Overview

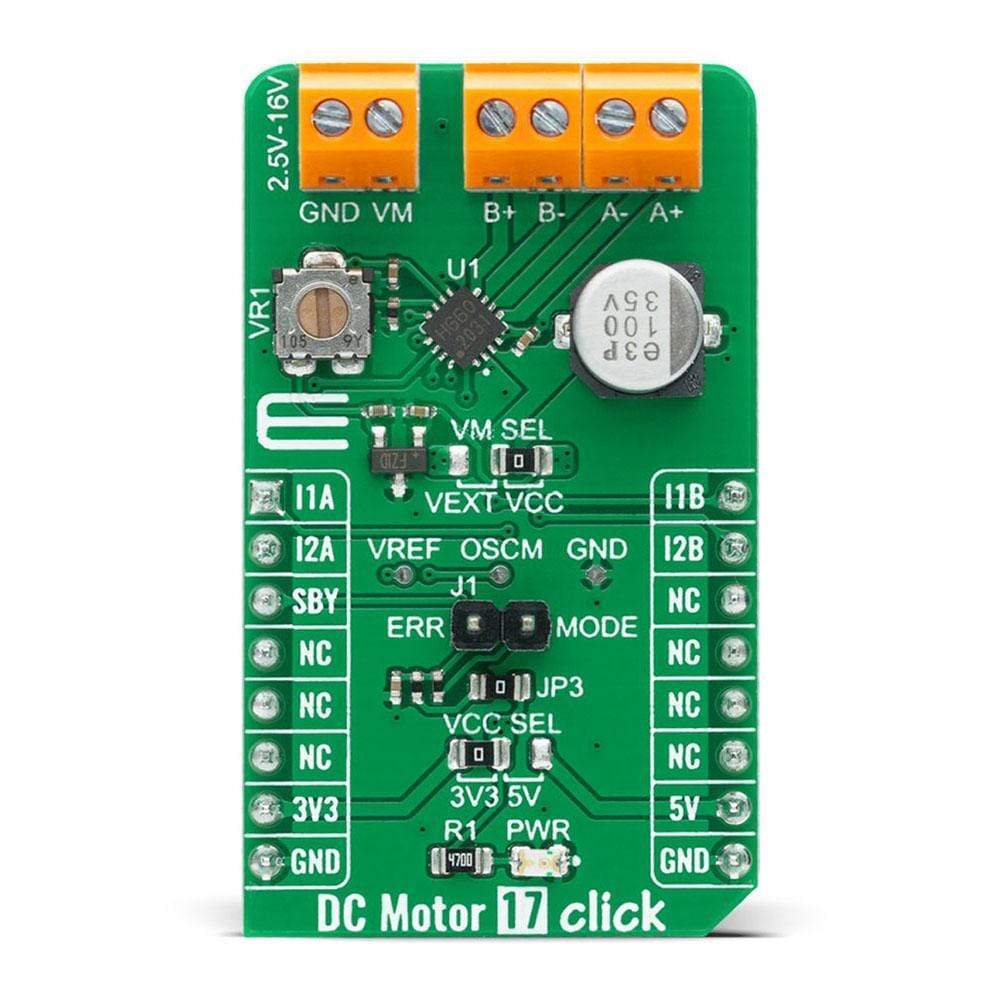

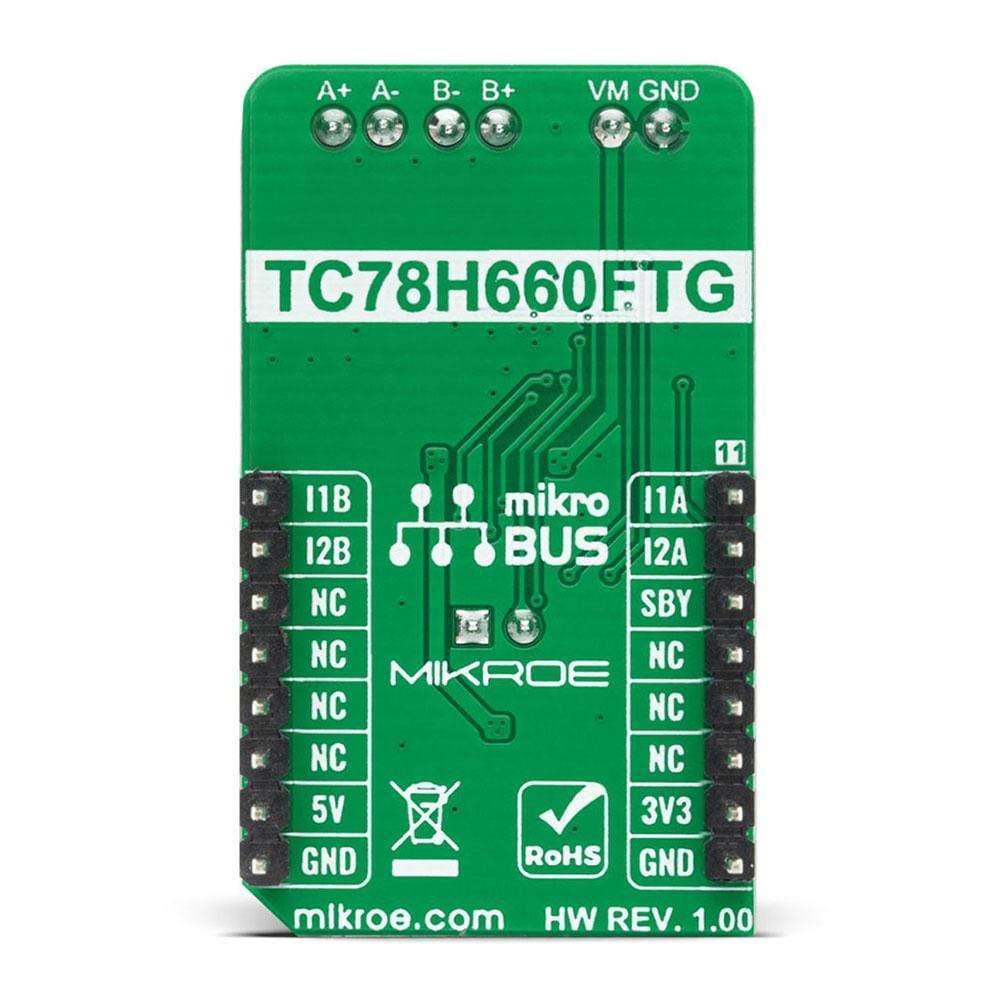

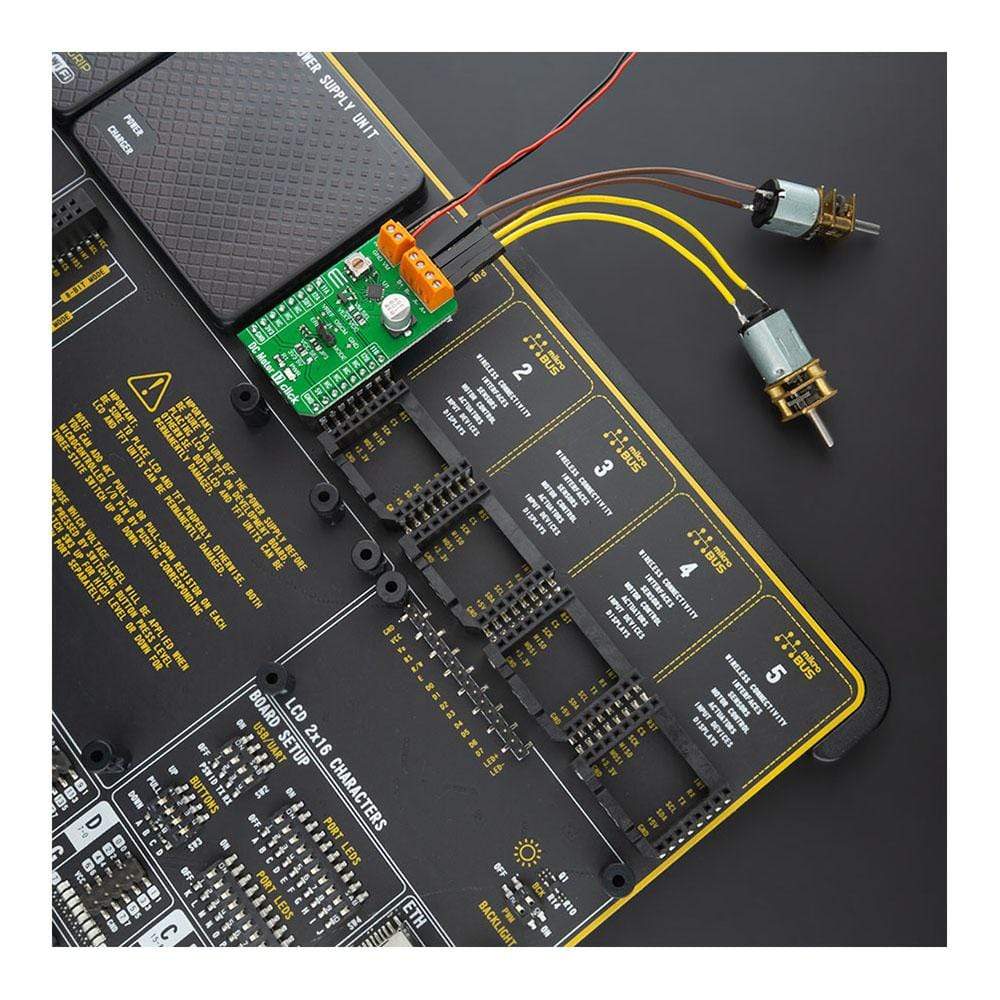

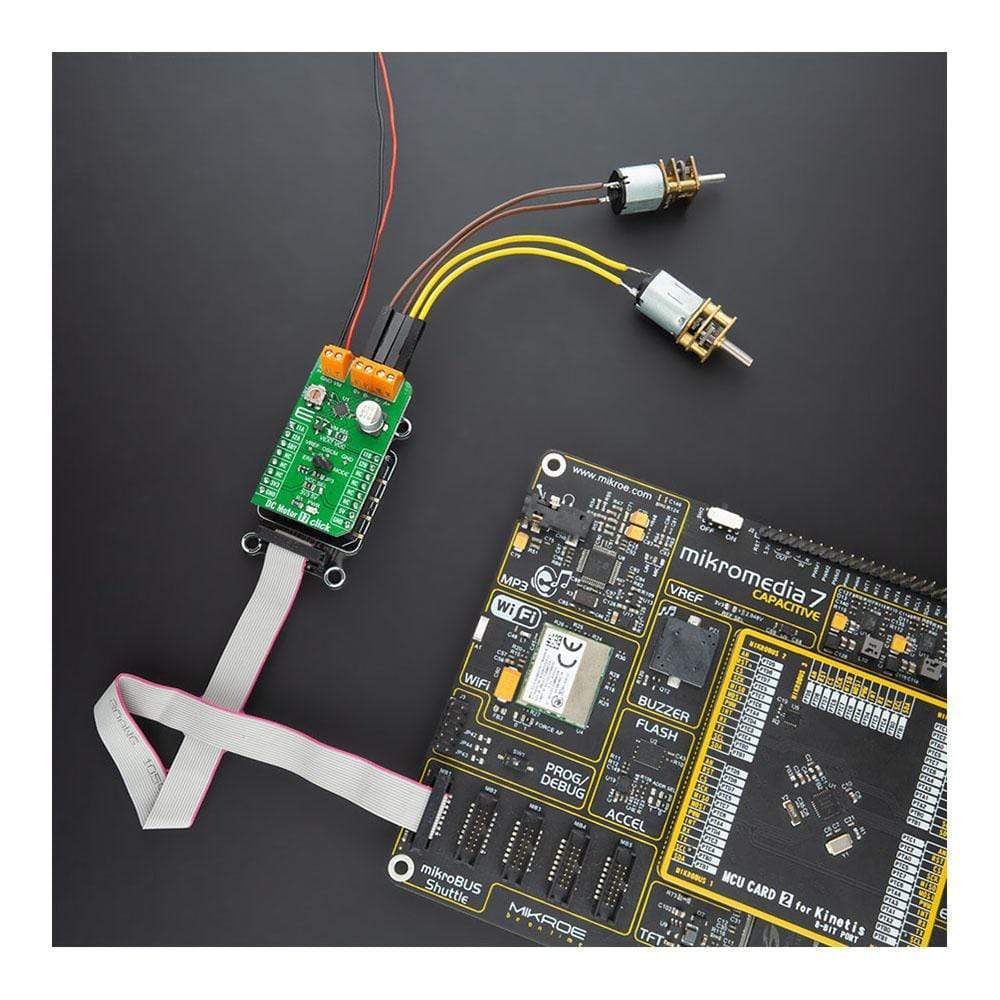

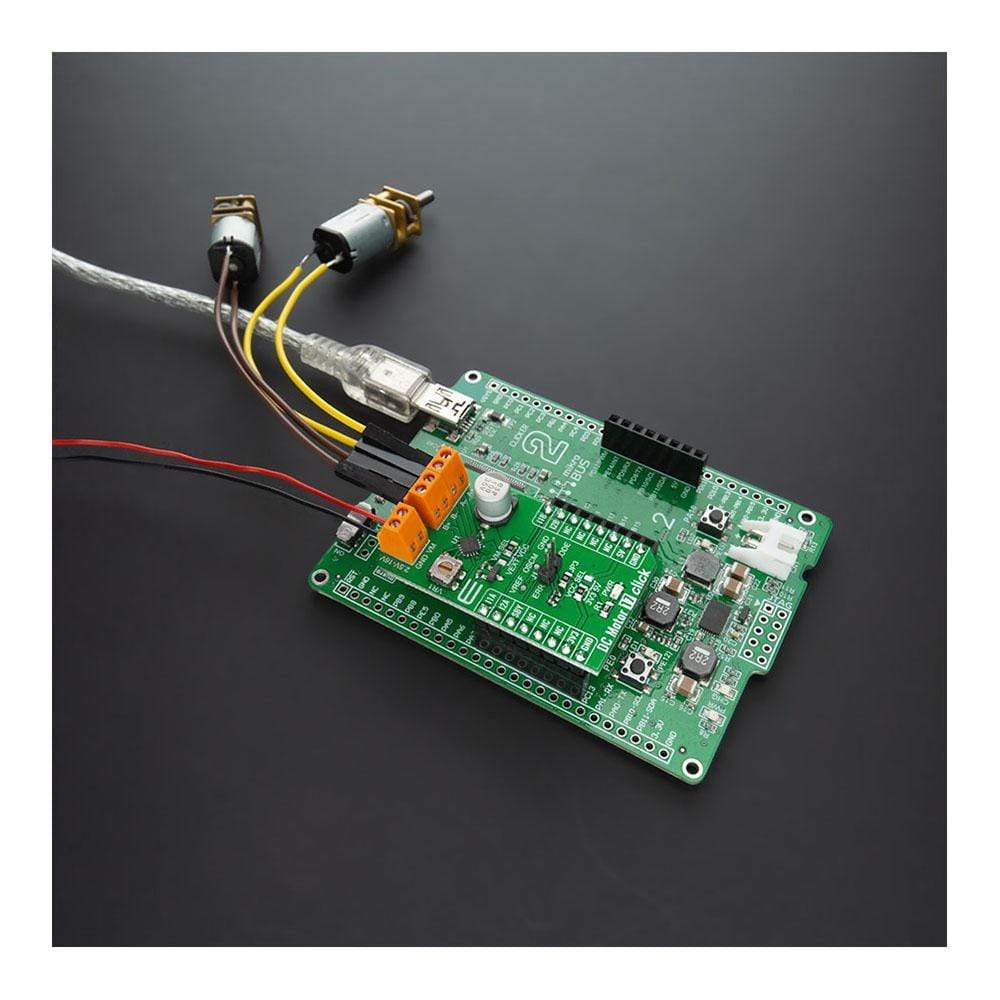

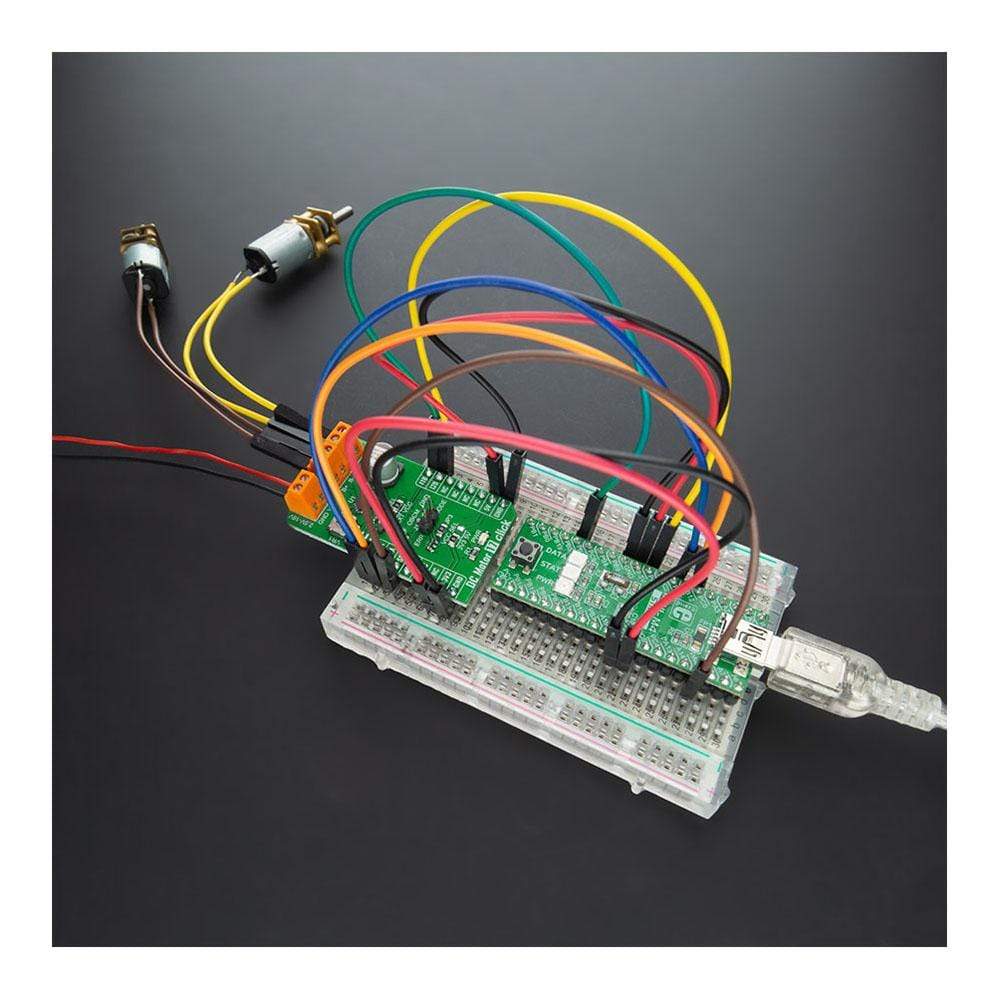

The DC Motor 17 Click™ Board is a compact add-on board that contains a brushed DC motor driver. This board features the TC78H660FTG, a dual H Bridge driver for one or two brushed motors that incorporate a DMOS output transistor with low on-resistance from Toshiba Semiconductor. This IC is a PWM controlled constant-current drive with supply voltages from 2.5V to 16V and 2A of output current. It features a sense-resistor less current control architecture and VCC regulator for the internal circuit. Also offers multi-error detect functions with error detection flag output function. This Click Board™ is suitable for driving DC motors, controlling the direction of the rotation, as well as brake and regulating the motor current.

The DC Motor 17 Click Board™ is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Die DC Motor 17 Click™-Platine ist eine kompakte Zusatzplatine, die einen Treiber für einen bürstenbehafteten Gleichstrommotor enthält. Diese Platine verfügt über den TC78H660FTG, einen dualen H-Brückentreiber für einen oder zwei bürstenbehaftete Motoren, der einen DMOS-Ausgangstransistor mit niedrigem Einschaltwiderstand von Toshiba Semiconductor enthält. Dieser IC ist ein PWM-gesteuerter Konstantstromantrieb mit Versorgungsspannungen von 2,5 V bis 16 V und 2 A Ausgangsstrom. Er verfügt über eine widerstandslose Stromsteuerungsarchitektur und einen VCC-Regler für den internen Schaltkreis. Bietet außerdem Mehrfachfehlererkennungsfunktionen mit Fehlererkennungs-Flag-Ausgabefunktion. Diese Click Board™ eignet sich zum Antrieb von Gleichstrommotoren, zur Steuerung der Drehrichtung sowie zum Bremsen und Regeln des Motorstroms.

Das DC Motor 17 Click Board™ wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4454

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027381300

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.