Overview

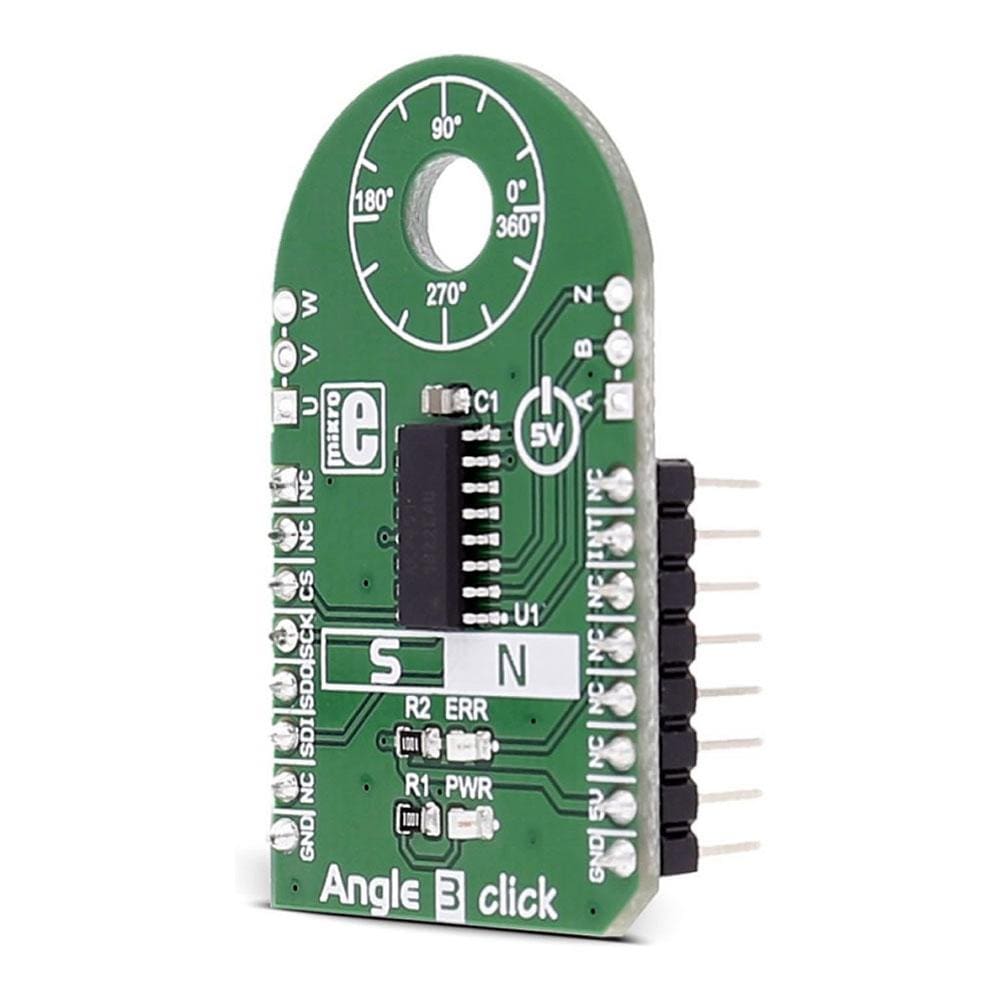

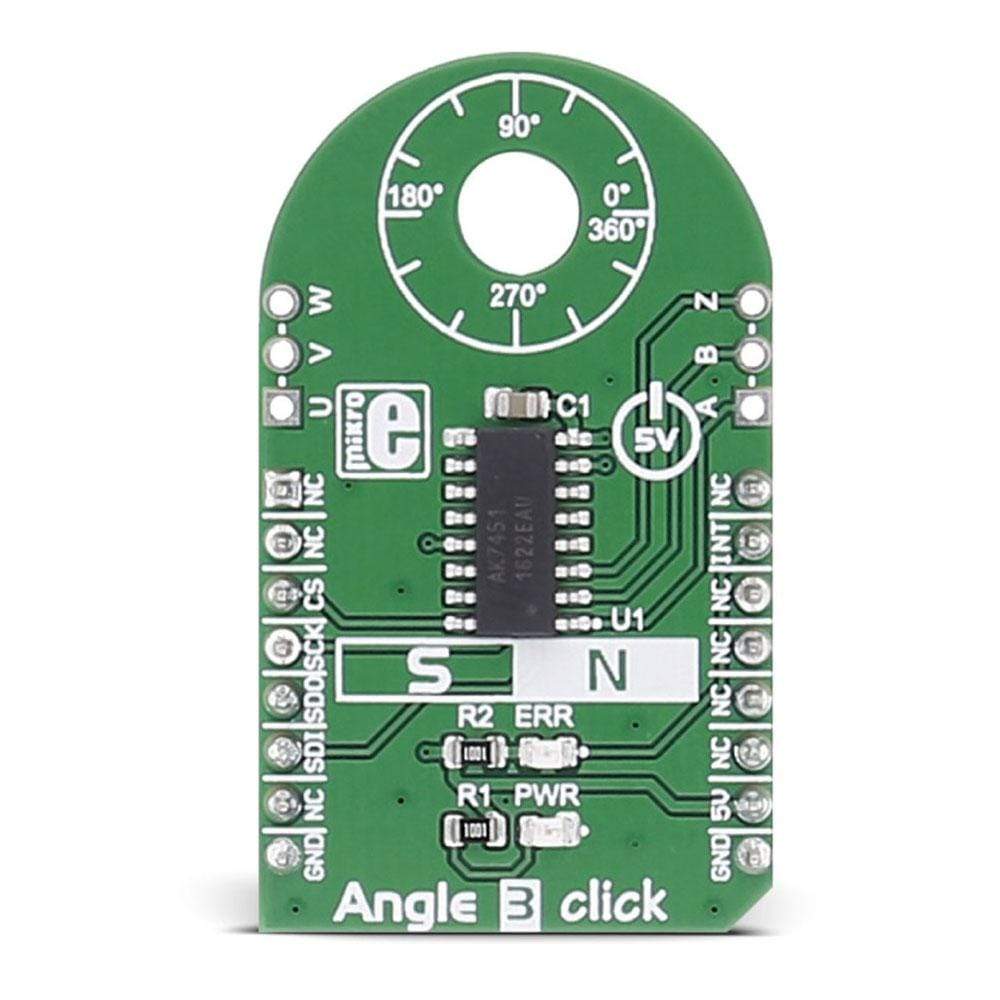

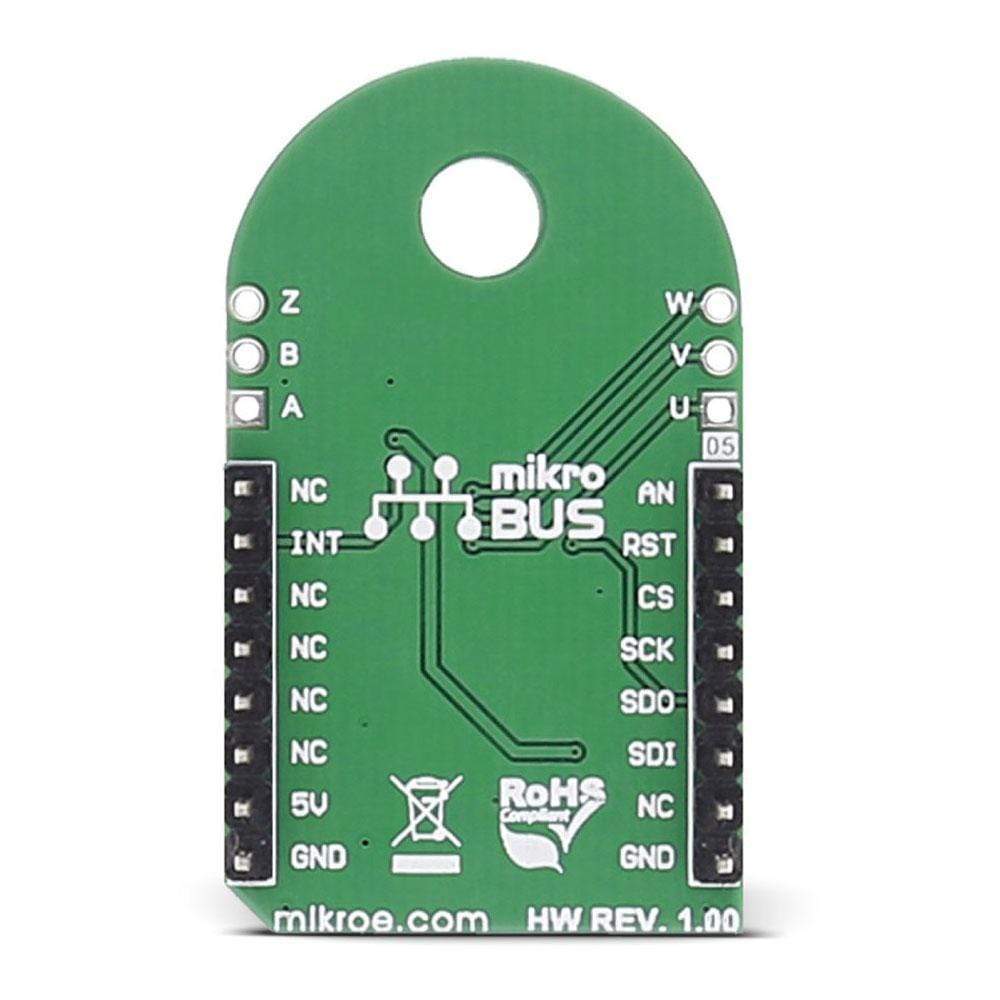

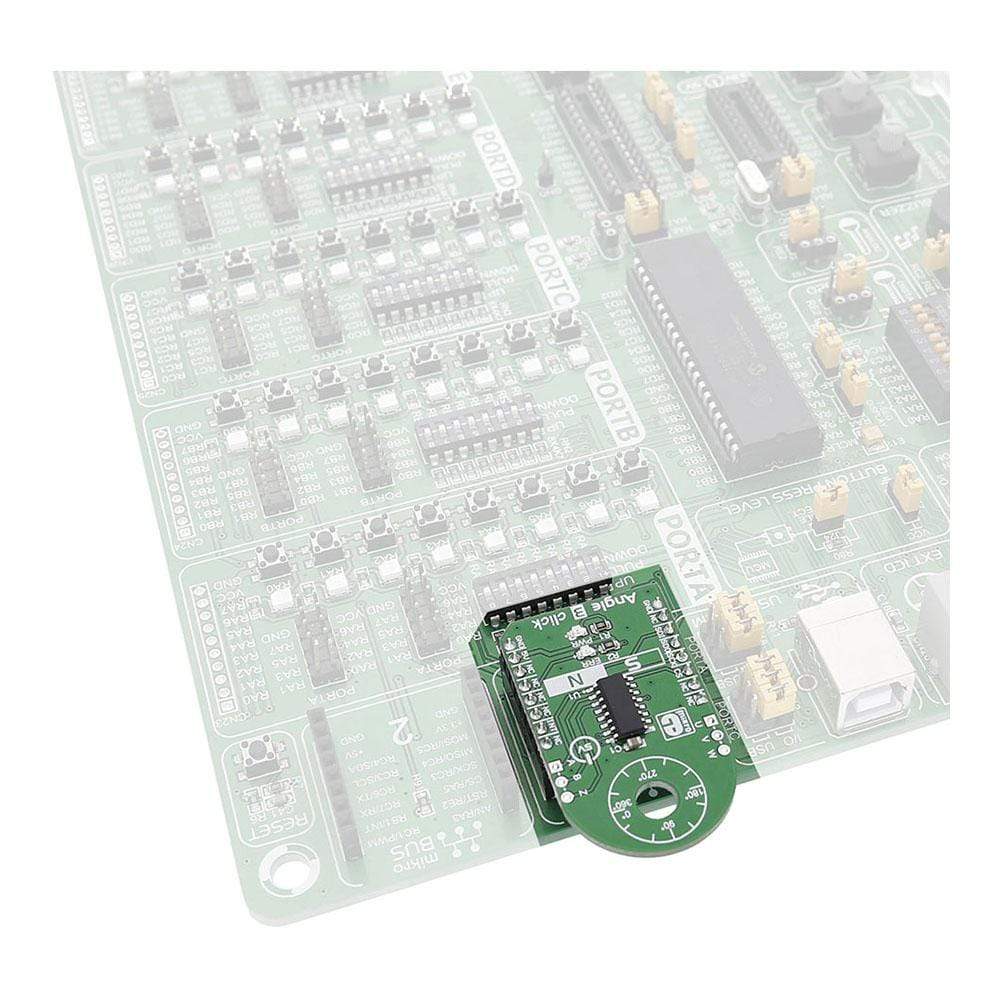

The Angle 3 Click Board™ carries the AK7451, a magnetic rotational angle sensor. The Click Board™ is designed to run on a 5V power supply.

It communicates with the target microcontroller over SPI interface, with additional functionality provided by the INT pin on the MikroBUSline.

Downloads

Le Click Board™ Angle 3 est équipé du capteur d'angle de rotation magnétique AK7451. Le Click Board™ est conçu pour fonctionner sur une alimentation 5 V.

Il communique avec le microcontrôleur cible via l'interface SPI, avec des fonctionnalités supplémentaires fournies par la broche INT sur la ligne MikroBUS.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2755

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018711420

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.