Overview

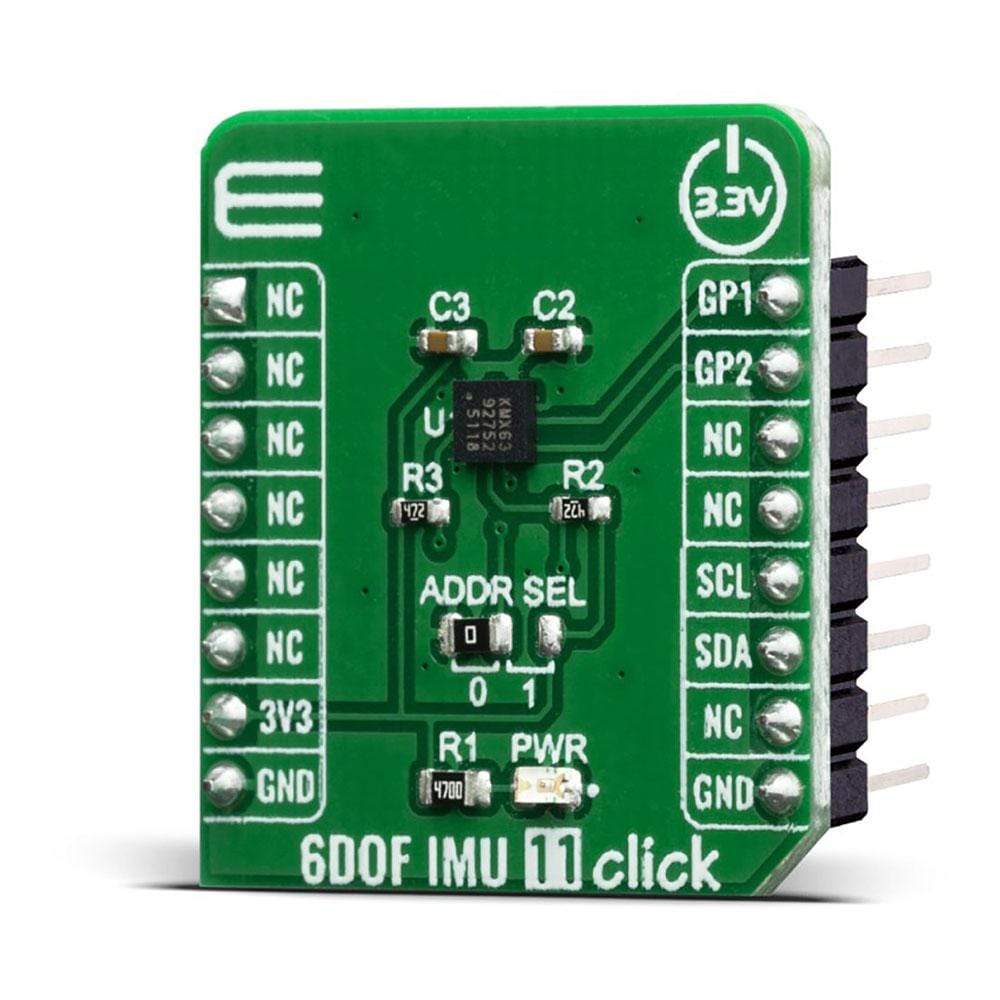

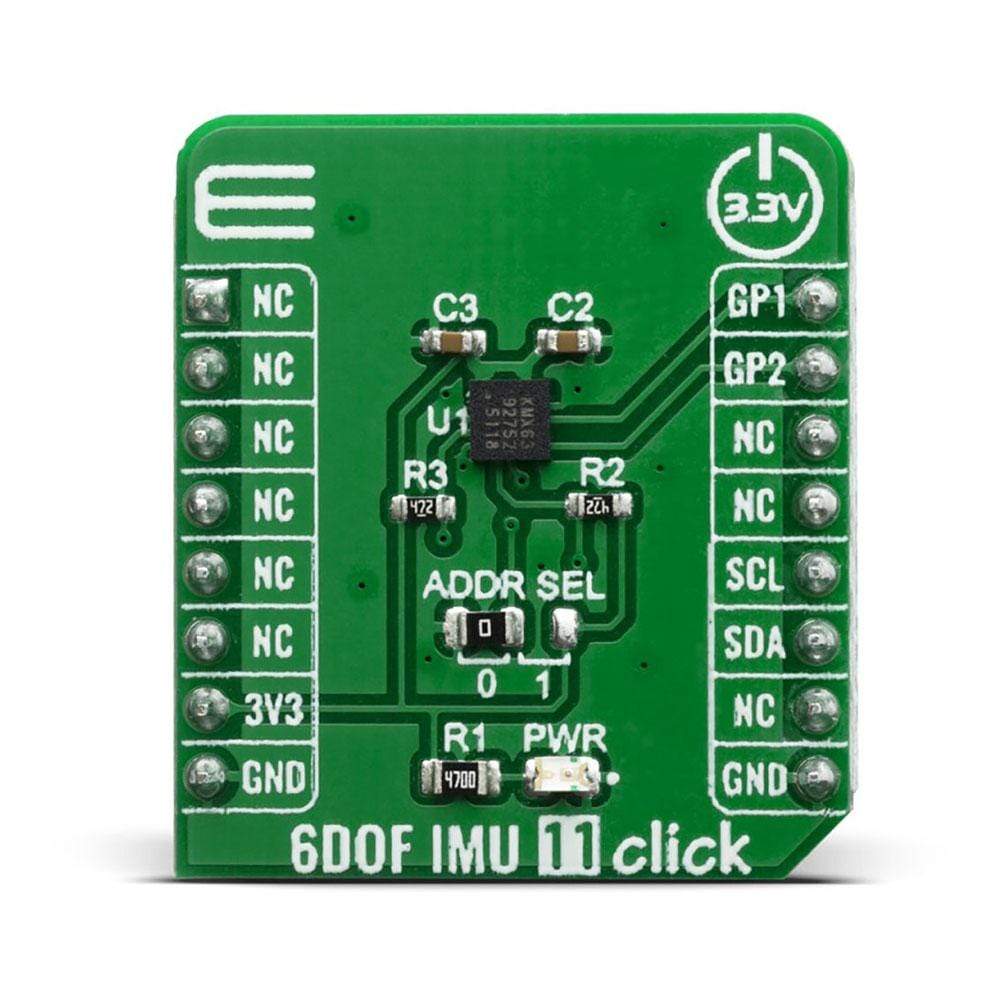

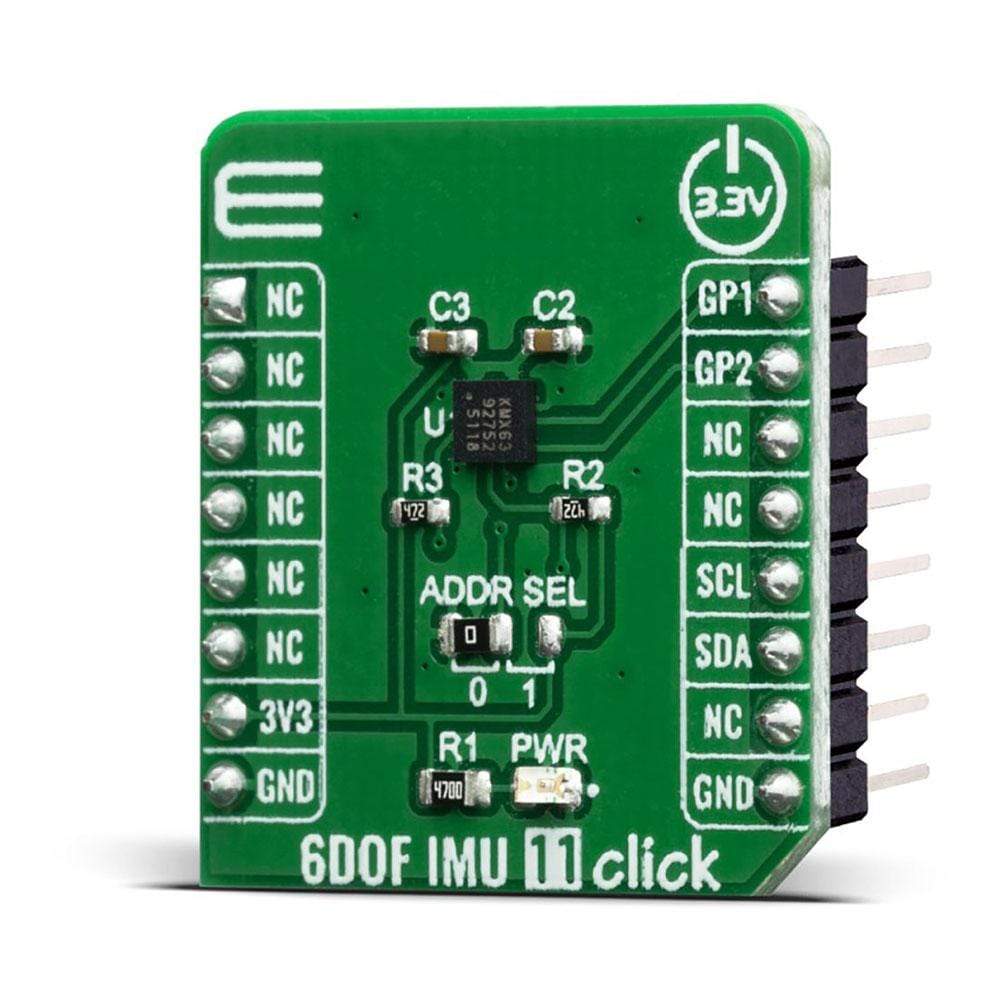

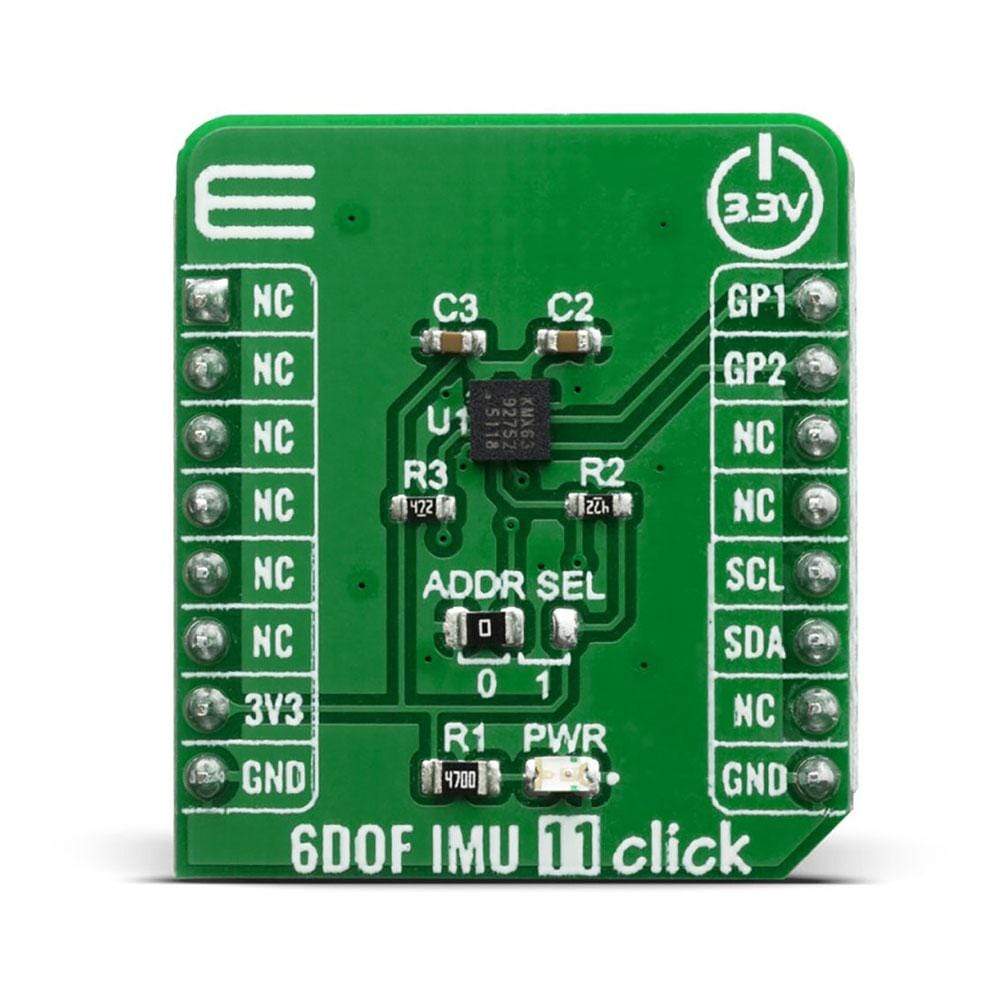

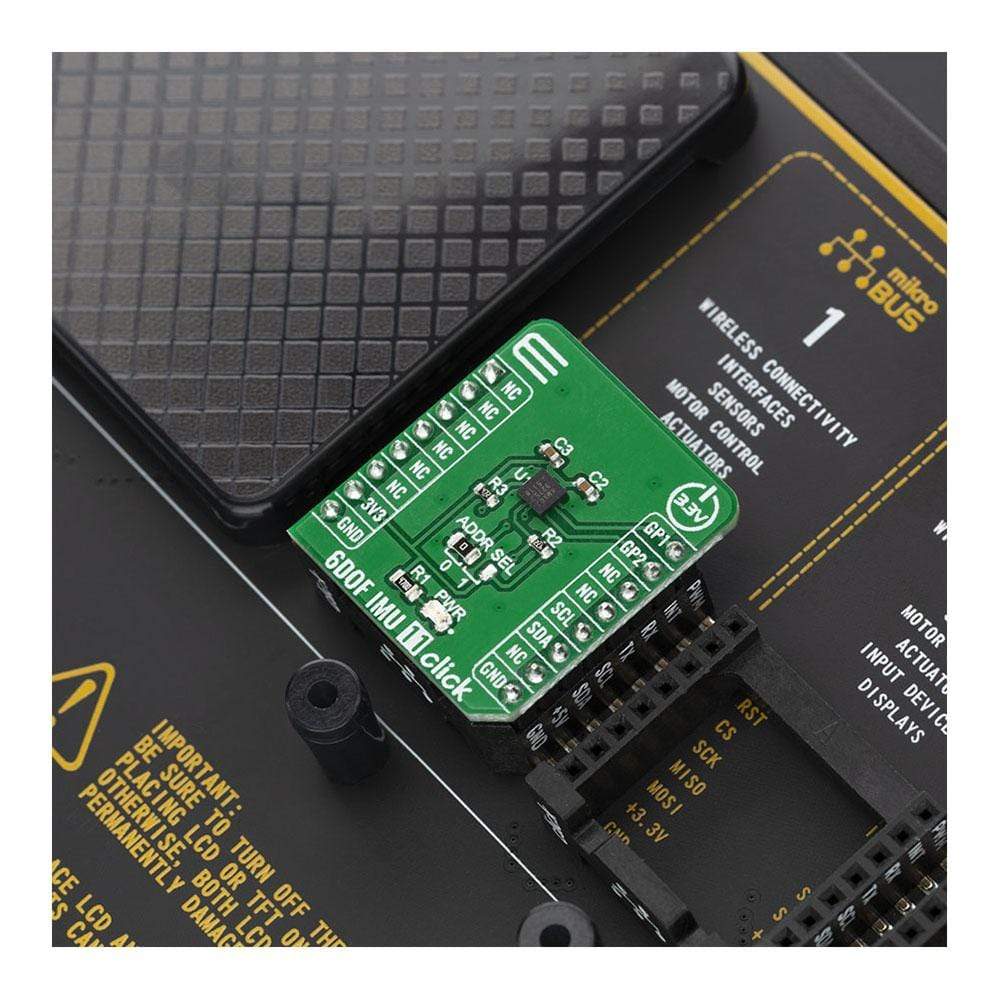

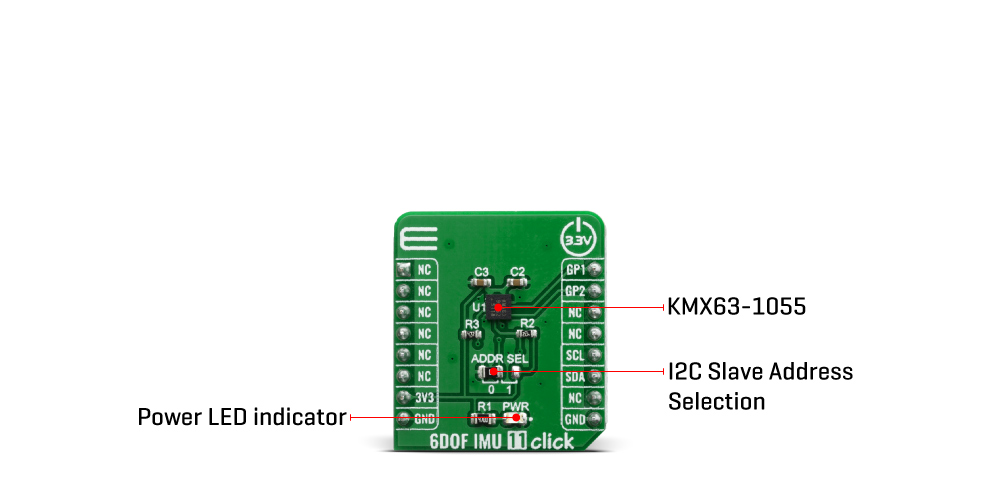

The 6DOF IMU 11 Click Board™ is based on the KMX63, a 6 Degrees-of-Freedom inertial sensor system on a single, silicon chip, which is designed to strike a balance between current consumption and noise performance with excellent bias stability over temperature. The KMX63 sensor consists of a tri-axial magnetometer plus a triaxial accelerometer coupled with an ASIC.

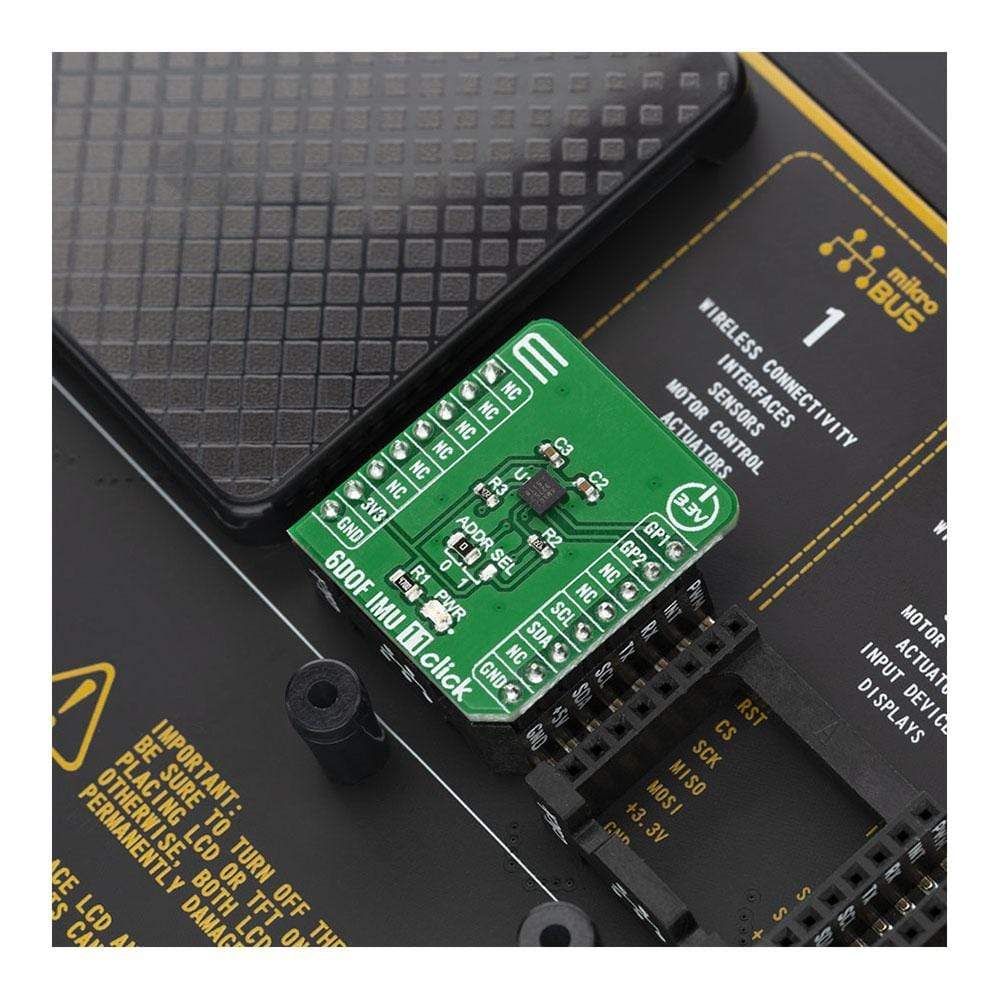

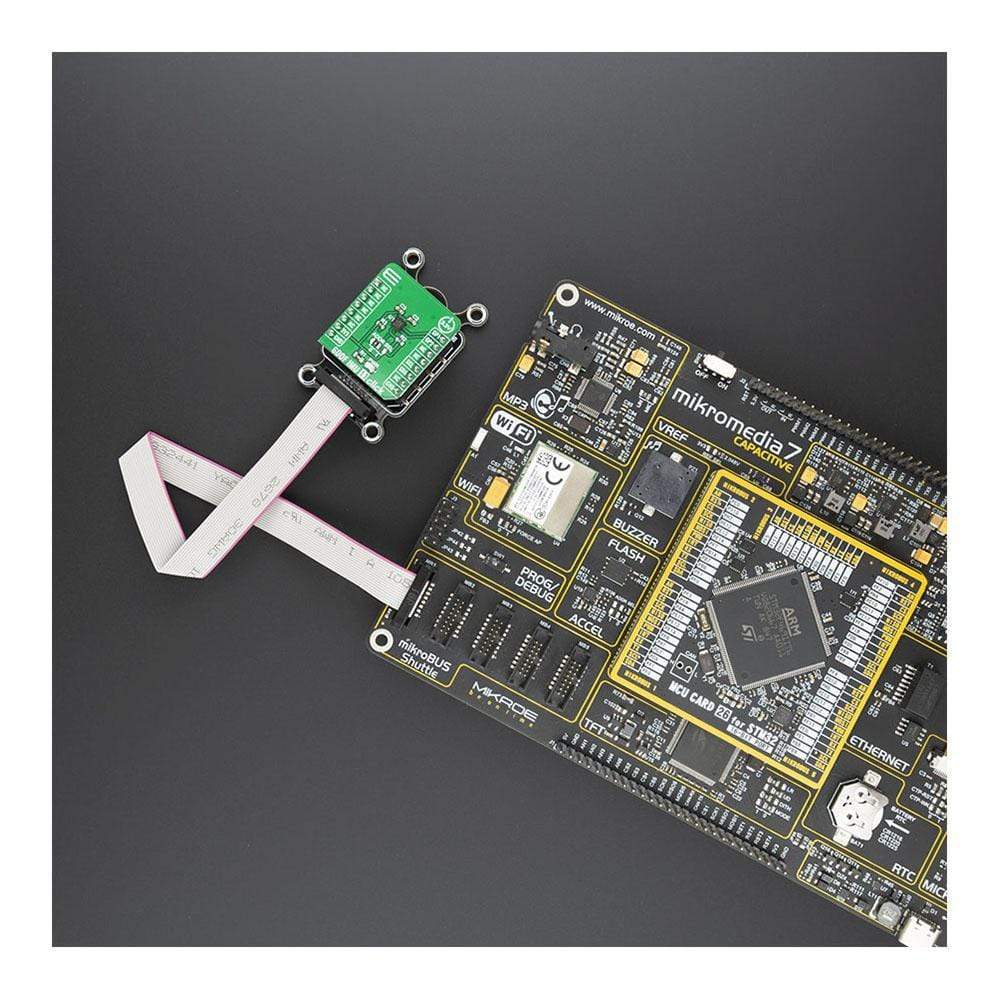

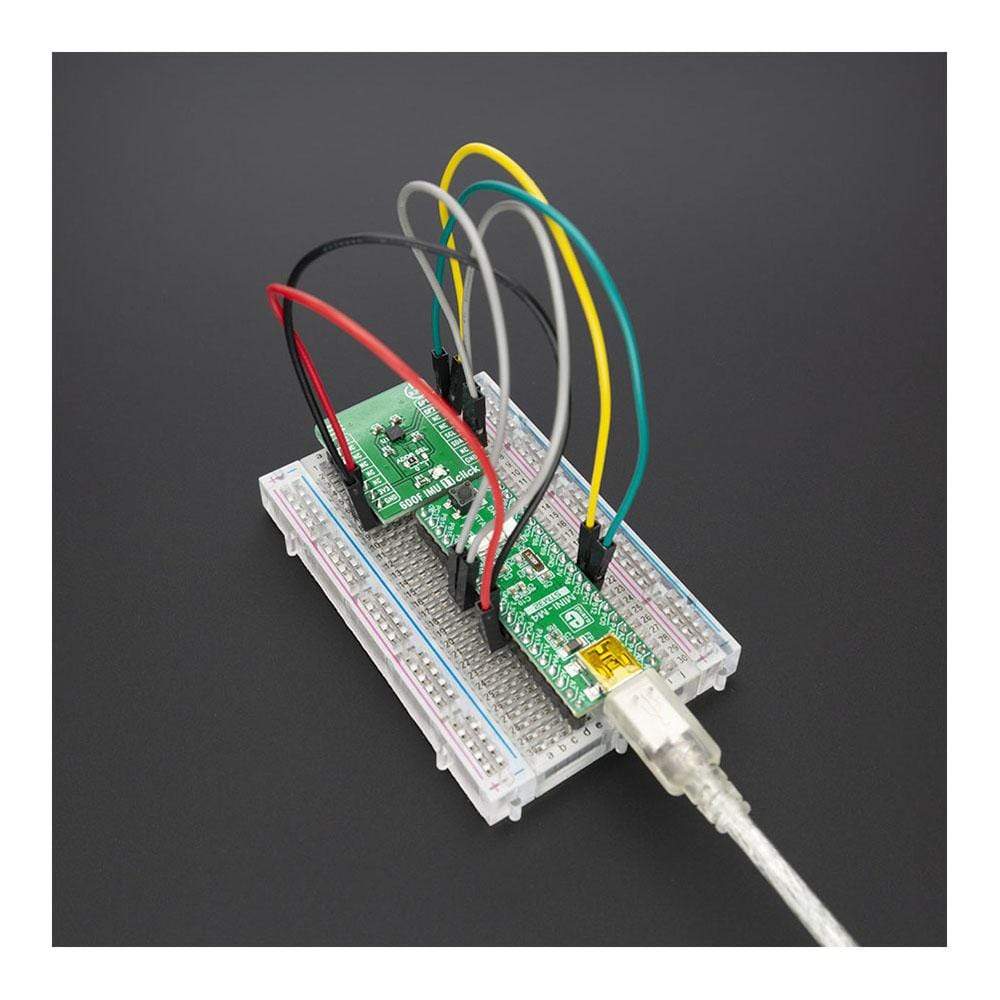

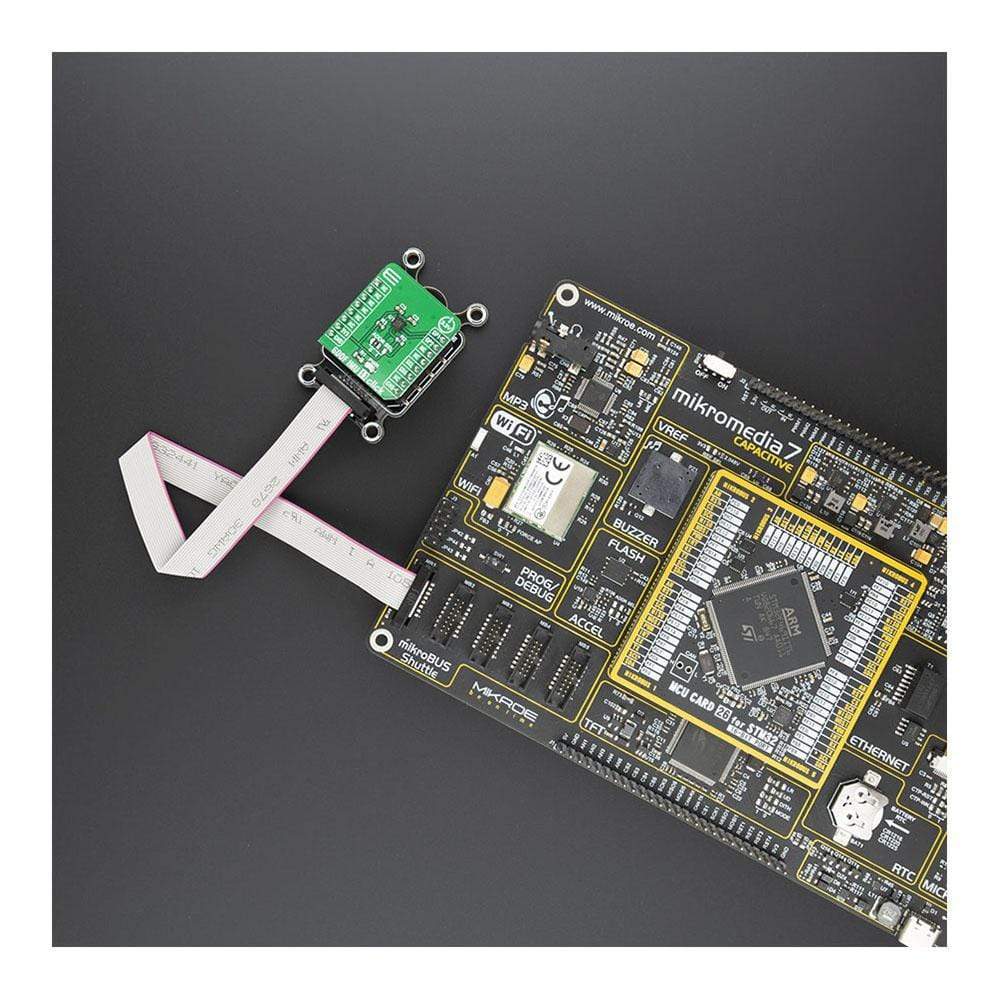

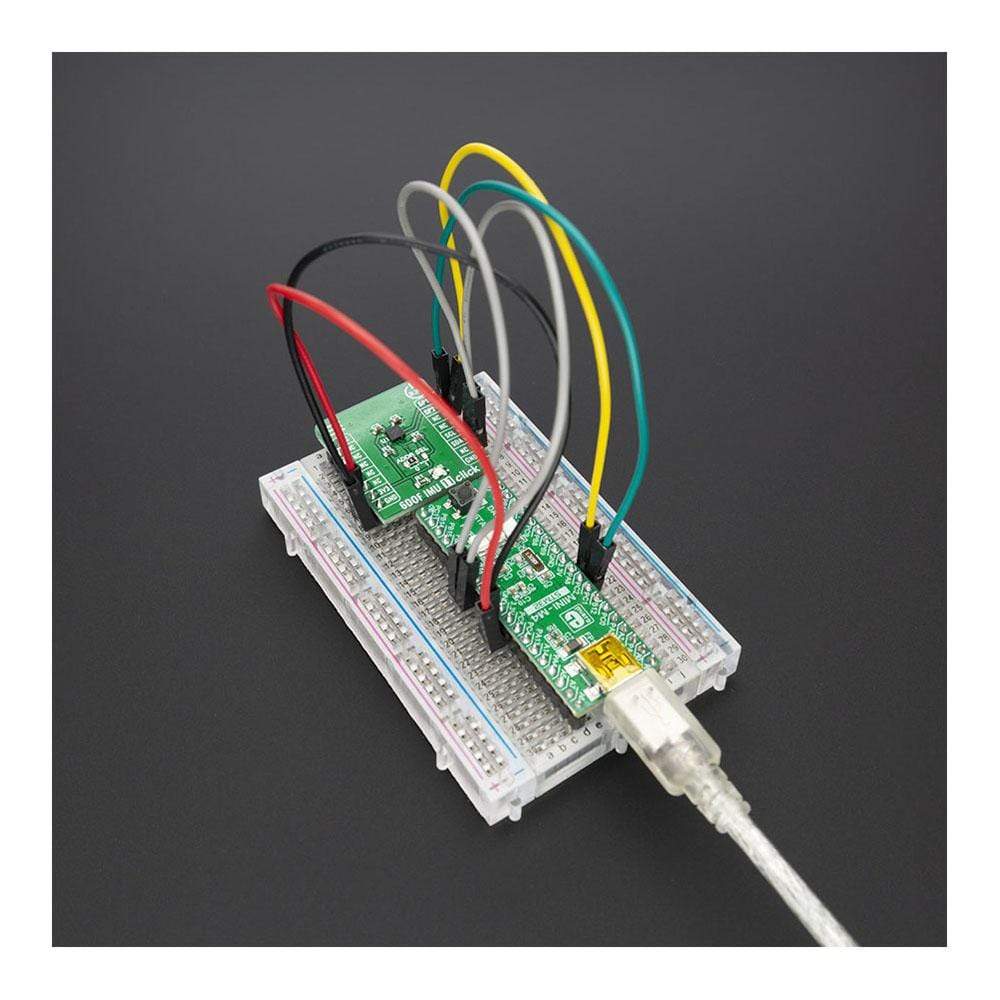

The 6DOF IMU 11 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

How Does The 6DOF IMU 11 Click Board™ Work?

Main component on 6DOF IMU 11 Click Board™ is the KMX63 from Kionix (ROHM company), a tri-axis accelerometer, tri-axis magnetometer, and temperature sensor on a single chip combo solution. The Accelerometer and Magnetometer data can be accumulated in an internal 384-byte FIFO buffer and transmitted to the application processor.

Acceleration sensing is based on the principle of a differential capacitance arising from acceleration induced motion of the sense element, which utilizes common mode cancellation to decrease errors from process variation, temperature, and environmental stress. Capacitance changes are amplified and converted into digital signals which are processed by a dedicated digital signal processing unit. The digital signal processor applies filtering, bias, and sensitivity adjustments, as well as temperature compensation.

Magnetic sensing is based on the principle of magnetic impedance. The magnetic sensor detects very small magnetic fields by passing an electric pulse through a special electron spin aligned amorphous wire. Due to the high Curie temperature of the wire, the sensor's thermal performance shows excellent stability.

Noise performance is excellent with bias stability over temperature. Bias errors resulting from assembly can be trimmed digitally by the user. These sensors can accept supply voltages between 1.7V and 3.6V, and digital communication voltages from the MCU between 1.2V and 3.6V.

The Kionix KMX63 digital sensor can communicate on the I2C digital serial interface bus. This flexibility allows for easy system integration by eliminating analog-to-digital converter requirements and by providing direct communication with system processors. The I2C interface is compliant with high-speed mode, fast mode, and standard mode I2C protocols.

With 6DOF IMU 6 Click Board™ you may communicate by using I2C serial interface. The I2C is primarily used for serial communication between a Master device and one or more Slave devices. The KMX63 always operates as a Slave device during standard Master-Slave I2C operation.

Given all of the possibilities its features offer, the 6DOF IMU 11 Click Board™ can be used for applications which require movement and orientation features, such as screen orientation, navigation, game playing, machine/vibration analysis, etc...

SPECIFICATIONS

| Type | Motion |

| Applications | A magnetometer accelerometer can be used to enable a variety of simultaneous features for Machine health, screen orientation, navigation, faming, automatic sleep mode |

| On-board modules | KMX63, a 6 Degrees-of-Freedom inertial sensor system from Kionix |

| Key Features | Programmable ±8g/±16g/±32g/±64g full scale range accelerometer range and a +/-1200 µT range for the magnetometer |

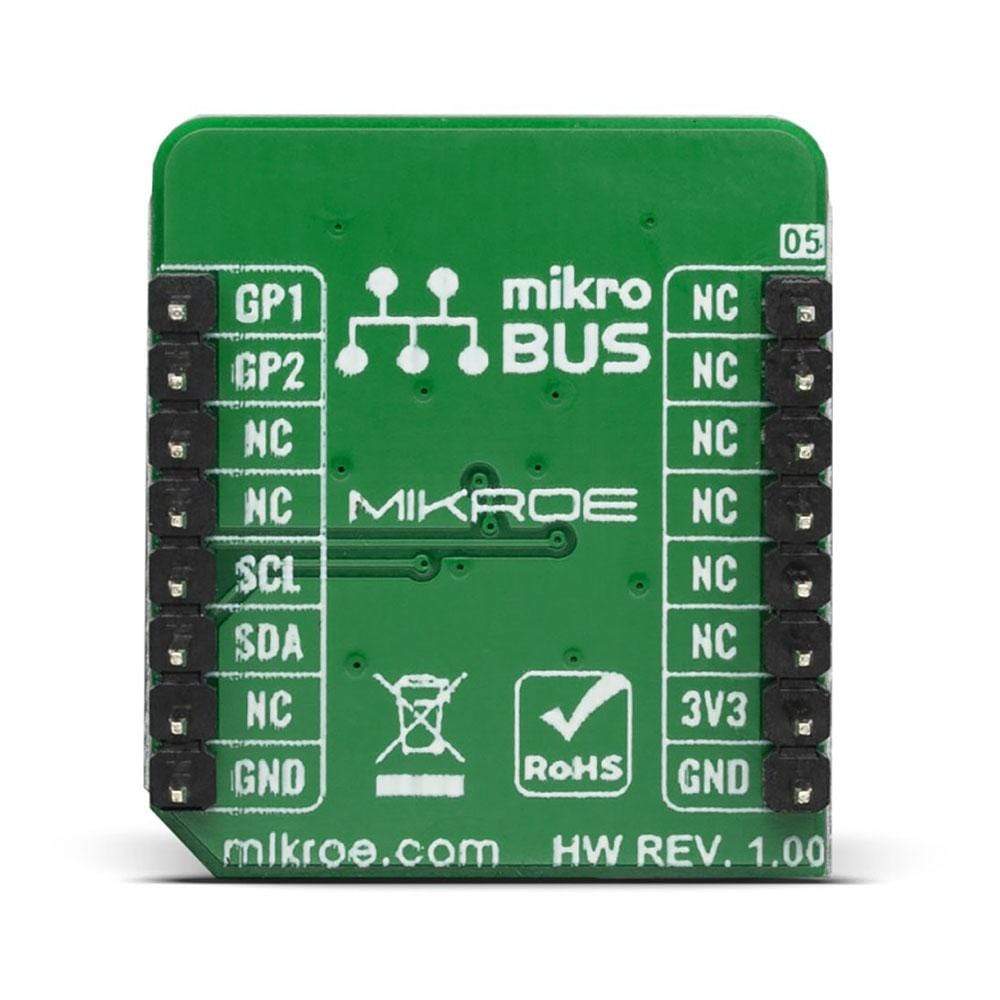

| Interface | GPIO,I2C |

| Compatibility | mikroBUS |

| Click Board™ size | S (28.6 x 25.4 mm) |

| Input Voltage | 3.3V |

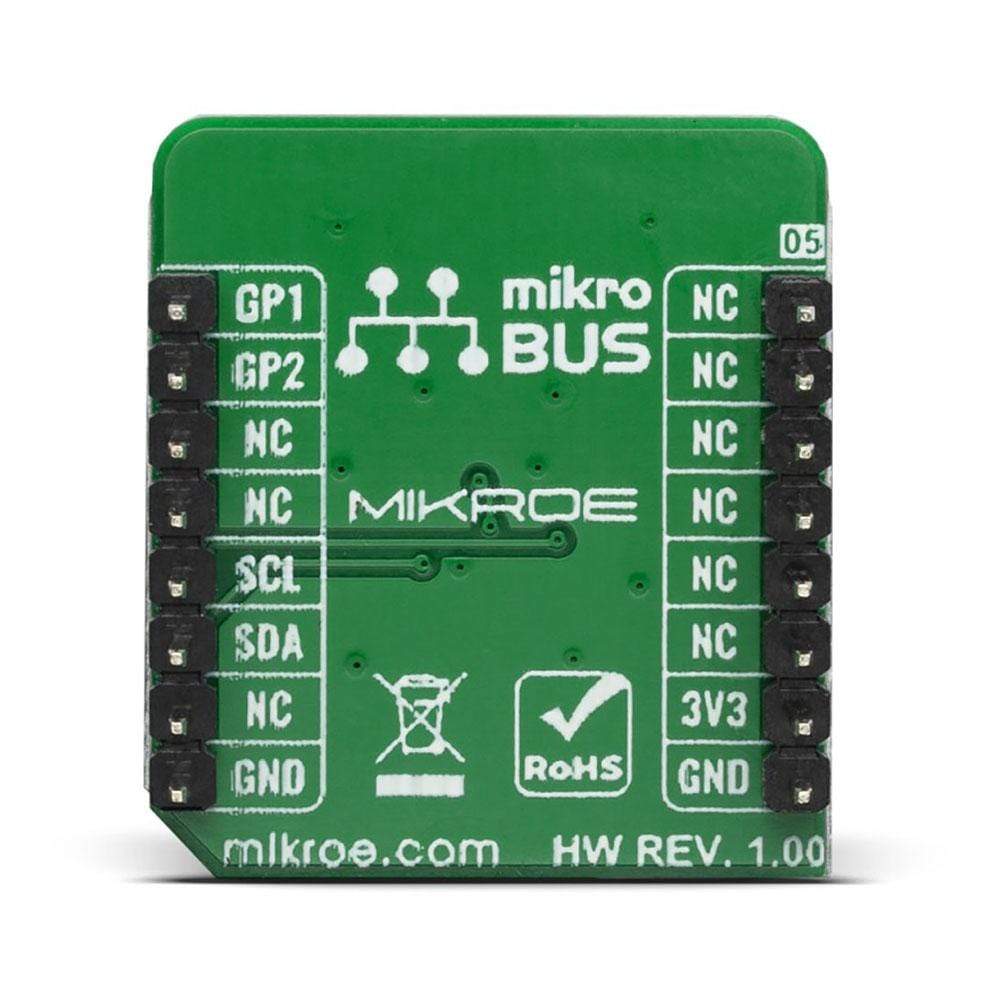

PINOUT DIAGRAM

This table shows how the pinout on 6DOF IMU 11 Click Board™ corresponds to the pinout on the mikroBUS socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | GP1 | General purpose #1 | |

| NC | 2 | RST | INT | 15 | GP2 | General puprpose #2 | |

| NC | 3 | CS | RX | 14 | NC | ||

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | SCL | I2C Clock | |

| NC | 6 | MOSI | SDA | 11 | SDA | I2C Data | |

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | NC | |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3869

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018719396

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.