Overview

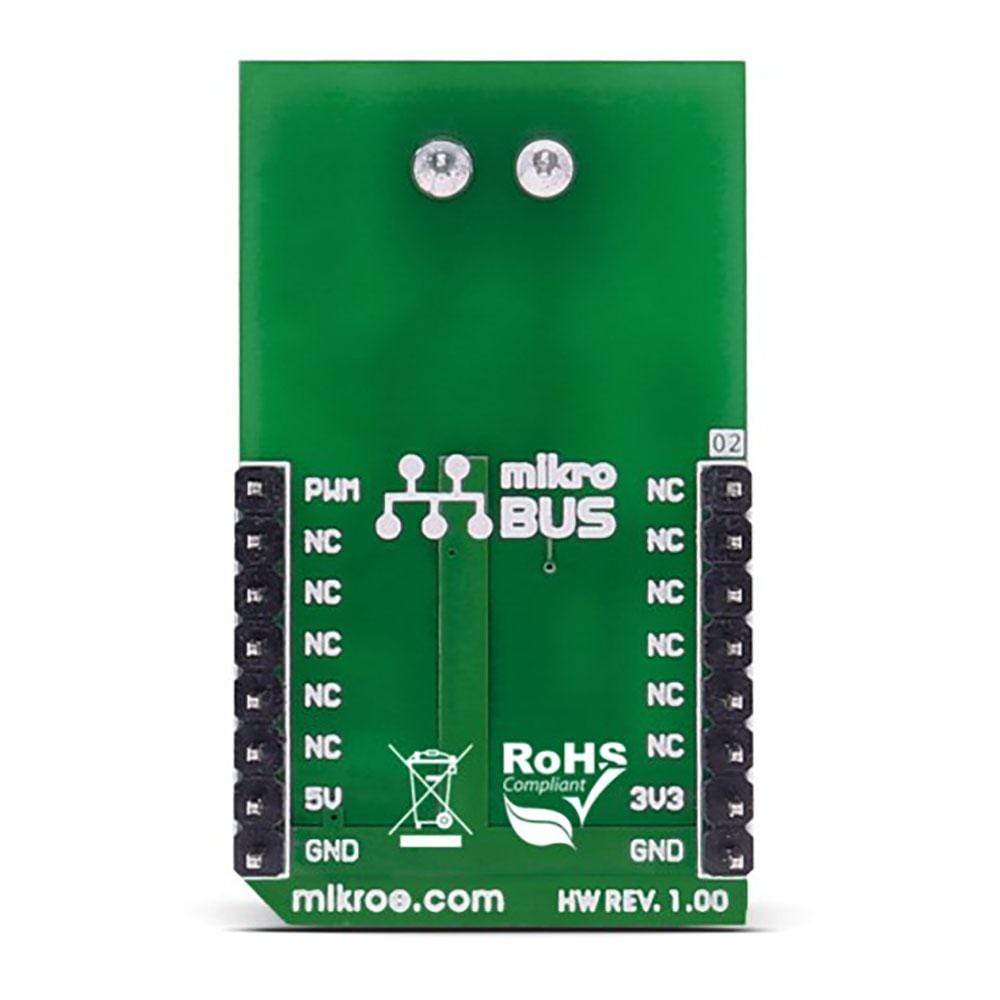

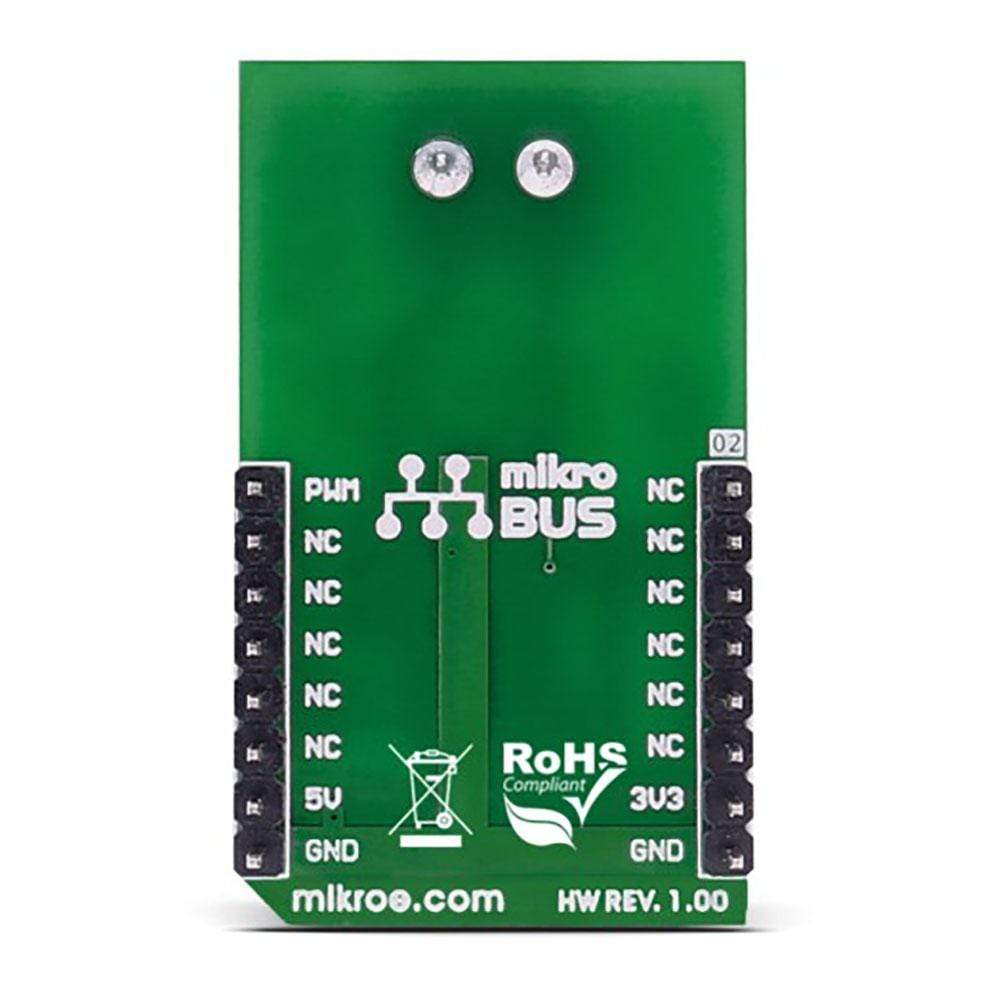

The LED Driver Click Board™ is based on the MCP1662 high-voltage step-up voltage driver from Microchip. The Click Board™ is designed to run on either 3.3V or 5V power supply. It communicates with the target microcontroller over PWM pin on the MikroBUS line.

Downloads

Le LED Driver Click Board™ est basé sur le driver de tension élévateur haute tension MCP1662 de Microchip. Le Click Board™ est conçu pour fonctionner sur une alimentation 3,3 V ou 5 V. Il communique avec le microcontrôleur cible via la broche PWM de la ligne MikroBUS.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2676

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.021 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018710867

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.