Overview

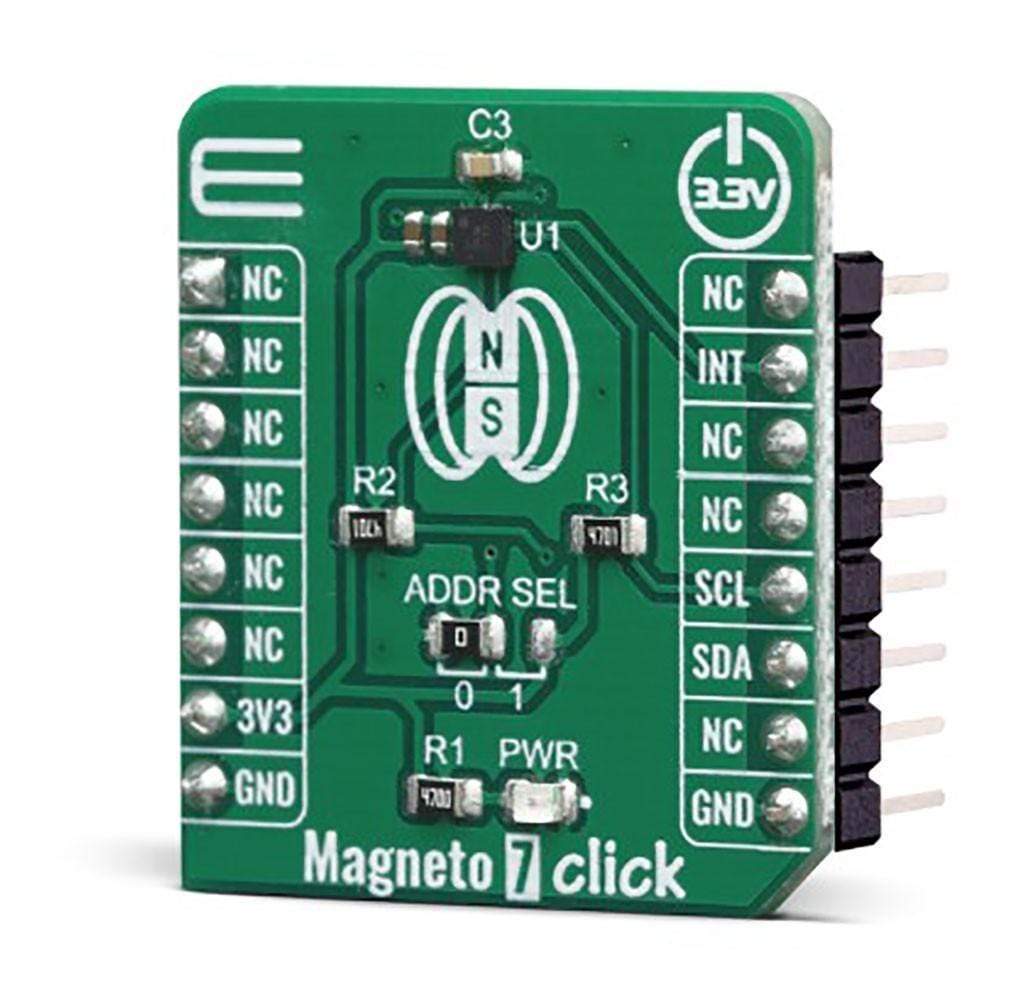

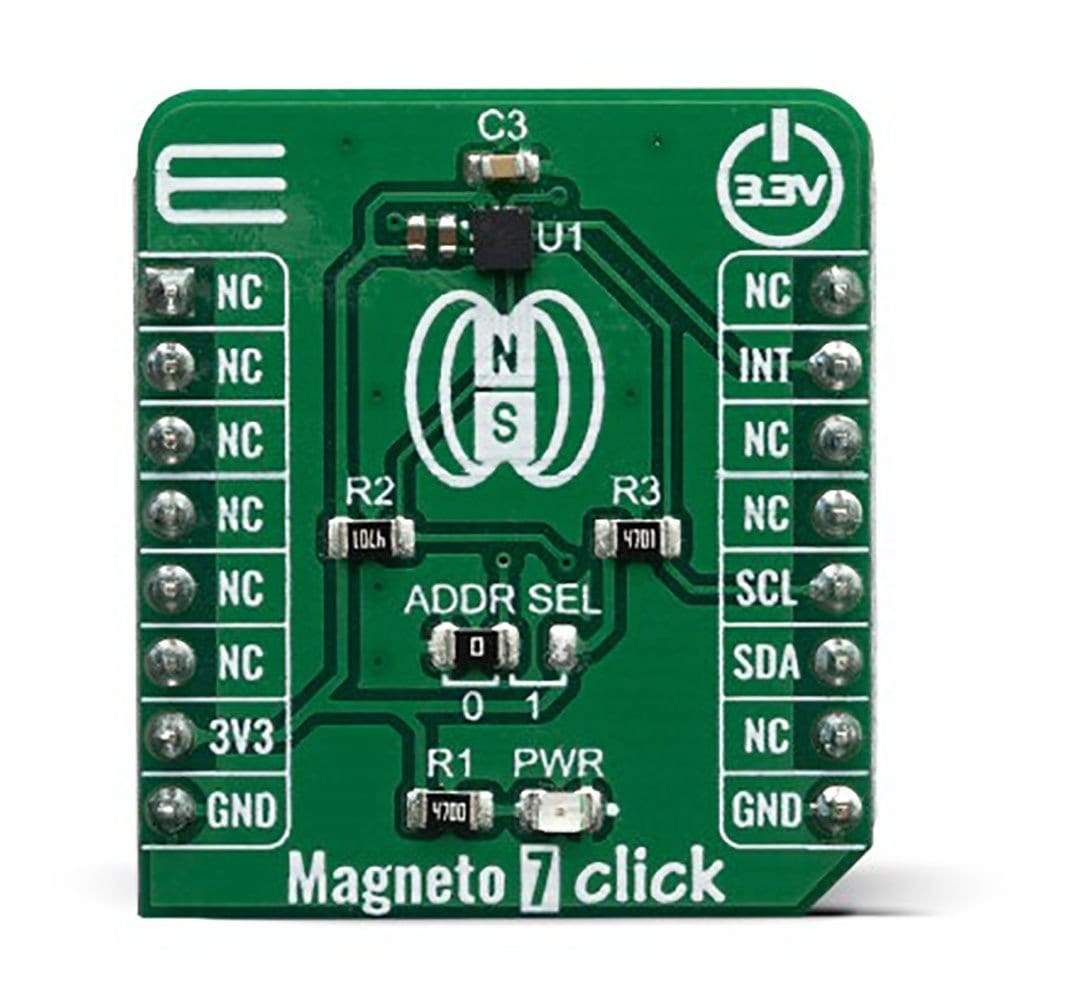

The Magneto 7 Click Board™ is a high-resolution magnetic sensor Click Board™ that allows contactless orientation sensing. It features the BM1422AGMV, a complete integrated solution with magneto-impedance (MI) elements, low-noise analogue AD converter, and digital signal processing (DSP) sections, on the same die.

Thanks to the internal DSP processing, the BM1422AGMV can output the absolute movement detection over the serial interface as a bitstream. The BM1422AGMV IC is ideal for use in various applications, such as wristwatches, smartphones, tablets, etc.

Downloads

The Magneto 7 Click Board™ is a very accurate and reliable magnetic sensor device, which features the BM1422AGMV, a 3-axis magnetic sensor IC from ROHM Semiconductor. The BM1422AGMV IC features an onboard signal processing and I2C communication, simplifying the application development and reducing the host MCU load. It is a very accurate sensor, which can sense the magnetic field with the precision of 0.042μT, with the full scale magnetic field detection of ±1200μT. Featuring onboard signal processing, fast I2C communication, low power consumption, and high precision with the low noise, this Click board™ is an ideal solution for developing portable electronic compass applications, but it is not limited only to directional measurement. It can be also used for the detection of a magnetic field, vehicle detection, and similar applications that rely on an accurate magnetic field sensing in all three axes.

How Does The Magneto 7 Click Board™ Work?

The Magneto 7 Click Board™ uses the BM1422AGMV, a 3-axis magnetic sensor IC from ROHM Semiconductor. This sensor incorporates magneto-impedance (MI) elements to detect magnetic field and a control IC in a small package. The magneto-impedance (MI) effect is a phenomenon in which the voltage induced by a high frequency current source in a ferromagnetic wire changes with the application of an external field. Just like a global positioning system (GPS) is effective for detecting the position, a magnetic sensor is usable for detecting the orientation of the user, and therefore simplify the development of motion tracking applications.

The resulting characteristics of this sensor IC, are impressive: it have measurable range of ±1200μT, a sensitivity of 0.042μT/LSB when using 14 bit ADC mode, and can be exposed to maximum 1000mT field. The Status register offers the status indication of the measured data. This, DRDY bit, is output to inform the preparation status of the measured data and is routed to the INT pin of the Click board™.

The Magneto 7 Click Board™ uses I2C, and it is designed to be operated only with 3.3V logic level. A proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with logic levels of 5V.

SPECIFICATIONS

| Type | Magnetic |

| Applications | It is an ideal solution for developing portable electronic compass applications, but it can be also used for the detection of a magnetic field, vehicle detection, and similar applications that rely on an accurate magnetic field sensing in all three axes. |

| On-board modules | BM1422AGMV, a 3-axis magnetic sensor IC from from ROHM Semiconductor. |

| Key Features | Accurate sensing of the magnetic field in all three axes, on-chip processing functions, 12bit / 14bit Digital Output |

| Interface | I2C |

| Compatibility | mikroBUS |

| Click board size | S (28.6 x 25.4 mm) |

| Input Voltage | 3.3V |

PINOUT DIAGRAM

This table shows how the pinout of the Magneto 7 Click Board™ corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | NC | ||

| NC | 2 | RST | INT | 15 | INT | Interrupt | |

| NC | 3 | CS | RX | 14 | NC | ||

| NC | 4 | SCK | TX | 13 | NC | ||

| NC | 5 | MISO | SCL | 12 | SCL | I2C Clock | |

| NC | 6 | MOSI | SDA | 11 | SDA | I2C Data | |

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | NC | |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

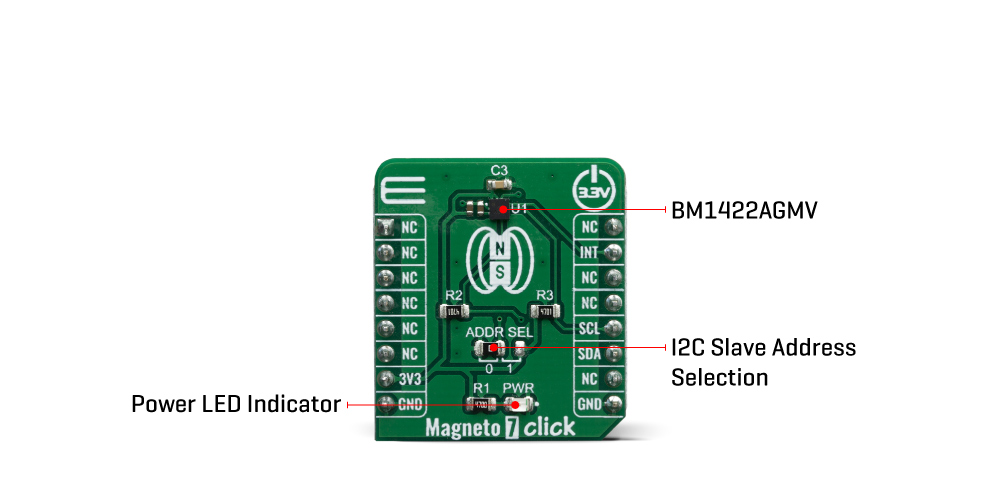

ONBOARD SETTINGS AND INDICATORS

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED Indicator |

| JP1 | ADDR SEL | Left | Slave I2C address LSB selection: left position 0, right position 1 |

MAGNETO 7 CLICK ELECTRICAL SPECIFICATIONS

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Magnetic field measurement range on each axis | -1200 | - | 1200 | μT |

| Magnetic Sensitivity | - 0.042 | - | 0.042 | μT |

| Operating Current (100SPS) | - | 0.15 | - | mA |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3657

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.017 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018716470

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.