Key Features

Overview

The ADC 5 Click Board™ is a device used to sample an analogue voltage on the input and convert it to digital information. In general, ADC (analogue to digital converters) are the most commonly used devices for converting the voltage signals into information, which can be then processed in the digital domain. There are many types of ADC converters commercially available. They can vary in bit depth, sample rate, used approximation algorithm (SAR, delta-sigma..) and so on. Those attributes affect how accurately the sampled voltage will be translated into the digital world.

Downloads

The features such as the low power consumption, two operational modes used to fine-tune the overall performance vs power consumption, consistency over a wide range of sampling frequencies, industry-standard SPI communication interface, make this device a perfect solution for using it in various applications which depend on linear and accurate analogue-to-digital conversion, such as the instrumentation and control applications, conversion of the analogue data from various sensors, remote data acquisition, and similar.

How Does The ADC 5 Click Board™ Work?

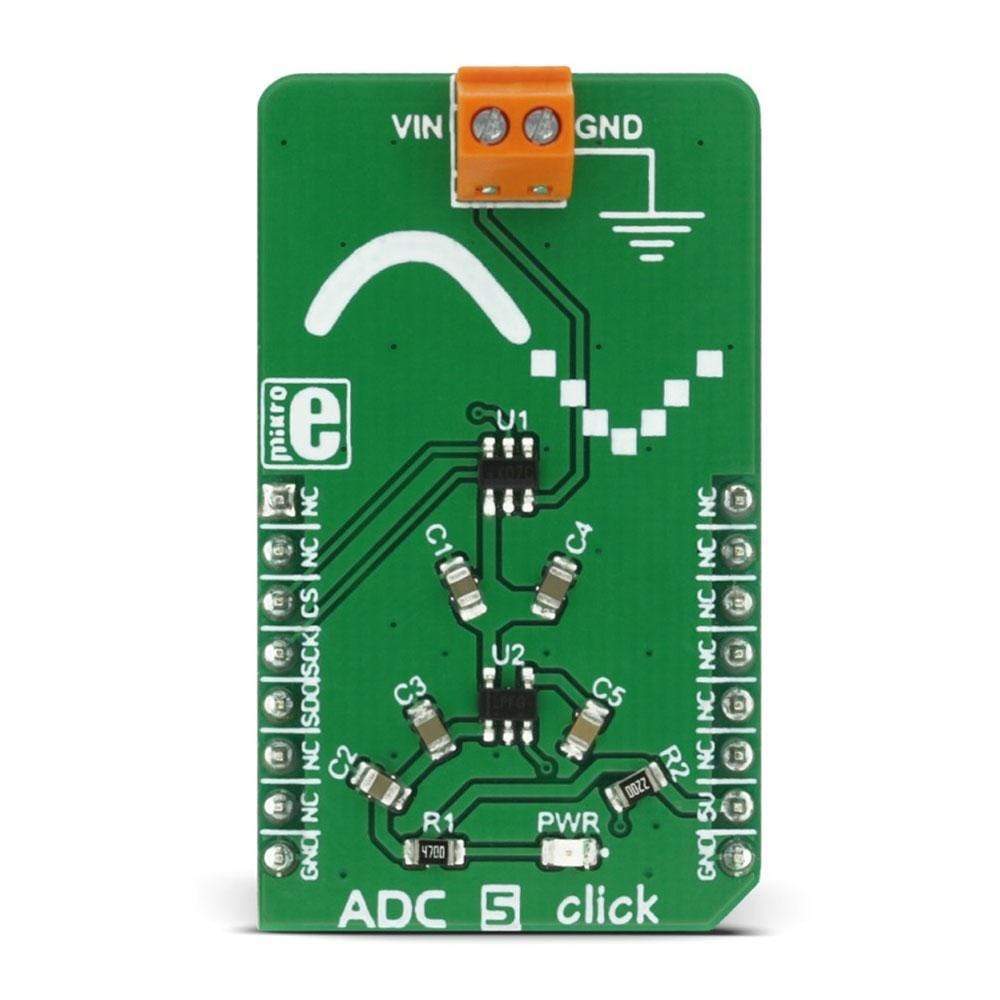

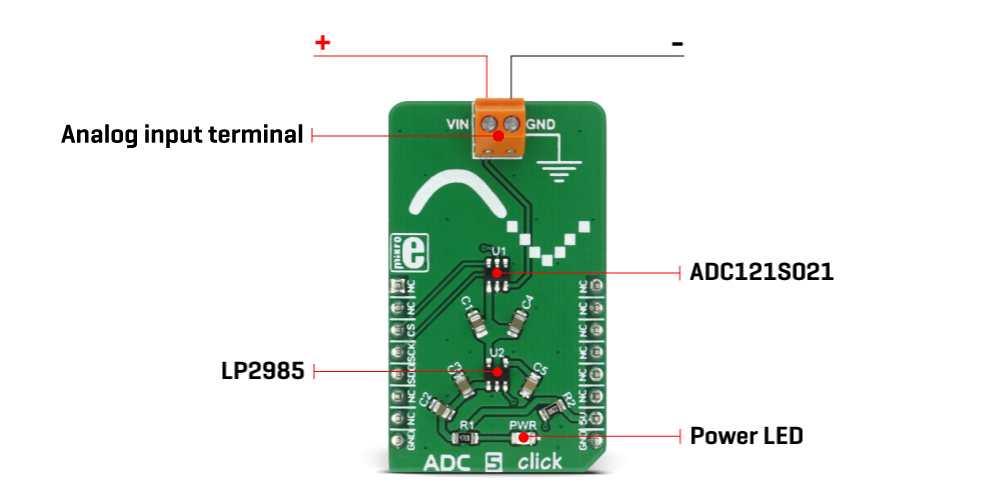

The ADC 5 Click Board™ is equipped with the ADC121S021, a 12-bit CMOS ADC device from Texas Instruments. This AD converter is using a reference voltage obtained from the LP2985 LDO regulator from the same company, which provides a clean and accurate regulated voltage on its output, perfectly suited to be used as the reference voltage for this converter. Since the reference voltage is set to 3.3V, the maximum value of the input voltage is also 3.3V.

The device uses SPI communication. The MOSI pin does not exist, since no communication from the MCU to the click board™ is going on. The reading speed, also known as the sample rate, directly depends on the clock rate of the SCK line. The sample rate over which the specified electrical performance is ensured is 50 Ks/s to 200 Ks/s. The ADC121S021 has the ability to use any clock signal frequency up to the rated maximum frequency, with no significant deviations from the specifications stated in the datasheet: it is specified over a wide range of sample rates, maintaining good linearity and high signal to noise ratio (SNR).

In general, ADC (analogue to digital converters) are the most commonly used devices for converting voltage signals into information, which can be then processed in the digital domain. There are many types of ADC converters commercially available. They can vary in bit depth, sample rate, used approximation algorithm (SAR, delta-sigma...) and so on. Those attributes affect how accurately the sampled voltage will be translated into the digital world.

The sample rate is usually the determining factor when the maximum frequency of the input signal is considered. The aliasing of the input signal can occur as the input signal frequency is nearing half the sample rate of the converter. The bandwidth of the input signal is limited by this frequency, also called the Nyquist frequency, so using input frequencies near or above the Nyquist frequency, results in a very inaccurate conversion.

The ADC121S021 AD converter uses the SAR, or the successive approximation method for the conversion, which consists of comparing the input voltage with a series of internally generated voltage values. At each step in this process, the approximation is stored in a successive approximation register. The comparing steps are continued until the desired resolution is reached.

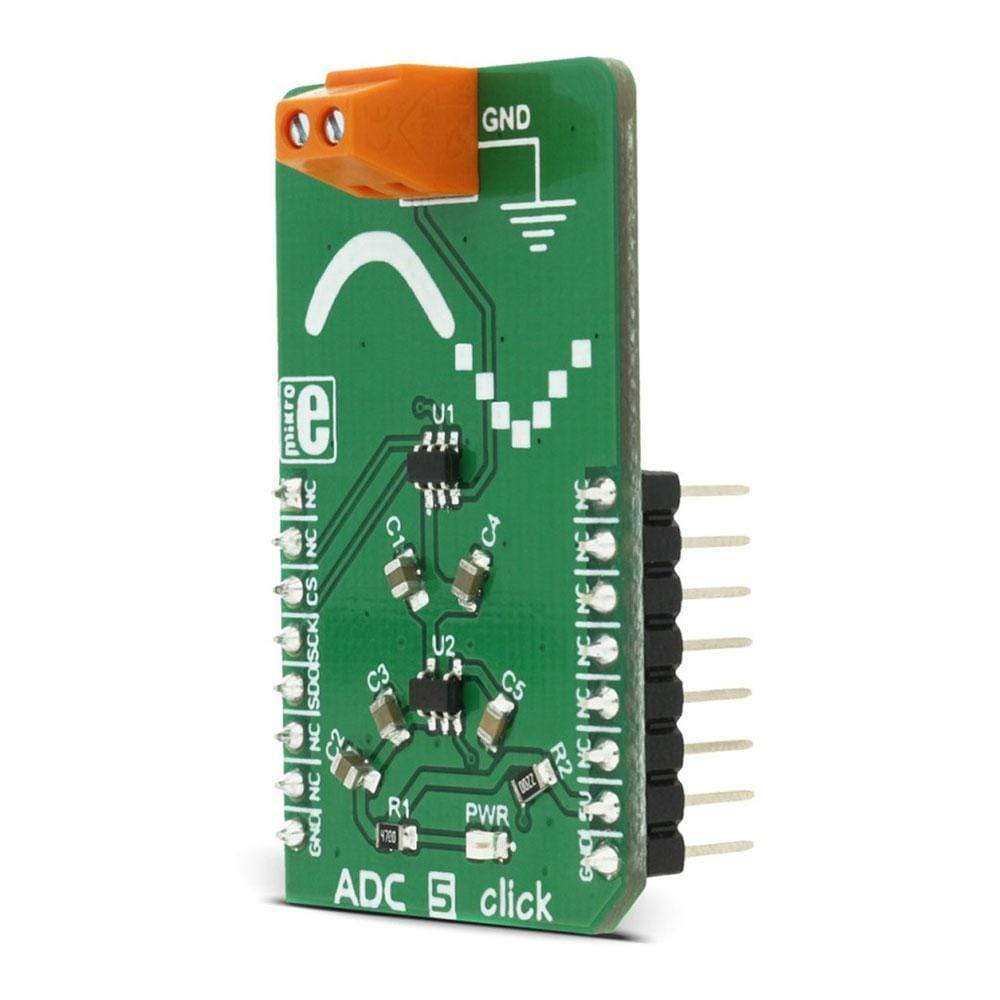

The ADC 5 Click Board™ is also equipped with the screw terminal which can be used for easy and secure connection of the input voltage rail. Although the reference voltage is 3.3V, it is powered only by the 5V rail from the mikroBUS™, used as the input for the LDO regulator.

Specifications

| Type | ADC |

| Applications | The ADC 5 Click Board™ can be used to digitally convert input voltage signals up to 3.3V so that the signals can be analysed by various algorithms on the CPU or a MCU. |

| On-board modules | ADC121S021 a single channel, 50ks/s to 200Ks/s, a 12-Bit SAR ADC, LP2950 - micropower voltage regulator with low voltage drop, both made by Texas Instruments. |

| Key Features | The ADC 5 Click Board™ specified to work with sample rates from 50Ks/s to 200Ks/s. It uses a precise LDO as a reference voltage source and SAR approximation method of sampling |

| Interface | SPI |

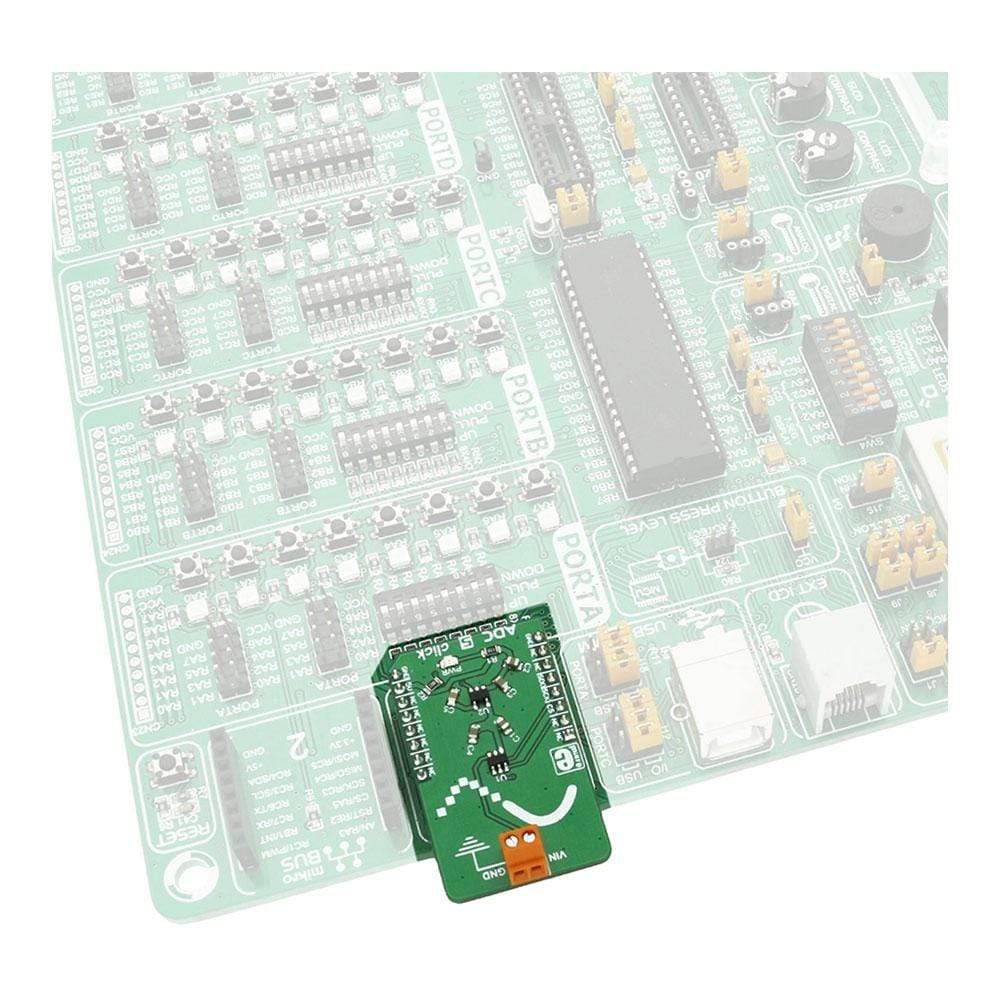

| Compatibility | mikroBUS |

| Click board size | M (42.9 x 25.4 mm) |

| Input Voltage | 5V |

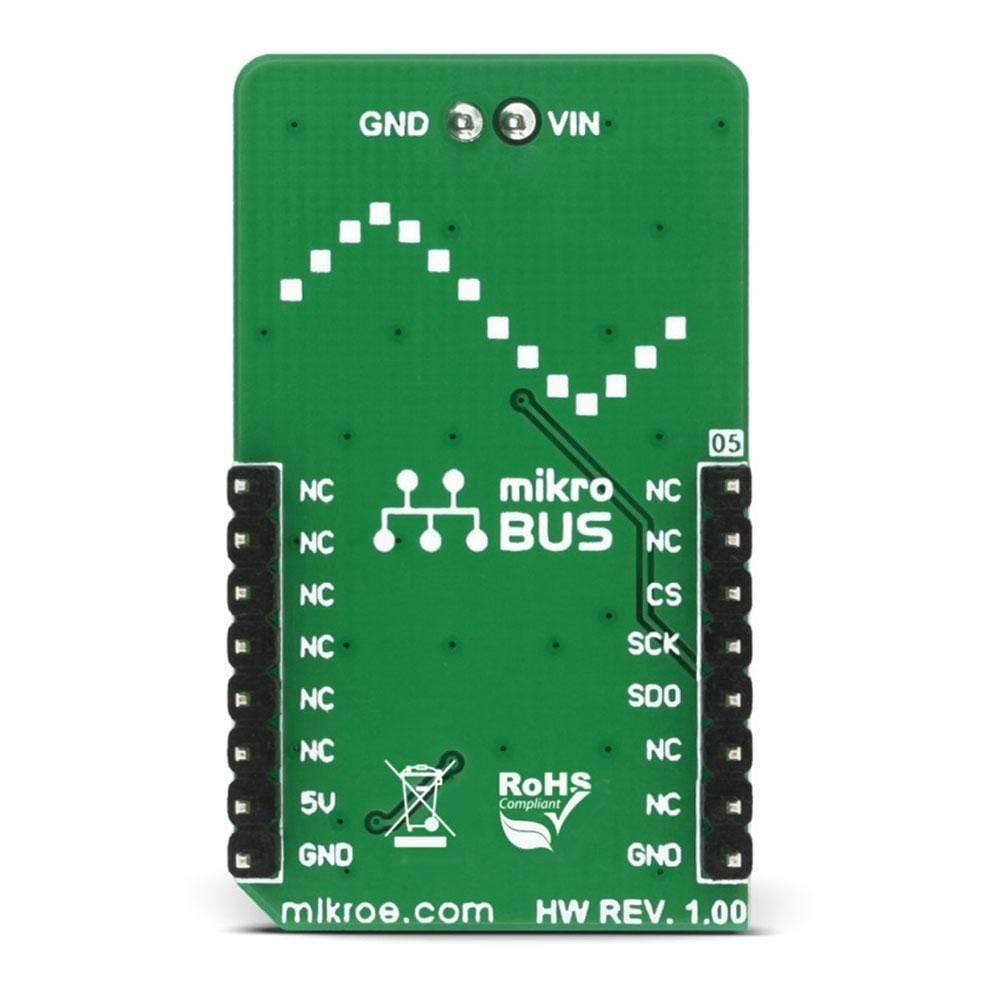

Pinout diagram

This table shows how the pinout on the ADC 5 Click Board™ corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | NC | ||

| NC | 2 | RST | INT | 15 | NC | ||

| SPI Chip Select | CS | 3 | CS | RX | 14 | NC | |

| SPI Clock | SCK | 4 | SCK | TX | 13 | NC | |

| SPI Data OUT | SDO | 5 | MISO | SCL | 12 | NC | |

| NC | 6 | MOSI | SDA | 11 | NC | ||

| NC | 7 | 3.3V | 5V | 10 | +5V | Power supply | |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

ADC 5 click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Vin (analogue input) | 0 | 3.3 | V | |

| ADC reference voltage | 3.3 | V |

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| PWR | PWR | - | Power LED indicator |

| TB1 | TB1 | - | Analog input terminal |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-2846

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.019 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018712083

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.