Overview

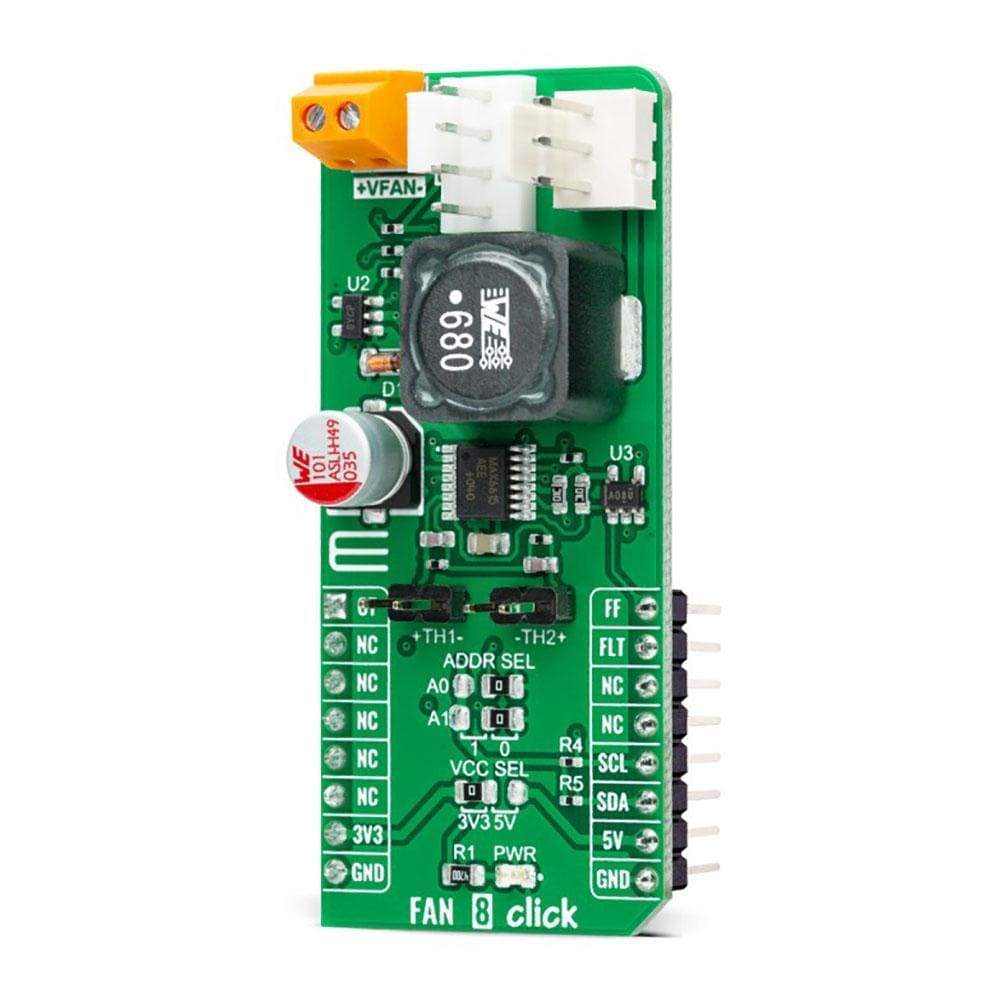

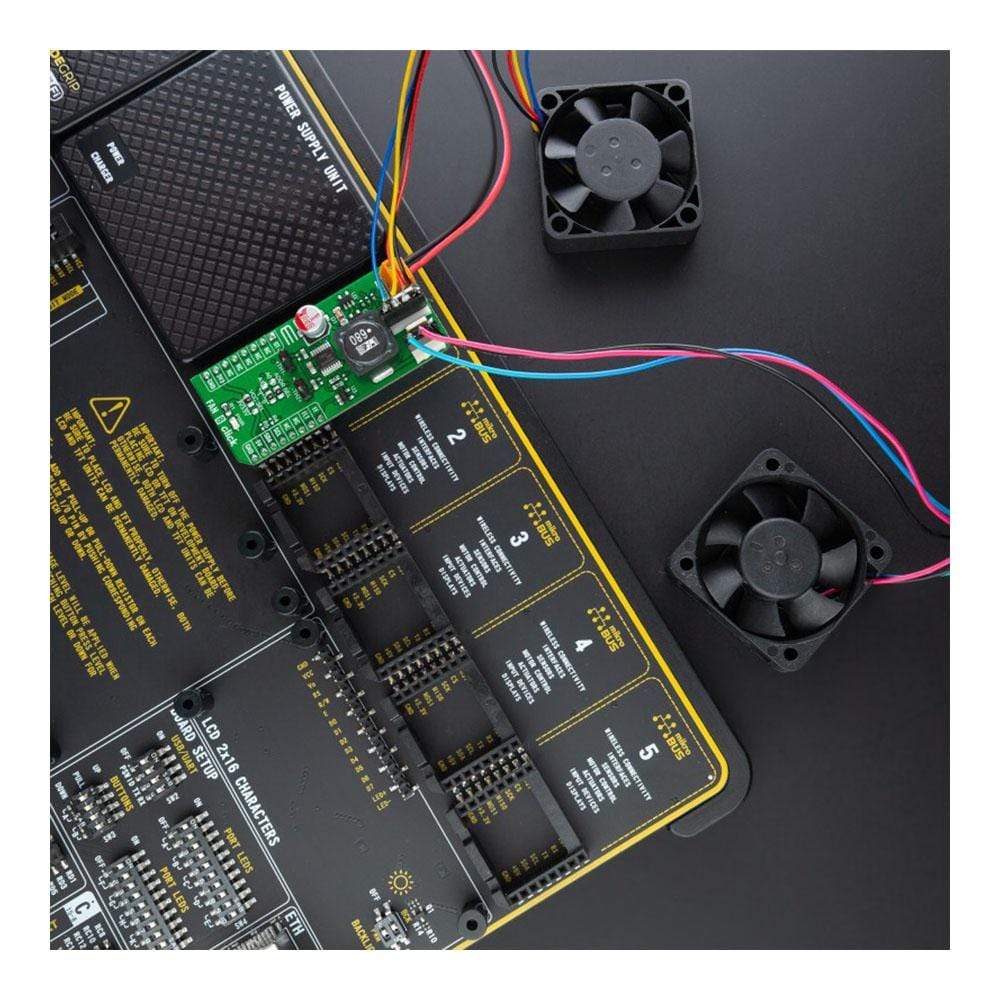

The Fan 8 Click Board™ is a compact add-on board that represents a compliant fan controller. This board features the MAX6615, a fan-speed controller, and a dual-channel temperature monitor with external thermistor inputs from Maxim Integrated, now part of Analog Devices. The MAX6615 controls the speed of two cooling fans based on the temperatures of external thermistors and the device's internal temperature, reporting temperature values in a digital form using the I2C serial interface. The temperature data controls a PWM output signal to adjust the speed of a cooling fan, minimizing noise when the system is running cool, but providing maximum cooling when power dissipation increases.

It also features an overtemperature alarm to generate interrupts, throttle, or shutdown signals. The combination of high accuracy and dual thermistor inputs makes this Click board a practical choice for networking equipment, servers, or other applications requiring cooling and temperature control.

Downloads

How Does The Fan 8 Click Board™ Work?

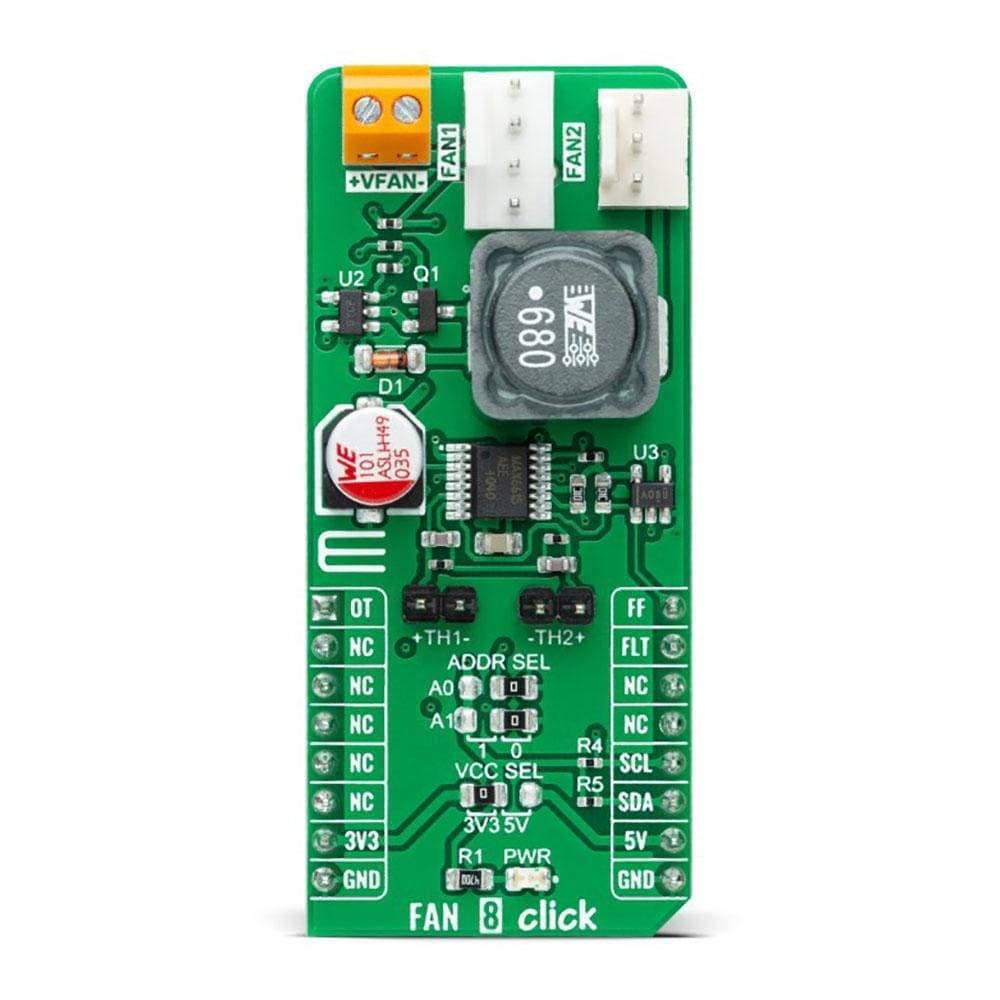

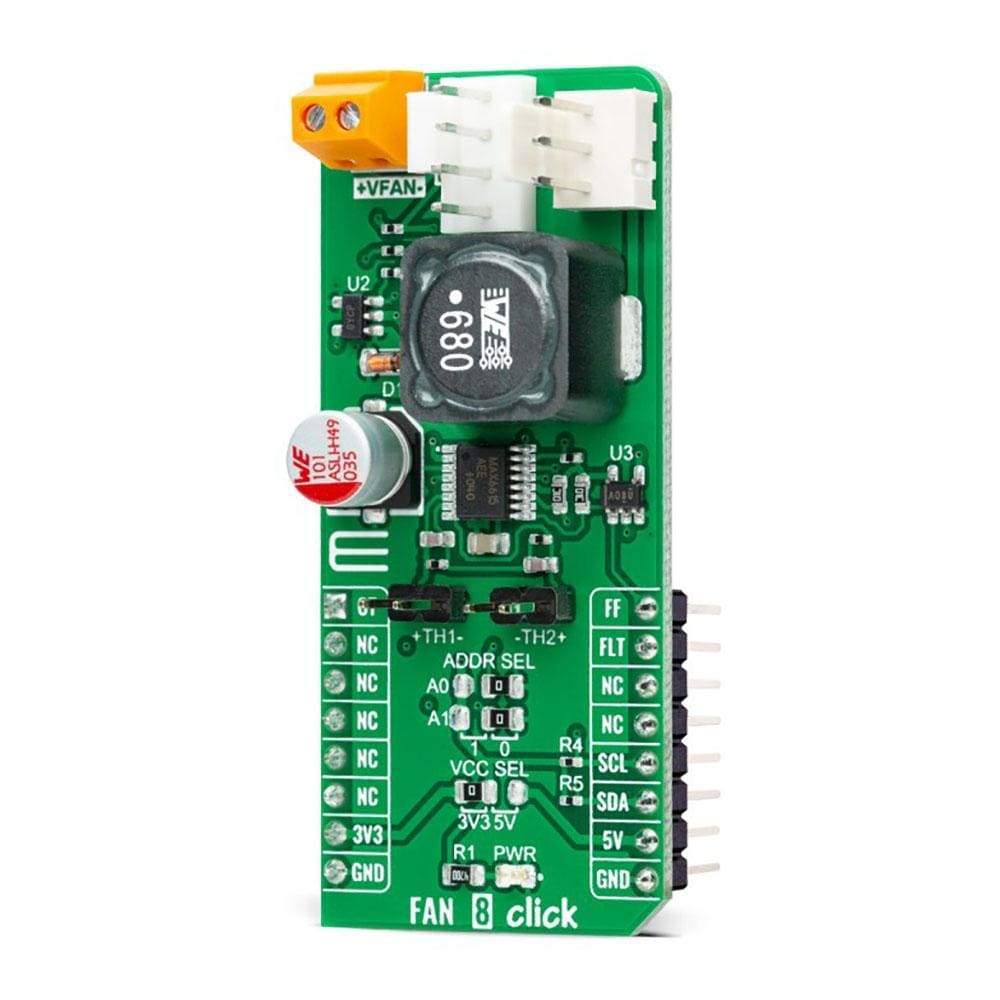

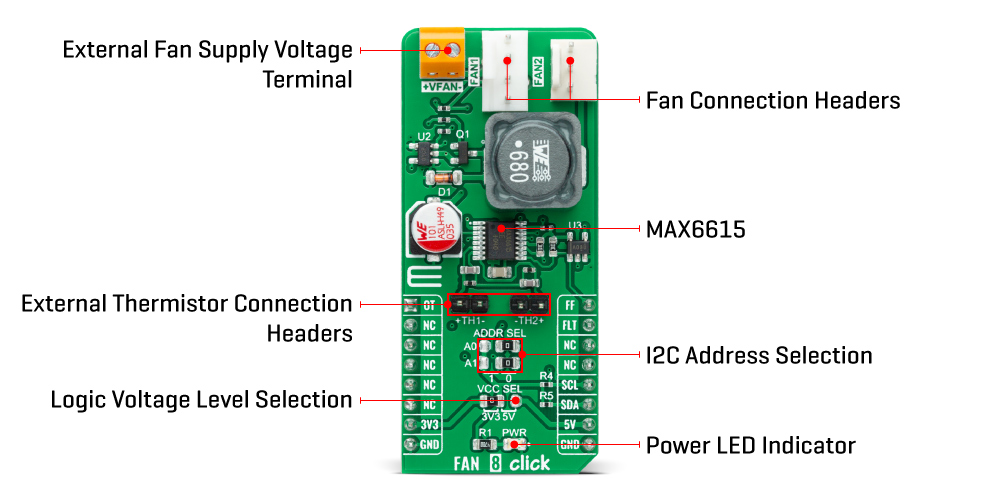

The Fan 8 Click Board™ as its foundation uses the MAX6615, a compliant fan controller, and accurately two temperature-channels monitors from Maxim Integrated, now part of Analog Devices. The MAX6615 monitors either the internal die temperature and the temperature of external thermistors connected on the onboard headers labeled as TH and reports temperature values in digital form using a 2-wire serial interface. To adjust the speed of the cooling fans, the temperature data controls the duty cycle of a PWM output signal, which minimizes noise when the system is running cool but provides maximum cooling when power dissipation increases.

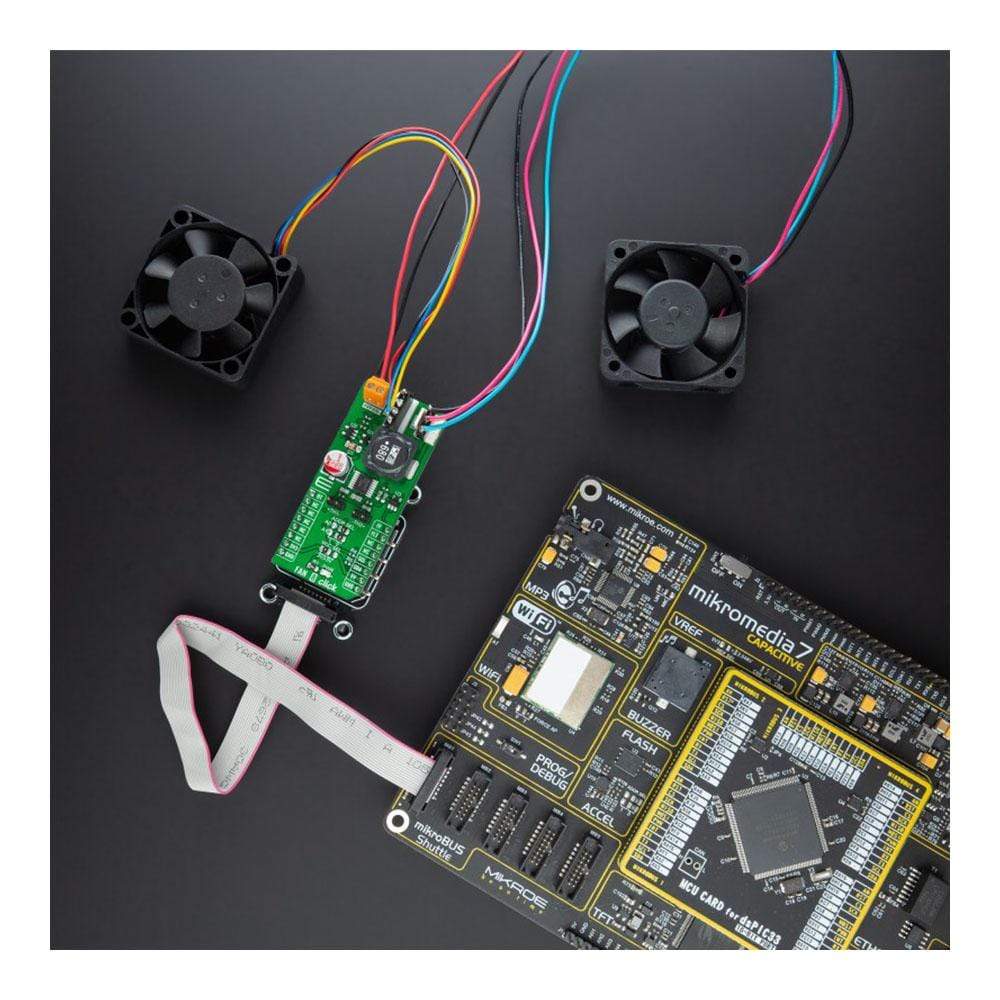

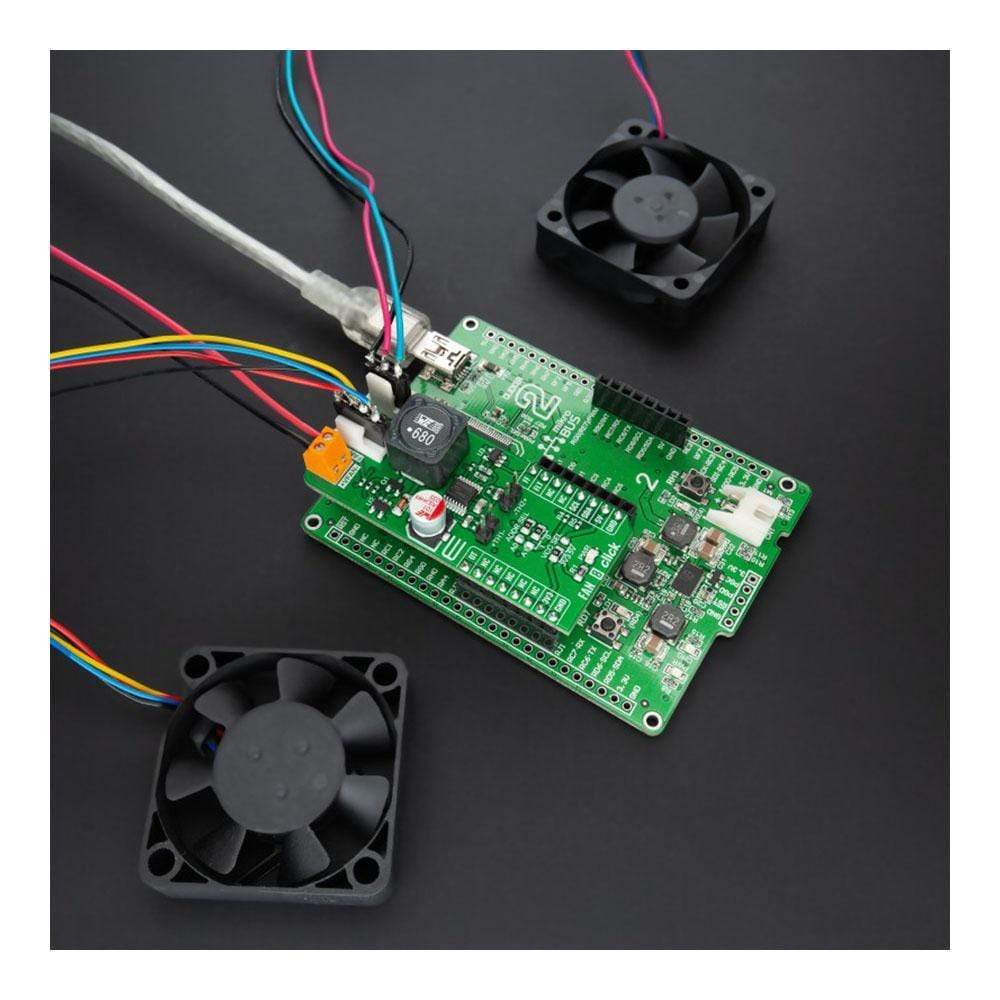

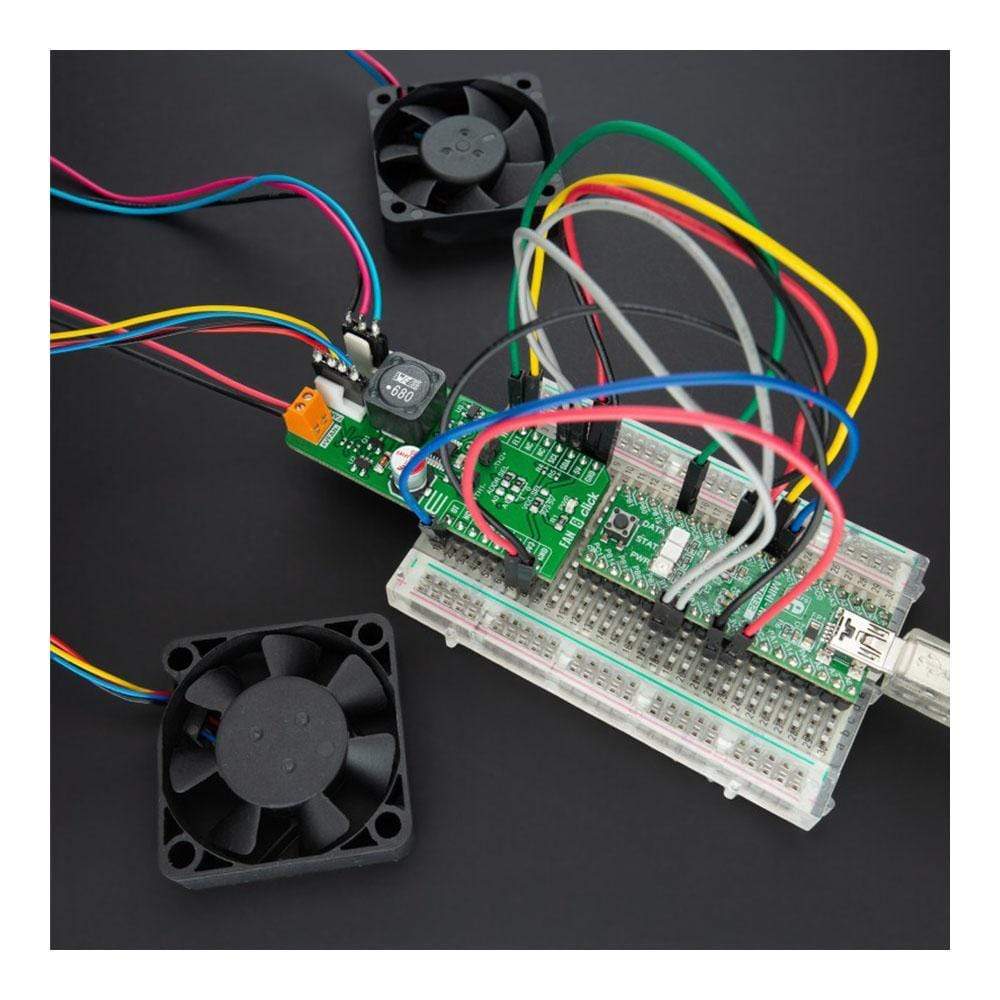

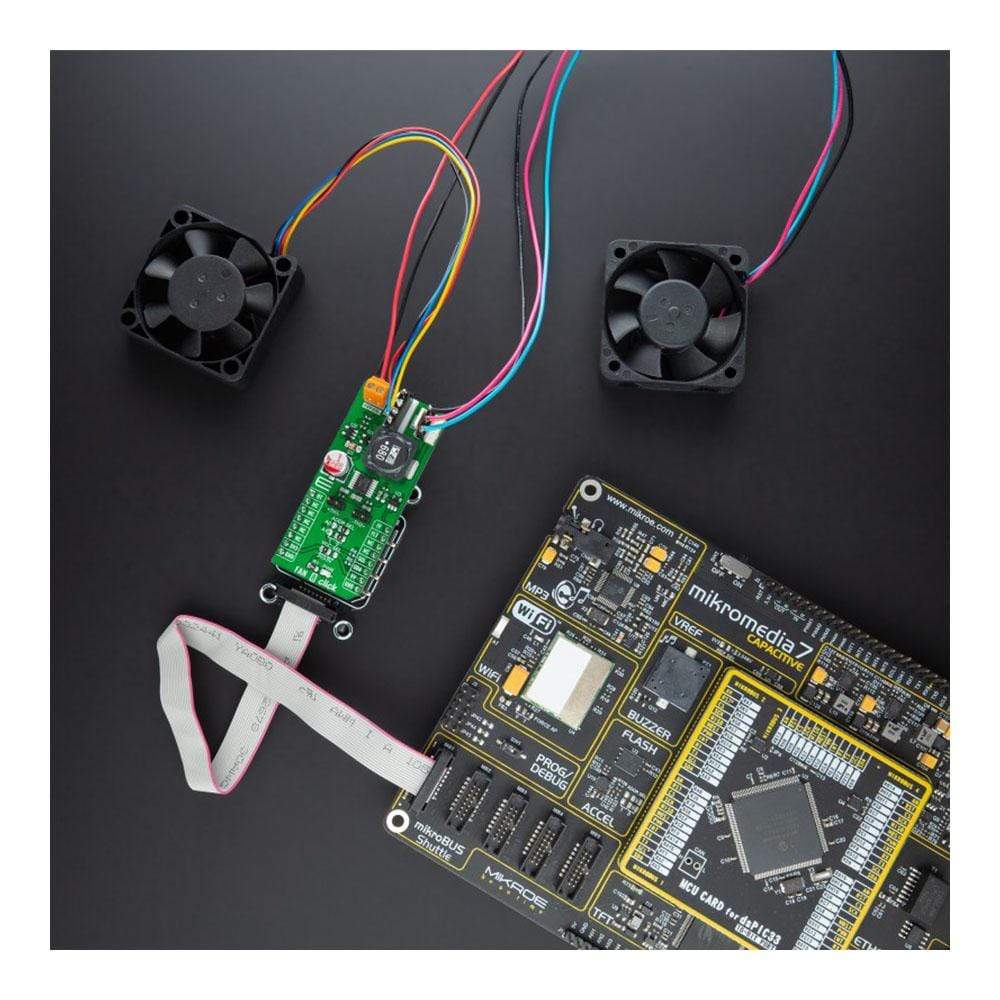

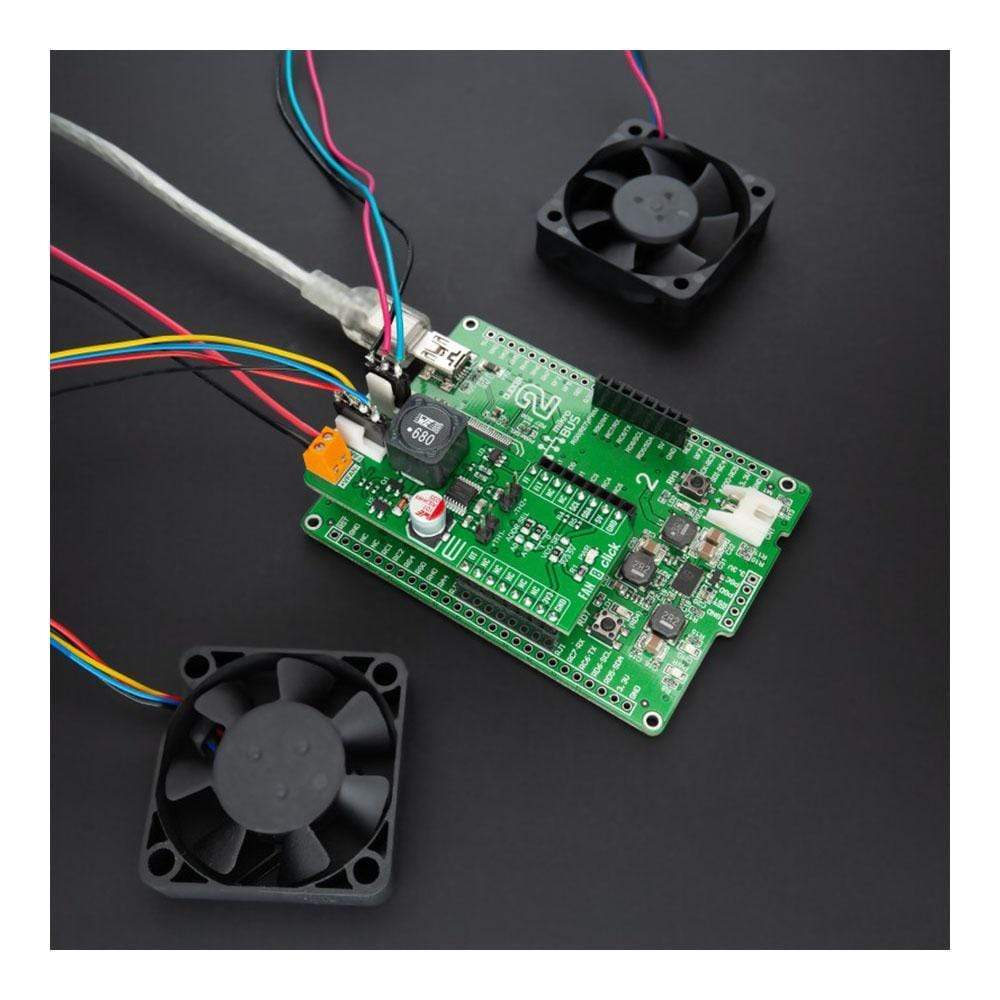

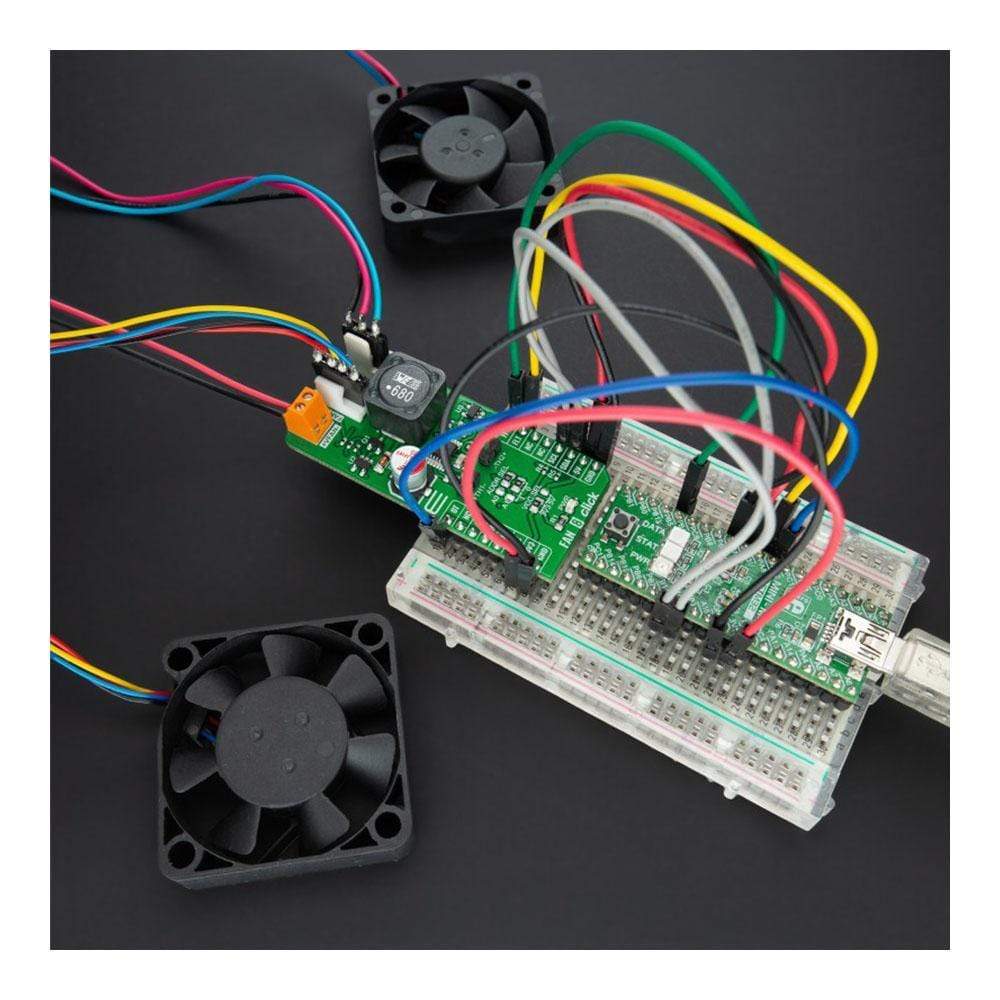

The Fan 8 Click Board™ communicates with MCU using the standard I2C 2-Wire interface to read data and configure settings with a maximum frequency of 400kHz. Besides, it also allows the choice of the least significant bit of its I2C slave address by positioning the SMD jumpers labeled as ADDR SEL to an appropriate position marked as 0 and 1. This way, the MAX6616 provides the opportunity of the nine possible different I2C addresses by positioning the SMD jumper to an appropriate position.

The MAX6615 monitors the fans' tachometer signals to detect fan failure. When the fan tachometer count is larger than the fan tachometer limit, the fan is considered failing. If that happens, the FAN_FAIL output represented by the FF pin, routed on the PWM pin of the mikroBUS™ socket, is asserted. Also, the MAX6615 features an over-temperature indicator routed on the AN pin of the mikroBUS™ socket, which sets high when a thermal fault occurs and can be used as a warning flag to initiate the system shutdown or to throttle clock frequency. In the event of any of these irregularities, the MCU will also receive information from an FLT pin (fault indicator), routed on the INT pin of the mikroBUS™ socket, in case of further necessary configurations necessary for proper operation.

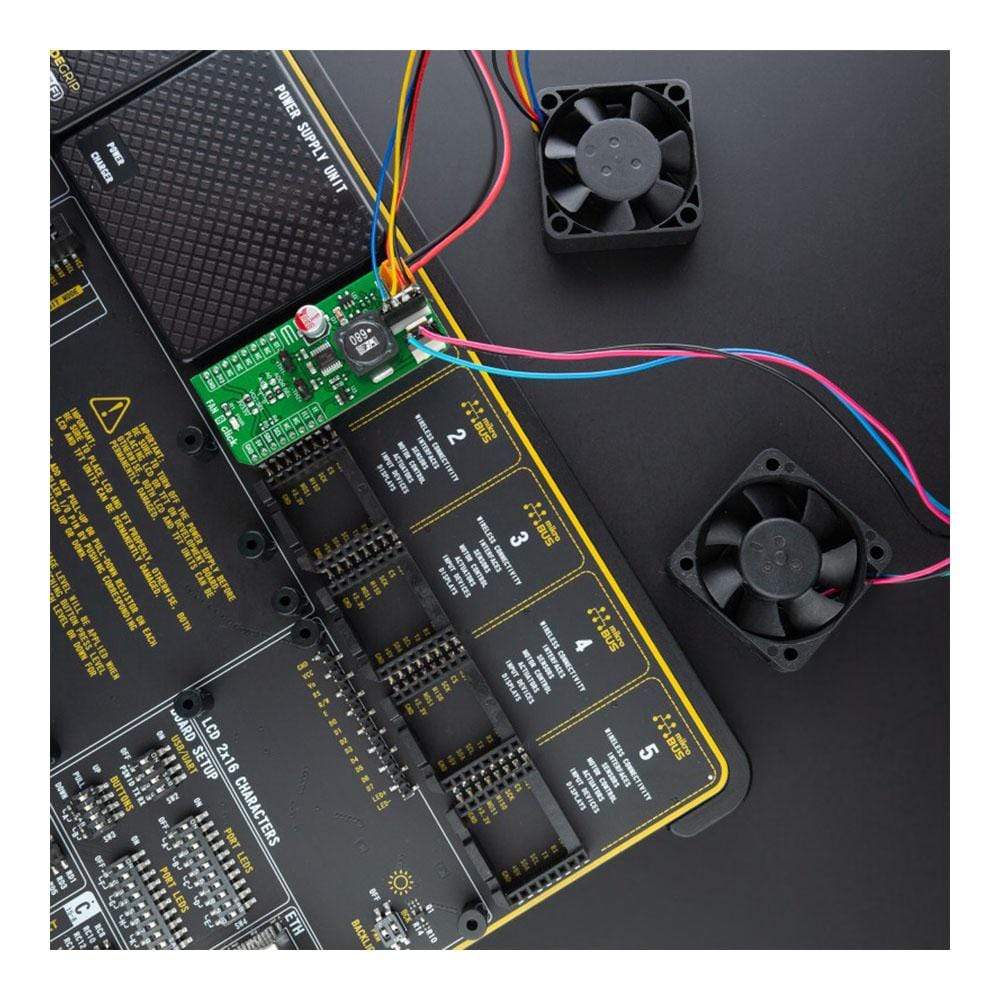

The Fan 8 Click Board™k supports an external fan power supply, connected to the input terminal labeled as VFAN with the value of 5V or 12V, while the fan connection wires can be connected to the onboard headers labeled as FAN1 and FAN2.

This Click board™ can operate with both 3.3V and 5V logic voltage levels selected via the VCC SEL jumper. This way, it is allowed for both 3.3V and 5V capable MCUs to use the I2C communication lines properly. However, the Click board™ comes equipped with a library containing easy-to-use functions and an example code that can be used, as a reference, for further development.

Specifications

| Type | Brushless |

| Applications | Can be used for networking equipment, servers, or other applications requiring cooling and temperature control |

| On-board modules | MAX6615 - compliant fan controller, and accurately two temperature-channels monitors from Maxim Integrated, now part of Analog Devices |

| Key Features | Two fan-speed controller, dual-channel temperature monitor, external thermistors, fail-safe system protection, shutdown in case of overtemperature, programmable I2C addresses, and more |

| Interface | I2C |

| Compatibility | mikroBUS |

| Click board size | L (57.15 x 25.4 mm) |

| Input Voltage | 3.3V or 5V,External |

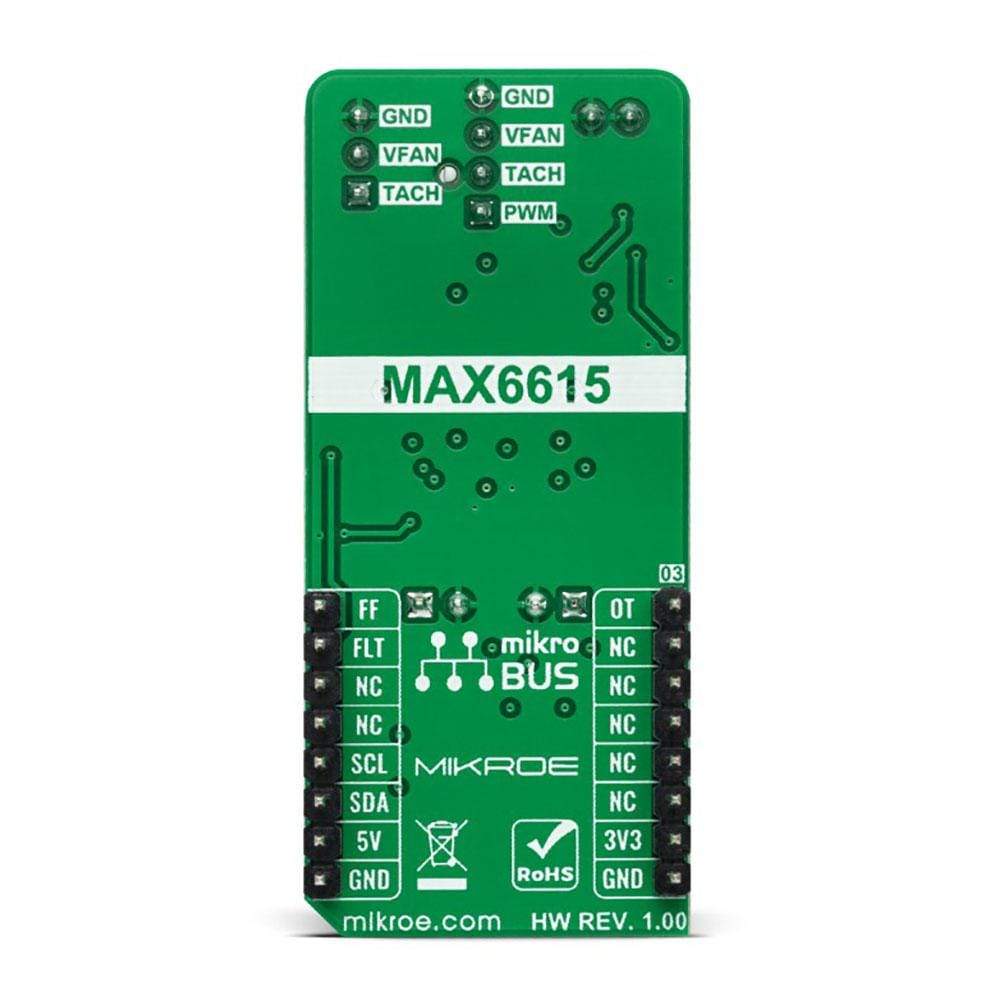

Pinout diagram

This table shows how the pinout on the Fan 8 Click Board™ corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| Overtemperature Indicator | OT | 1 | AN | PWM | 16 | FF | Fan-Fail Indicator |

| NC | 2 | RST | INT | 15 | FLT | Fault Indicator | |

| NC | 3 | CS | RX | 14 | NC | ||

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | SCL | I2C Clock | |

| NC | 6 | MOSI | SDA | 11 | SDA | I2C Data | |

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | 5V | Power Supply |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

Onboard settings and indicators

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| JP1-JP2 | ADDR SEL | Right | I2C Address Selection 0/1: Left position 0, Right position 1 |

| JP3 | VCC SEL | Left | Logic Level Voltage Selection 3V3/5V: Left position 3V3, Right position 5V |

| TH1-TH2 | TH1-TH2 | Populated | External Thermistor Connection Headers |

| J1-J2 | FAN1-FAN2 | Populated | Fan Connection Headers |

Fan 8 Click electrical specifications

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Supply Voltage VCC | 3.3 | - | 5 | V |

| Fan Supply Voltage VFAN | - | 5 (12) | - | V |

| Accuracy | - | - | ±4 | °C |

| Operating Temperature Range | -40 | +25 | +125 | °C |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4824

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027383915

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.