Overview

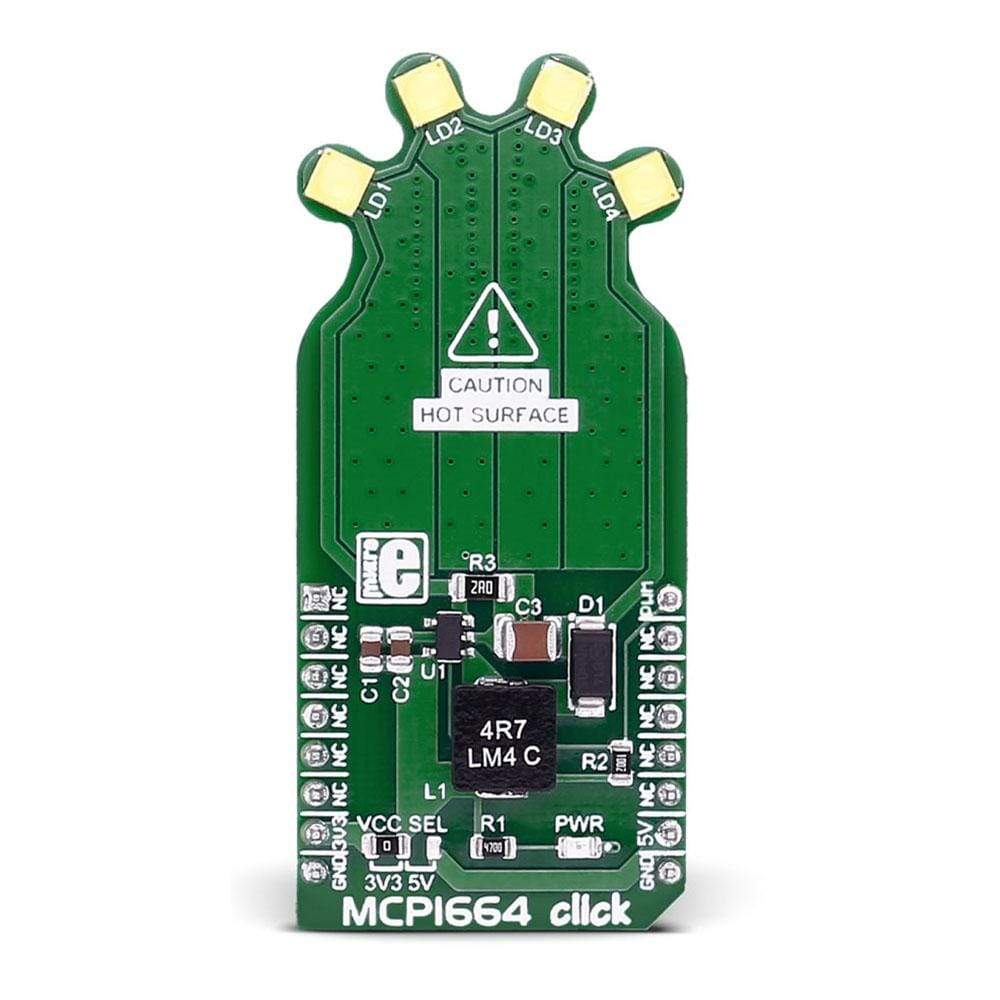

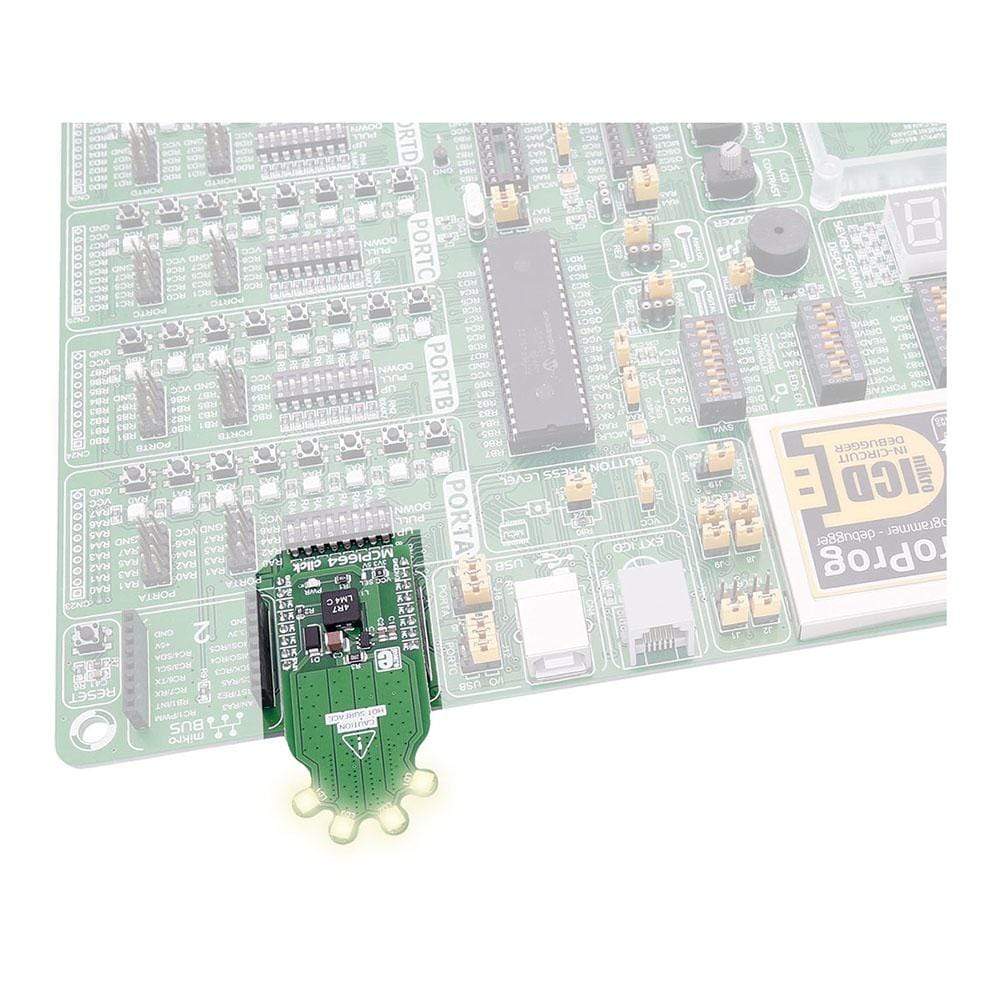

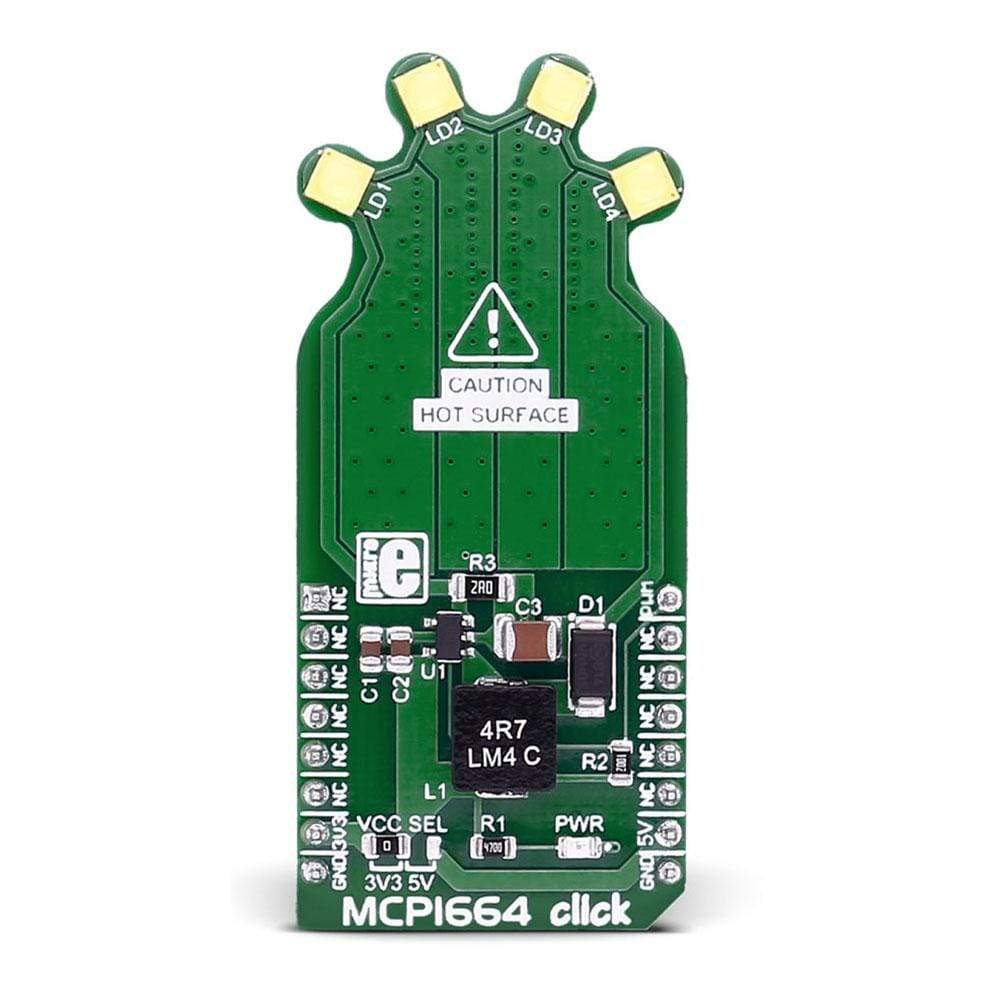

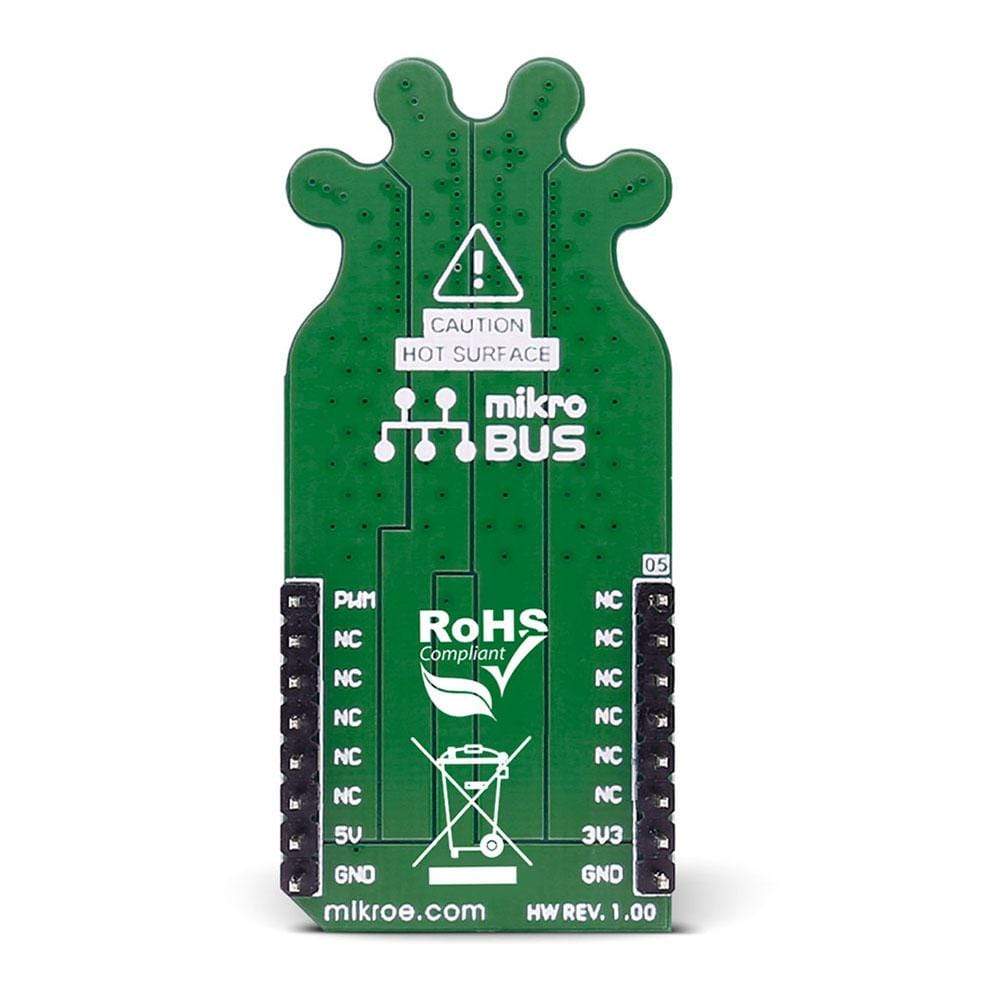

The MCP1664 Click Board™ contains 4 high-power white LEDs. It carries the MCP1664, a high-voltage step-up LED driver from Microchip.

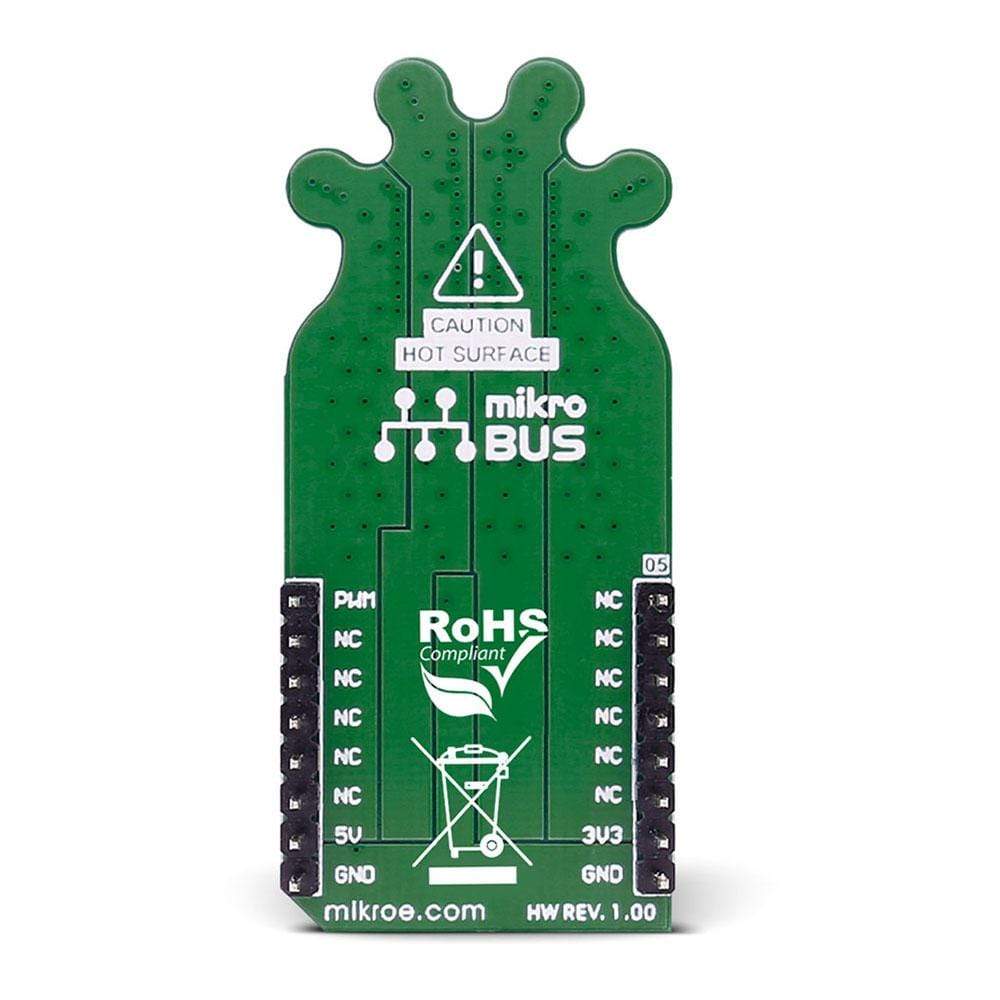

The MCP1664 Click Board™ is designed to run on either 3.3V or 5V power supply. It communicates with the target board microcontroller over the PWM pin on the MikroBUS lines.

Downloads

Le MCP1664 Click Board™ contient 4 LED blanches haute puissance. Il est équipé du MCP1664, un pilote LED élévateur haute tension de Microchip.

La carte Click Board™ MCP1664 est conçue pour fonctionner sur une alimentation de 3,3 V ou 5 V. Elle communique avec le microcontrôleur de la carte cible via la broche PWM sur les lignes MikroBUS.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2548

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.021 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018710546

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.