Overview

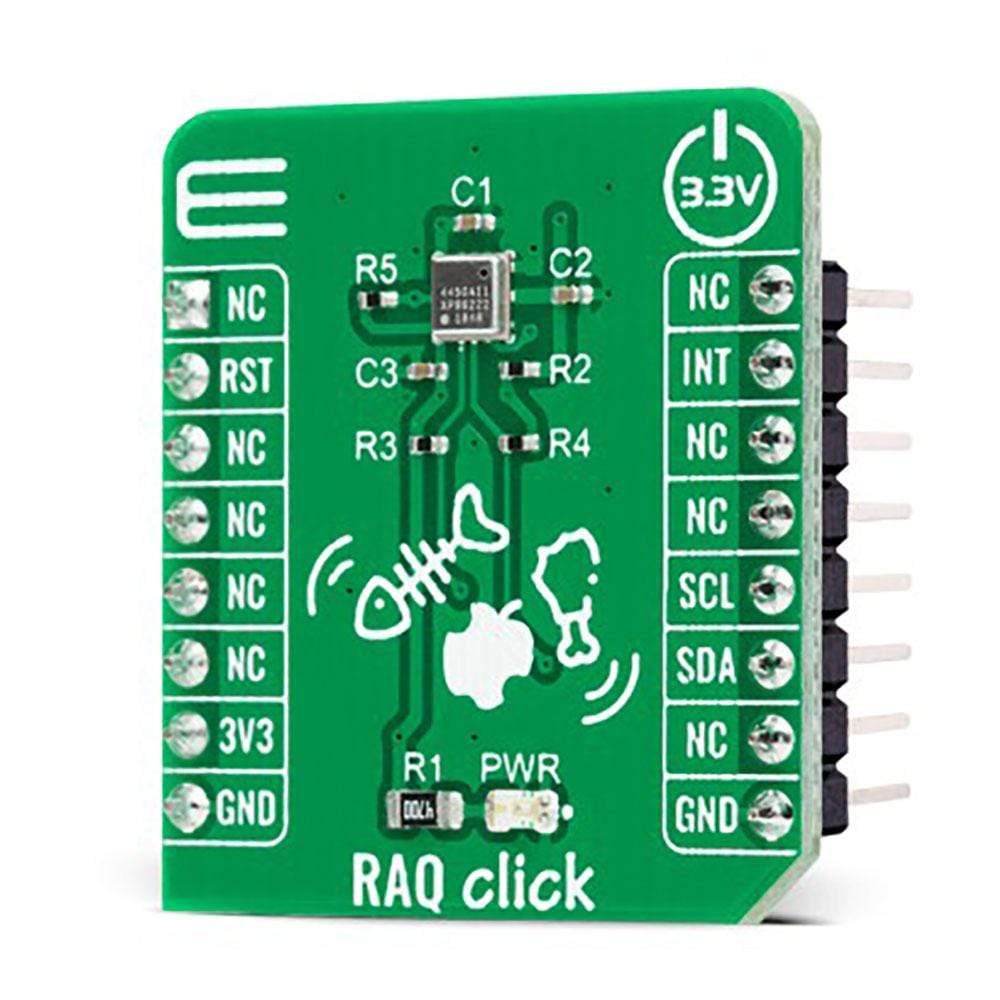

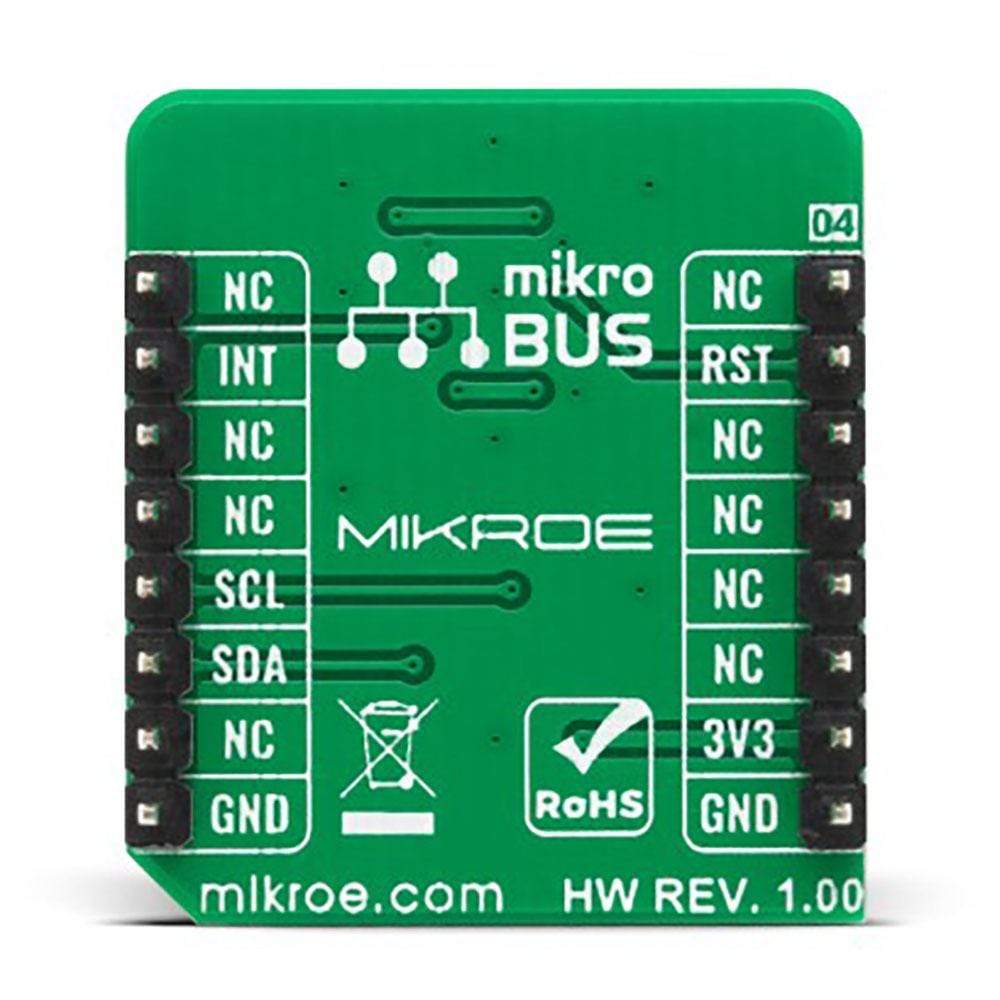

The RAQ Click Board™ is a compact add-on board targeted for use in refrigeration air quality (RAQ) applications. This board features the ZMOD4450, a gas sensor module designed for detecting gases associated with food ripening or rotting from Renesas Electronics Corporation. The module’s sense element consists of a heater element on a silicon-based MEMS structure and a metal temperature sensor. It measures the MOx conductivity, which is a function of the gas concentration, and measurement results read via the I2C interface. This Click Board™ makes an excellent choice for various applications like refrigerator systems control or as monitors for fruit and vegetable quality, shipping, and storage conditions.

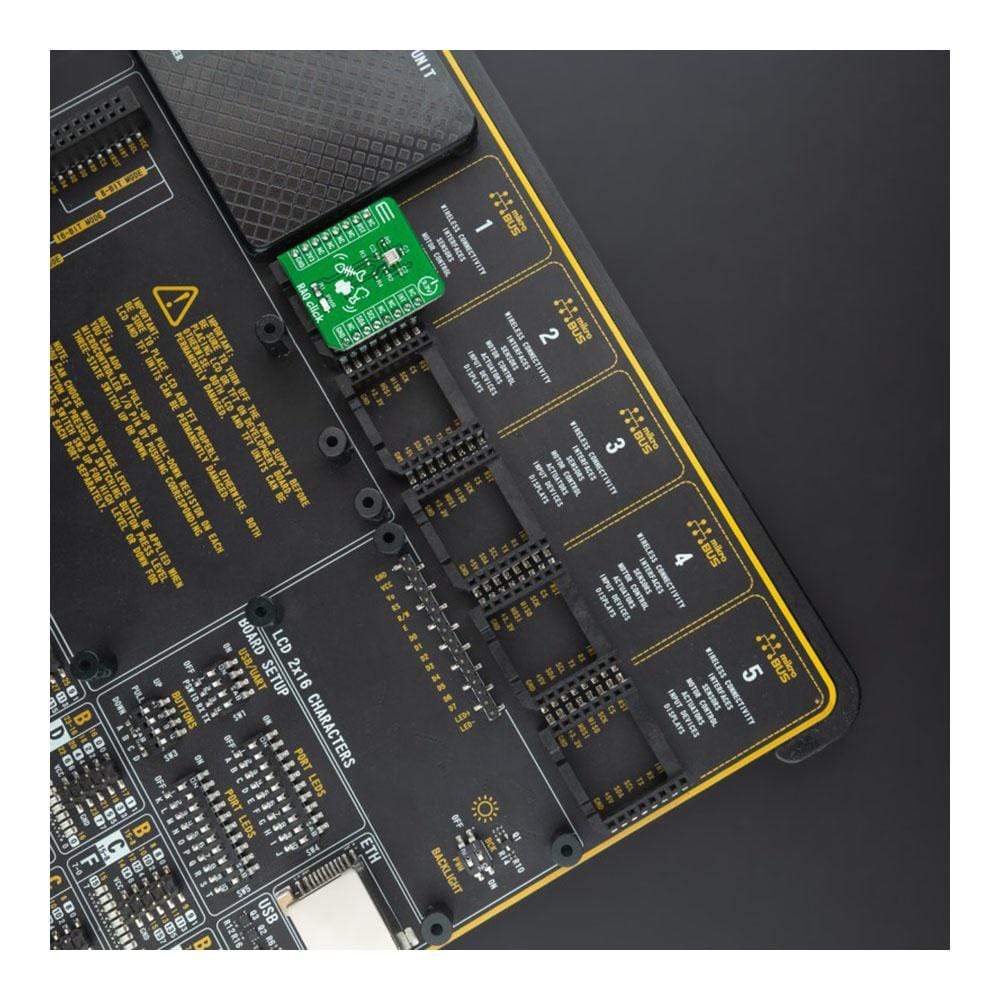

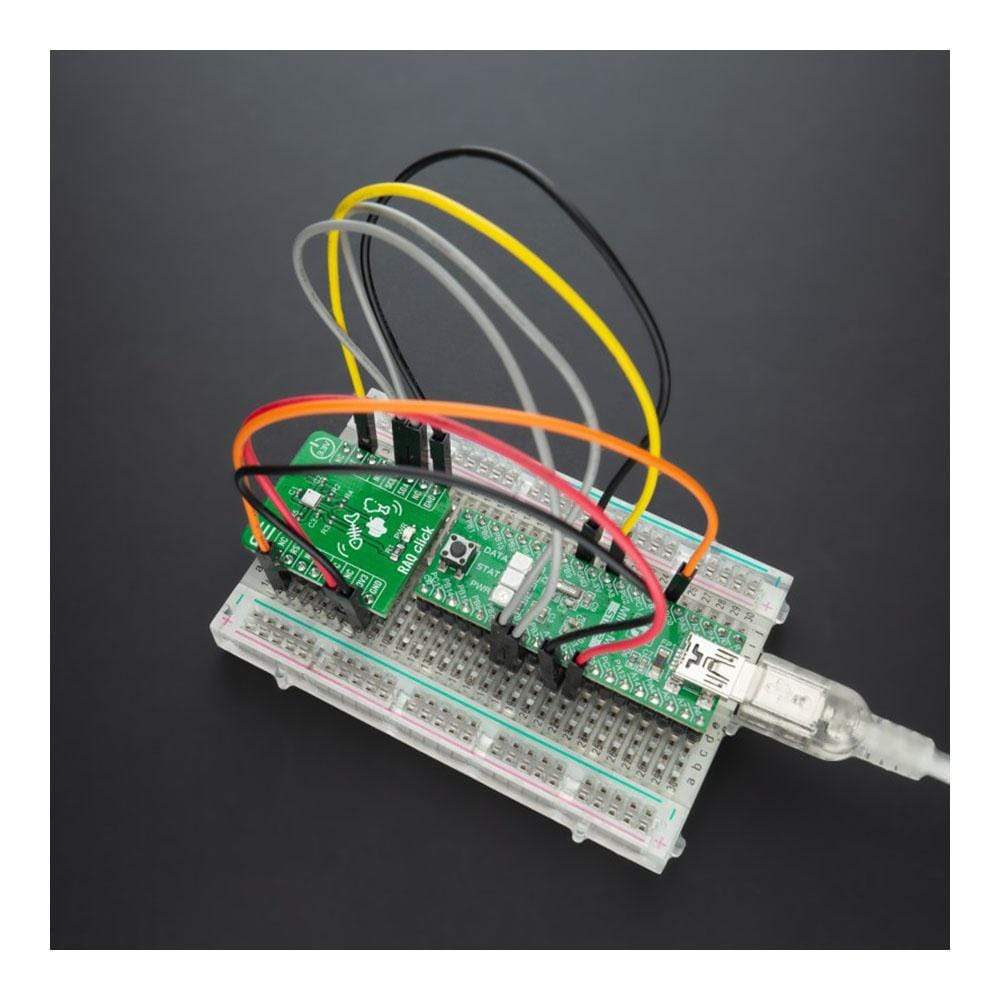

The RAQ Click is supported by a mikroSDK compliant library, which includes functions that simplify software development. This Click Board™ comes as a fully tested product, ready to be used on a system equipped with the mikroBUS™ socket.

Downloads

Das RAQ Click Board™ ist eine kompakte Zusatzplatine für den Einsatz in Anwendungen zur Luftqualität in Kühlanlagen (RAQ). Diese Platine verfügt über das ZMOD4450, ein Gassensormodul zur Erkennung von Gasen, die mit der Reifung oder Verrottung von Lebensmitteln in Zusammenhang stehen, von Renesas Electronics Corporation. Das Sensorelement des Moduls besteht aus einem Heizelement auf einer MEMS-Struktur auf Siliziumbasis und einem Metalltemperatursensor. Es misst die MOx-Leitfähigkeit, die eine Funktion der Gaskonzentration ist, und die Messergebnisse werden über die I2C-Schnittstelle ausgelesen. Dieses Click Board™ ist eine ausgezeichnete Wahl für verschiedene Anwendungen wie die Steuerung von Kühlsystemen oder als Monitor für Obst- und Gemüsequalität, Versand und Lagerbedingungen.

Das RAQ Click wird von einer mikroSDK-kompatiblen Bibliothek unterstützt, die Funktionen enthält, die die Softwareentwicklung vereinfachen. Dieses Click Board™ wird als vollständig getestetes Produkt geliefert und ist bereit für den Einsatz auf einem System, das mit der mikroBUS™-Buchse ausgestattet ist.

| General Information | |

|---|---|

Part Number (SKU) |

MIKROE-4385

|

Manufacturer |

|

| Physical and Mechanical | |

Weight |

0.02 kg

|

| Other | |

Country of Origin |

|

HS Code Customs Tariff code

|

|

EAN |

8606027381157

|

Warranty |

|

Frequently Asked Questions

Have a Question?

Be the first to ask a question about this.