Overview

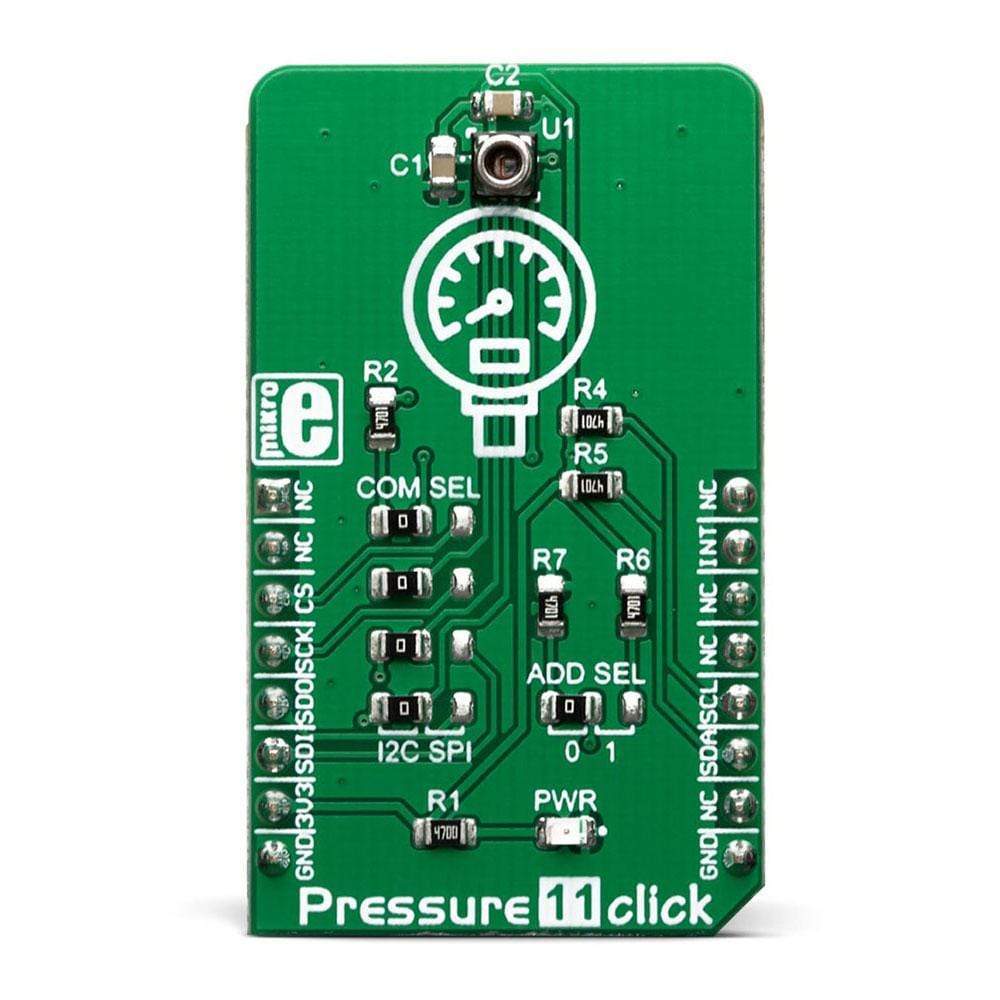

The Pressure 11 Click Board™ is a digital barometer on a Click Board™. Pressure 11 is equipped with the LPS33HW, an absolute piezoresistive pressure sensor, manufactured using proprietary technology. This sensor offers many benefits, including low power consumption, high resolution of the pressure data, embedded thermal compensation, FIFO buffer with several operating modes, temperature measurement, etc.

The most distinctive feature of this sensor is its ability to measure the pressure within the wide range between 260 - 1260hPa, offering calibrated readings over the SPI or I2C digital interface.

Downloads

The pressure sensor contains protective gel, preventing water or humidity to damage the circuit. Additionally, it is protected from overpressure, allowing it to withstand pressure peaks up to 20x its measurement range. These features make the Pressure 11 Click Board™ a perfect tool for development of various pressure-based applications, especially when low power consumption is required: portable weather stations, IoT and other battery-operated pressure-related applications, wearables, and similar.

HOow Does The Pressure 11 Click Board™ Work?

The Pressure 11 Click Board™ features the LPS33HW, an absolute digital output barometer IC in water-resistant package, from STMicroelectronics. It can be used to measure absolute pressure values from 260 - 1260hPa. The sensor can be exposed up to 2MPa of pressure peaks, without causing any permanent damage. However, prolonged exposure to such high pressure can affect the reliability and accuracy of the sensor.

The LPS33HW IC comprises a piezoresistive MEMS and an ASIC. The MEMS consists of a suspended membrane manufactured using a proprietary technology, developed by ST. The piezoresistive elements on the membrane form a Wheatstone bridge. By applying a pressure, the balance of the bridge is disturbed, which causes a proportional voltage to appear on its output. The output of the Wheatstone bridge is then processed by the ASIC, which outputs conditioned and factory-calibrated data over the SPI or I2C interface, in 24-bit, two's complement format.

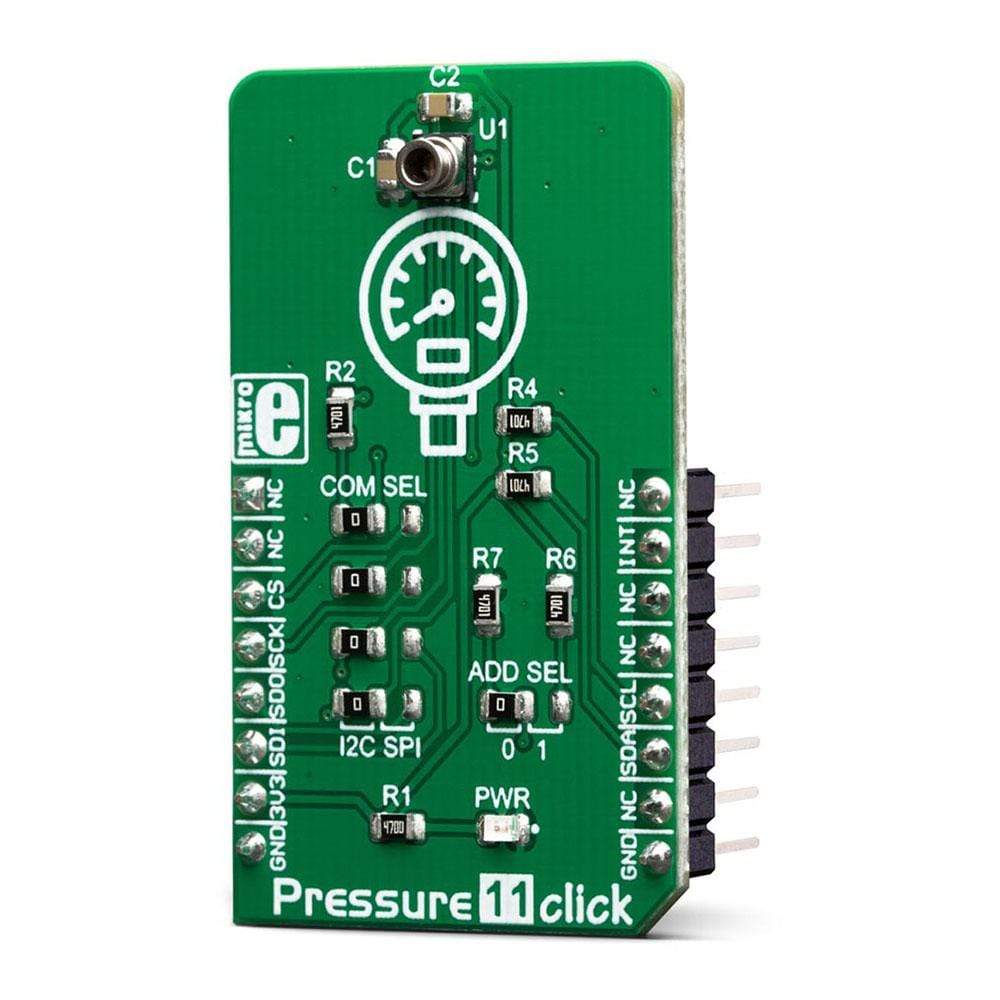

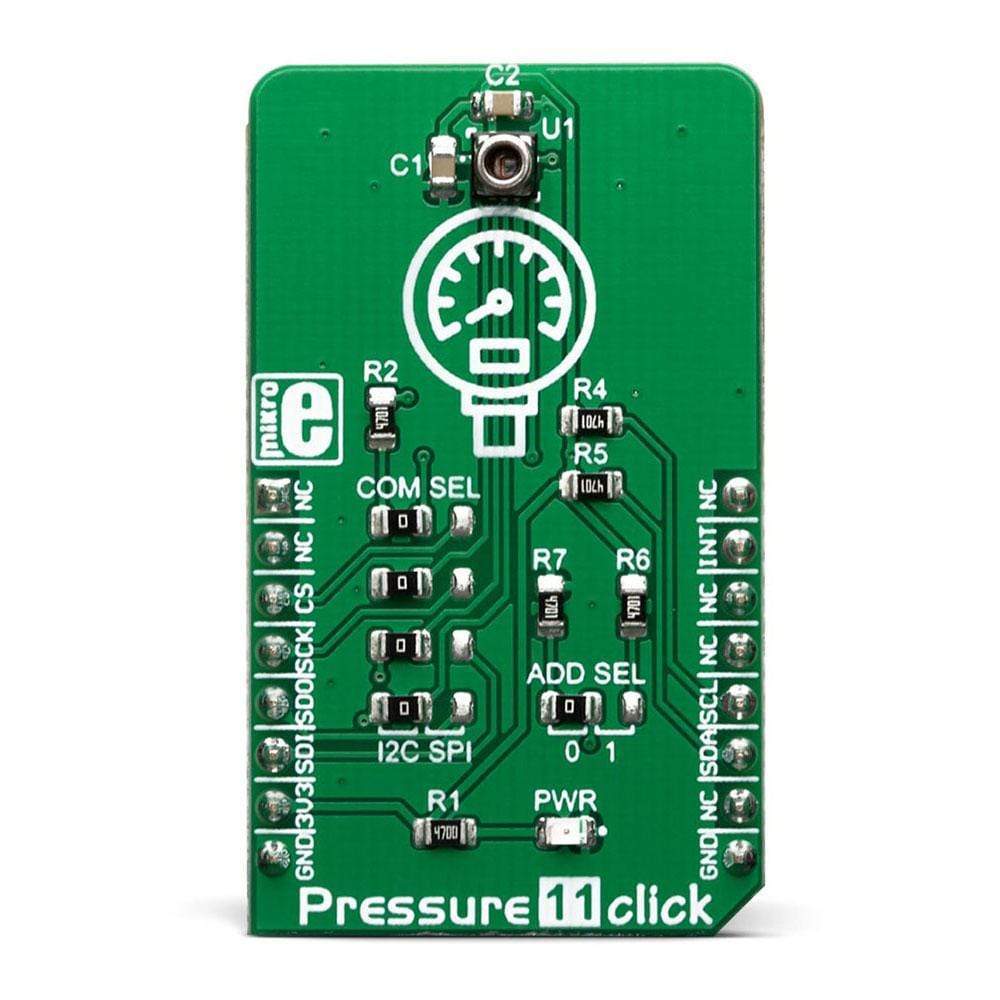

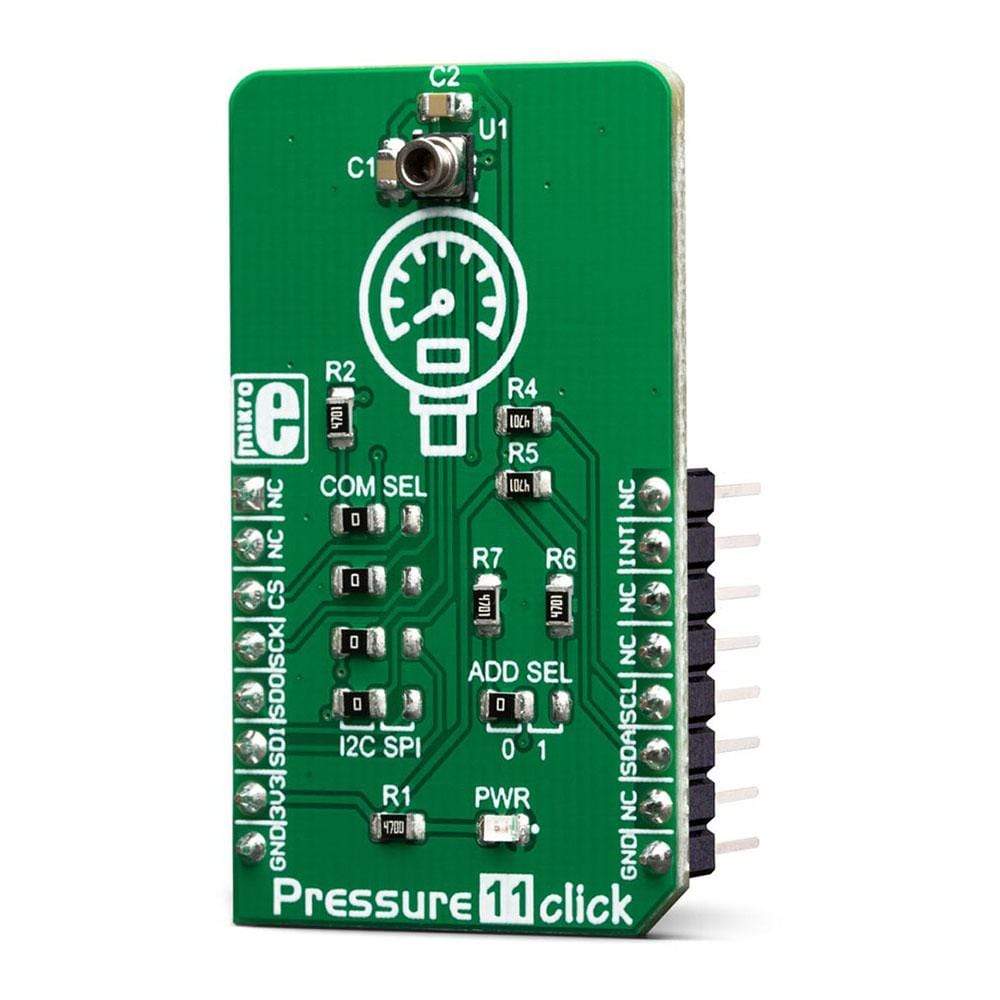

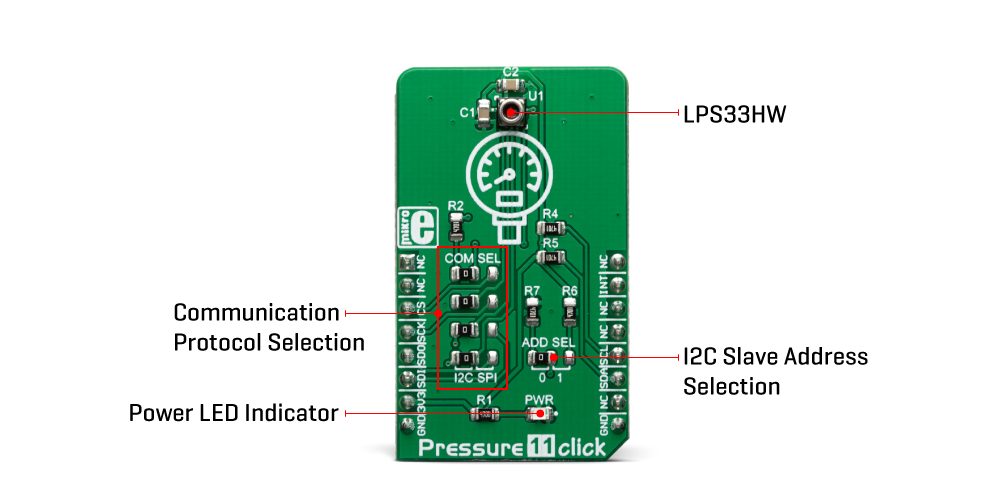

The Pressure 11 Click Board™ supports both SPI and I2C communication interfaces, allowing it to be used with a wide range of different MCUs. The communication interface can be chosen by moving SMD jumpers grouped under the COM SEL to an appropriate position (SPI or I2C). The slave I2C address can also be configured by a SMD jumper, when the Click board™ is operated in the I2C mode: a SMD jumper labeled as ADD SEL is used to set the least significant bit (LSB) of the I2C address. When set to 1, the 7-bit I2C slave address becomes 0b1011101x. If set to 0, the address becomes 0b1011100x. The last digit (x) is the R/W bit.

One of distinctive features of the LPS33HW is a highly configurable FIFO buffer, with 32 slots of 40-bit data, allowing to buffer both pressure and temperature readings. The FIFO buffer can be configured to work in one of several available modes, offering a great flexibility. Along with the extensive interrupt engine which can signal several FIFO-related events over a dedicated INT_DRDY pin, the FIFO buffer can be very useful for writing an optimized MCU firmware.

Besides FIFO-related events, the extensive interrupt engine of the LPS33HW IC can be configured to signal several other events over a dedicated INT_DRDY pin, including events when a programmable low or high threshold level is exceeded, and events when there is a data ready to be read from the output. The INT_DRDY pin of the LPS33HW IC is routed to the mikroBUS™ INT pin. Its active state (active LOW or active HIGH) is freely configurable.

Pressure data at the output is in 24-bit, two's complement format. Thanks to the highly advanced ASIC, the output is already formatted in physical units, with minimum operations required from the host MCU. Since the sensitivity is 4096 LSB/hPa, the output result should be divided by 4096 in order to obtain the value in hPa units. Temperature data is in 16-bit two's complement format, and it does not require any conversions. The sensitivity of the temperature sensor is 100 LSB/⁰C so the output result should be divided by 100 in order to obtain the value in ⁰C units. ASIC also offers some other processing functions such as the lowpass filtering of the output data, which helps reducing the inconsistencies due to sudden pressure changes.

The Pressure 11 Click Board™ uses both I2C and SPI communication interfaces. It is designed to be operated only with 3.3V logic levels. A proper logic voltage level conversion should be performed before the Click board™ is used with MCUs with logic levels of 5V.

SPECIFICATIONS

| Type | Pressure |

| Applications | The Pressure 11 Click Board™ is a perfect tool for development of various pressure-based applications, especially when low power consumption is required: portable weather stations, IoT and other battery-operated pressure-related applications, wearables, and similar. |

| On-board modules | LPS33HW, an absolute digital output barometer IC in water-resistant package, from STMicroelectronics. |

| Key Features | Built in ASIC for output data processing, 24-bit conversion, low count of external components required, water-proof casing offers reliability and long-term stability, extensive programmable interrupt engine, advanced FIFO buffer with several operating modes, etc. |

| Interface | I2C,SPI |

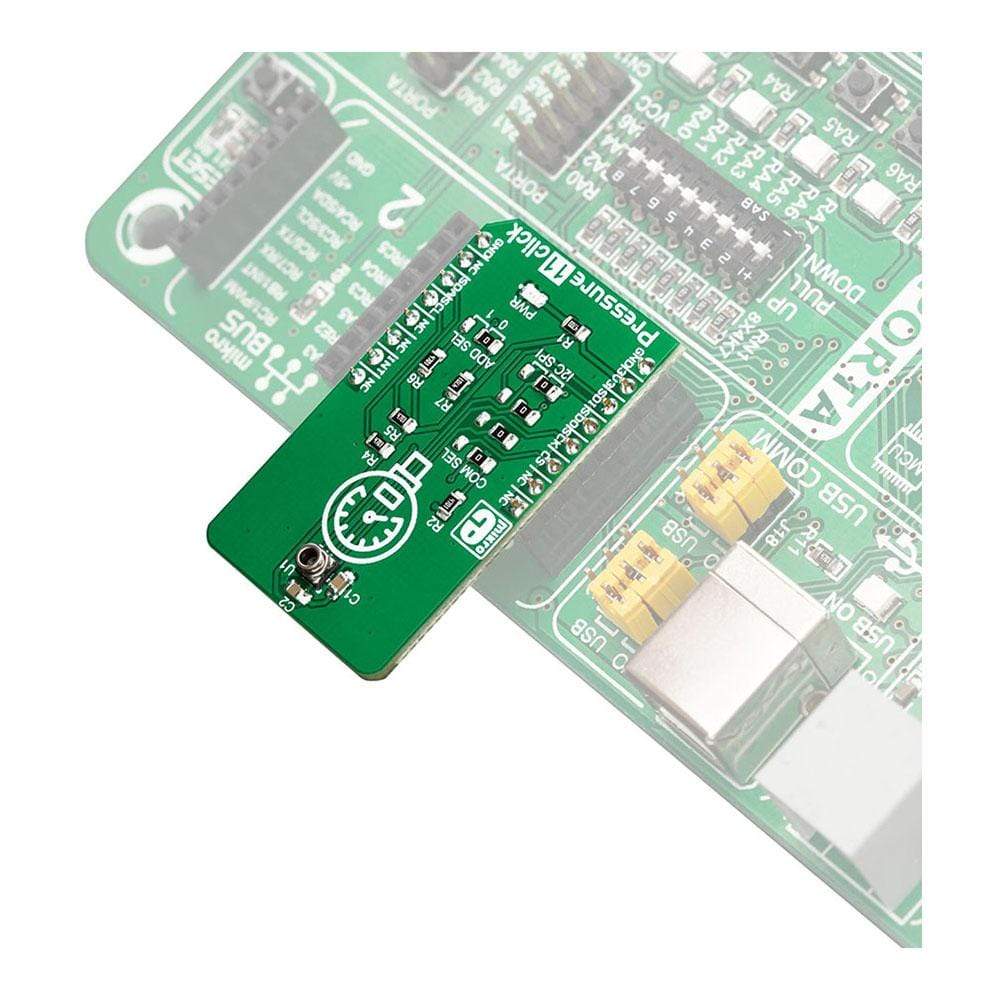

| Compatibility | mikroBUS |

| Click board size | M (42.9 x 25.4 mm) |

| Input Voltage | 3.3V |

PINOUT DIAGRAM

This table shows how the pinout on the Pressure 11 Click Board™ corresponds to the pinout on the mikroBUS™ socket (the latter shown in the two middle columns).

| Notes | Pin |  |

Pin | Notes | |||

|---|---|---|---|---|---|---|---|

| NC | 1 | AN | PWM | 16 | NC | ||

| NC | 2 | RST | INT | 15 | INT | Interrupt | |

| SPI Chip Select | CS | 3 | CS | RX | 14 | NC | |

| SPI Clock | SCK | 4 | SCK | TX | 13 | NC | |

| SPI Data OUT | SDO | 5 | MISO | SCL | 12 | SCL | I2C Clock |

| SPI Data IN | SDI | 6 | MOSI | SDA | 11 | SDA | I2C Data |

| Power Supply | 3.3V | 7 | 3.3V | 5V | 10 | NC | |

| Ground | GND | 8 | GND | GND | 9 | GND | Ground |

ONBOARD SETTINGS AND INDICATORS

| Label | Name | Default | Description |

|---|---|---|---|

| LD1 | PWR | - | Power LED indicator |

| JP1, JP4 | COM SEL | Left | Communication interface selection: left position I2C, right position SPI |

| JP5 | ADDR SEL | Left | Slave I2C address LSB selection: left position 0, right position 1 |

RPRESSURE 8 CLICK ELECTRICAL SPECIFICATIONS

| Description | Min | Typ | Max | Unit |

|---|---|---|---|---|

| Pressure range | 260 | - | 1260 | hPa |

| Operating temperature range | -40 | - | +85 | ˚C |

| Output Data rate | 1 | - | 75 | sps |

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-3411

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.018 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606018714766

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.