Overview

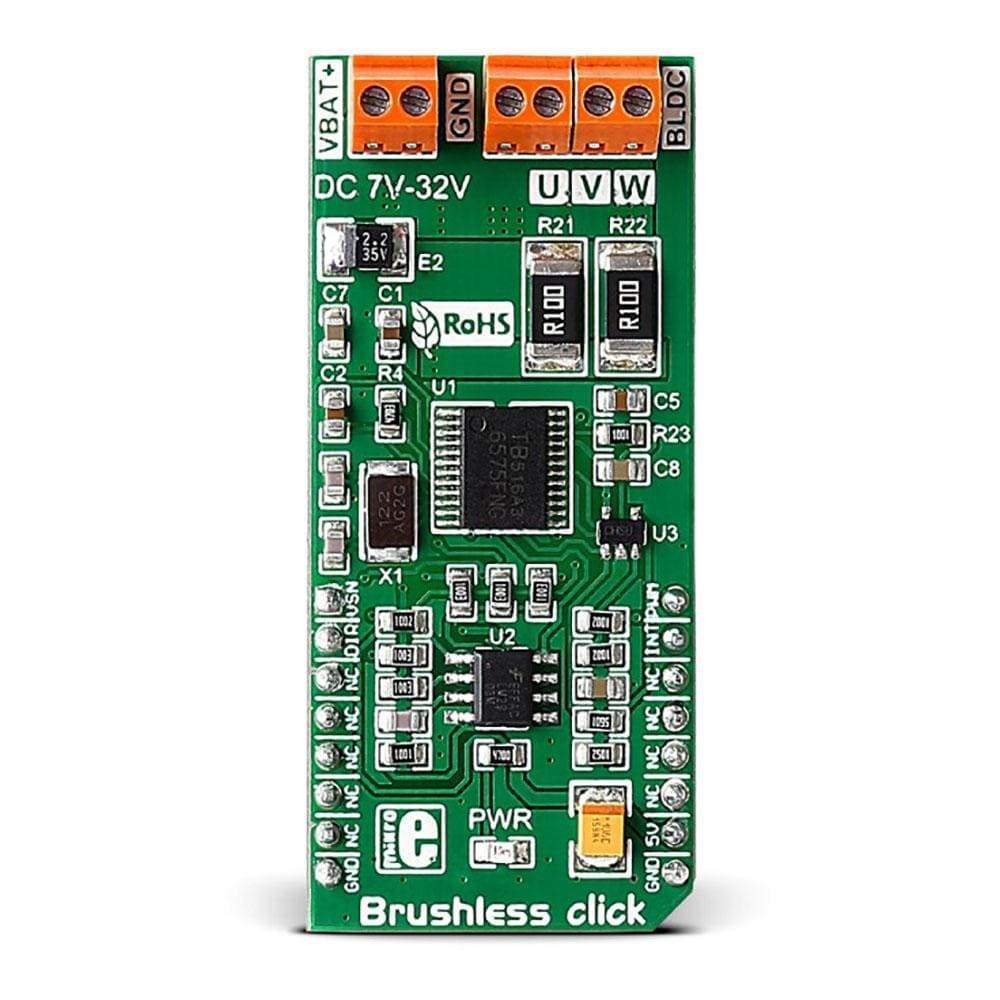

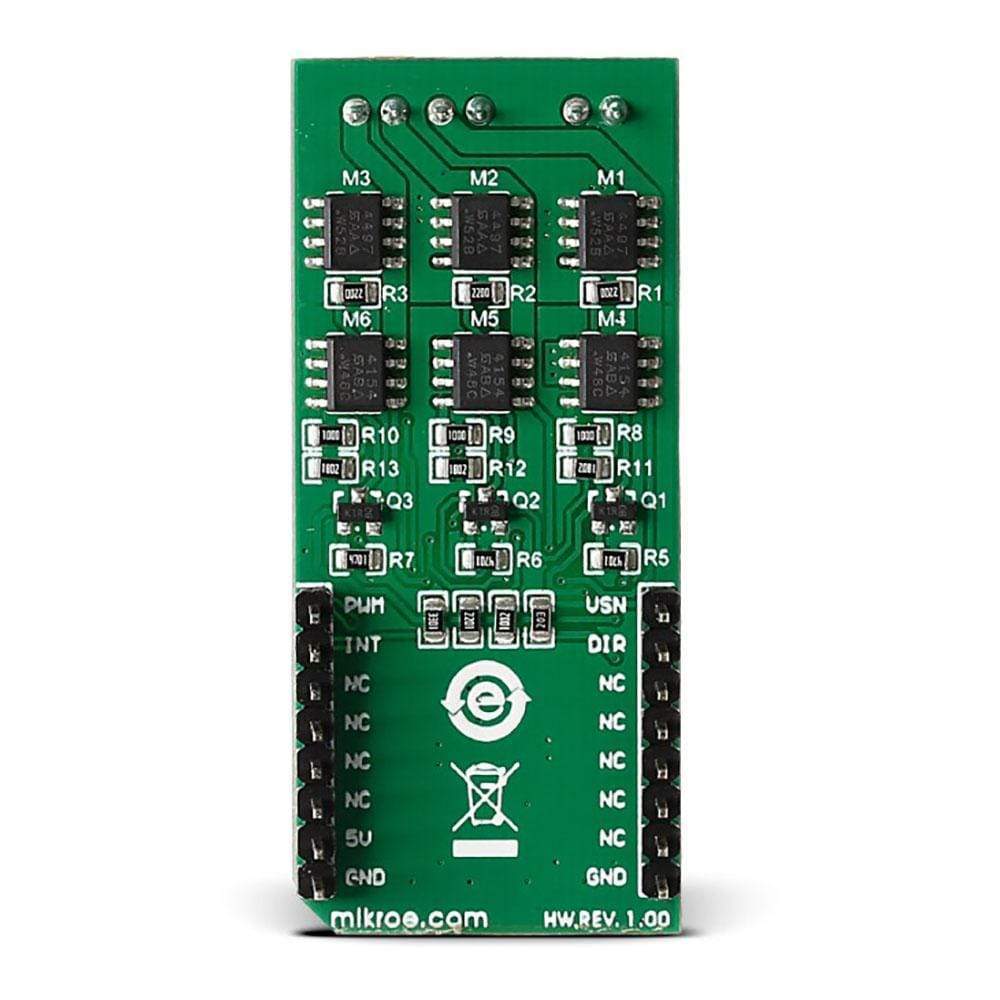

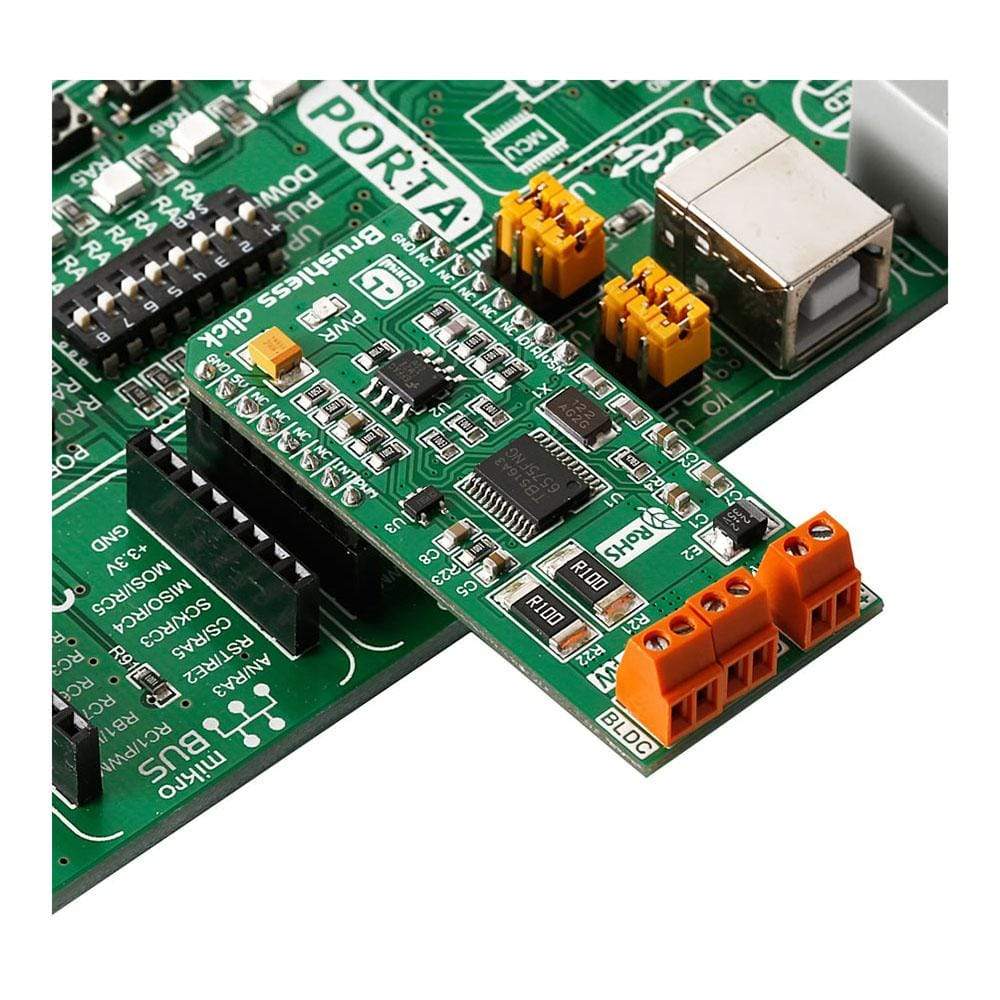

The Brushless Click Board™ carries Toshiba's TB6575FNG IC for driving 3-phase full-wave Brushless DC motors ' which are ideal for powering flying drones.

Downloads

La carte Brushless Click Board™ intègre le circuit intégré TB6575FNG de Toshiba pour piloter des moteurs à courant continu sans balais triphasés à onde complète, idéaux pour alimenter des drones volants.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2441

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.019 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606015079271

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.