Key Features

Overview

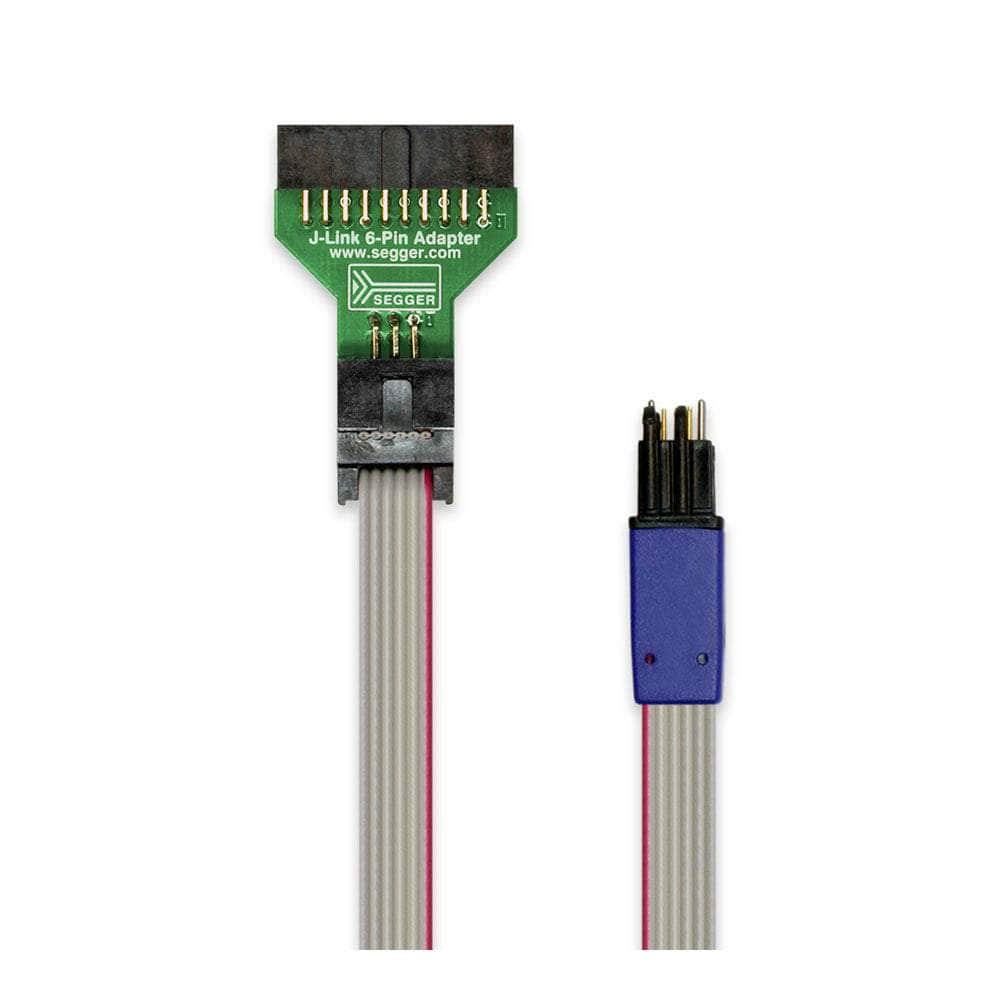

SEGGER 8.06.16 – J-Link 6-Pin Needle Adapter connects a J-Link or SEGGER Flasher to a PCB that omits a mating connector or header. It adapts from the standard 20-pin 0.1″ J-Link/JTAG connector to a compact 6-pin spring-needle pattern intended for SWD-based bring-up and production programming. A tri-pin locating pattern ensures correct orientation, while high-reliability spring pins provide stable contact during test and programming.

This 6-pin variant targets SWD; if full JTAG or target-power pin support is required, consider the SEGGER 10-Pin Needle Adapter (8.06.04). For alternative compact connectors (e.g., Cortex-M 10-pin 0.05″), see the 50-Mil 10-Pin Patch Adapter, and for general J-Link probes visit J-Link BASE Compact.

Engineers choose the needle approach to save PCB area and remove BoM and assembly cost associated with fitted headers, particularly in space-constrained or high-volume designs. The footprint and pinout are widely documented, simplifying PCB library creation and production use.

What to know: Six pins support SWDIO, SWCLK, RESET, SWO (optional), VTref and GND; for JTAG (TMS/TCK/TDI/TDO) use the 10-pin needle adapter.

Downloads

Why Engineers Choose The SEGGER J-Link 6-Pin Needle Adapter (8.06.16)

Eliminate Headers On Production PCBs

Orientation-Safe, Repeatable Contact

Fits Existing J-Link Workflows

| General Information | |

|---|---|

Product Type |

Adapter

|

Part Number (SKU) |

8.06.16

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Warranty |

|

HS Code Customs Tariff code

|

|

EAN |

5055383614318

|

Frequently Asked Questions

Have a Question?

-

What if I need a different connector standard later on?

SEGGER provides adapters such as the 50-Mil 10-Pin Patch Adapter and the Target Supply Adapter to cover other scenarios.

-

Any workflow tips for first bring-up?

Follow SEGGER SWD pin guidance (VTref, RESET handling, optional SWO). Verify pull-ups/downs per device vendor before first connection.

-

How does this compare to more expensive fixtures?

Versus custom bed-of-nails fixtures, needle adapters offer much lower NRE and faster setup while still giving repeatable contact for programming.

-

What PCB footprint size should I plan for?

Use SEGGER’s published pad pattern from the datasheet; the footprint is smaller than a fitted header, aiding dense layouts.

-

Will it work with J-Link BASE/PLUS/PRO and SEGGER Flashers?

Yes—designed for J-Link and Flasher families via the 20-pin 0.1″ connector. See also the J-Link BASE Compact.

-

Is this the same as Tag-Connect?

It’s a similar “spring-pin to pad” concept. SEGGER notes its needle pinout is based on Tag-Connect but not identical; the 10-pin variant includes a 5 V supply pin.

-

How does it ensure correct orientation?

A three-pin locating pattern keys the adapter so it only mates one way. This reduces operator error and rework.

-

Does it supply power to the target?

The 6-pin version is intended for SWD signalling. If you need JTAG and the 5 V target-power pin via needle connection, use the 10-pin needle adapter (8.06.04).

-

Which signals are available on the 6-pin footprint?

VTref, SWDIO, SWCLK, RESET, GND and optional SWO for trace/printf. For JTAG signals, use the 10-pin version.

-

What problem does the 6-pin needle adapter solve?

It enables SWD debug/programming on boards without connectors, reducing BoM and PCB area while preserving J-Link workflows.