Key Features

Overview

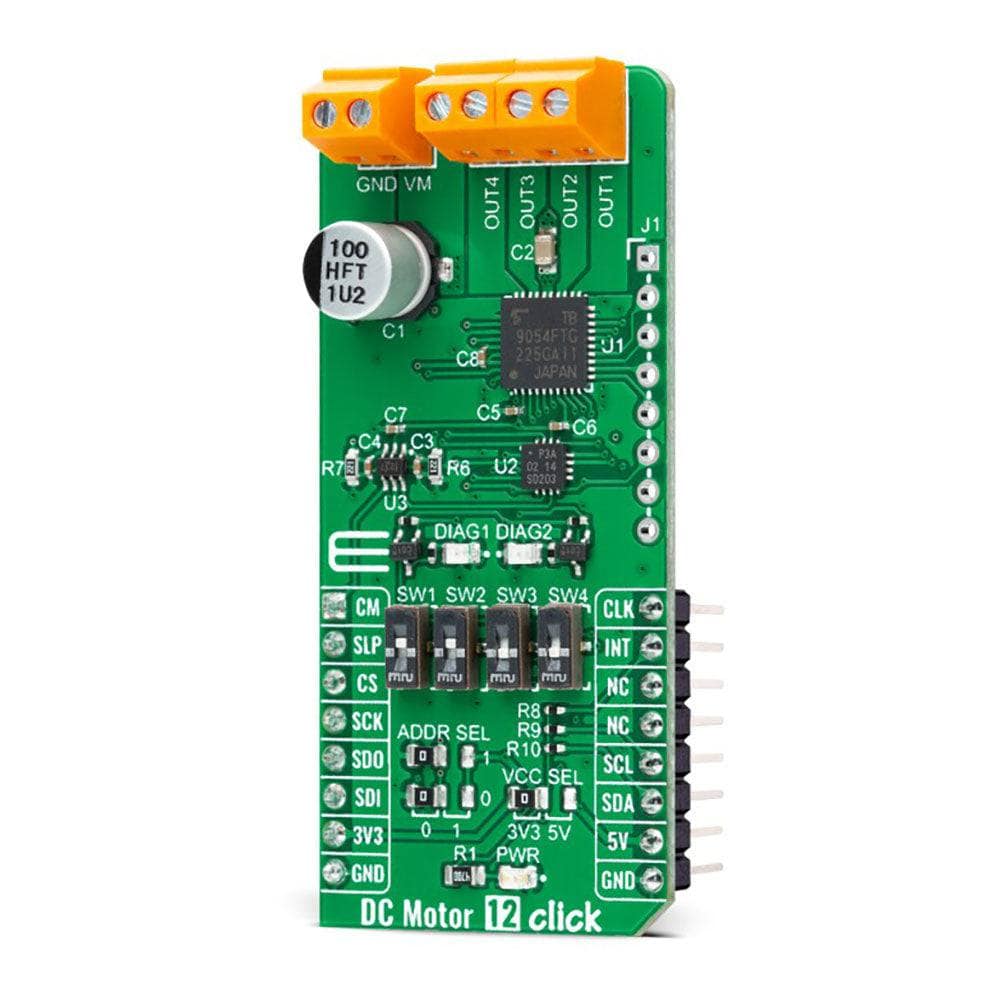

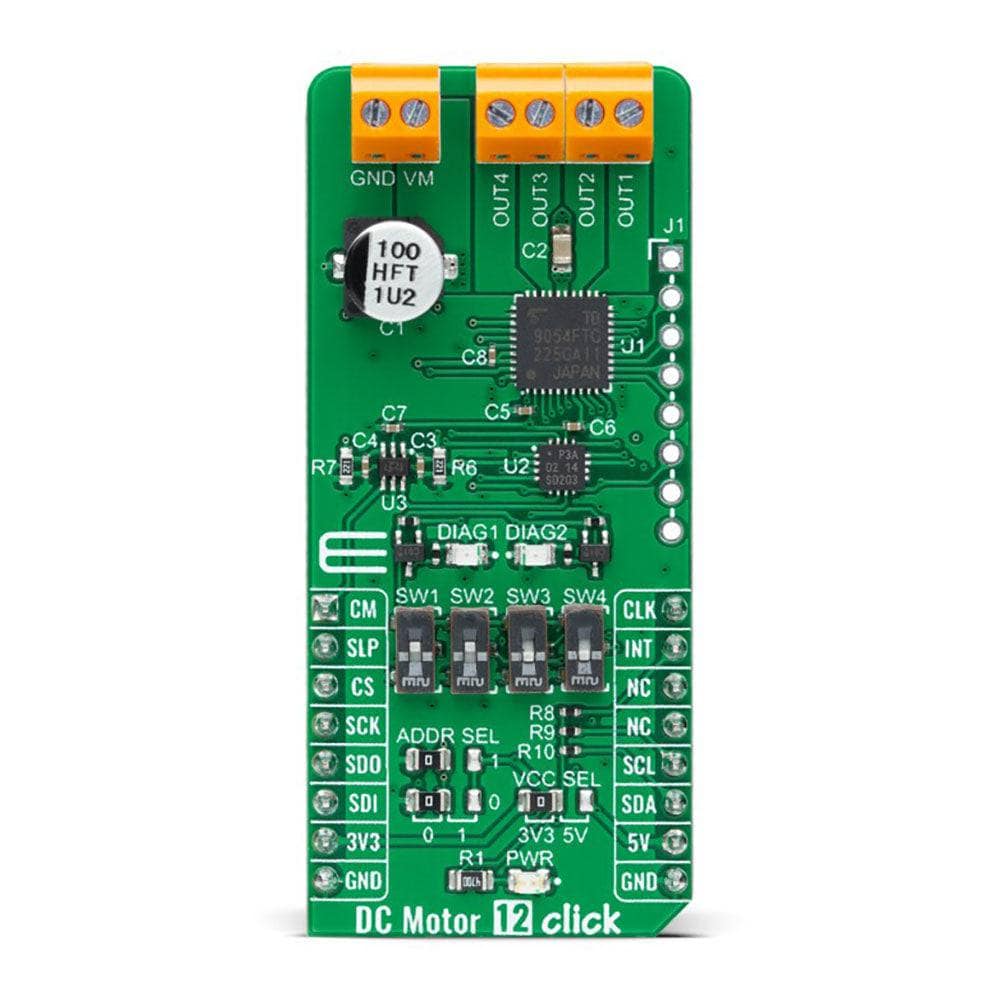

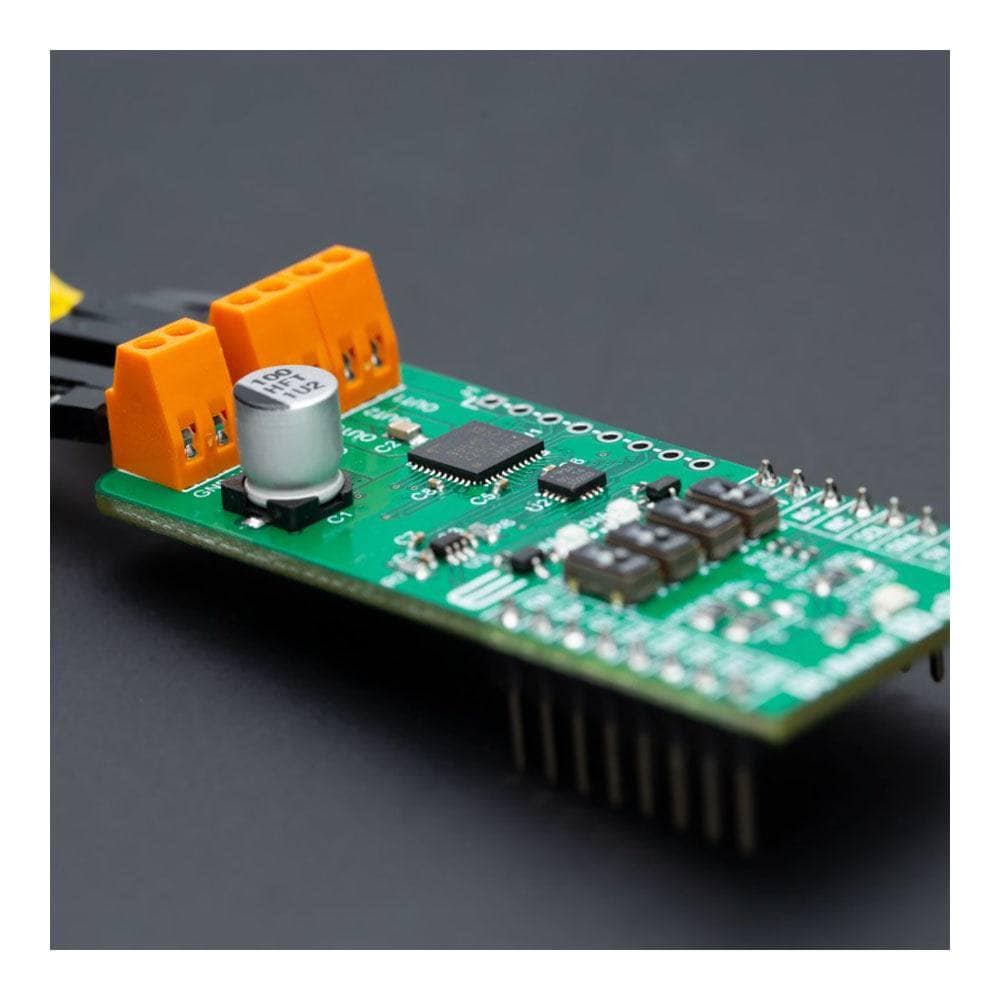

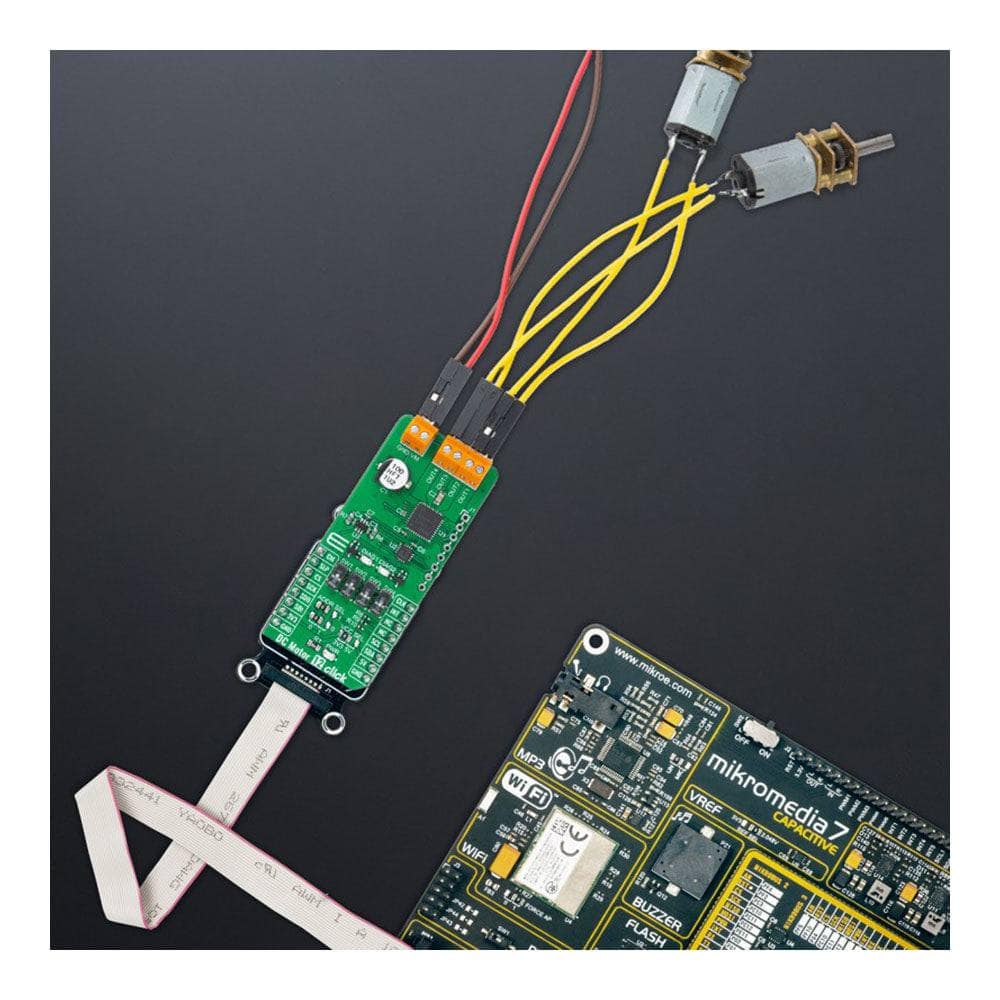

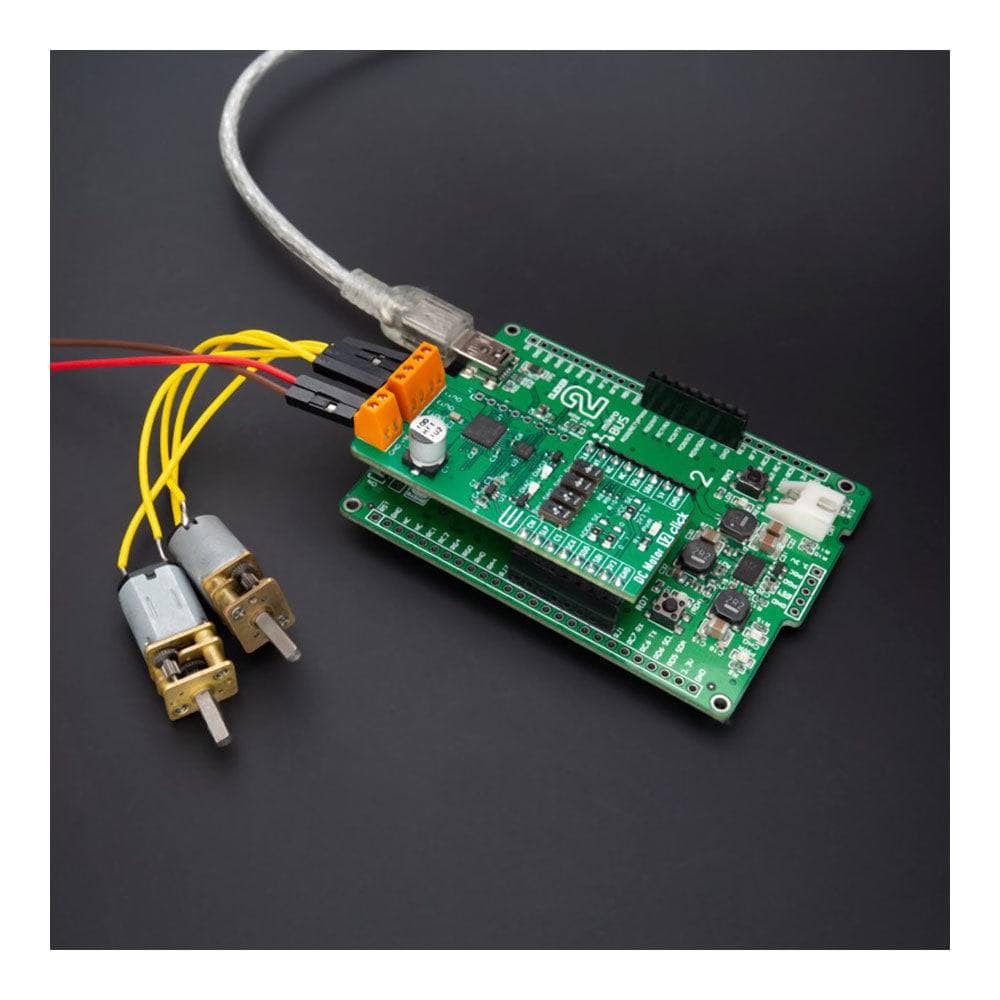

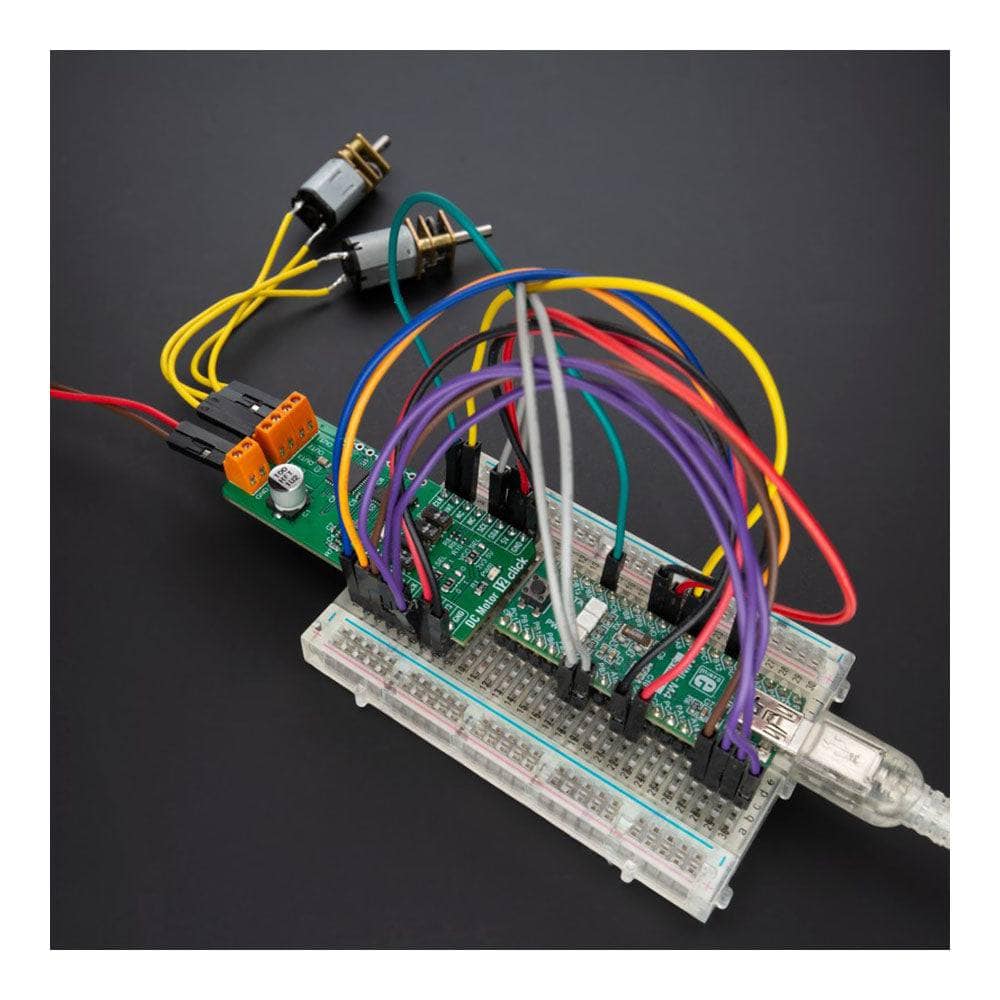

The DC Motor 12 Click Board™ is a compact add-on board with a brushed DC motor driver. This board features the TB9054FTG, a PWM-type, dual-channel, H-bridge, brushed DC motor driver from Toshiba Semiconductor. The TB9054FTG is rated for an operating voltage range from 4.5V to 28V, with the motor controlled directly through a PWM signal or SPI serial interface. In addition, this driver allows a dual configuration with two motors with 5A current ratings per channel or one 10A channel drive in a Parallel mode of operation. It also has complete diagnostic and protection capabilities supporting robust and reliable operation. This Click board™ is suitable for driving DC brushed motors in various automotive applications such as control of the throttle valve, engine valves, retractable door mirrors, and seat heater.

The DC Motor 12 Click Board™ is supported by a mikroSDK-compliant library, which includes functions that simplify software development. This Click board™ comes as a thoroughly tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Das DC Motor 12 Click Board™ ist eine kompakte Zusatzplatine mit einem bürstenbehafteten Gleichstrommotortreiber. Diese Platine verfügt über den TB9054FTG, einen PWM-Typ, zweikanaligen H-Brücken-Bürsten-Gleichstrommotortreiber von Toshiba Semiconductor. Der TB9054FTG ist für einen Betriebsspannungsbereich von 4,5 V bis 28 V ausgelegt, wobei der Motor direkt über ein PWM-Signal oder eine SPI-Seriellschnittstelle gesteuert wird. Darüber hinaus ermöglicht dieser Treiber eine Dualkonfiguration mit zwei Motoren mit 5 A Nennstrom pro Kanal oder einem 10 A-Kanalantrieb im Parallelbetrieb. Es verfügt außerdem über vollständige Diagnose- und Schutzfunktionen, die einen robusten und zuverlässigen Betrieb unterstützen. Dieses Click Board™ eignet sich zum Antrieb von bürstenbehafteten Gleichstrommotoren in verschiedenen Automobilanwendungen wie der Steuerung der Drosselklappe, Motorventile, einklappbarer Türspiegel und Sitzheizung.

Das DC Motor 12 Click Board™ wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ ist ein gründlich getestetes Produkt und kann auf einem System verwendet werden, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-5374

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027386824

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.