reset cycle (POR).

The Gaussmeter Click Board™ supports both I2C and SPI communication protocols, allowing it to be interfaced with the wide range of different MCUs.

Downloads

Le Gaussmeter Click Board™ est un appareil utilisé pour mesurer le champ magnétique sur les axes X, Y et Z. Ce Click Board™ est équipé du MLX90393, un magnétomètre micro-puissance basé sur la technologie propriétaire Triaxis de Melexis. Il peut détecter le champ magnétique jusqu'à 0,8 µT (8 mG) grâce à cette technologie. Le capteur de température intégré fournit des données pour la compensation thermique, tandis que la mémoire non volatile sur puce peut stocker les différents paramètres de fonctionnement et de compensation, afin qu'ils puissent être réutilisés après le cycle de réinitialisation Power ON (POR).

Le Gaussmeter Click Board™ prend en charge les protocoles de communication I2C et SPI, ce qui lui permet d'être interfacé avec une large gamme de différents MCU.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3099

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713301

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.