Overview

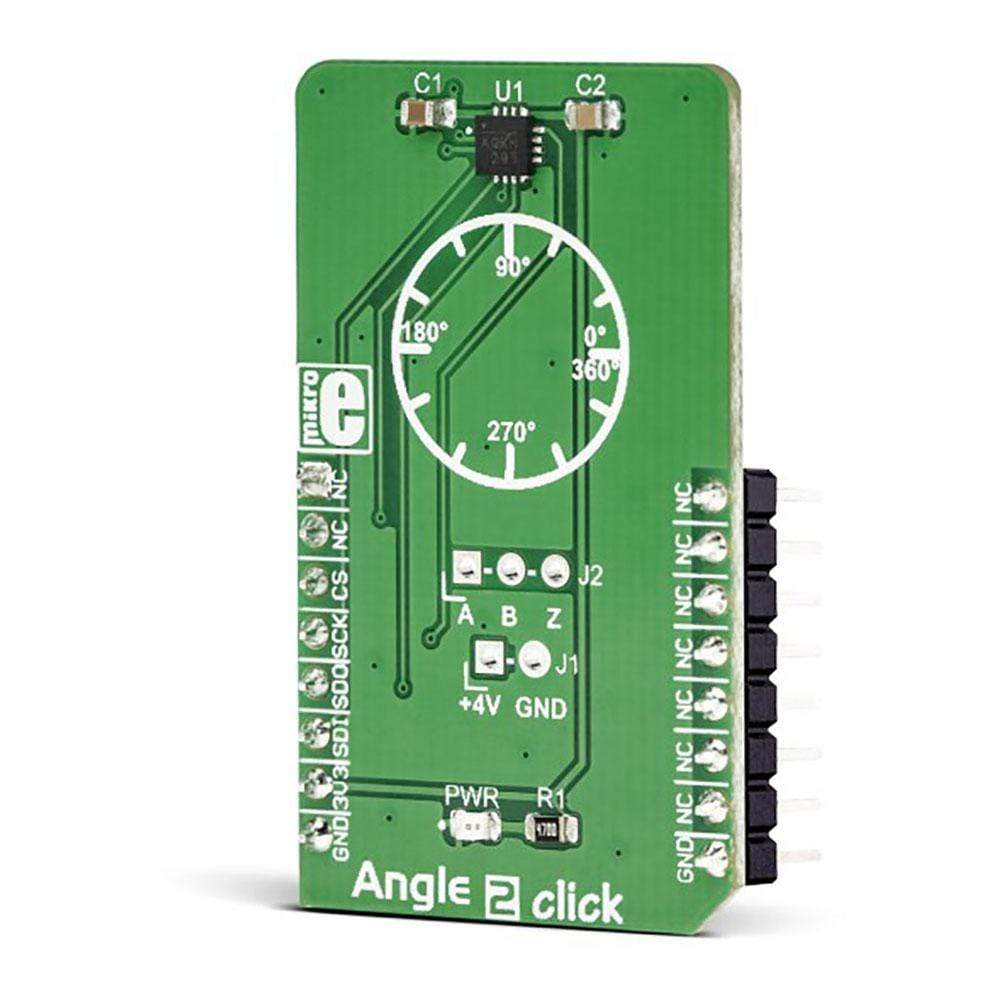

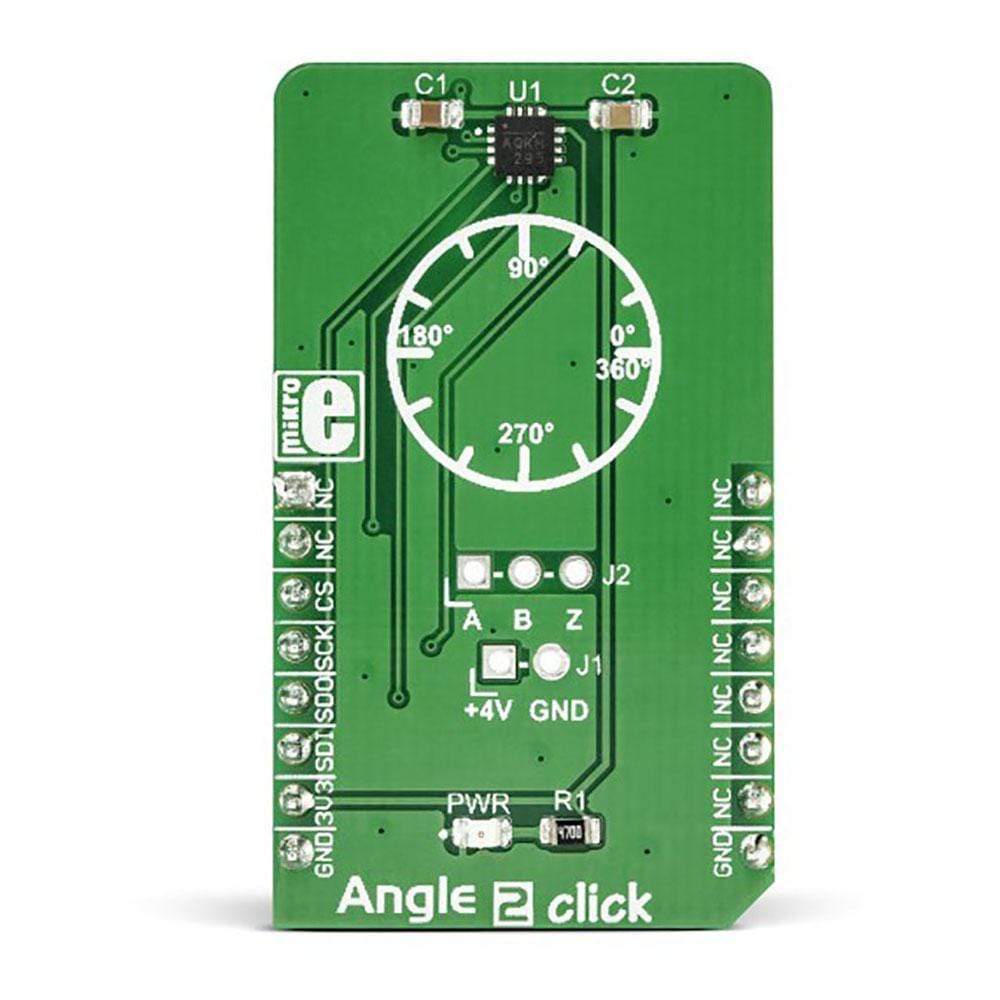

The Angle 2 Click Board™ is a magnetic rotational sensor that relies on the ultra-fast MA700 angular sensor IC. Due to a high data output rate of 500kHz, the MA700 IC is able to provide reliable absolute angular positional data at speeds up to 100,000 RPM. This can be achieved by utilizing the advanced Spinaxis technology based on a direct angle sampling approach, instead of using the extensive arctangent computations and other similar solutions. This also allows for relaxed mechanical tolerances, allowing even the off-axis magnetic field to be used.

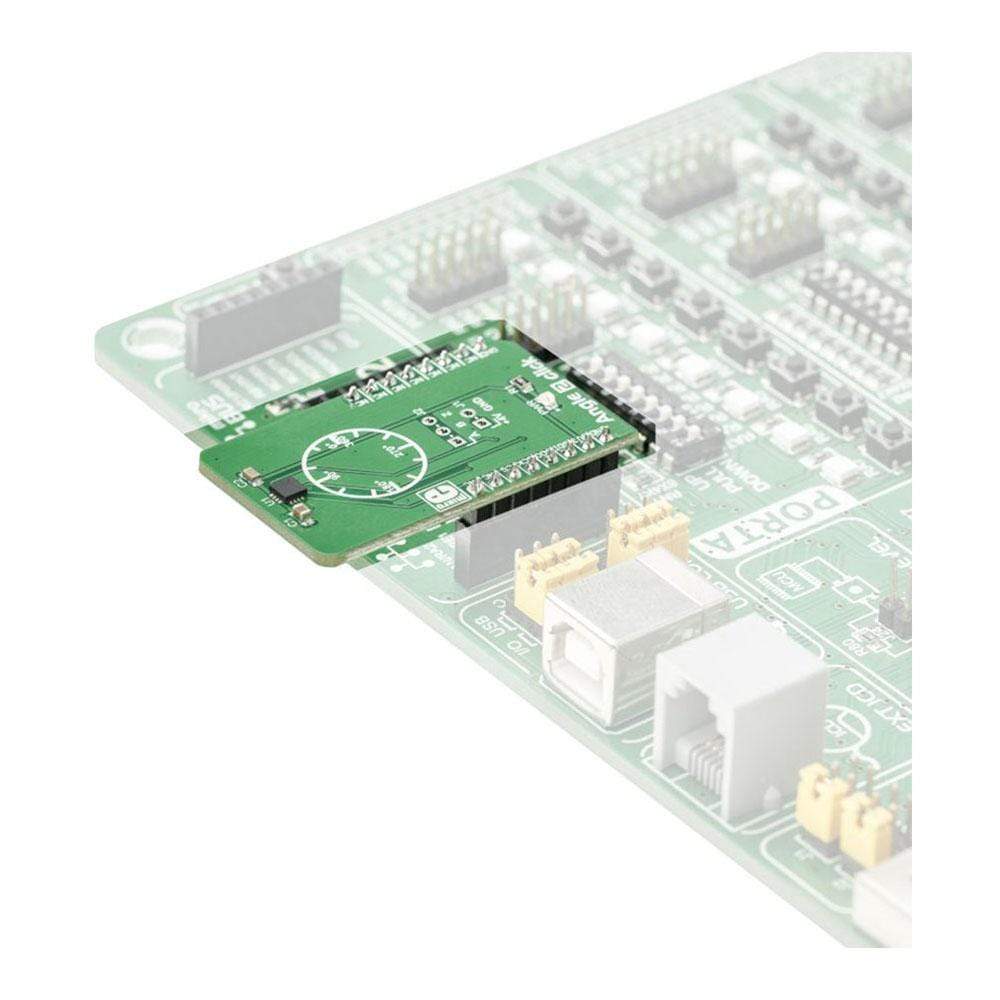

It comes in a package that also includes the mikroSDK software and a library with all the functions. The Click Board™ comes as a fully tested and approved prototype, making it a reliable device ready to use on the development board.

Downloads

Le capteur Angle 2 Click Board™ est un capteur rotatif magnétique qui s'appuie sur le circuit intégré de capteur angulaire ultra-rapide MA700. Grâce à un taux de sortie de données élevé de 500 kHz, le circuit intégré MA700 est capable de fournir des données de position angulaire absolues fiables à des vitesses allant jusqu'à 100 000 tr/min. Cela peut être réalisé en utilisant la technologie avancée Spinaxis basée sur une approche d'échantillonnage d'angle direct, au lieu d'utiliser les calculs d'arctangente extensifs et d'autres solutions similaires. Cela permet également d'assouplir les tolérances mécaniques, ce qui permet même d'utiliser le champ magnétique hors axe.

Il est livré dans un package comprenant également le logiciel mikroSDK et une bibliothèque avec toutes les fonctions. Le Click Board™ est livré sous la forme d'un prototype entièrement testé et approuvé, ce qui en fait un appareil fiable prêt à être utilisé sur la carte de développement.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2338

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018713936

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.