Overview

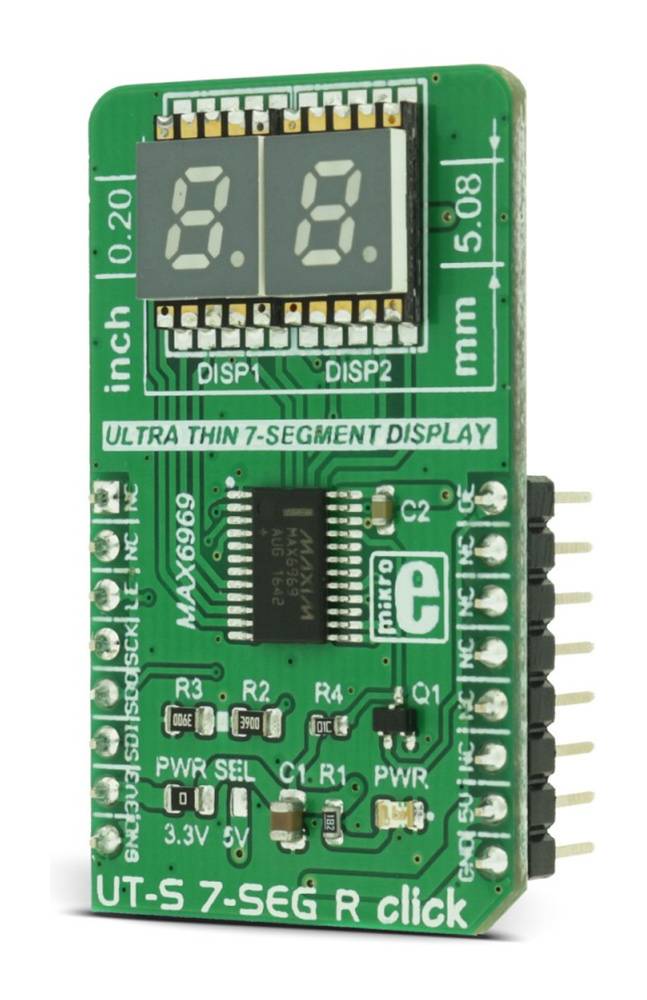

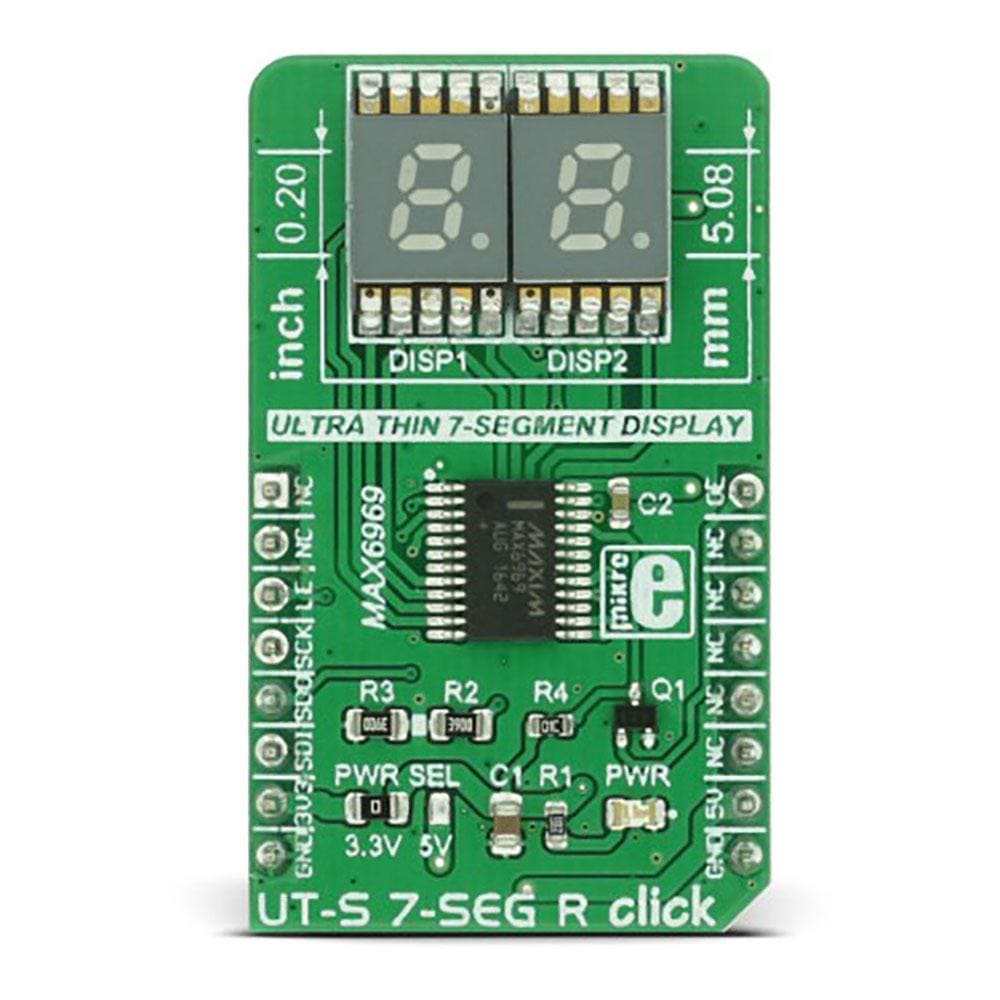

The UT-S 7 Seg R Click Board™ uses two SMD ultra-thin DSM7UA20101 7-SEG LED displays, made with the patented technology that delivers a thickness of only 2.1 mm. These displays are driven by the MAX6969, a constant current LED integrated driver from Maxim Integrated, which uses the SPI serial interface for communication and delivers a steady and constant power source for the LED segments.

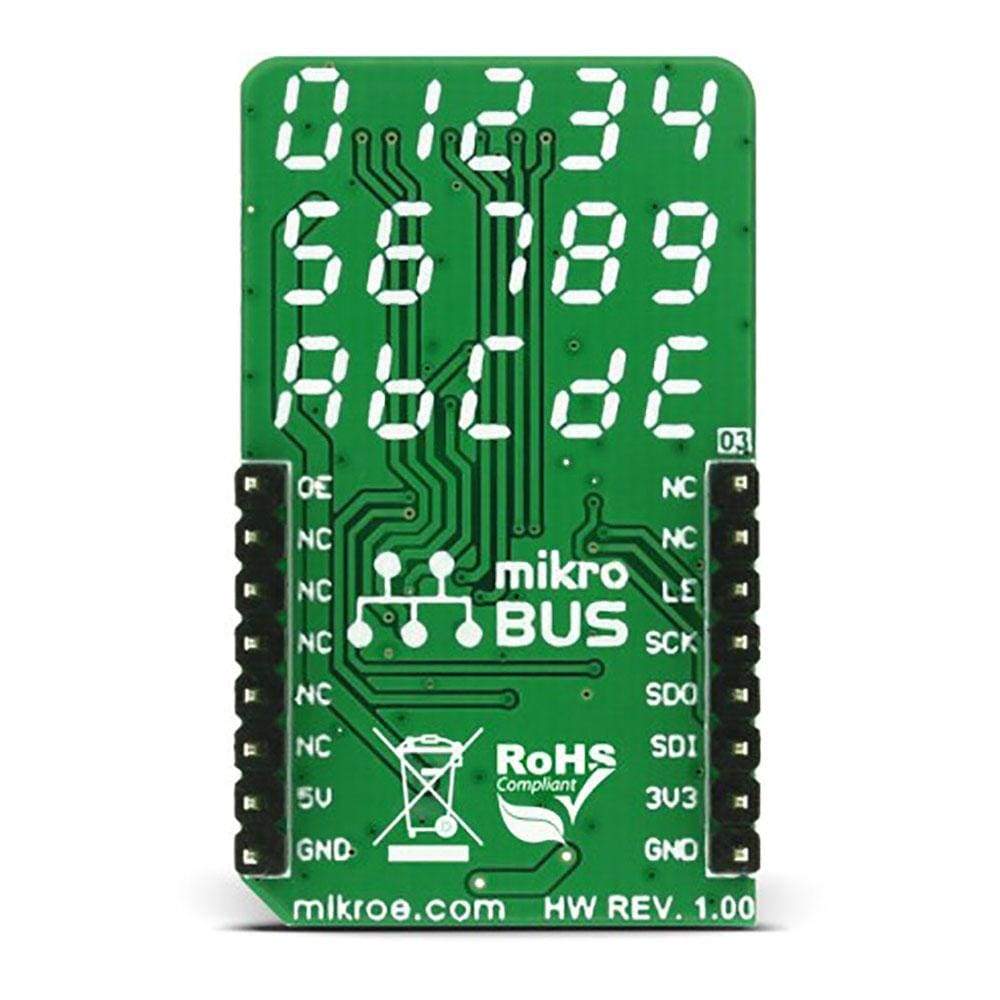

7-segment LED display is the most commonly used type of display to represent changing numerical values. The principle is very simple - seven LED segments are positioned in a certain shape and by turning specific segments on or off, the shape that resembles a specific number is lit. This method of displaying numbers was first used in the beginning of the 20th century, but after the invention of the LED in ‘70, it is the most commonly used method to display numbers. It utilizes a fairly simple and cheap design with the numbers clearly visible. Be it a clock on the nightstand, a billboard at the airport, a gauge on some machine, a panel on some instrument or a display on the pump at the gas station - the numbers will be always easy to see and read, even in the dark.

Downloads

Le UT-S 7 Seg R Click Board™ utilise deux écrans LED SMD ultra-minces DSM7UA20101 7-SEG, fabriqués avec la technologie brevetée qui offre une épaisseur de seulement 2,1 mm. Ces écrans sont pilotés par le MAX6969, un pilote LED intégré à courant constant de Maxim Integrated, qui utilise l'interface série SPI pour la communication et fournit une source d'alimentation stable et constante pour les segments LED.

L'affichage LED à 7 segments est le type d'affichage le plus couramment utilisé pour représenter des valeurs numériques changeantes. Le principe est très simple : sept segments LED sont positionnés dans une certaine forme et en allumant ou en éteignant des segments spécifiques, la forme qui ressemble à un nombre spécifique s'allume. Cette méthode d'affichage des nombres a été utilisée pour la première fois au début du 20e siècle, mais après l'invention de la LED en 1970, c'est la méthode la plus couramment utilisée pour afficher les nombres. Elle utilise une conception assez simple et bon marché avec les chiffres clairement visibles. Qu'il s'agisse d'une horloge sur la table de nuit, d'un panneau d'affichage à l'aéroport, d'une jauge sur une machine, d'un panneau sur un instrument ou d'un affichage sur la pompe de la station-service, les chiffres seront toujours faciles à voir et à lire, même dans l'obscurité.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2840

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018712052

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.