Overview

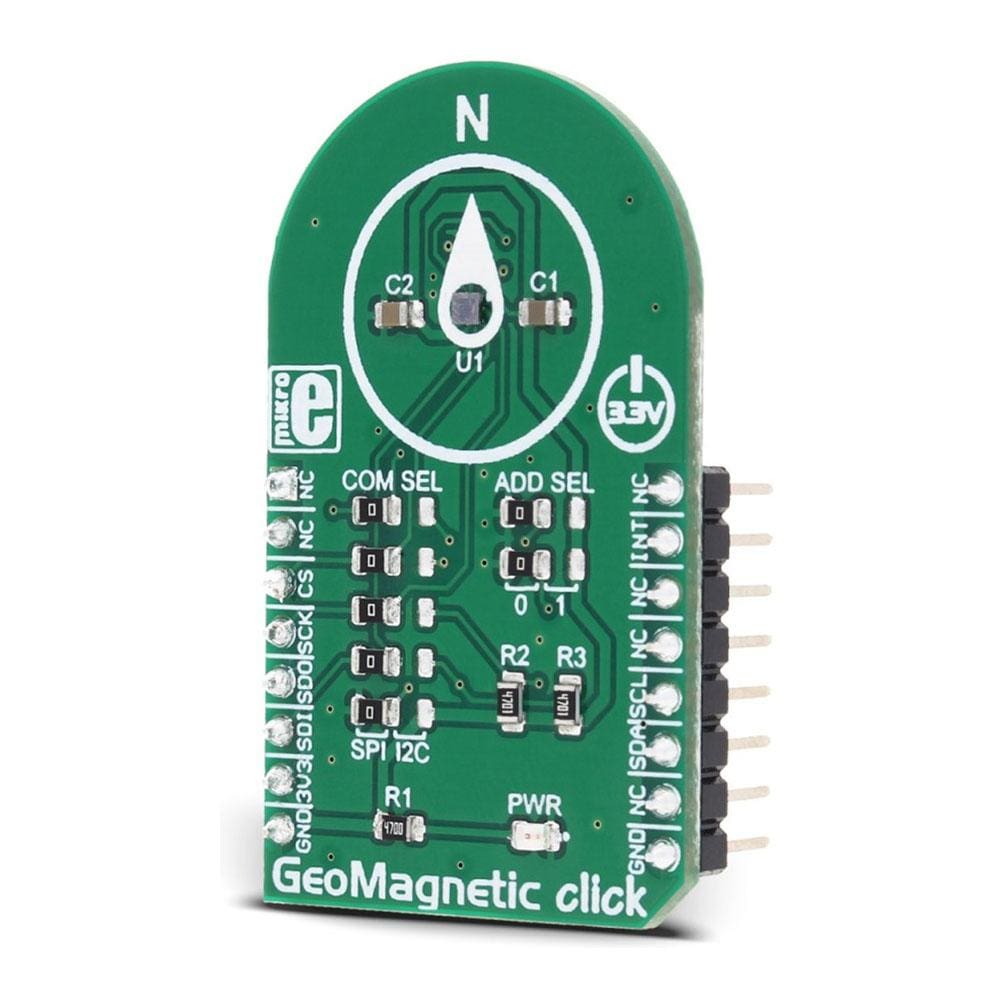

The GeoMagnetic Click Board™ is a digital magnetometric Click Board™ that can measure the geomagnetic field in three perpendicular axes. The onboard sensor uses FlipCore - a proprietary technology from Bosch, which results in a carefully tuned performance, tailored for demanding 3-axis mobile applications, such as a tilt-compensated electronic compass, gaming controllers, augmented reality applications and similar applications which require reliable and precise 3-axis magnetometric measurement.

Downloads

Le GeoMagnetic Click Board™ est un Click Board™ magnétométrique numérique capable de mesurer le champ géomagnétique sur trois axes perpendiculaires. Le capteur embarqué utilise FlipCore, une technologie exclusive de Bosch, qui permet d'obtenir des performances soigneusement réglées, adaptées aux applications mobiles à 3 axes exigeantes, telles qu'une boussole électronique à compensation d'inclinaison, des contrôleurs de jeu, des applications de réalité augmentée et des applications similaires qui nécessitent une mesure magnétométrique à 3 axes fiable et précise.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2935

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018712595

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.