Key Features

Overview

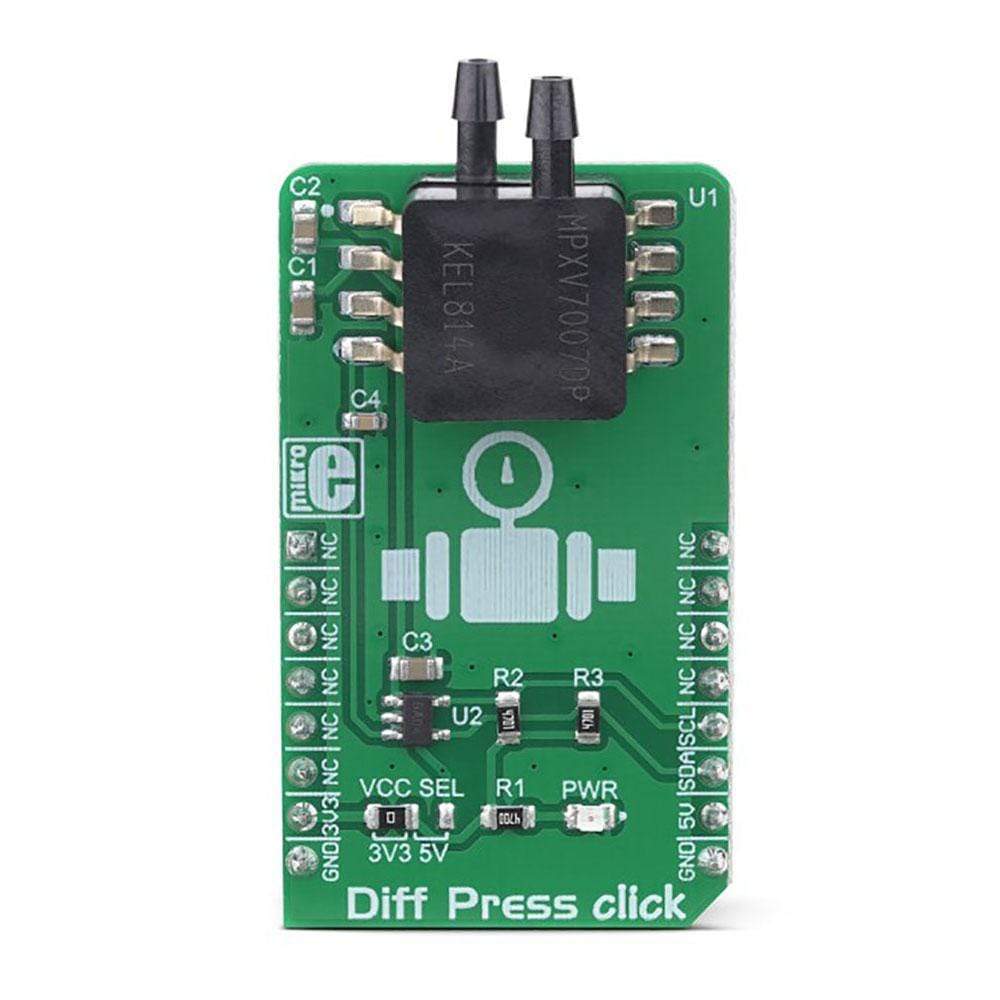

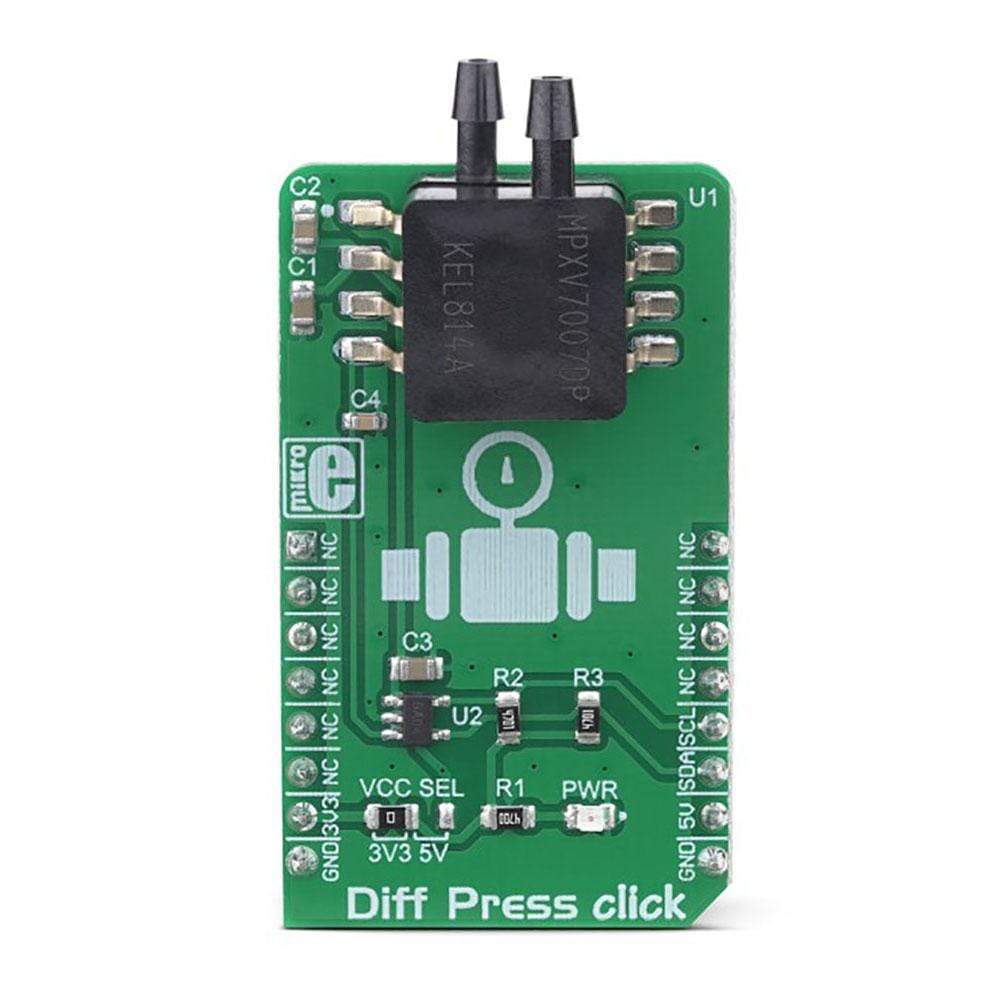

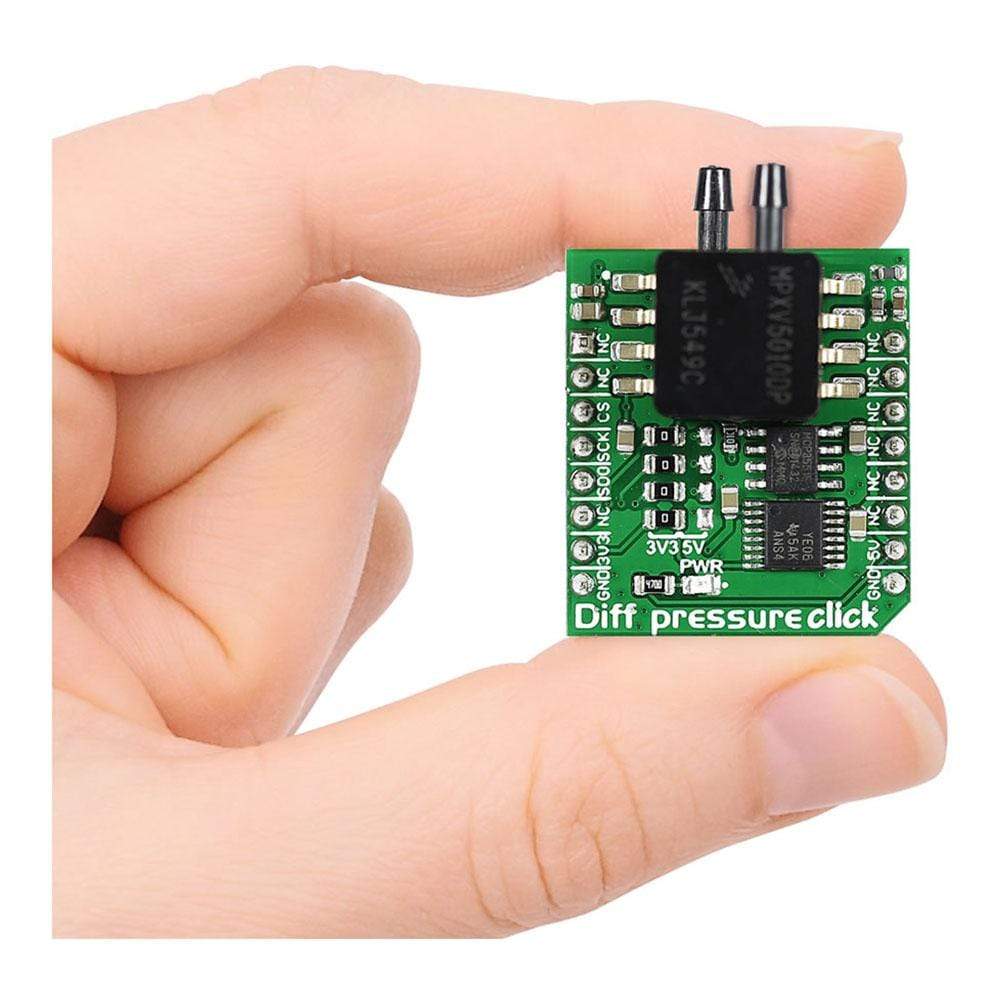

The Diff Press Click Board™ is an accurate pressure sensor Click Board™ capable of measuring differential pressure. This Click Board™ utilizes a very precise differential pressure sensor from NXP, labelled as MPXV7007DP. This piezo-resistive transducer is an advanced monolithic pressure sensor, combining advanced MEMS manufacturing technologies with on-chip signal processing, providing accurate measurement with very low drift over temperature. The sensor outputs an analogue voltage, linearly dependent on the applied pressure. This voltage is digitized by an accurate A/D converter and delivered over the I2C interface.

Downloads

The MPXV7007DP sensor is shaped so two small tubes can be attached to it, simplifying its practical application. This makes the Diff Press Click Board™ an ideal solution for monitoring the pressure in different kinds of HVAC applications, hospital beds, respiratory systems, process control, and similar applications which rely on an accurate and reliable pressure monitoring.

How Does The Diff Press Click Board™ Work?

The Diff Press Click Board™ utilizes a highly advanced, integrated monolithic differential pressure sensor, labelled as MPXV7007DP, from NXP. This sensor features piezo-resistive MEMS sensing element, combined with the integrated electronic components that allow it to achieve a high degree of linearity, as well a very low drift over temperature. It can be used to measure the differential pressure within the range of ±7kPa. The casing of the sensor contains two small tubes referred to as "ports" in the datasheet. They can be used to easily interface the sensor with various components which produce gas pressure, preventing leakage that might appear if the sealing is not good enough. The sensor is guaranteed to operate according to specifications only if used in dry air conditions. Please refer to the datasheet of the MPXV7007DP for more details.

The MPXV7007DP sensor has two ports in a form of two tubes for simplified attachment to a pressurized system, as already discussed. One of these ports is designated as the Pressure side, while the other one is designated as the Vacuum side. The Pressure side is protected by a fluoro-silicone gel which protects the die from harsh media. However, the sensor is designed to be used with both positive and negative differential pressure values, depending on the application requirements (P1 > P2 or P2 > P1).

The sensor outputs half the maximum output voltage when there is no pressure difference between two input ports. As the difference increases, the voltage either decreases down to 0V (-7kPa) or increases up to its maximum value of 4.5V, typically (+7kPa). The internal calibration and a signal conditioning circuit ensure that the output voltage changes linearly with the pressure difference. The MPXV7007DP datasheet offers a graphic diagram, displaying the output voltage in respect to the pressure difference. Besides the diagram, the datasheet also offers the transfer function for the sensor output voltage, in a form of an equation. All the parameters can be found within the datasheet, if a precise calculation of the pressure is required.

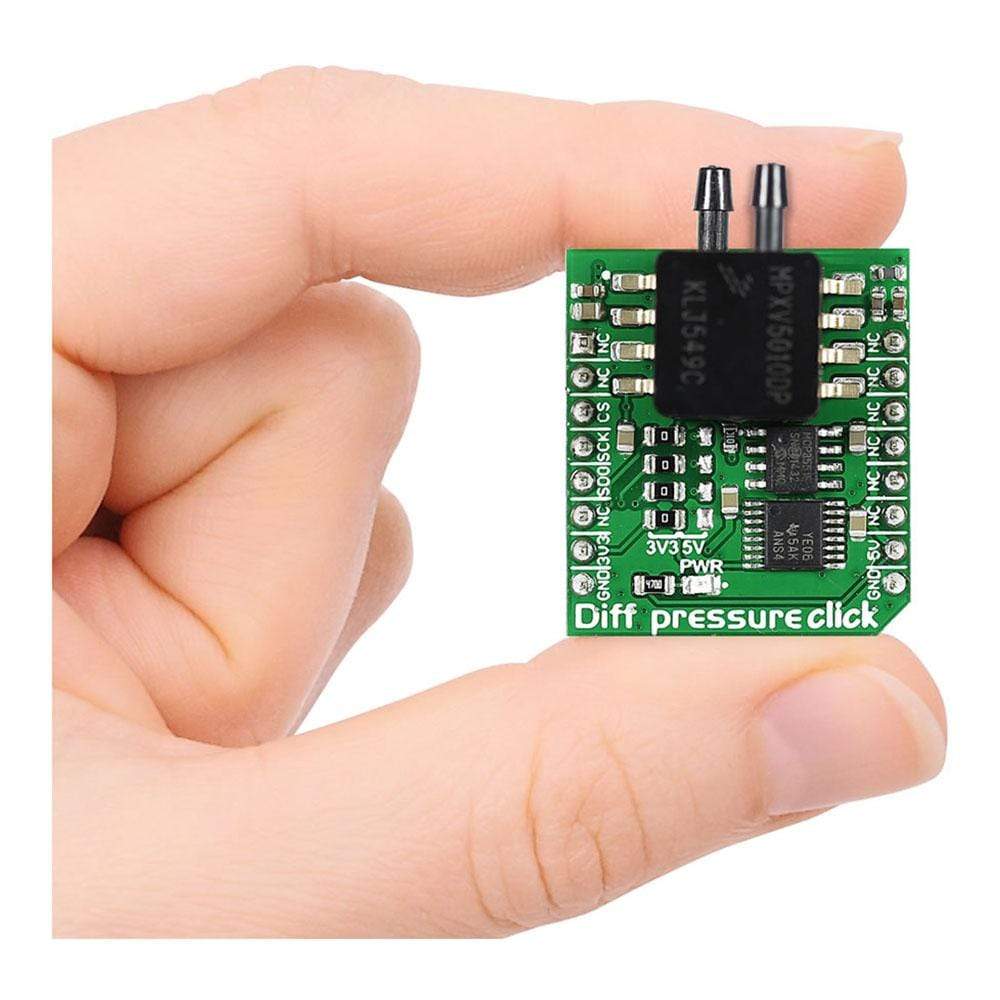

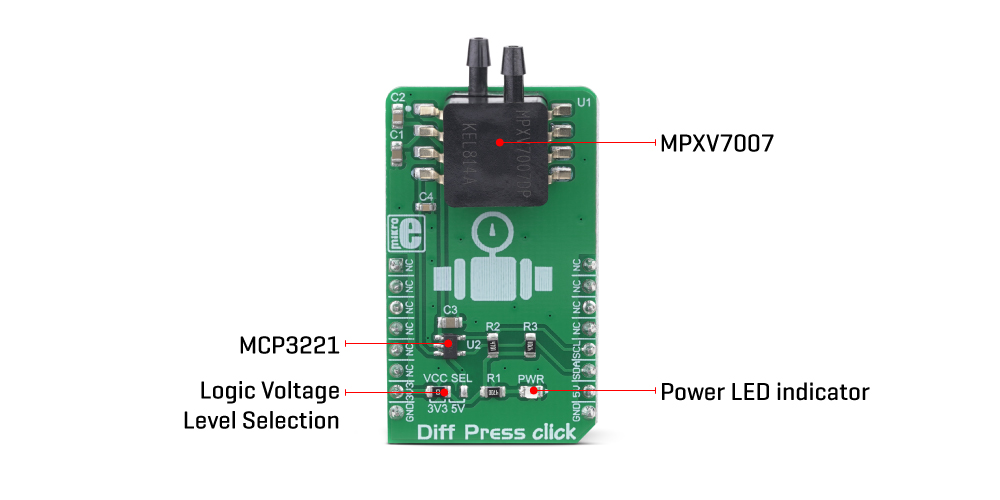

Besides the MPXV7007DP, Diff Press click utilizes an additional IC. It uses the MCP3221, a 12-bit successive approximation A/D converter (ADC) with I2C Interface, from Microchip. It is used to sample the output voltage from the sensor, providing data for the microcontroller (MCU) or some other device capable of communicating over the I2C bus. The voltage is sampled to a 12-bit value using the 5V mikroBUS™ rail as the voltage reference. The relation between the ADC value and the voltage on the output pin is given by the formula: VOUT = 5/4096 x VAL

Where VOUT is the output voltage of the sensor and VAL is the 12-bit ADC value. However, the Click board™ is supplied with the mikroSDK library which contains functions for data conversion, providing readings in physical units.

Two resistors are used to pull up I2C bus lines. An onboard jumper labelled as VCC SEL offers selection of the I2C communication voltage level by connecting these resistors either with 3.3V or 5V mikroBUS™ rail. This jumper can be used to interface the Diff Press Click Board™ with both 3.3V and 5V MCUs, allowing a wide range of different MCUs to be used with the Click board™.

SPECIFICATIONS

| Type | Pressure |

| Applications | The Diff Press Click Board™ is an ideal solution for monitoring the pressure in different kinds of HVAC applications, hospital beds, respiratory systems, process control, and similar applications which rely on an accurate and reliable pressure monitoring. |

| On-board modules | MPXV7007DP, an integrated monolithic differential pressure sensor, from NXP; MCP3221, a 12bit D/A converter with I2C Interface, from Microchip |

| Key Features | High measurement accuracy, low drift over temperature, specially designed inlet ports for simplified use, very linear measurement readings available in 12-bit format over the I2C interface, etc. |

| Interface | I2C |

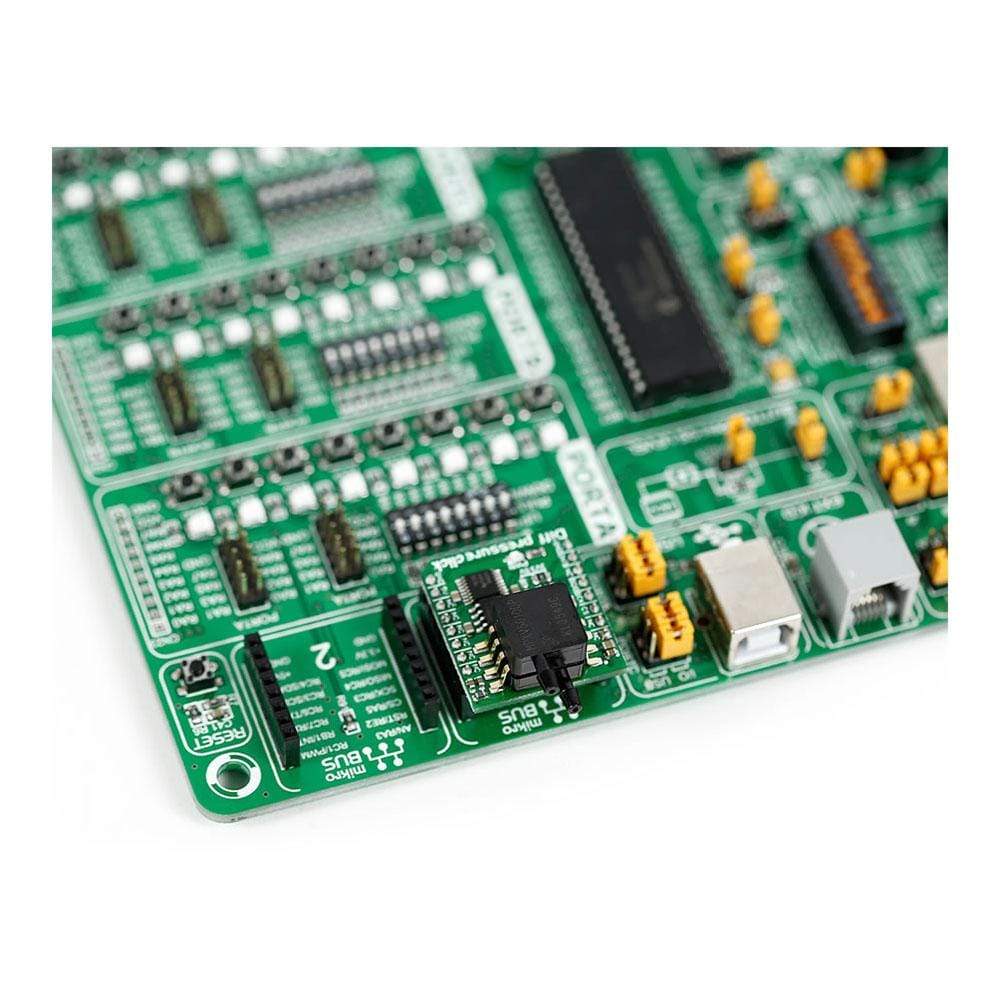

| Compatibility | mikroBUS |

| Click board size | M (42.9 x 25.4 mm) |

| Input Voltage | 3.3V or 5V |

PINOUT DIAGRAM

This table shows how the pinout of the Diff Press Click Board™ corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | NC | ||

| NC | 2 | RST | INT | 15 | NC | ||

| NC | 3 | CS | RX | 14 | NC | ||

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | SCL | I2C Clock | |

| NC | 6 | MOSI | SDA | 11 | SDA | I2C Data | |

| Power Supply | 3V3 | 7 | 3.3V | 5V | 10 | 5V | Power Supply |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

ONBOARD SETTINGS AND INDICATORS

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED indicator |

| JP2 | VCC SEL | Left | Logic voltage level selection: left position 3.3V, right position 5V |

DIFF PRESS CLICK ADDITIONAL SPECIFICATIONS

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Pressure range | -7 | - | 7 | kPa |

| Sensitivity | - | 286 | - | mV/kPa |

| Accuracy (0 ˚C to 85 ˚C) | -5 | - | 5 | % |

| Warm-up time | - | 20 | - | ms |

| Operating temperature range | -40 | - | 125 | ˚C |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3332

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018714346

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.